04-27-2012, 12:07 AM

not much been going on... I lost interest for a bit and got into a gaming habit doh... oh ya... and I've gone back to school... school is done in a few weeks and I hope/plan to get some stuff done to the truck...

I traded a conical housing for a flat flange housing to someone here on TB... looking into a V band flange setup for the exhaust... I think it'll give me just enough room to keep the blower fan housing (i'd like to have heat down the road haha)...

so my intent is to finish up with the trans mount then work on the exhaust... I'm debating on pulling the drivetrain or not... I need to do the accumulator mod the trans and it's so much easier on a bench (or I imagine having never done it in car) also have the later engine with big rods that needs gone over that i'd love to put in but I think i'll stick with the old engine... I'll prob just leave it all for now as is...

once the trans mount is all mounted I think i'll work on getting the front end together... first the exhaust, then on to the other million odds and ends.

05-04-2012, 06:36 PM

got the V-band ... being sent off to a T-bricks member to be TIG welded to the exhaust housing next week... it'll fit much better then with an adapter to the conical housing... all while keeping the blower fan in place with out mods... the additional flow is just an extra benefit honestly...

next week is last week of school so i'll get to work on it very soon...

05-25-2012, 02:21 AM

took me longer then I wanted to get the housing and V band shipped out but thats how life is sometimes... anyway DNAsEqUeNcE got pics back to me today...

looks real nice, going to make building the down pipe much easier no need to transition for the 3"... so going to get some stuff done this week on the truck... FINALLY :)

05-31-2012, 09:31 PM

got the rubber trans mount... as I mentioned before its some very dense rubber from an old snow plow blade that a friend gave me... I ended up cutting it with metal cut off disc on the angle grinder and while the disc... went MUCH faster then cutting it with a hand saw

it's a bad pic but whatever...

it puts the drive angle at about 5 degrees down so it gives me a little wiggle room for shimming as needed for the driveshaft

so some actual real progress... not big but it's something :)

06-08-2012, 11:05 AM

big news... I'm moving about 500 miles away (outside houston)... into an apartment no less... I've got a garage there but it's going to be much smaller... so i've got to get everything together.

so today I finished the trans cross member...

I needed a bit of 1 1/2" or so square tubing for the under support portion on the cross member... I didn't have any around and because i'm the cheapo that I am and wanting to use stuff i've got laying around I ended up using a bit of bed railing (L steel) that I found some time back, I just cut it and welded it together to make a square...

I didn't take any pics in process but this is the finished product after paint and stuff... all mounted up

came out well IMHO, I'm def getting better welding (still not pretty but hey it's flux core so it's never going to be REAL pretty lol)

now i've got to get the bed back on and load as much of the garage into the bed of it and get the front body panels on to move it (sucks cause they just have to come back off to work on it :-/)

but whatever... the fact that we've got any progress is nice and it came out quite well...

06-12-2012, 02:19 PM

well minor update... we're moving... load up tomm... the truck is being towed without front body panels but the bed is on... when I removed it it was only held on with 4 or 5 bolts... 2 of them snapped while being removed.

the 2 bolts that broke on removal where both passenger side (front and rear center)

I'd tried soaking in PB blaster for literally weeks, did the weld a nut to the exposed bolt... it would extract about 2 full turns then the bolt would snap again... I ended up just drilling both of them out and picked up some grade8 bolts/nuts/washers

the bed is now mounted firmly with all 6 bolts and i'm confident that it won't be going anywhere while being towed down the interstate with the cap on.

06-12-2012, 05:10 PM

webster to be exact... but yup... and i'm super excited as i'll have e85 3 miles from my house

just got the LEER cap on and made a ghetto tail gate (stock one was folded in 1/2 after using the truck to "snatch" trees after the huricane some years back when a big branch fell on it lol)

the tailgate though... I used the bed rails of an old water bed that was sitting in the storage shed (2x8 solid wood)... kinda goofy but it'll keep anything from sliding out of the bed when it's being towed

06-21-2012, 08:02 PM

made it to webster safe n sound... have interwebz... started working on orginizing the garage... it's small, and no 220v but I should be able to finish the project... just have to find a decent 110v wire feed welder so I can build the exhaust...

06-22-2012, 07:19 PM

picked up a mig/flux welder from CL... lots of control adjustment and plenty to weld up my exhaust

its already set up for gas I'd just need a bottle... but will stick with flux for what I need right now

07-16-2012, 04:52 PM

got the turbine housing in and it looks nice... drilled out the bolt holes so it would fit on the 90+ manifold and then went to work with the welder... er sorta...

it was having some serous issues, finally got around to looking at it and the welder was wired backwards (for MIG instead of flux... even though thats what the guy had a few feet of still in there... flipped the polarity and things didn't get any better... took a closer look at the grounding clamp it is was BAD... the clamp itself was pretty bad and so was where the cable attached to the clamp... thankfully the guy gave me a nice ground lead with a good copper clamp... all rated for 600a

things got much better from there but it still wasn't perfect... welds didn't penetrate as well as I liked... adjusted the settings over and over and didn't seem to help... THEN I finally looked closer and had mistaken the power and speed for each other... suddenly the bead was flowing beutifully, sounding perfect and getting great penetration... going to have to ground the bird poop welds so I can re-weld properly...

note to self always double check by READING and not going by memory... and practice on scrap... would have saved a lot of time...

so next time i'm out things should go a lot smoother...

07-22-2012, 05:42 PM

well I ground off the non penetrating ugly bird poop welds on the outside and did a test fit... the fit is about perfect... the fit for the entire downpipe is going to be a bit tight running past the frame and the trans but should be just fine... also very happy as I have a nice spot for the wideband sensor... all while keeping the heater blower motor box without any massaging/modification

well I ground off the non penetrating ugly bird poop welds on the outside and did a test fit... the fit is about perfect... the fit for the entire downpipe is going to be a bit tight running past the frame and the trans but should be just fine... also very happy as I have a nice spot for the wideband sensor... all while keeping the heater blower motor box without any massaging/modification

working on the a/c on the volvo at the moment, a/c compressor is almost out (was leaking past the front seal)... I've got a known good one from my parts car... so i'll be working on that over the next day or so (a/c in TX is a good thing)... after that I'll go back to playing with the downpipe and then finally a clean final wiring of the engine bay...

minor update without my own pics at the moment...

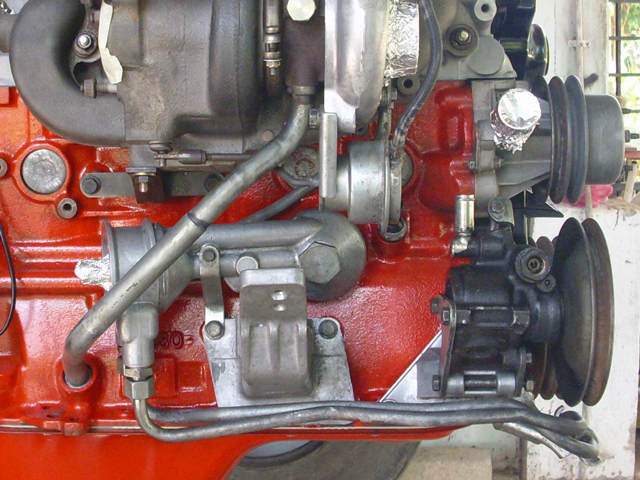

I wanted to see how the downpipe would fit with the 700 oil filter bracket relocation...

barrowed pic from googlez

plenty of room to install/remove the filter although it won't be fun when/if the exhaust is hot lol... still thinking some exhaust wrap for the downpipe would be a good idea... also going to be interesting figuring out how to run the oil cooler lines...

then I tossed the alternator in the low exhaust side mount... I'm amazed at how much more access it gives to the back of the alternator.

then I decided to look at the powersteering options... my last plans was to use the intigrated resovure type from a newer 240 which would require a custom PS line built... I had considered building a bracket for the stock s10 pump (it's the same style pump just with different bracket/pulley)... upon a closer look I found I could use the high pressure line from the s10, It just needs the high pressure portion bent to fit...

also had to cut the botton of the bracket (a/c portion) off so it would clear the frame and fuel lines... next time I'm in the garage I'll work on re-bending that high pressure line so it'll fit... and get some snaps

I'm still not crazy about the alternator being mounting under the exhaust side but the relocation bracket makes me much happier with it... add that I have 2 or 3 other alternators kicking around I'm not really worried/concerned about longevity to be honest... but that wire run still really sucks...

tuna55

UltraDork

7/31/12 8:06 p.m.

We are very excited. This is the perfect no $, no time, GRM weirdo engine swap build. Nicely done.

yesterday I ordered some gaskets I need (oil drain pipe, and exhaust manifold gaskets)... O want to get to the point that I can mount the turbo up and not take it off again... so I had to work out a solution for some tidbits...

... pulled off the PS pump... I'll work on bending that hard line at a later point...

I then re-bent the fuel return line so it'll clear the wiper motor... then I drilled a hole in the firewall to feed a self tapping screw that holds the fuel line bracket... not pretty but it works well...

then... I ran the wire for the alternator and will have to shorten it a smidge... keeping wires away from the exhaust is a good thing lol...

then yanked the alternator so I could fiddle/figure out my oil cooler line run... the stock lines run under the original mounts so the mounts have some space to let them fit... my mounts did not do that...

at first I thought I could turn the outlets to point towards the frame rail and get some banjo bolts so the line would just run along the frame rail... but that didn't fit with the turbo's oil drain line... and I'd MUCH rather use the stock hard line for this bit... thankfully I have loads of room under the engine between the cross beam... I thought i'd have to do some bending of the lines to get it to fit but one of them fit just right... the other not so much... but then I was happy to find that i hadn't gotten rid of the 2nd set... so this is what we've got.

I'll need to make a support bracket (er modify the stock one) to support the front hard lines at the front of the engine (keep them from braking and getting tangled in the steering linkage)... if I bend bend the 90* bends at the front I also should be able to use the stock soft lines and mount the cooler up front (considering in the bumper with some holes cut and mesh for some protection)... we'll see what things look like after I start getting the body back on...

little more time out with the car

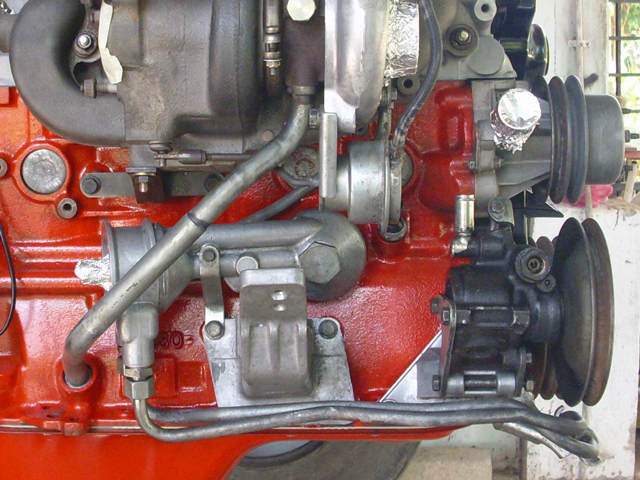

I'm working on buttoning up the passenger side of the engine... i've got all the gaskets and crap and the electric stuff is all on the other side

anyway most of my time was spent searching for parts :-/...

anyway I started with trying to bend the hard lines for the oil cooler... didn't work as I'd hoped, just to little room to get a hold of it... ended up putting a kink in it... so I pulled out the tubing cutter and just cut it straight at the end...

then I went to looking for the original bracket brace that clamps the oil cooler hard lines together at the front of the engine... didn't find it... It's got a few other possible hiding spots... with such a small garage it's not easy to organize grr... my plan was to use the clamp portion of that and weld a small T to support the oil lines... if I can't find it I'll just have to improvise...

while looking for that I found the SS oil feed... I pulled the oil filter attachment so I could install the oil feed... got that on then the oil filter back on and called it a day...

I'm so happy with how far you've come, keep on keeping on!

This is pretty fantastic. I'd love to see it finished.

man I love S dime racers...This is gonna be one bitchin challenge entry. Keep up the good work man, youve come so far!

Alan Cesar wrote:

This is pretty fantastic. I'd love to see it finished.

you and me both... I've fought hard to keep this thing...

Cool build that defines the GRM/Challenge spirit! :D Lemme know if you need a hand with anything, seeing as I'm in Clear Lake.

Hopefully I'll be able to finally meet you lol.... Very interesting build friend!

finally some stuff for the s10...

bought some used lugnuts for the weld racing wheels... when I got them they had some short and some long shank... the wheel needs all long shank... guy on GRM had some for real cheap in the s10 threading...

also waiting to finalize getting some suspension parts from a guy on GRM, a bunch of random things, lower springs, a few sets of lowering blocks, I won't use all of it but I'd like to have a decent selection when it comes time to setup the suspension... also have to order a few other tidbits while I have the $$$...

anyway today I finished my Eng midterm (got a 95% BTW :)... I'd picked up a crimping tool for non-insulated wires aka a ghetto way to crimp molex pins earlier this week...

sat down with my 14point7 SLC2 DIY kit... it's no circuit board building, just have to attach the pins to the wires, solder 5 wires to the circuit board and screw everything together... so got everthing crimped and I added a dab of solder on each just to insure a good electrical connection...

I'll do a temp wiring job of it on my volvo here soon just to verify it works correctly and check my AFR's on the volvo...

for anyone that is looking for a good deal in a pretty full featured wideband hop over to http://14point7.com/ $190 plus shipping gets you data logging on AFR, boost, EGT, intake air temp, coolant temp, fuel pressure and oil pressure, and dual axis accelerometer (granted most of those you have to buy extra sensors... but he gives the specs so you prob can find most of them cheaper then he sells em for)

Good job on the mid-term!

That wideband setup looks pretty nice for the money. If I ever get another turbo vehicle (that I plan on modifying) I'll keep that in mind. The Spitfire/Miata is using the stock electronics, so no need for it there.

ya it's good for the $$$... there was cheaper options even at the time... right now he's got one built into the sensor for $105 or something like that... but I sold myself on the idea of using it on other vehicles

well I ground off the non penetrating ugly bird poop welds on the outside and did a test fit... the fit is about perfect... the fit for the entire downpipe is going to be a bit tight running past the frame and the trans but should be just fine... also very happy as I have a nice spot for the wideband sensor... all while keeping the heater blower motor box without any massaging/modification

well I ground off the non penetrating ugly bird poop welds on the outside and did a test fit... the fit is about perfect... the fit for the entire downpipe is going to be a bit tight running past the frame and the trans but should be just fine... also very happy as I have a nice spot for the wideband sensor... all while keeping the heater blower motor box without any massaging/modification