Now for the string! I told you I'd do this tonight.

Strings can be made of many things, and in many ways. First, the material. I use Dacron:

It's fairly common for bow strings. It comes in many colors, and it performs fairly well. It is about equivalent to a very high quality string made from flax performance-wise. The best performing strings are very light, and have no stretch. There is a string material known as "fast flight" and others that are stronger and less stretchy than Dacron. If it is stronger, you can use less of it, meaning there is less mass. Less mass to accelerate means more energy is available to the arrow. Less stretch means the string absorbs less energy, making the bow more efficient. You have to be careful, however, as a string with no stretch is like a car with no suspension. Ever gone over a pothole in a gokart? Your spine has to absorb the energy. The bow will always have energy left in it after the arrow leaves, and a stretchy string takes some of that. If the string doesn't stretch, the wooden limbs must take it all, and this can damage them. Stick with dacron, it's safer and WAY cheaper. You won't notice a speed difference unless you use a chronograph.

There are many other materials as well. Rawhide, flax(linen), sinew, hemp, human hair, etc... The main consideration is amount of stretch, strength, and weight. Human hair would have to weigh too much to be strong enough, rawhide and sinew stretch a lot (though they 'break in' and much of that goes away), and hemp is somewhat difficult to grow without some legal troubles. You may be tempted to use artificial sinew, as well. All the cool looks without the stretching, humidity, and processing troubles. Don't. It's made of nylon, and nylon is crazy stretchy. You'll have to make the string too thick to resist the stretchyness, and it'll weight too much. I say use dacron, or use high quality linen twine. You can grow your own pretty flax flowers, too, if you're interested. Bowyers Bible book 2 has TONS of string stuff in it, like 80 pages if you're interested.

There are many types of strings. Many purchased strings are either 'flemish' twisted or endless loop. Endless loop strings aren't that twisted, and therefor perform better. More twist means longer string fibers (because they aren't going point to point in a straight line) and they stretch more. I do the twisty kind. A flemish loop on one end, and an adjustable knot on the other. That way, they can be adjusted (duh).

You must first gather up your string pieces:

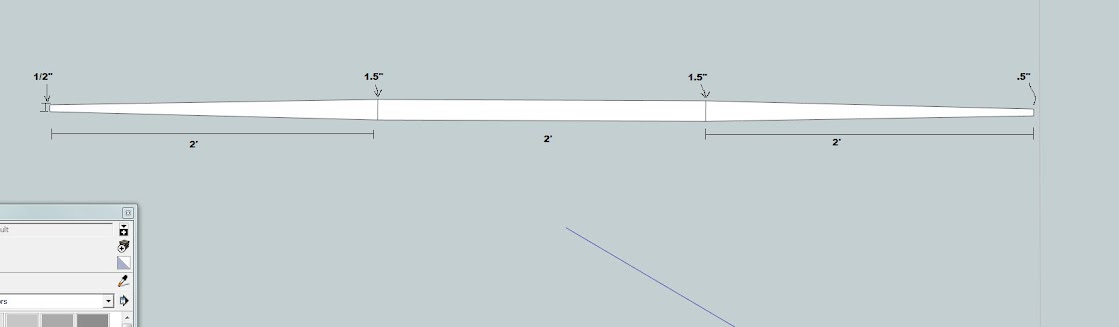

I use 8 pieces, 4 of each color (yellow and brown, in this case). The number of pieces is very important. Too many, and it'll weigh too much. Too few, and it'll break. There are 2 tricks to choosing. One is draw weight at full draw times 4, the other is draw weight at 10" times ten. I use the first one. I don't know the breaking strength of dacron. I have heard from 35 to 50lb for a strand of B50 dacron. My goal here is a 50# bow, so I need a string with a minimum breaking strength of 200# to be safe. if B50 dacron breaks at 50lbs, then I need 4 strands. If it breaks at 35lb, then I need about 6. With very few fibers, an arrow will have trouble "clicking" onto the string (modern arrow nocks will click and stay on while you draw as a convenience, and old school self arrows can be made to do the same). It can also dig into the arrow tips. 4 would be too thin, 6 might too. I'm not making a flight bow, so the extra fps won't really be notices. I also choose 8 minimum because it's more than I need. More means it won't break. I don't like things that break. I cut the pieces about 7 feet or so long. Again, more than I need, but i've made bow strings that were 1" too short before, and that SUCKS.

Take the fibers and separate them into 2 bundles of 4 (by color in this case) and hold them about 9" from the end. I do this with one of those spring clamps. You can use like 3 or 4 of them to make this process a lot faster, and use them as drop spindles to twist quickly, but my whole arsenal is currently at my friend's place. I only have 2.

Now, twist both of those bundles like so, in the same direction:

Do this for like 3 inches or so, leaving the rest (6") untwisted. Now, twist those 2 bundles together in the opposite direction, like this:

This is called reverse twisting. Ever twist some string and let go? It'll untwist. It's not stable. Ever twist a string a lot and watch it do this?:

That is the string trying to achieve stability. It reverse twists itself, we're just using those forces to make 2 reverse twisted strands hold themselves together. Now, fold that 3" of reverse twisted thread back on itself and clamp the ends together, with the untwisted strands gathered together.

At this point, you may be thinking i'm going to knot it somehow, but that's not true. I will be using this, however:

String wax. Get some. It lubricates the strands in the string so they don't rub up against each other wear themselves down. It also holds the strands together when you are twisting the string, so that's a plus. Dacron comes waxed, but more can't hurt.

Now, you'll notice you have 4 long and 4 short strands of each color. Group them together, waxed, and twist. Do it to both, and then reverse twist them. You'll see this:

A couple strands stick out of the last half inch or so, but the 5 1/2" before that are twisted together. When the string is on a bow and the bow is strung, the sting will be under a lot of tension. This makes the strands try to straighten, but since they are twisted, they tighten against each other. The stronger the pull, the stronger they clamp together. The friction keeps the short strands from pulling out of the bundle. I've never had one of these pull out, and it wont, unless you untwist the string. Now, just keep going. Twist and reverse twist until you reach the end:

If you let go, the string won't straight up unravel on you, but it would stay together. At this point, I tie a knot before unclamping

Now, you can unclamp, and you have a string with a loop on one side!

You need the knot on the other side. It's called a bowyers knot, or a timber hitch.

First, do this:

It's hard to explain knots, I hope the pictures will do. Now, do this:

See how it's working? around the string, then twisted back on itself. Do this a few times

When it's tightened, it'll look like this:

This knot will tighten onto the bow. Remember how the tension holds the short strands together in the loop? That's what holds this knot tight. Move the knot, and the string will be a different length between that and the loop. Use this to adjust string length when it's on the bow. You can make the string extra long and use it for tillering, and then cut the extra off when it's on the strung bow. A knot works on the end, or you can use a lighter to melt the fibers at the end together.

The string isn't totally done yet, but it is for now.

Would either one be more optimal given no knots or runoff?

![]()

The limb on the left is hinge city. A hinge must be corrected before pulling the bow any farther, or permanent damage to the belly fibers there will result in set. Once it is bending balanced with no hinges at half the draw weight, pull it another 10lb or so, and check again.

The limb on the left is hinge city. A hinge must be corrected before pulling the bow any farther, or permanent damage to the belly fibers there will result in set. Once it is bending balanced with no hinges at half the draw weight, pull it another 10lb or so, and check again.