I have had my 2003 SVT Focus since my senior year of high school. It has survived college and the rest of the last 8 years with only a few issues and with even less maintenance. Working on my car was about the last thing I had time and money to do. However, the symptoms of age are creeping up, with 120,000 miles accumulated, so I am spending some time making up for past neglect. Car, will you forgive me?

Over the last few weeks, I have been working on an extensive (for me) parts swap out. I am currently in the middle of the process. Here's what I am replacing:

Flywheel, clutch, slave cylinder, pressure plate Starter motor Left and right lower control arms Left and right c/v axles Front O2 sensor (had it laying around) Rear main seal (might as well) Lots of surprisingly expensive one-time-use hardware.

I think that's everything.

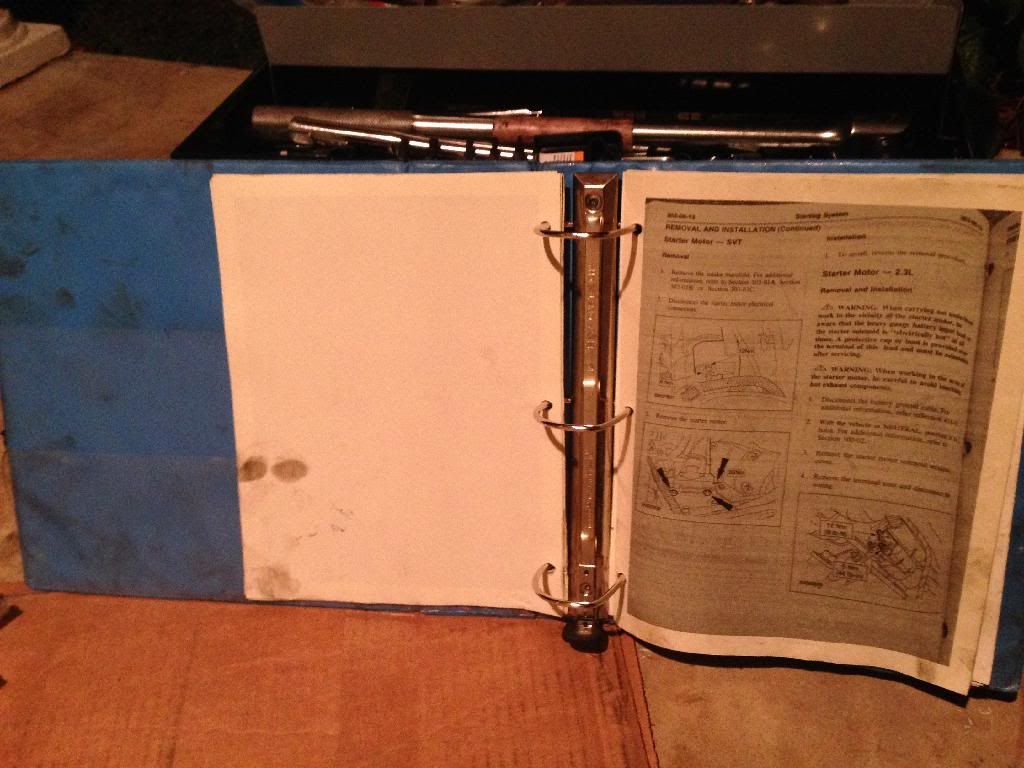

I am working as close to the factory service manual as possible. There have been a few places where I deferred, but honesty, these "shortcuts" have so far made my life more difficult.

I'll start with the beginning:

Step 1 - 4 of 100: Remove easy stuff in engine bay. Feel confident. Feel like things are certainly going smoothly. Step 5: book says, "Remove starter motor bolts. Book implies, "Oh, your tools don't click with .05 degrees of movement! Sloppy amateur with sloppy wrench, proceed to step 5's substeps 1-25, remove intake manifold." "Oh, and you need to first depressurize the fuel system, which means doing steps 4 - 1, then 1 - 4 again. Pull the fuel pump fuse, and run the injectors dry. But don't worry, it's not so dry that fuel won't spill all over the place anyway."

My first surprises: I touched a vacuum line and broke it, requiring a fix a bit further down the line, and now I need to change out the injector gaskets. Off to the parts store (herein referred to as "TTPS." It happens a lot.)

When I first began this little project, I thought that I would wrap it up in a long weekend. Hah! How naive I was.

The new portion is the shorter segment.

The new portion is the shorter segment.