Still out there working on things.

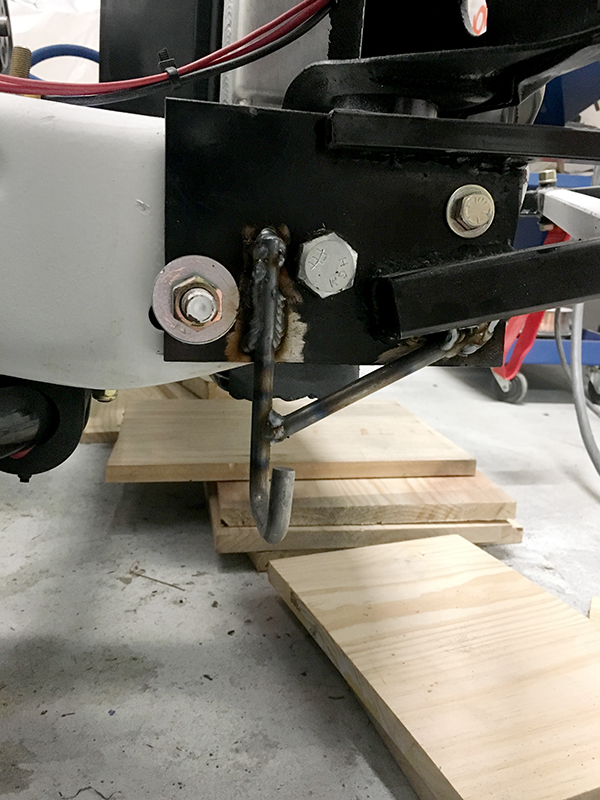

Not pictured - the other weekend Larry and I got the car up in the air, replaced the clutch, hoped to replace the bellhousing (more on that another time), cleaned things up, and welded four (yup) O2 bungs into the exhaust. We also tweaked a few things like pinion angle, etc. That same weekend, the winch on my trailer exploded, so I got to learn how fun it is to push this car on a trailer with two people. I'll have pictures of the winch carnage later, but the company is working with me to replace it.

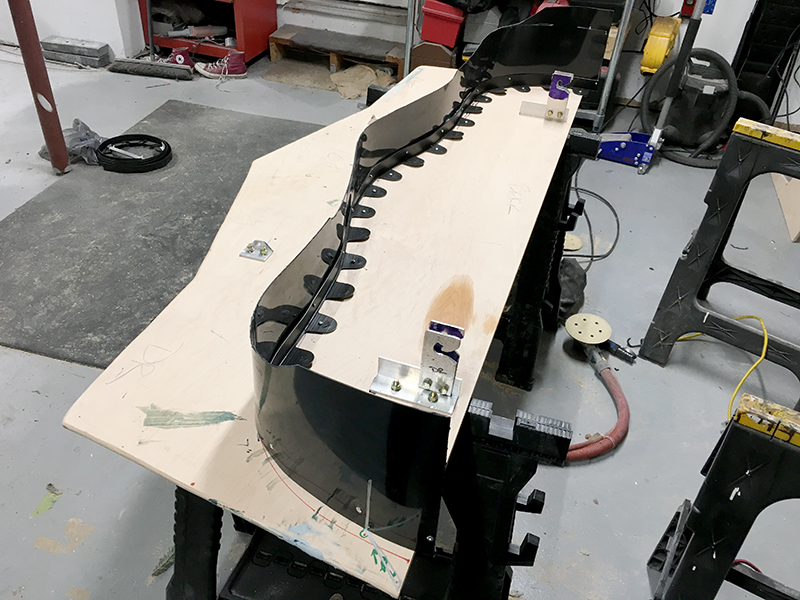

With winter being here, we need to move into bodywork. A bunch of years ago I scored a fiberglass front clip for this car, and it was in rough shape. I didn't mind, as I knew I'd be cutting it up a bunch, but now is the time to start fixing things so I can get it on the car and make it not look like total trash.

Years of dirt on the front clip are not helping it in the looks department.

The driver side rear corner was completely broken off. I had someone cut off a big chunk of the rear of a steel fender, covered it in packing tape, and screwed it to the underside of my fiberglass fender as a sort of mold. Seems to have laid up well for the first pass.

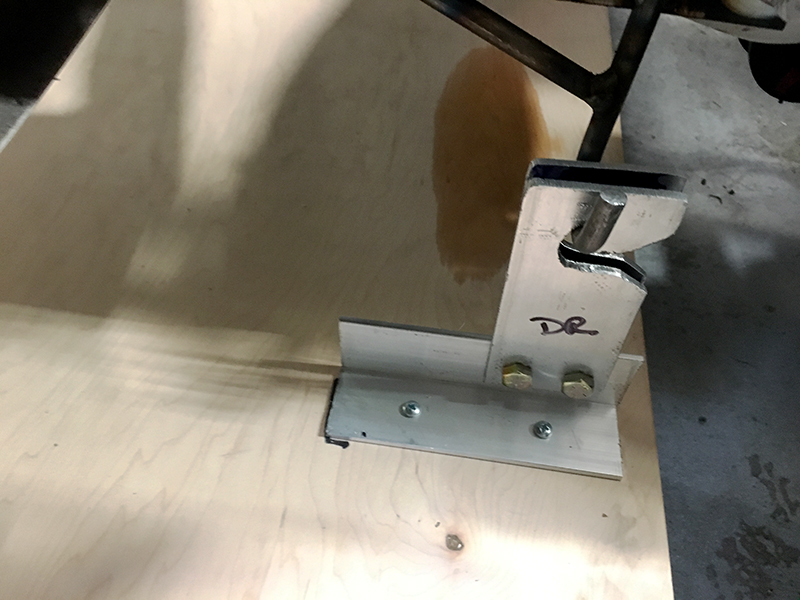

This was the other, worse part. The section on the driver's side where it bolts to the core support was missing completely. I just created a wood buck with the ledge where I needed, covered it in the same packing tape, and went to town. There will probably be some more fiberglass, and a bunch of trimming, but it's a start.

With the temps lower, it took a little longer to cure (both garage heater and heat gun), but I hope to pop the molds off tomorrow and start test fitting things.