hhaase

Reader

2/12/17 10:50 a.m.

If your mind is hesitating, trust it. May not be able to quantify why but there's usually a reason buried in there somewhere.

Wait till you're confident and your mind is clear. I'm sure there's plenty of other stuff at the moment you can do on the project.

Any resealing that calls for any type of silicone consider using either Hondabond or the Toyota alternative, which I believe is called FIPG.

There is NOTHING as good as those when it comes to sealing, especially when oil is involved.

I would suggest also Yamaha Bond 4 or ThreeBond 1184

itb76

New Reader

2/12/17 12:23 p.m.

Mad_Ratel wrote:

can we blame 50% of those BAT listings as guys who decided to get rid of theirs after reading about yours?... :P

and duster. I've been eyeing 540i's after driving my wifes 330i for two days... that 330i is SUCH a nice highway cruiser but I need something a bit bigger... Mazdeuce is NOT helping...

E60 545i's are fabulous cars. Not completely trouble free but not nearly as problematic as people make them out to be.

my 2 cents

Loctite 518 between all machined flanges never breaks down, remains flexible, suitable up to 300f.

Loctite 515 to dress all paper gaskets,an extreme use of this was to coat the shims that set the liner heights in wet sleeve engines, never had a coolant leak :)

These are my sealants for all occasions and I never have oil leaks,even on rally motors.

At this point given the effort to get there I would have all the parts laid out on a bench including fasteners and covers etc and contemplate them over a slab of beer :)

Always hard to believe when you tackle something this far out of your comfort zone that it will run again. But given your methodical approach it will be good :) D

itb76 wrote:

Mad_Ratel wrote:

can we blame 50% of those BAT listings as guys who decided to get rid of theirs after reading about yours?... :P

and duster. I've been eyeing 540i's after driving my wifes 330i for two days... that 330i is SUCH a nice highway cruiser but I need something a bit bigger... Mazdeuce is NOT helping...

E60 545i's are fabulous cars. Not completely trouble free but not nearly as problematic as people make them out to be.

Dad had a 2004 545i manual m-sport. He loved that car, from 45k miles to 180k miles when he sold it to my Brother in law who drove it for 10k more miles before plowing into the back of someone on his way home. BIL promptly bought a 550i manual with 40k miles on it. I think he paid 17k?...

Dad replaced the 545i with a 2012 550i 6 spd, m-sport (18k miles) and a lot of additional goodies. 2k miles later it had nearly $12k in parts on it. (cpo car.) The flywheel was gone (dual mass.) Clutch had melted to it, fuel system was completely revamped, and two of the four wheels were cracked... Warranty covered all but the wheels. He was able to convince bmw that there is no way he fried the clutch that badly (there was no material left the studs that hold the friction material were wearing into the flywheel) in 2k miles... Dad sold it for a loss and now drives a silverado z71. (He also bought some farmland that the bmw could not exactly traverse).

Dad's 2004 only had a few issues, starter died (have to take the intake manifold off to get to it.) and all the seals on the back of the motor dried up and started leaking a E36 M3 load of oil. The fan that cools the ecu died and int he summer the car would die if it got too hot. BIL was waiting to fix that when he rear ended the jeep.

In reply to Slippery:

That tool is simply bad a**.

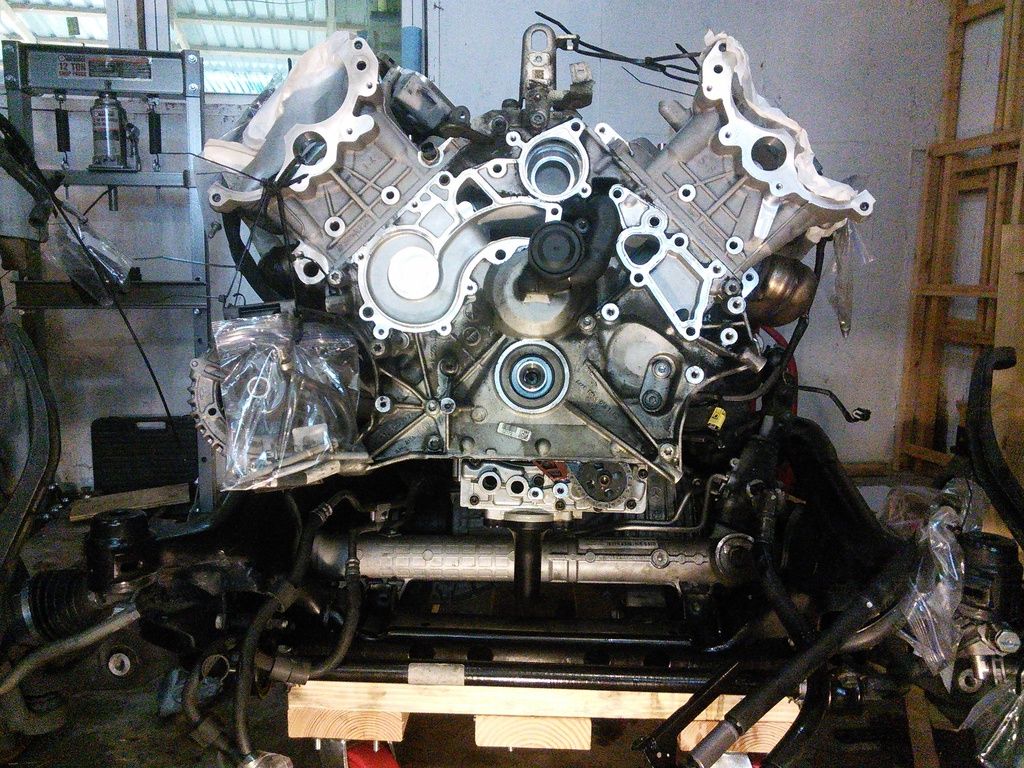

First time using a hoist, working well so far.

I pulled another set of oil lines off the driver's side of the block that wrap around the front of the engine. This is mostly a note for me so I remember to put them back on.

I pulled another set of oil lines off the driver's side of the block that wrap around the front of the engine. This is mostly a note for me so I remember to put them back on.

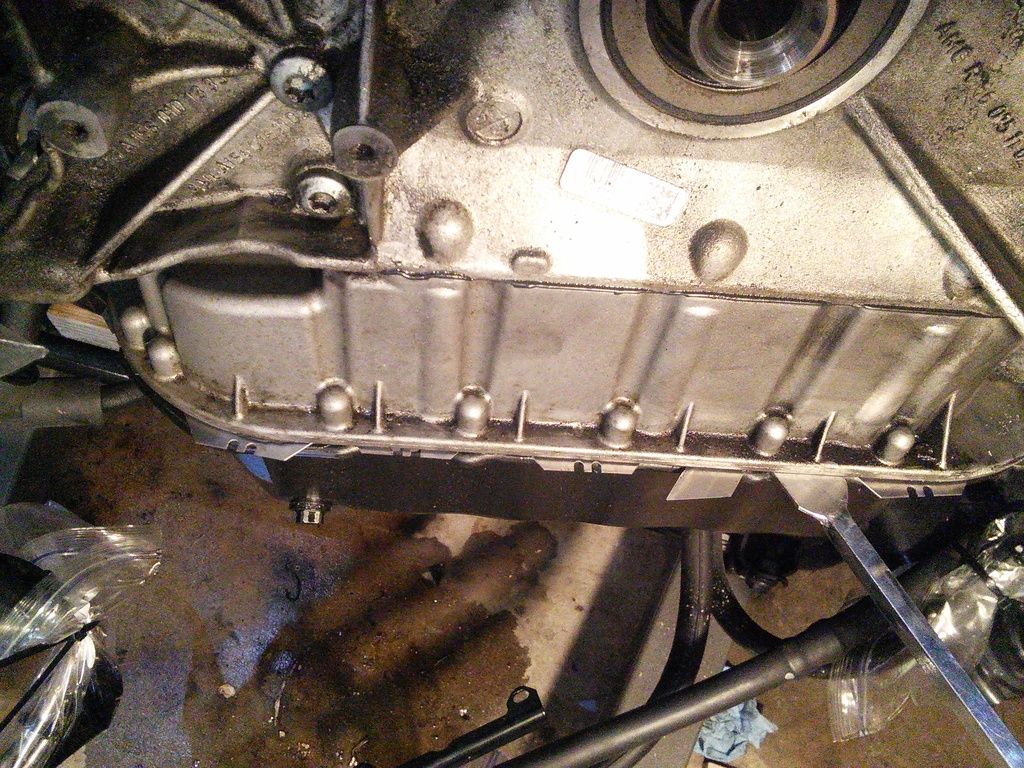

All of the bolts out of the lower pan and.....it's stuck. Some gentle tapping with a hammer and a block of wood has gotten me nowhere. Now what?

Ian F

MegaDork

2/13/17 12:31 p.m.

Remembering the video with the CNC gasket application, that gasket is likely an adhesive as well. You'll probably have to pry the pan off.

Stepped away to start some laundry. It occurred to me that I needed something super thin, like a knife blade. Knife blade.........

That's a handful of utility knife blades hammered very gently in until the pan started to lift and I could get the big flat pry thingy in there. And it's off!

That's a handful of utility knife blades hammered very gently in until the pan started to lift and I could get the big flat pry thingy in there. And it's off!

man, I HATE taking oil pans off- and that one looks like more of a pain than most. well done on the multiple razor blades.

itb76

New Reader

2/13/17 8:42 p.m.

mazdeuce wrote:

That's a handful of utility knife blades hammered very gently in until the pan started to lift and I could get the big flat pry thingy in there. And it's off!

Very clever, I'll file that away in my brain for future reference.

Cotton

UberDork

2/13/17 9:14 p.m.

Oh the engine crane. You might want to pick up one of the air assist hydraulic rams. It will still function as a standard ram, but if you hook it up to an air source it will lift easily with just the touch of a button instead of jacking away. Also nice when you're trying to clear a bunch of stuff and want to raise it slowly while looking around the engine and oppposed to working the handle. I put one on mine when the original ram failed and love it.....wish I had bought one years ago.

http://m.harborfreight.com/8-ton-long-ram-air-hydraulic-jack-94562.html?utm_referrer=direct%2Fnot%20provided

Cotton

UberDork

2/13/17 10:12 p.m.

In reply to m4ff3w:

Lol, you'll love that air assist ram too, it's awesome!

Galane

New Reader

2/14/17 2:20 a.m.

Nice idea on the air ram. Unfortunately (?) for me, dad invested in a Bluebird KD1500 over 30 years ago and it's never had a bit of trouble. No reason/excuse to replace a USA made cylinder with a potentially dodgy Asian one. I got tools up the yinyang and out the wazoo. ;) One of my favorites is a Monarch 12CK lathe from WW2. $400 rescue from a scrapyard.

Now if I just could gather the $ to finish the 9x20 CNC lathe conversion and the round tuit to finish the refit on my 1990 Acra 10x50" table CNC knee mill. Slow time of year for my reproduction plastic Hudson parts.

That's very interesting that they cross-hatch the sealing lands. We do that for some applications here at work, but high temp/high pressure environments are not one of them. Cool nonetheless though.

I bet it's a chore to get the sealant off those surfaces, which I guess is the point of them. Razor blades (or switch plates!) are no good there. Maybe the plastic roloc bristle disc?

GPz11

Reader

2/14/17 3:11 p.m.

We use a small wire brush on a dremel to clean the sealant off the surfaces at work

In reply to GPz11:

That's also what I found worked well on my SBC...but damn those little wires get everywhere!

Simply the tooling marks from machining on a CNC mill. Being a cast part, it has to be machined to be flat.

Greywynd wrote:

Simply the tooling marks from machining on a CNC mill. Being a cast part, it has to be machined to be flat.

Machining marks on aluminum don't have any depth. Those are intentional.

lnlogauge wrote:

Greywynd wrote:

Simply the tooling marks from machining on a CNC mill. Being a cast part, it has to be machined to be flat.

Machining marks on aluminum don't have any depth. Those are intentional.

To me, whenever you see machining like that it is because of cost cutting. The feed is too high for the rpm used.

It could be intentional in order to help with the sealant, but I highly doubt it. That is a part that is probably used in many engines across the brand and they want to make it as fast as possible. At the end of the day time = money.

I'm with Slippery on this one. Time to change the cutter insert.

I pulled another set of oil lines off the driver's side of the block that wrap around the front of the engine. This is mostly a note for me so I remember to put them back on.

I pulled another set of oil lines off the driver's side of the block that wrap around the front of the engine. This is mostly a note for me so I remember to put them back on.

That's a handful of utility knife blades hammered very gently in until the pan started to lift and I could get the big flat pry thingy in there. And it's off!

That's a handful of utility knife blades hammered very gently in until the pan started to lift and I could get the big flat pry thingy in there. And it's off!

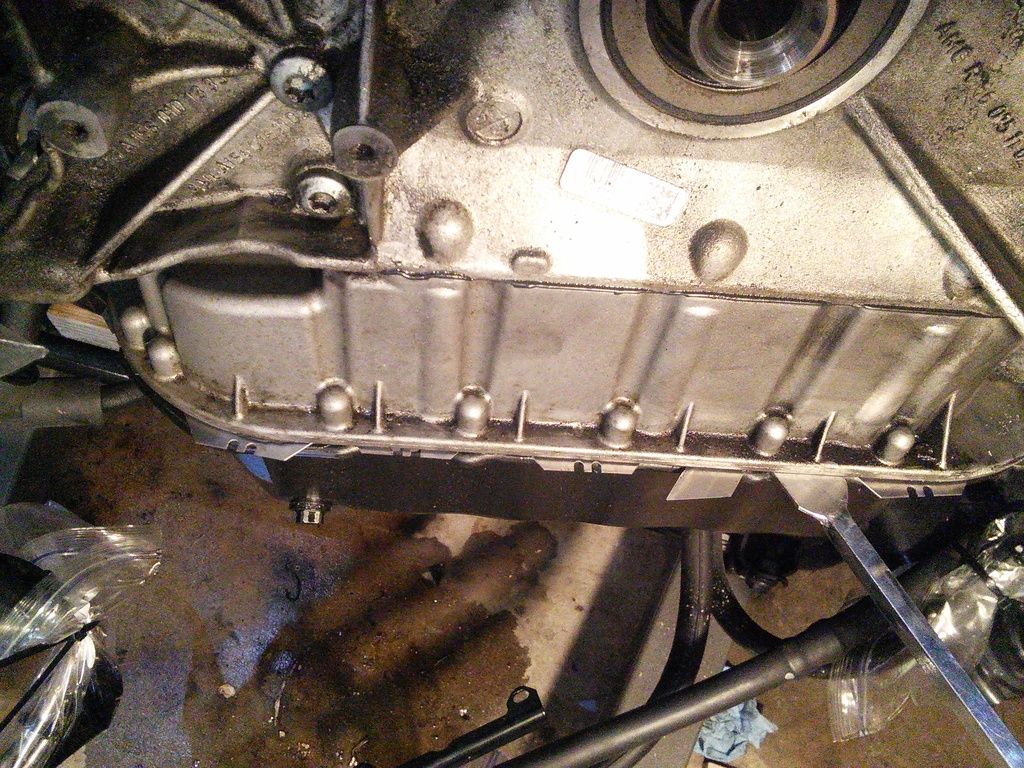

Another cool overly complicated MB part.

Another cool overly complicated MB part.

All of the machined surfaces have these cool patterns in them, I assume to hold the sealant and seal better.

All of the machined surfaces have these cool patterns in them, I assume to hold the sealant and seal better.

And now it's back on the motor mounts waiting for me to pull the chain case.

And now it's back on the motor mounts waiting for me to pull the chain case.  I also dumped the 1/2 quart or so of oil from the bottom of the lower pan this morning and was very happy to see just oil and a little wattery sludge. Nothing shiny. That makes me happy.

I also dumped the 1/2 quart or so of oil from the bottom of the lower pan this morning and was very happy to see just oil and a little wattery sludge. Nothing shiny. That makes me happy.