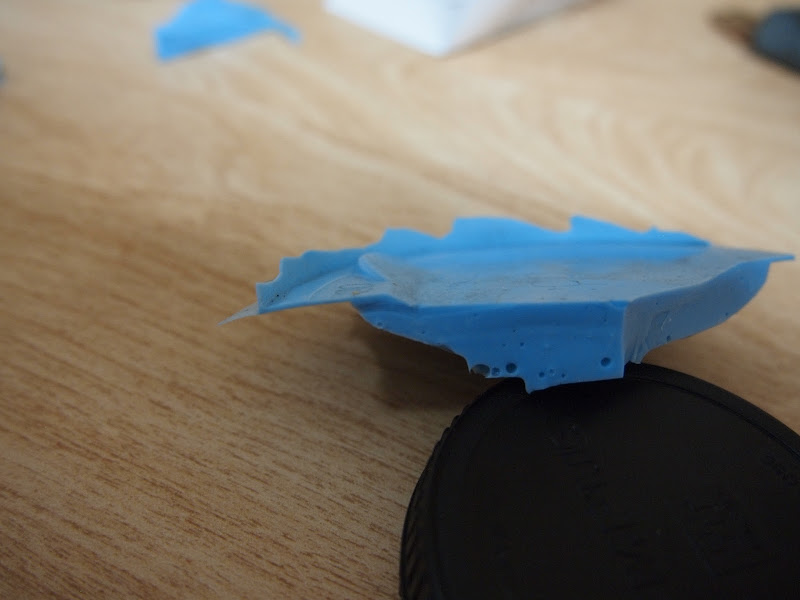

So this is a ( not very good ) cross section of a mold of an AE101 head over the top of AE111 pistons. It's not very good because I have to thin the silicone to get it to flow out and it's hard to work with like that. I would normal do this at TDC, but these pistons stand just BARELY proud of the deck, so this piston is positioned down the bore to simulate a 0.75mm headgasket. The volume this mold fills is sometimes referred to as the "clearance volume".

This mold is cross-sectioned down the middle. On the left is the center intake valve, split in two. On the right it gous between the two exhaust valves. At the bottom you can just barely see the indentation in the mold made by the dowe of the AE111 pistons. This shows how short that dome really is. On the exhaust side you can see the prominent squish, and how far the dome is from it' making a small volume between the dome and the squish. When the cross-section of the chamber gets smaller it slow the travel of the flame. If it's small enough the flame won't propogate, and you get squish! half-assed squish is bad. Well executed squish is good!

This second picture is a top view of this mold. Here you can see the silicone didn't flow well betwen the intake and exhaust valves. That's fine, we're looking elsewhere in the port anyway. The prominent squish on the intake side is evident here.

This third picture is a cut made between the intake and exhaust valves. On the left you can see the dome stops well before the curve of the wall of the head. Otherwise the cross section of the volume is quite good from the spark plug, which is on the far left, across the dome. Once again, for the compression ratio that can be achieved from these pistons they offer a damned good clearance volume geometry.

This third picture is a cut made between the intake and exhaust valves. On the left you can see the dome stops well before the curve of the wall of the head. Otherwise the cross section of the volume is quite good from the spark plug, which is on the far left, across the dome. Once again, for the compression ratio that can be achieved from these pistons they offer a damned good clearance volume geometry.

I flipped this piece over to show the profile the piston dome follows. The cut on the left is the bisection of the mold. The cut on the right goes from the spark plug down the center of the intake squish pad between the center valve and a side valve. The squish there is very prominent. Just to the left of it is the profile of the piston dome. I have heard some say that the cross section leading from the dome to the intake side of the clearance volume is insufficient for flame propogation, specifically on AE111 heads. This shows the cross section is maintained rather well through this area. This is very similar on the AE111 head. This cut also shows the clearance allowed between the AE101 head and AE111 piston.

I flipped this piece over to show the profile the piston dome follows. The cut on the left is the bisection of the mold. The cut on the right goes from the spark plug down the center of the intake squish pad between the center valve and a side valve. The squish there is very prominent. Just to the left of it is the profile of the piston dome. I have heard some say that the cross section leading from the dome to the intake side of the clearance volume is insufficient for flame propogation, specifically on AE111 heads. This shows the cross section is maintained rather well through this area. This is very similar on the AE111 head. This cut also shows the clearance allowed between the AE101 head and AE111 piston.

This last picture is of the bisection cut of the same mold piece shown above. The exhaust side squish is on the left. Here you can prominently see the exhaust valve relief. It is worth looking at the angle of the relief. This actually says something, believe it or not. On some pistons the valve relief is machined parallel to piston travel. Others, such as this one, is parallel to valve travel. My assumption is that this is based on the relationship between piston and valve travel. It is also worth noting that the clearance volume retains a respectable cross section in a section that tends to be compromised.

This last picture is of the bisection cut of the same mold piece shown above. The exhaust side squish is on the left. Here you can prominently see the exhaust valve relief. It is worth looking at the angle of the relief. This actually says something, believe it or not. On some pistons the valve relief is machined parallel to piston travel. Others, such as this one, is parallel to valve travel. My assumption is that this is based on the relationship between piston and valve travel. It is also worth noting that the clearance volume retains a respectable cross section in a section that tends to be compromised.

What does all of this mean? It means the AE111 piston do very well with the AE101 head. It also shows many areas for improvement, particularly where the dome does not extend to the walls of the bore. This would involve changing the shape of the squish pads and the combustion face of the head quite a bit. The advantage of the AE101 head over the AE111 in this regard is that there is more metal to work with to do so.

So we're going to look at some different pistons for build B ( not this engine but the next one ). Plan of action here is to determine how deep valve pockets need to be based on the profile of these camshafts. This will dictate much of the shape of the dome. The remaining sections of dome will be squish, and the head and dome will be modified to create a cohesively designed clearance volume.