Georgia Tech's Wreck Racing team is a place where GT engineering students can learn to apply engineering knowledge gained in the classroom to real-world problems, all while scratching the car itch while in school.

The team was started in 2003 to compete in the Grassroots Motorsports $20xx Challenge, which rewards creative thinking and innovative problem-solving, essential skills for engineers.

The team first campaigned a VW Golf in the $2004 Challenge, then a turbocharged BMW 325e for $2005-2008, a V8-swapped Miata for $2007-2011, and most recently, a 2JZ-swapped MG Midget. The Miata won the $2010 Challenge and has since been converted to track duty.

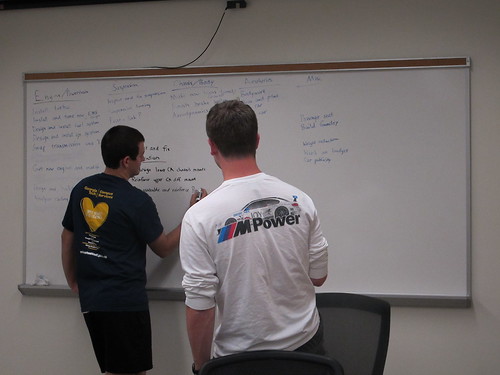

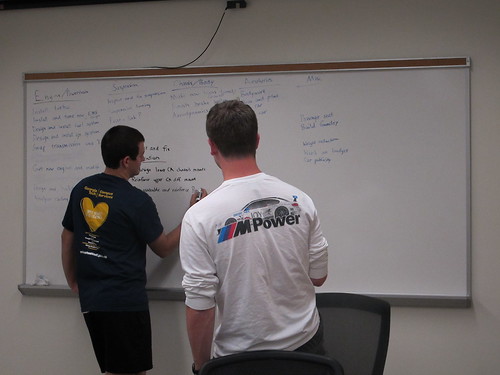

The team leaders met in October of 2012 to plan the next chapter of the Wreck Racing Miata’s life.

The goal: Compete in the 2013 Grassroots Motorsports Ultimate Track Car Challenge at Virginia Int’l Raceway.

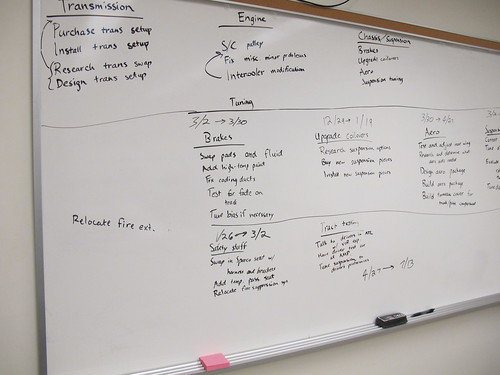

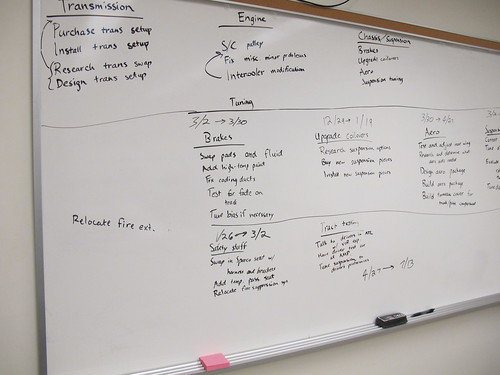

At this initial planning meeting, all the projects were laid out and given timelines.

Main projects to complete:

-manual transmission swap

-smaller supercharger pulley (more boost)

-better engine tune

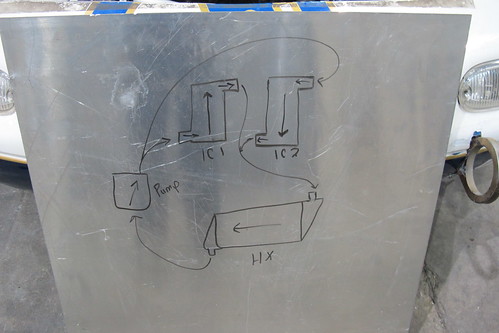

-intercooler system modification (going from one-shot auto-x setup to steady-state track setup)

-upgraded suspension components

-aerodynamic improvements including front splitter

-overall reliability and quality improvements (lots of testing!)

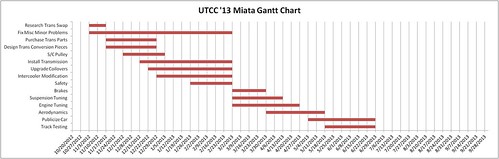

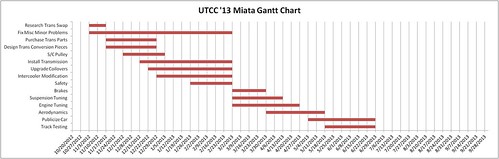

The resulting timelines:

The first order of business was to begin the process of swapping transmissions. The automatic transmission previously mated to the engine, while adequate for autocross and drag racing, would need to be replaced to get the most out of the car on track. Here is the (5-spd manual) R154 transmission that was to be used instead. It comes from the ‘86-‘92 Toyota Supra Turbo.

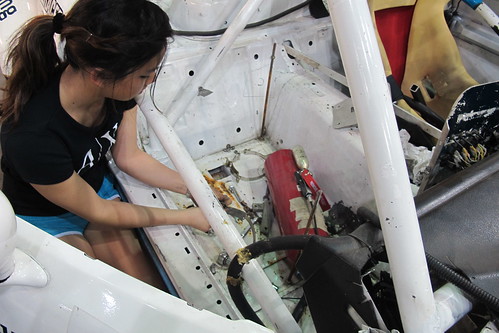

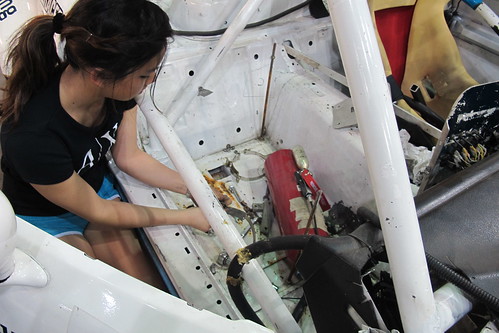

Dropping the engine and transmission out of car for the trans swap

A clutch pedal and master cylinder needed to be installed to actuate the manual transmission’s clutch. Luckily, we still had the original Miata units.

A custom bracket was added to allow the cylinder to clear the brake booster, which had been moved over in the process of modifying the firewall and transmission tunnel when the car originally received the larger 1UZ V8 engine.

Now that the car was no longer under the $20xx Challenge rules, we could splurge on a transmission bellhousing adapter instead of designing and building one ourselves.

Here the new flywheel and clutch is installed. The flywheel is a modified version of the one on the 3S-GTE engine (Toyota MR2 Turbo and Celica All-Trac Turbo).

The transmission uses a hydraulic throw-out bearing to actuate the clutch.

Next the eBay 6-puck unsprung clutch was installed.

Transmission mated to engine

While the engine was out, the supercharger pulley was swapped.

With the supercharger assembly reinstalled, the drivetrain was ready to be reinstalled.

Reinstalling the drivetrain

Some driveshaft modifications were necessary for the new transmission.

The old automatic transmission controller could now be removed

While trying to bleed the hydraulic throw-out bearing for the first time, it was discovered that the Miata’s clutch master cylinder didn’t displace nearly enough fluid to actuate the clutch.

A new master cylinder from a Camaro application was ordered and installed. No more issues there.

The old Igloo cooler that housed the intercooler’s ice water supply was removed, the fire suppression tank was relocated, and some wiring was cleaned up.

This way, a passenger seat could be installed to make engine tuning easier.

An 80’s Celica shifter was used (after several cut-and-reweld modifications were made).

Our Miata’s radiator originally came on a semi truck and was cut down to fit in the engine bay. Another part of that original radiator would be used for the intercooler’s heat exchanger.

The heat exchanger end tanks were designed in CAD, cut out on the waterjet, and welded to the core.

Leak testing the end tanks.

Tabs were cut out for mounting the heat exchanger to the radiator.

Mounted

The intercooler lines were then re-routed.

The bilge pump that was already used to cycle the intercooler water was relocated to the engine bay. A ball valve was installed to allow system bleeding.

Doing some late-night idle tuning before the GT Auto Show

The Miata on display at the 2013 GT Auto Show (March 30th). This is a free event for anyone to attend, by the way. Lots of very cool cars every year.

We did some “road” tuning at our test lot after the GT Auto Show

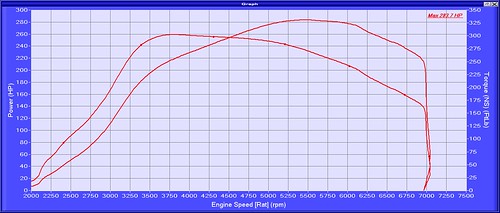

The next step was dyno tuning at Forged Performance, one of our wonderful sponsors!

The Dyno Dynamics dyno read about 280 hp and 320 ft-lb of torque on one of the mid-tuning pulls. It’s definitely no LSx, but the 1UZ does alright for a cheap junkyard engine with very little monetary investment and several psi of boost.

Unfortunately, the engine threw two rods during high-speed, high-load tuning, but we still got all the tuning we needed.

Videos:

http://www.youtube.com/watch?v=WCX-aWn_Cpc

http://www.youtube.com/watch?v=gDE1AOtIF9o

It punched a small hole in the oil pan.

It’s cheapest and easiest to replace the whole engine at ~$200 from the junkyard.

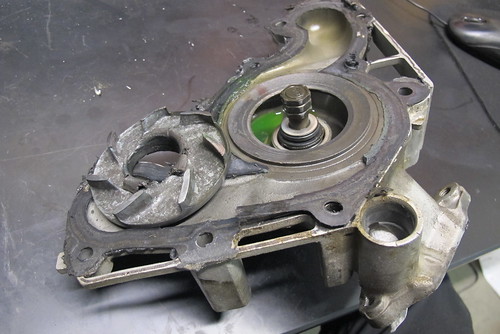

Here is the aftermath of the dyno session.

The water pump sounded funny when it was spun by hand, so it was removed. Yikes! The pump from the old engine was used instead.

We noticed the new manual transmission did not want to stay in 4th gear on the dyno, so it was torn down. The selector fork was damaged, and a new one was ordered and installed. No more problems!

The drivetrain was re-assembled and put back into the car.

Baffles were made for the side pipes to meet the 92dB noise restriction at Atlanta Motorsports Park, where we’ll be track testing.

The baffle tubes were packed with milling swarf for added noise damping.

First track testing to shake down the car and make sure everything's working correctly. Atlanta Motorsports Park has generously given us access to their facility for testing. Thanks, AMP!

The car got about 30 minutes of track time in between minor tweaks and fixes. Overall, everything went well though. AMP is a very neat, very technical track with lots of elevation change.

Fresh tires from Hoosier (another WR sponsor)!

Next up: custom alignment done at Gran Turismo East, yet another great Wreck Racing sponsor

Later that same day, we took the Miata to Drew Charter School in Atlanta for an event called the Design-O-Rama that was meant to get kids interested in STEM (science, technology, engineering, and math). Look at all the future Wreck Racers!

The Miata got some new goodies from a new WR sponsor, Flyin’ Miata, who donated V-Maxx Track Pack coilovers, FM front and rear sway bars, and a Wilwood brake proportioning valve.

At our second day of track testing at AMP, our UTCC driver Scott Siegel started getting used to the car and making recommendations.

The day went very well. We only had to make a few adjustments throughout the day, and we got lots of valuable feedback from Scott.

We took the Miata to the June Caffeine & Octane car meet in Alpharetta and talked to a lot of nice folks. This is held on the first Sunday of every month.

The next weekend, we took the Miata to an Atlanta Region SCCA autocross for some more testing and publicity. It was a lot of fun and we got to talk to more racers about our project.

Since the new coilovers were installed, it was time for another alignment at GTE.

This engine had always shown some strange oil-pressure behavior, often running unusually high or low. At the third AMP test day, the pressure dropped to zero and the crankcase vent started releasing lots of smoke.

When the car was brought in, rod knock was audible. Due to the rapid oil-pressure loss, it was thought that a plugged oil galley was responsible for this failure. Time for another new engine :(

We recorded it back at the shop:

http://www.youtube.com/watch?v=wZREWtDkgqU

The drivetrain comes out again.

There were bits of rod bearing in the oil pan. No rod chunks though, so improvement!

A final engine was pulled from a junkyard LS400.

Here we go again.

Ready to go back in again

The new engine was installed just in time for another round of track testing. This time we attended a Siegel Racing track day at Talladega Gran Prix in Alabama.

Flyby video featuring S/C whine: http://www.youtube.com/watch?v=oSESakxO54M

The car ran great for dozens of laps. Things were looking very positive for the Ultimate Track Car Challenge the next the month.

Meanwhile, a front splitter had been in development. The initial measurements and mockup:

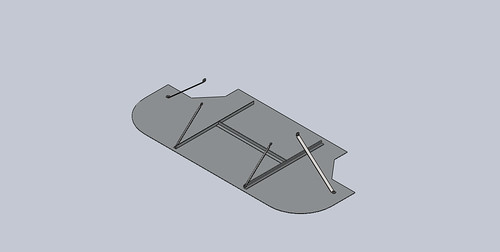

The SolidWorks model of the splitter.

The fabrication begins:

Some side plates and wheel covers were planned for the splitter but there ended up being no time to implement them.

Aluminum L-channel was riveted on and adjustable struts were added for stiffening.

Brackets were added to the side to maintain rigidity near the wheels, and the splitter was complete (enough).

Some initial testing in the parking lot of our shop:

The brake ducts were relocated to give the radiator and heat exchanger more airflow and for a more direct path to the brakes

Final track testing at AMP.

The car’s final track testing did not go so well. The bottom end on this engine started knocking after a few laps. Several things could have been to blame, including oil starvation. The knock was relatively faint, and with so little time before the competition, the decision was made to replace the rod bearings rather than try to source a new engine.

On-track video: http://www.youtube.com/watch?v=3KxCYY2evCM

That same day, we removed the drivetrain to begin the teardown process (the oil pan cannot be removed while the engine is in the car).

Things were worse than expected when the oil pan was removed.

The bad rod journals compared to good rod journals

More bad news: the main bearings were severely worn, but with only a few days before the competition, it was too late to order replacements. Thicker oil was used in an attempt to take up any extra clearance in the bearings.

Not what you want your engine looking like a few days before the competition!

We had to replace the rods on the #3/#4 crank pin, so we took them from an old engine. Engine disassembly is very fast when you don’t need to be careful with the parts (impact gun).

All rod journals measured within the 0.0002” tolerance window. Bearing technology is incredible!

Reassembling the engine with new headgaskets

The exhaust baffling was removed since there was no noise restriction at Virginia International Raceway, the site of the GRM Ultimate Track Car Challenge

The old hood had been damaged, and a new one had to be made.

The engine was started and no bottom-end problems presented themselves. We changed the oil and filter after a few minutes to hopefully remove the last bits of old bearing that were left in the oil system.

Leaving for the UTCC with a new hood and clean paint.

Once at the competition, we bled the brakes and tweaked a few other things. Scott (our driver) test drove the car around the paddock before suiting up for the timed track sessions. The engine was still acting normally.

However, on its first lap on track, the same old bearing problems crept up and ended our day.

The Miata had again been robbed of its day on track, but the lessons learned were worth all the time and effort put into the car. Learning is what this team’s all about!

UTCC compilation video including on-track action: http://www.youtube.com/watch?v=GeM3PW3T2j8