Hi everyone-

Just so there's no confusion following the light-hearted harness bar banter, I believe that a harness bar + 6-pt FIA harness + FIA race seat + HANS device is safer on the race track than a stock seat and seatbelt.

Thanks to the fine folks here, I scored a nice closeout deal on some Racequip 6-pt pull-up harnesses.

I assumed because of the large discount that they would have older hole punches on the dates.

Nope. Fresh as a daisy.

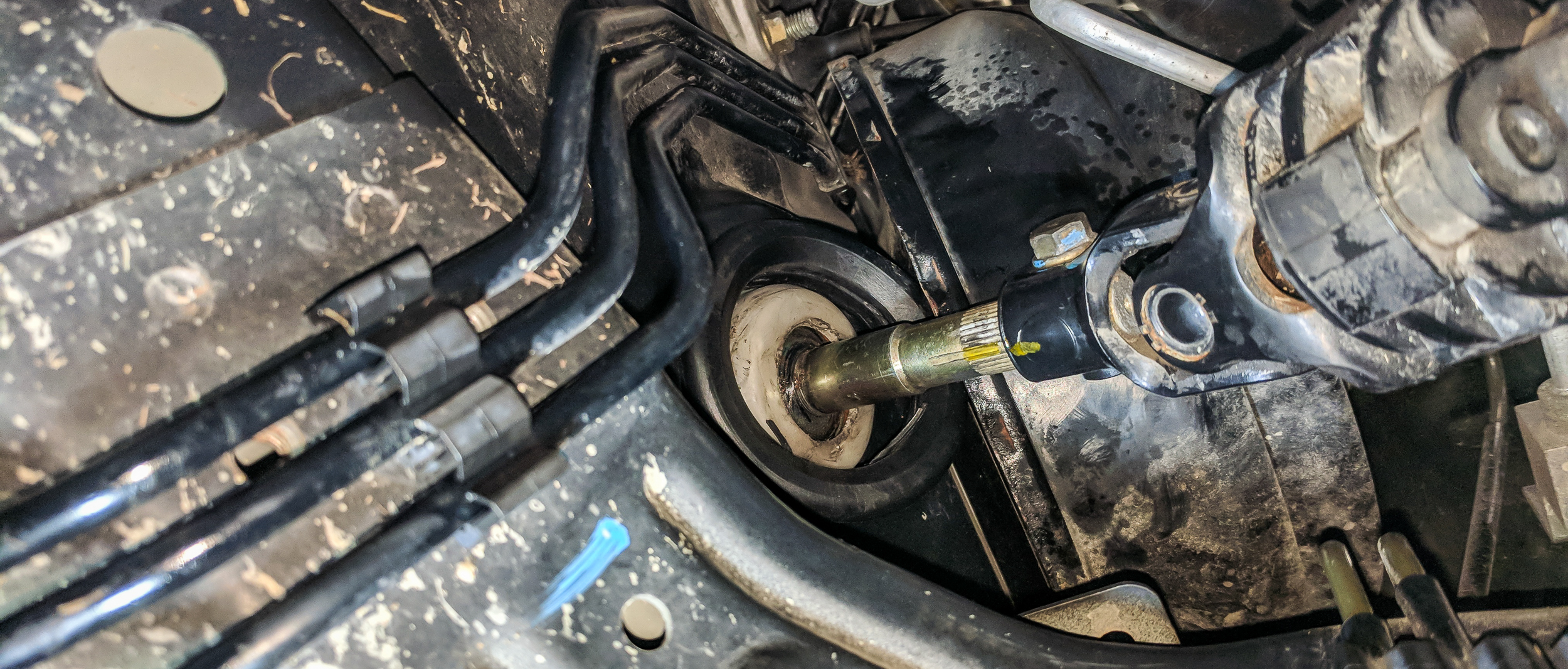

It comes with some nice eye bolts that threaded right into the stock seatbelt and seat mount holes. Yay.

I do need to sort the sub belt; it's mild-to-moderately cheese-rigged at the moment. I wanted to get it close enough to drive around the neighborhood.

I figured I should be able to get one side mounted in 30 minutes or so. It took almost 2 hours, and it's still not totally done. Classic.

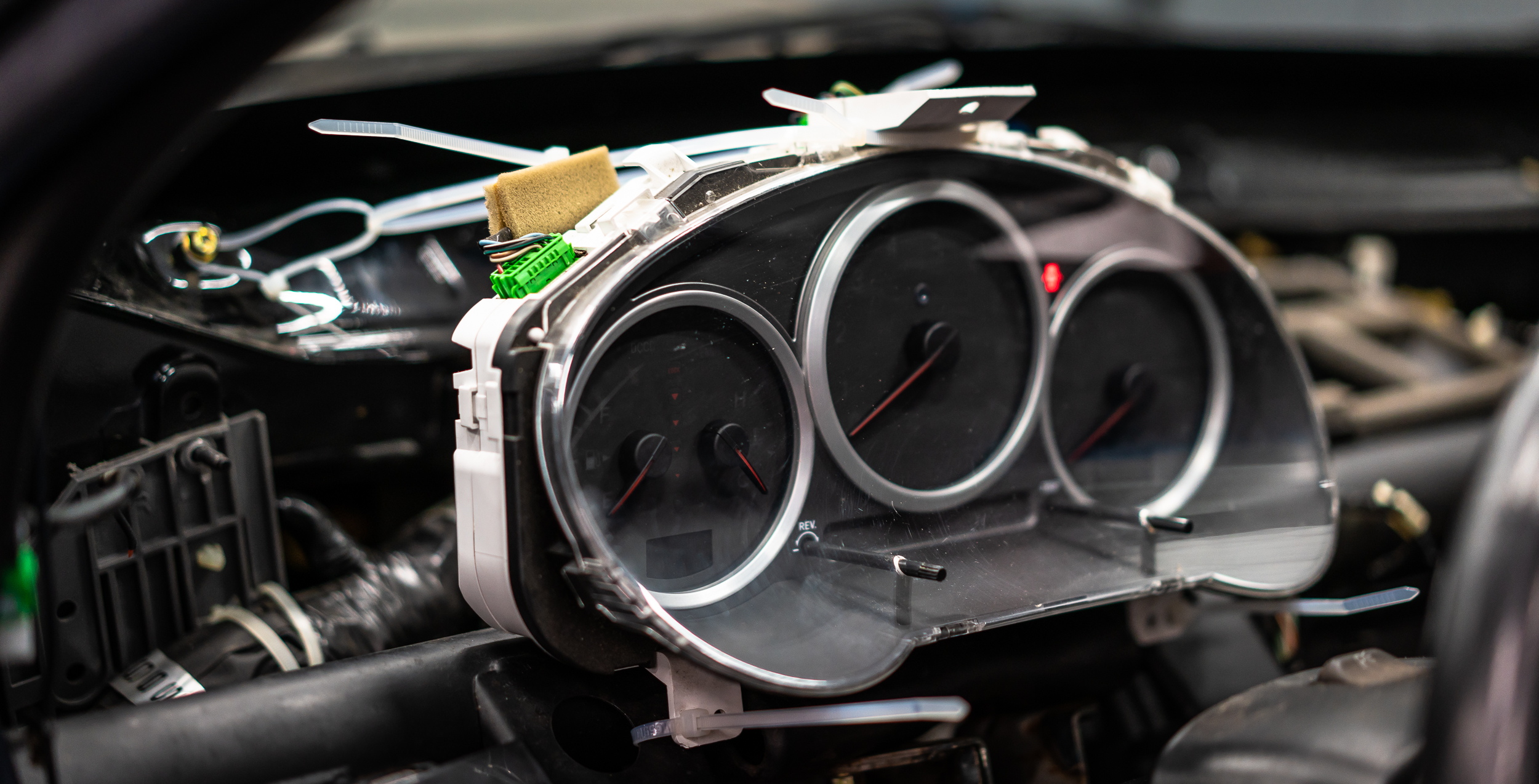

I considered hopping in right then, but driving a flooded car with no gauges was a step too far, even for me.

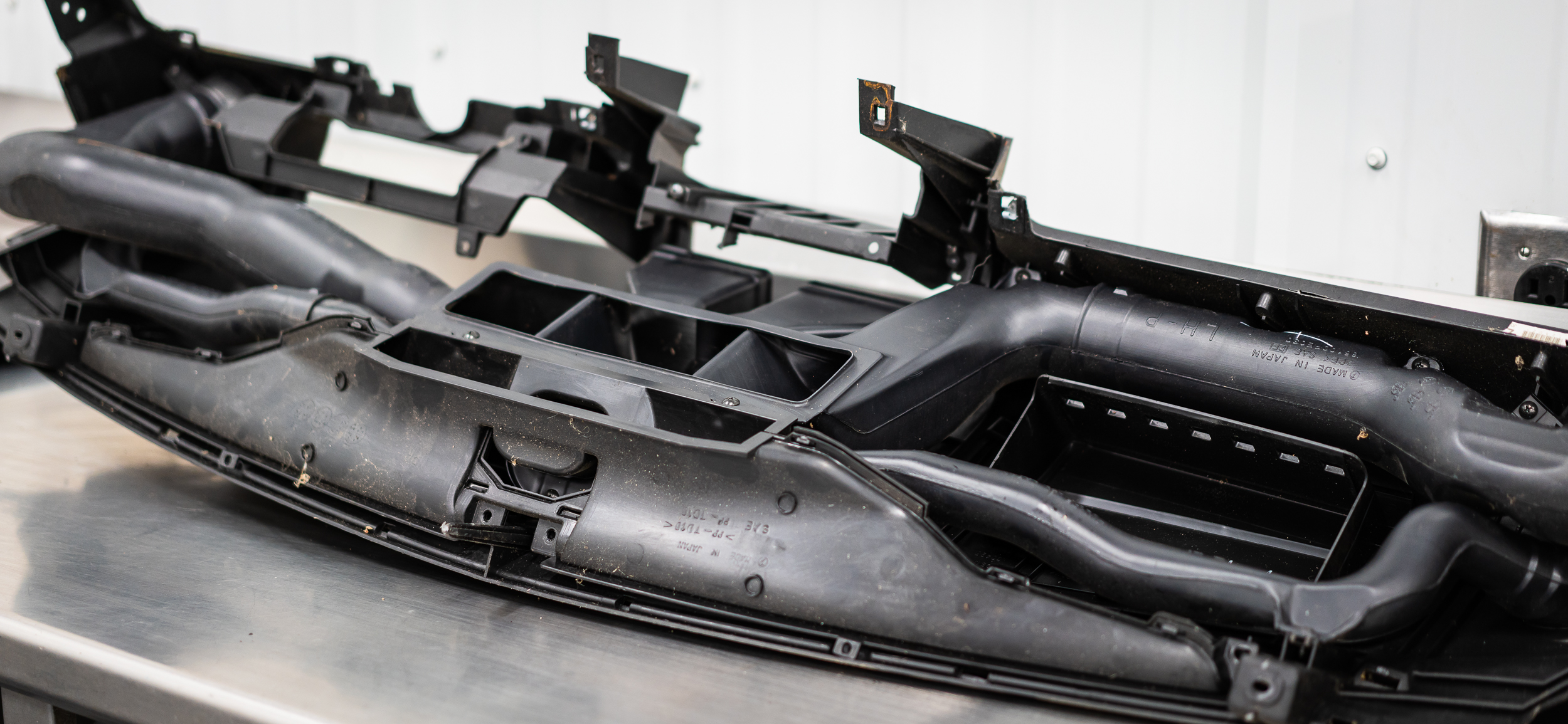

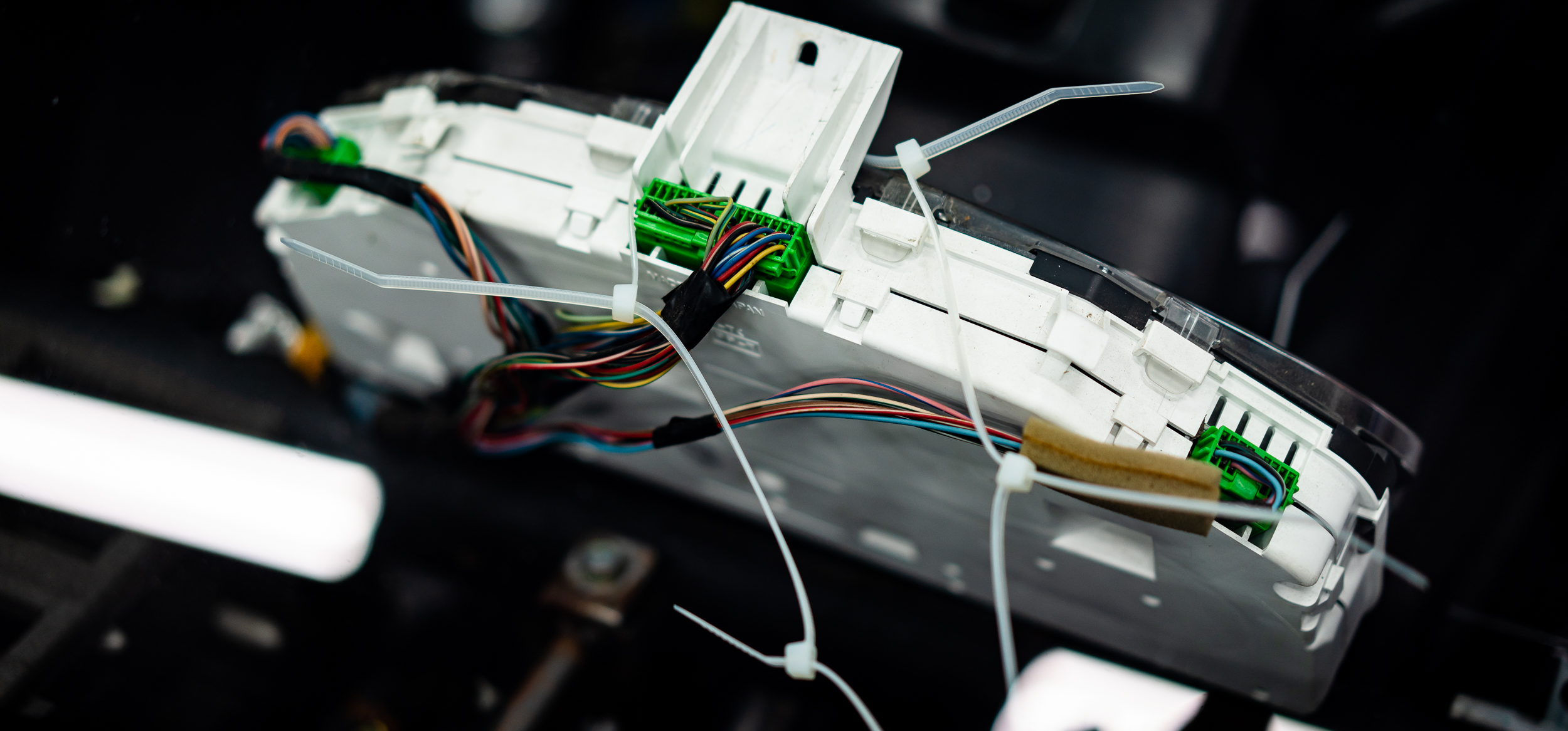

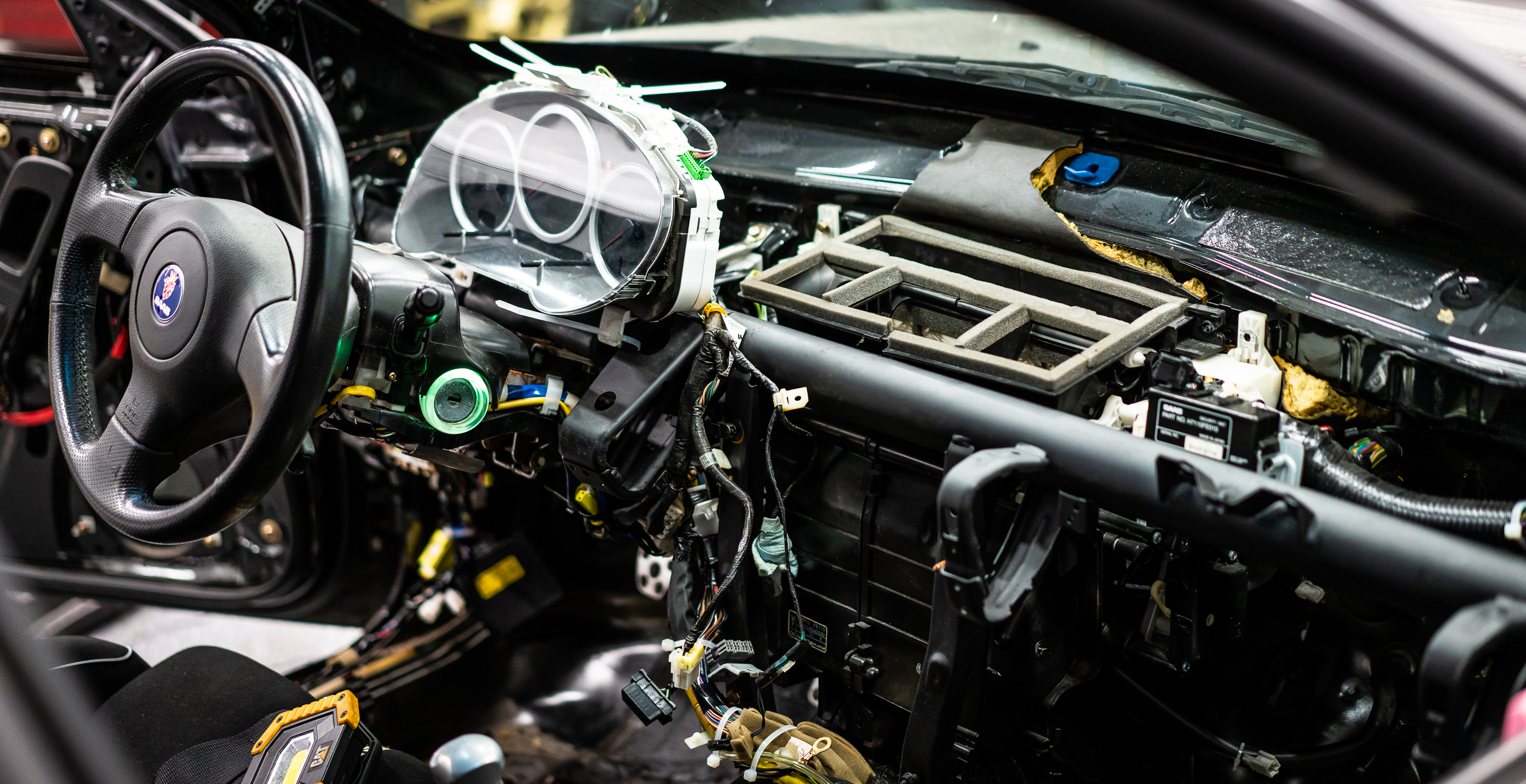

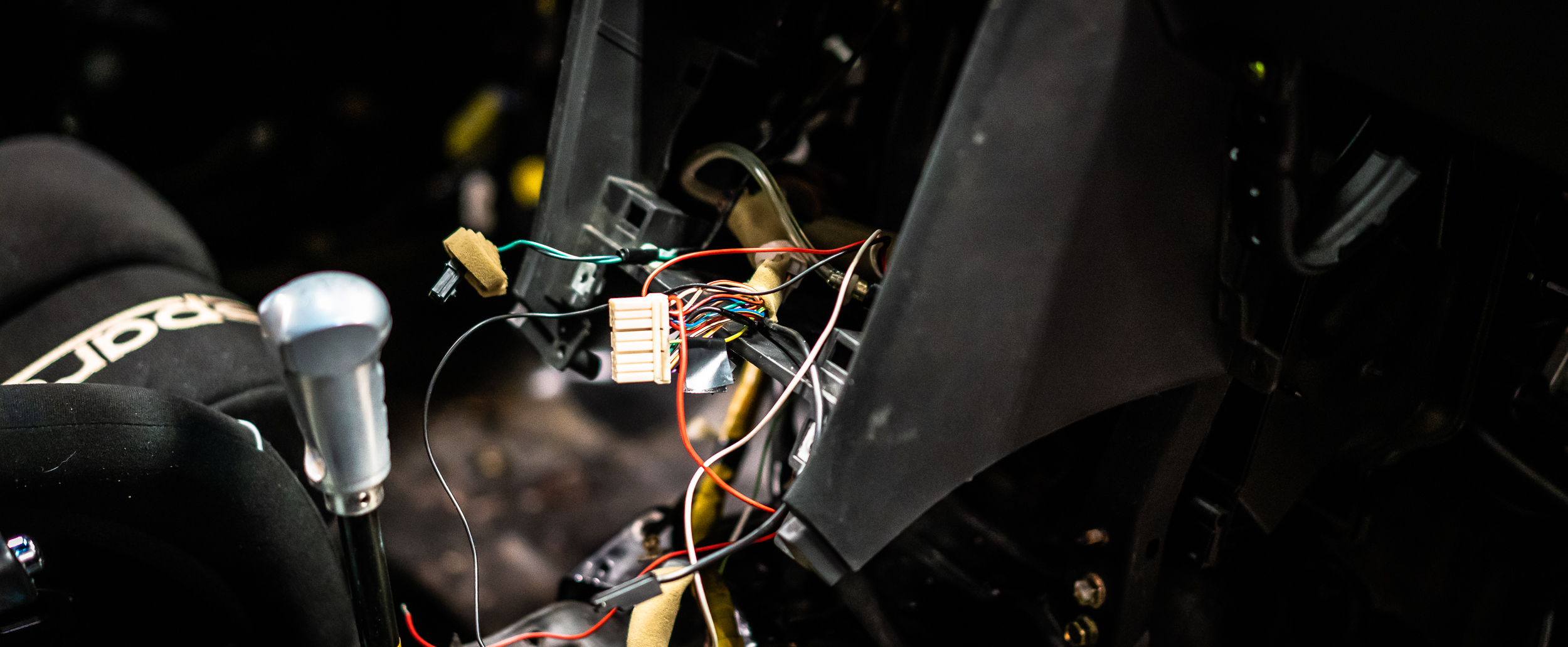

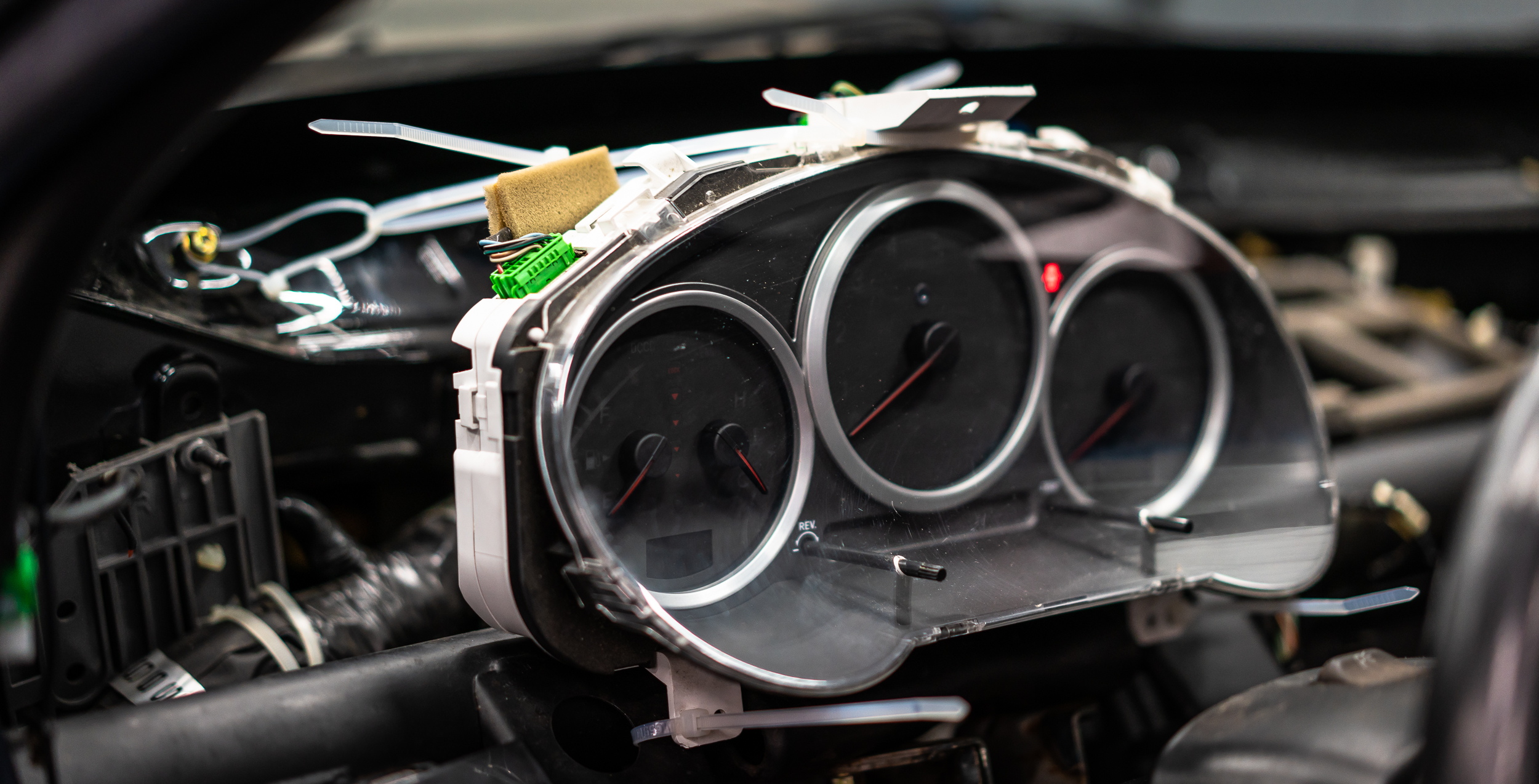

So I spent a few minutes unbolting the gauge cluster from the whoa-thats-heavy stock dash and using some milspec fasteners to mount it to the dash support bar.

Test drive time!

When I turned the key, the car started, but the gauges were a full Chevy Chase Christmas display of lights. In fact, the check engine light was actually flashing about 2x per second.

Not great, but it was running.

My brother had purchased a COBB Accessport V1 handheld tuner for the car way back when. One of the features of these handheld tuners is code reading and clearing, so after Nik found it in the shop (!), I plugged it in and pulled the codes.

"No codes found!"

Huh? The CEL was flashing! I made sure I'd followed the procedure right with having the key in the right position and all that, but still nothing.

Well then, I decided I would take it for a test drive anyhow.

It was a pretty uneventful drive. Too uneventful, I'd say: the car was painfully slow. It didn't seem like it was misfiring or running down on cylinders or anything like that, just reeeeeally slow. The water temp came up properly and stayed right where it should be, but without the extra gauges hooked up, I couldn't tell much else. I drove back to the shop and parked.

At that point, I noticed the idle was very low, like 400 - 500 rpm and hunting around. Nik and I half-heartedly poked around the engine bay a bit and didn't come up with anything. It was late, so I packed up and went home, not feeling too great about it all.

I did some internet searching later and found that the CEL will flash like that if you have the "Test Connector" hooked up in the car.

Huh?

Apparently, on some earlier years of the WRX, Subaru installed a one-wire green connector, found under the steering column, that you plug in to put the car into "Test / Diagnostic Mode". The CEL flashes constantly while in test mode.

I was really hoping that was the problem, so on my next shop night, I went straight in and looked for the Test Connector.

I was so excited, I failed to get a photo, but yes! I found it and it was connected. So I disconnected it. In my haste to get the car back in running form, I had just gone around plugging everything back in that I could find, so this all made sense.

I started the car again. Success! The CEL was no longer flashing.

My excitement lasted about 1 second, as the CEL went on solid. So, I turned off the car, hooked up the Accessport, turned the key to the on position, and read the codes.

"No codes found!"

Oh great, now I'm thinking there's something wrong with the OBDII port, or the Accessport, or who knows what. There is clearly a code. In a last ditch effort, I "cleared the code" with the Accessport, then started the car again.

CEL turned back on. This time, I turned the car off, but I didn't take the key out, then turned back to the "ON" position and checked one last time for codes.

Hallelujah! A clue!

"P1560: Backup circuit voltage low"

Uh oh. An electrical problem.

I'm not sure why I thought I wouldn't have electrical problems in a flooded car, but I guess I subconsciously hoped?

My first troubleshooting step: To the internet!!

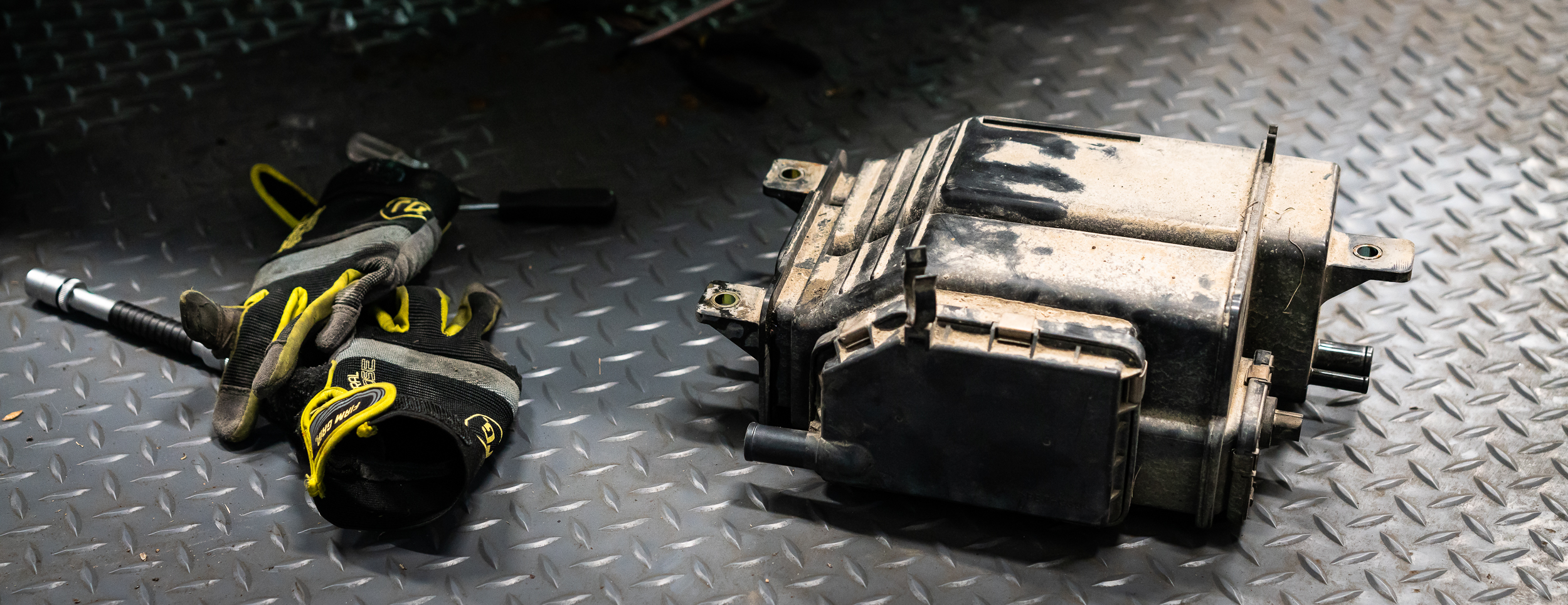

Apparently, this code is thrown when the ECU doesn't see proper (or any) voltage on a certain pin that provides constant +12V, even when the car is off. The easy fix is a blown fuse in the underhood fuse box, but that checked out fine. So I dug the ECU back out of it's home in the passenger footwell.

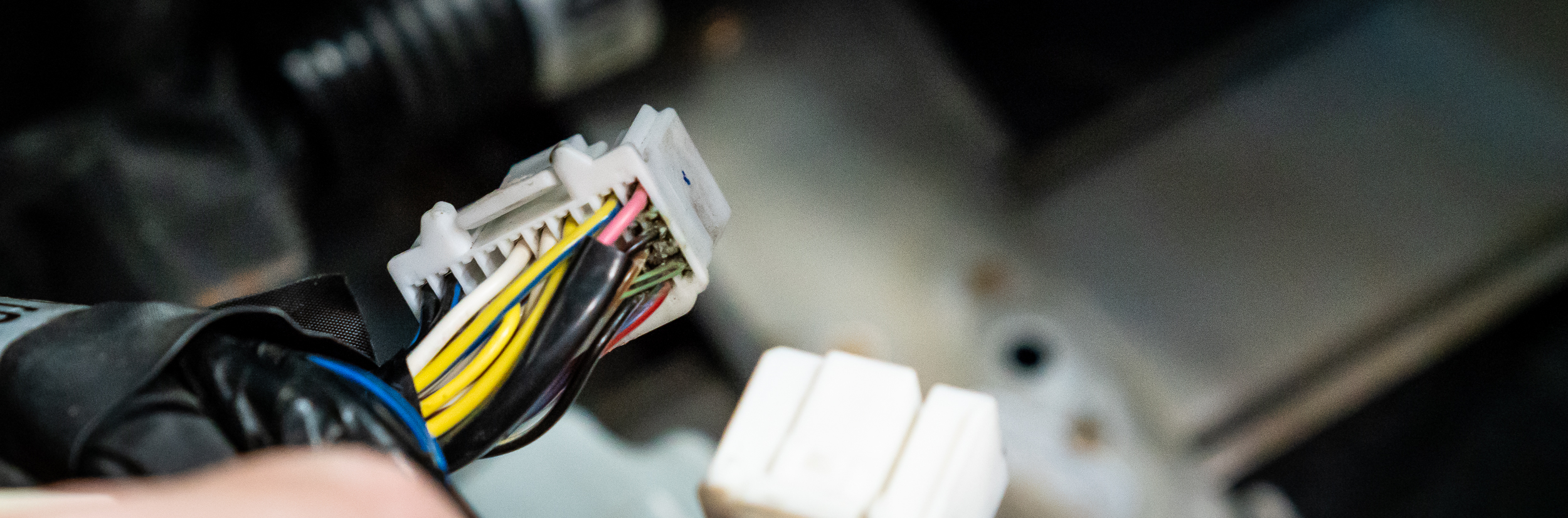

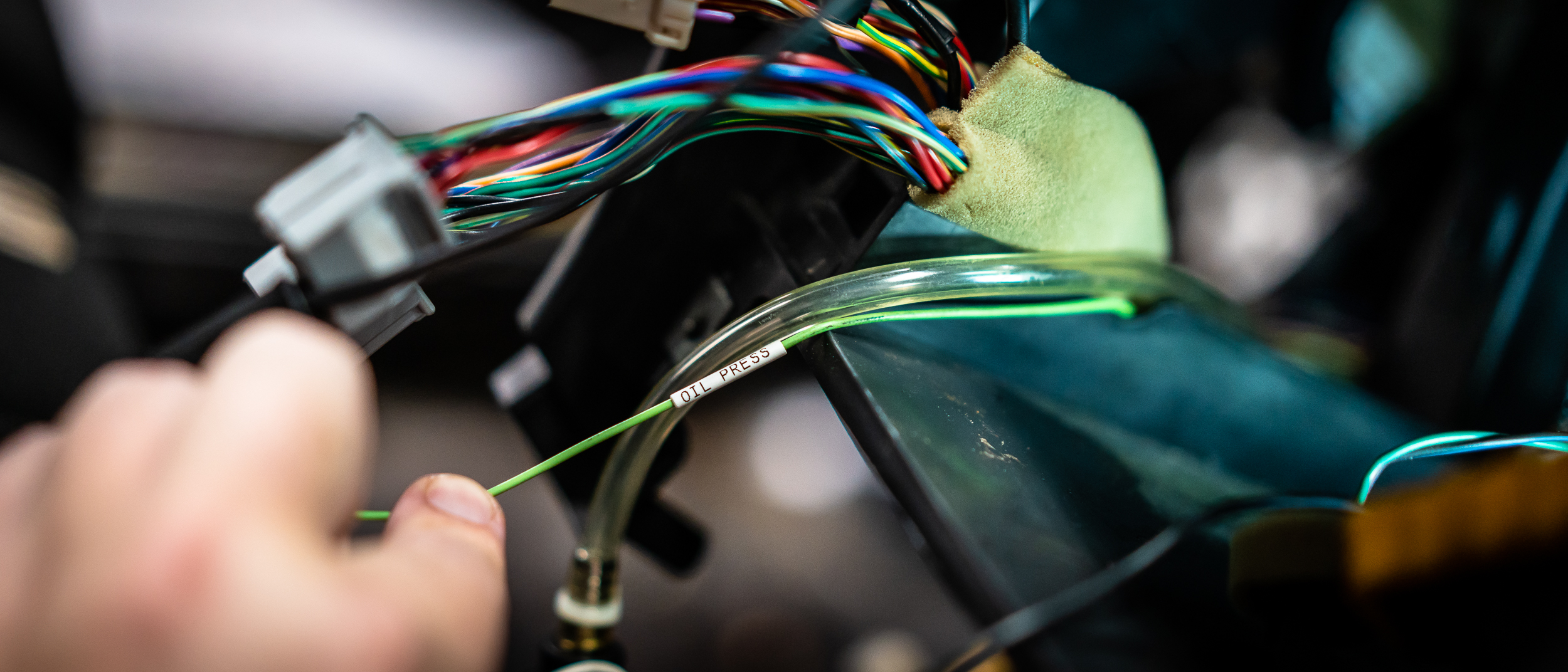

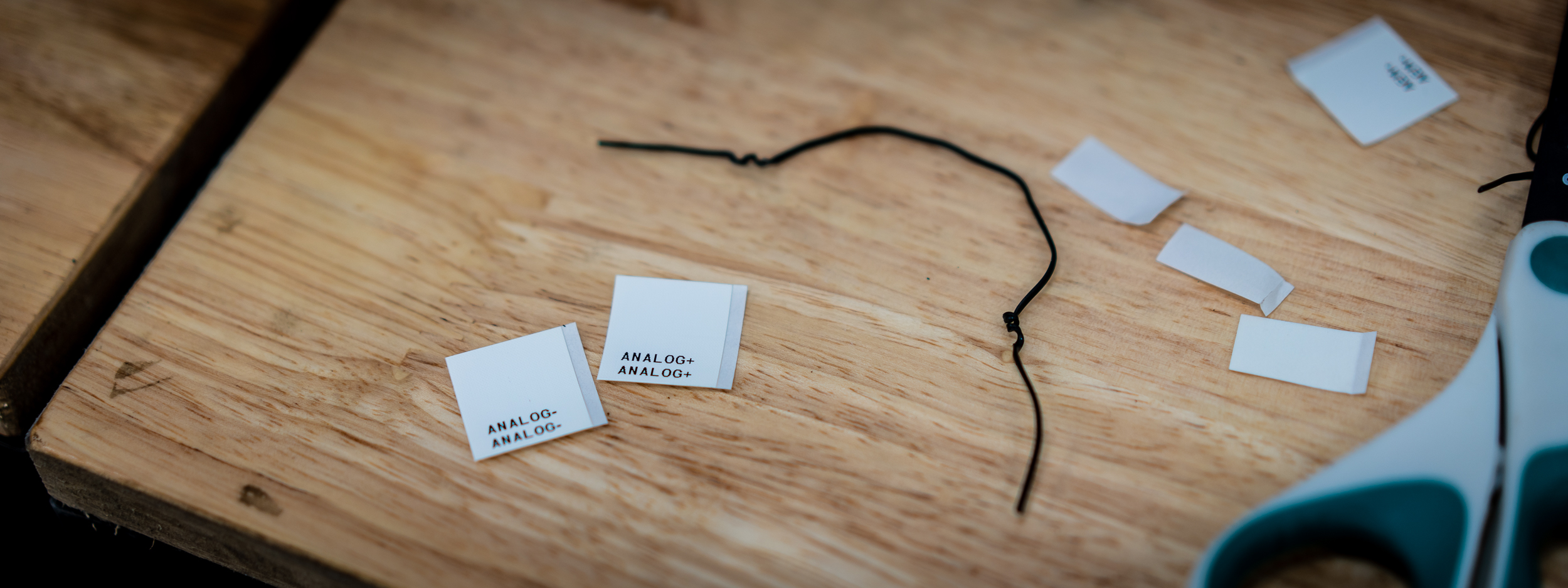

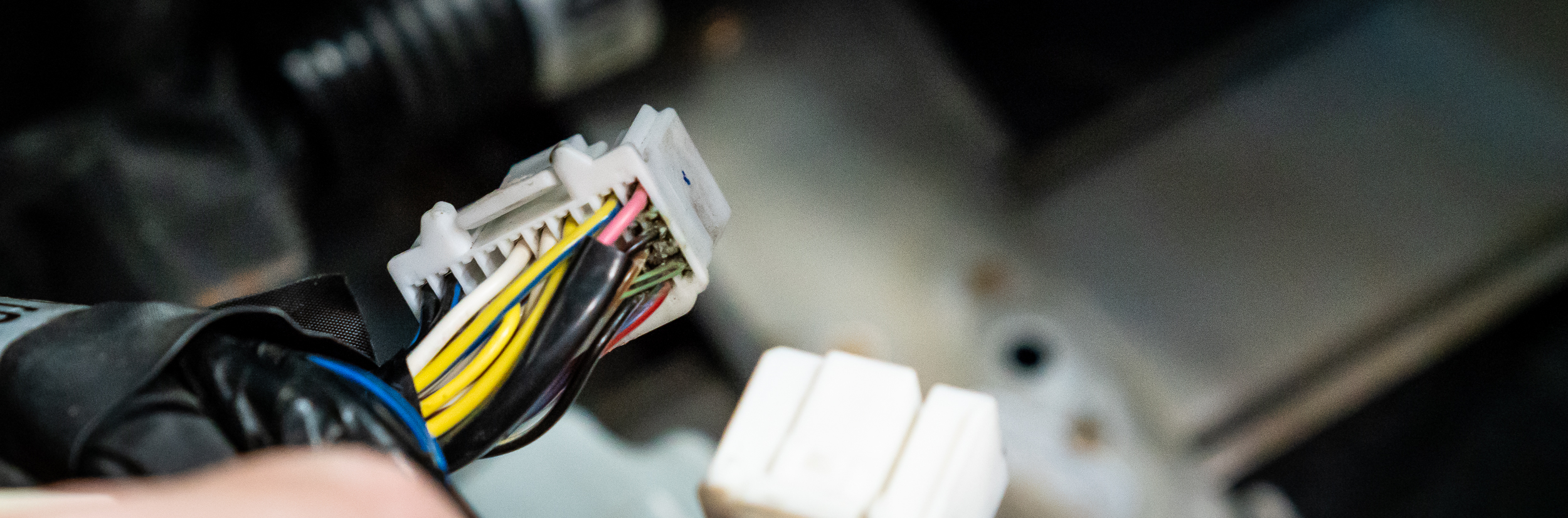

It took me an unreasonably long time to find which pin/wire exactly was responsible for this voltage. Without a factory service manual, I just kept digging up wiring diagrams that were close, but not an exact match. These ECU's changed pinouts a lot from year to year.

Eventually, I found it.

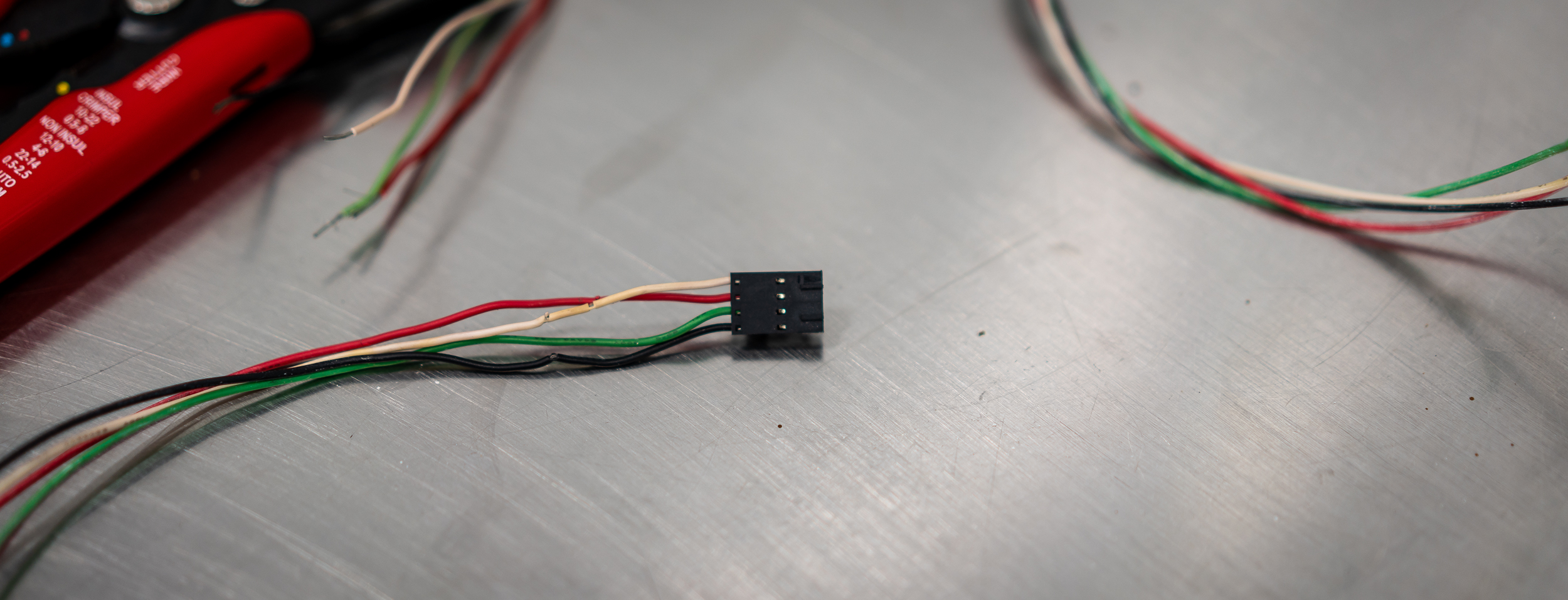

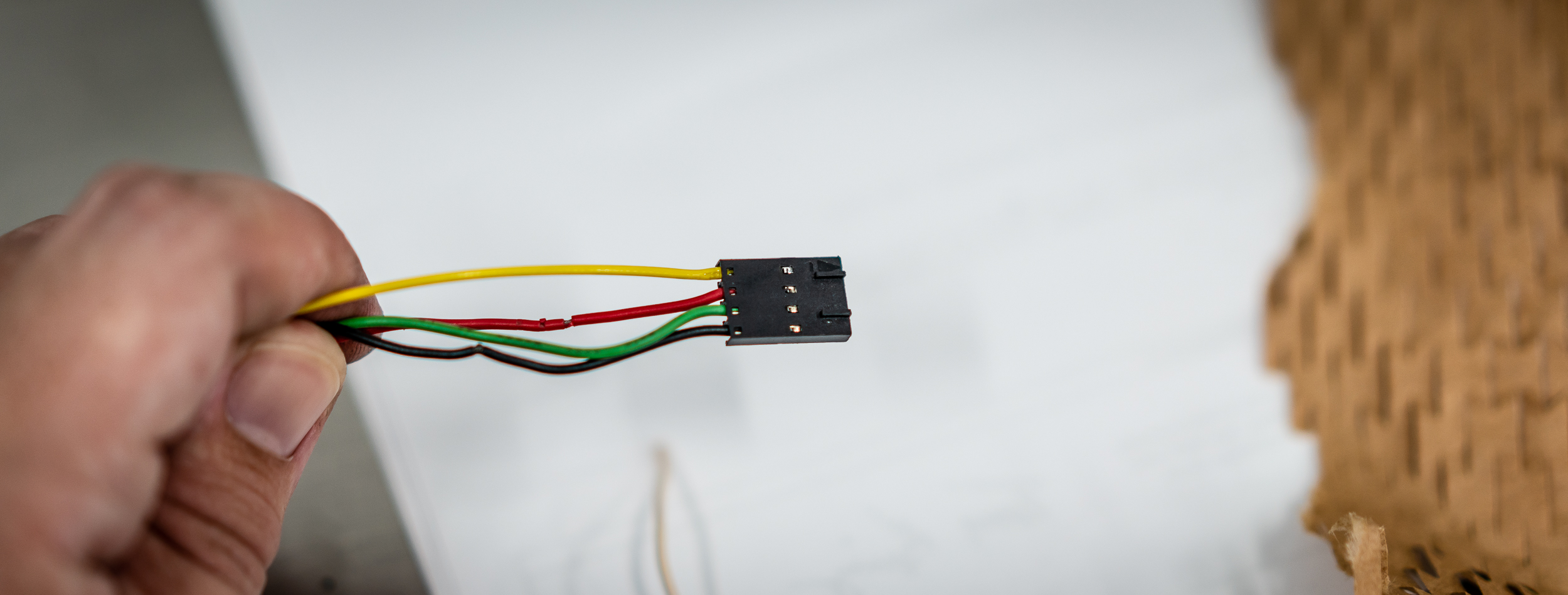

The middle wire on the far right (pin 10 on connector B137, which is the leftmost plug, for anyone finding this in the future) was looking pretty suspicious. I pulled a multimeter out to check for voltage on the wire.

Just fine. So that eliminated problems from the fuse to the connector. Some people in the past had found problems in their harness to explain this code, but it wasn't my problem here.

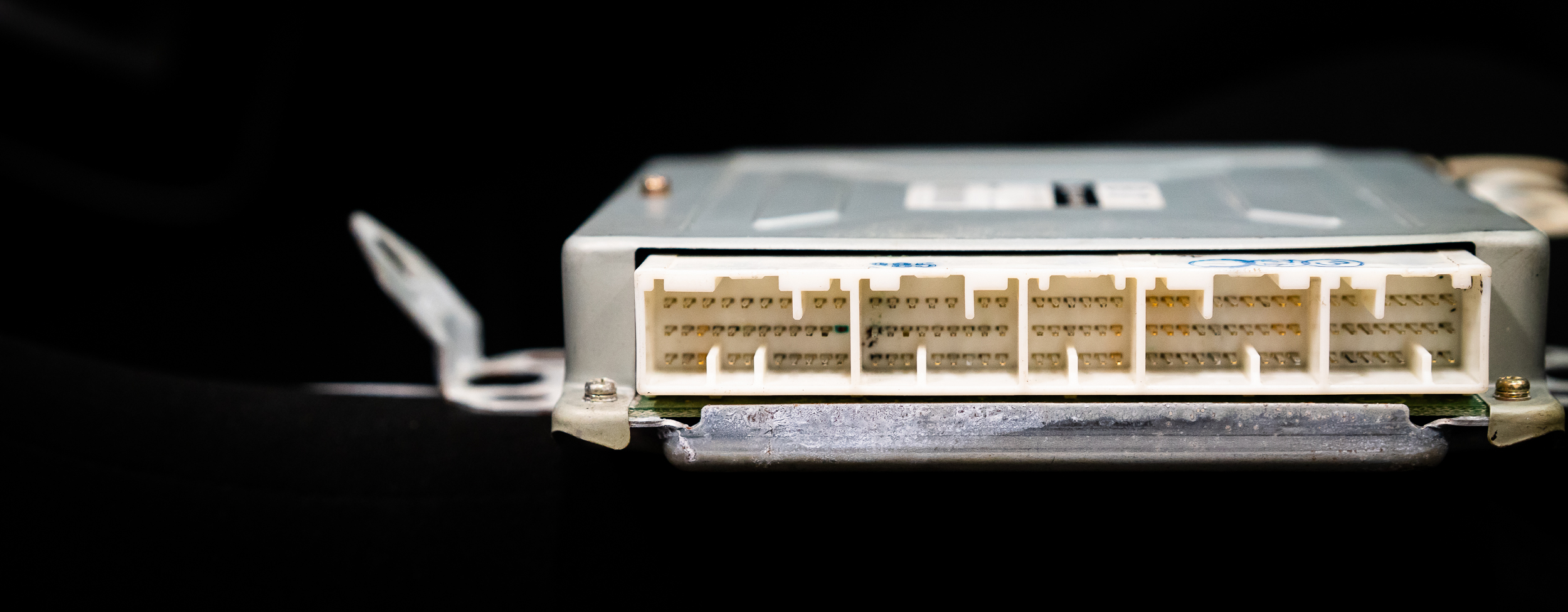

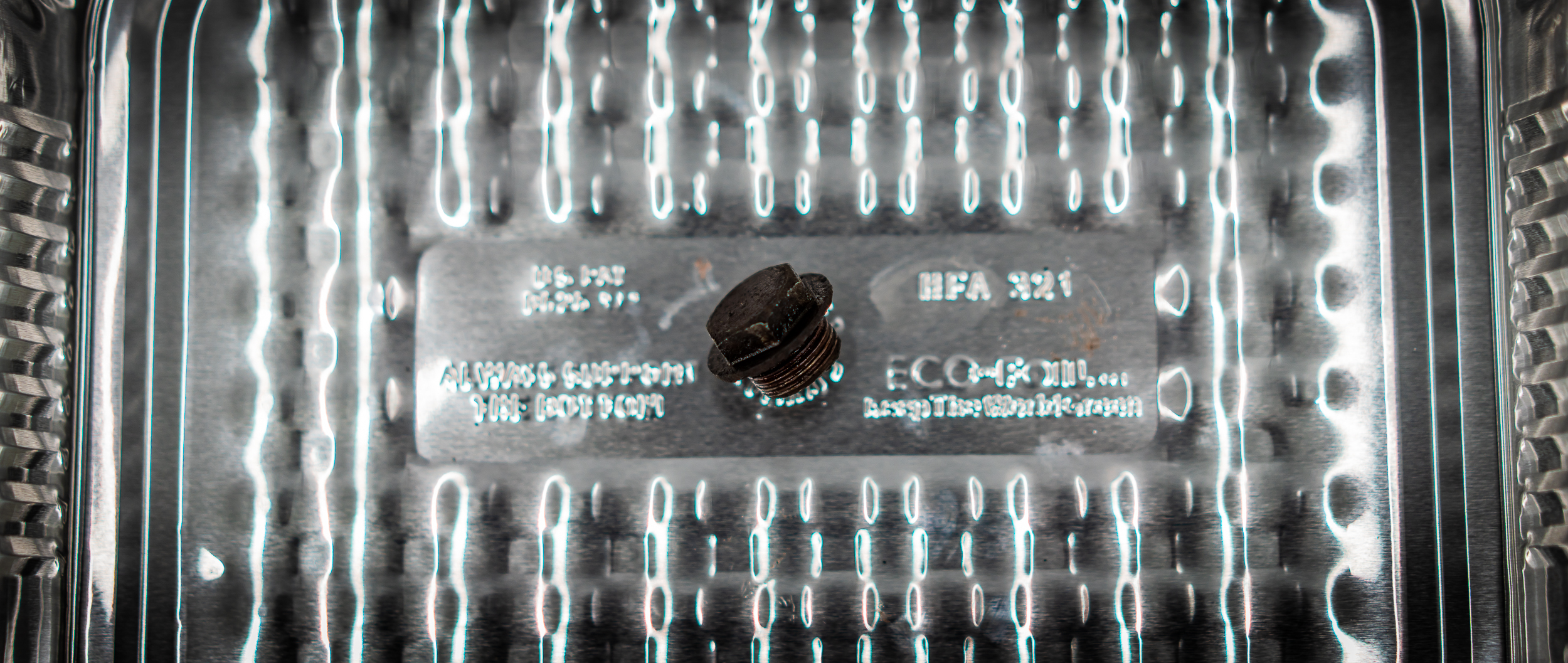

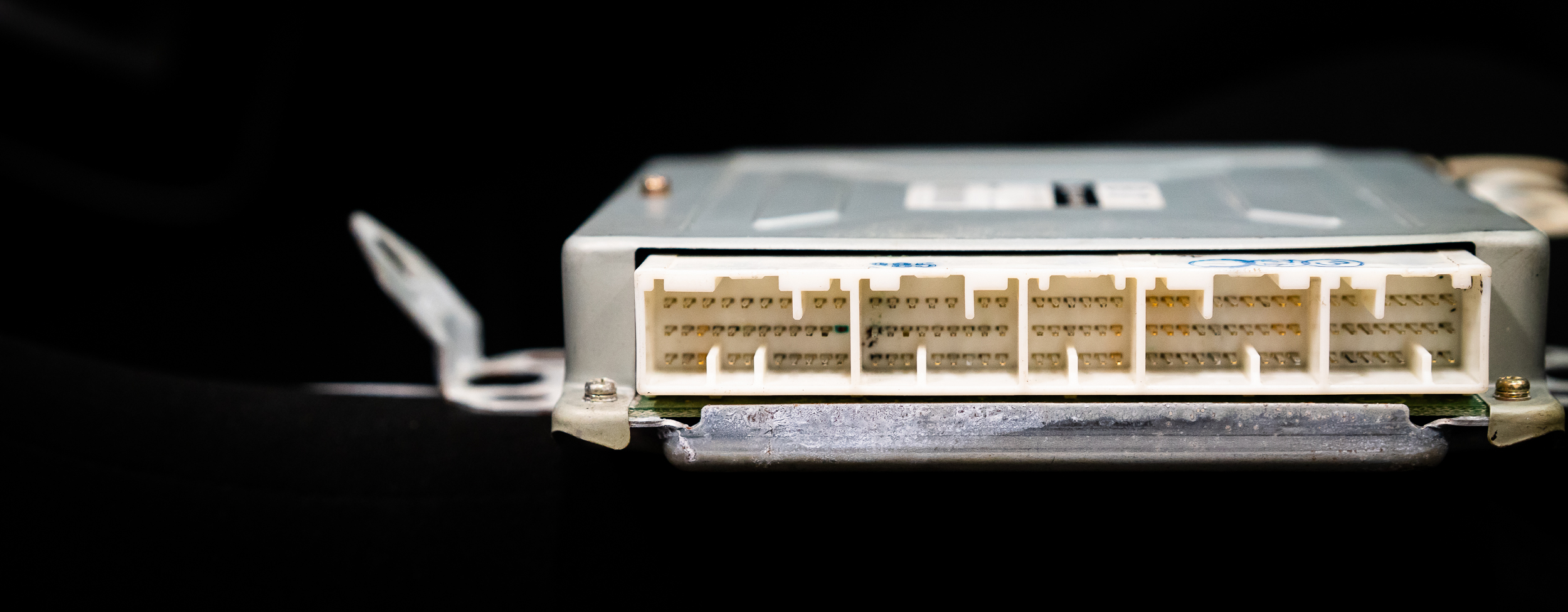

I took a look at the pin on the ECU side, then.

Anybody else see the problem here?

Leftmost connector, middle row, far right position.

THERE'S NO PIN!

But there is some nasty remnants of something?! So the wire on the connector wasn't connected to anything. The pin wasn't stuck in the connector, it was just gone.

?!?!?!

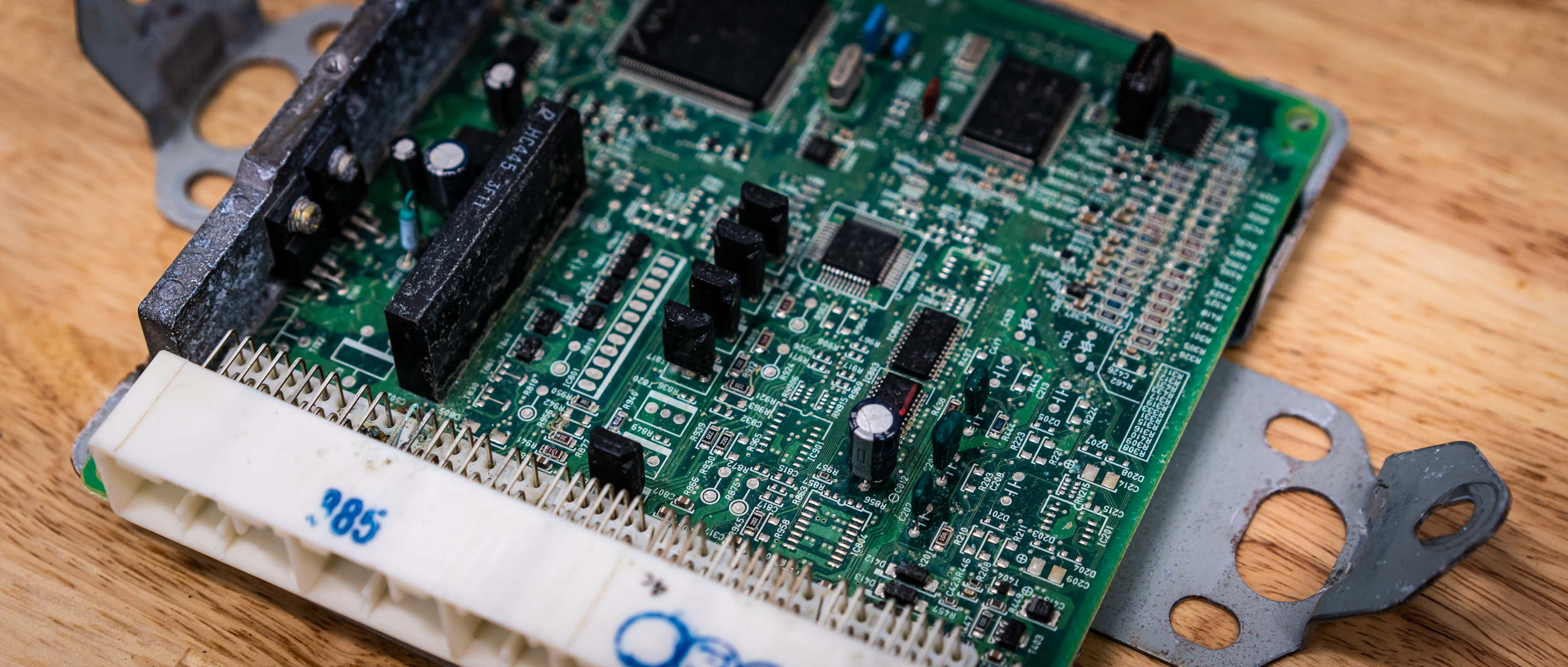

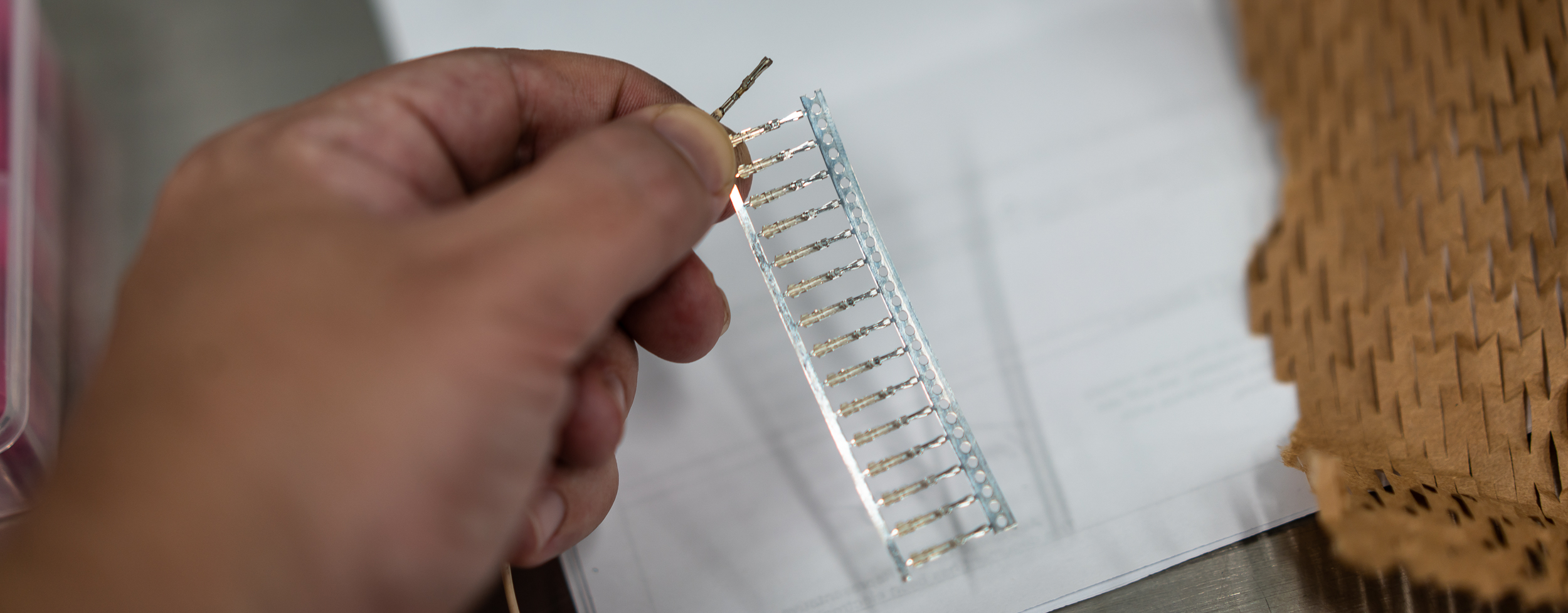

I guess it was time to pull the ECU apart and see what was going on. I was hoping this all just needed cleaned, but that hope was fading fast.

Ugh.

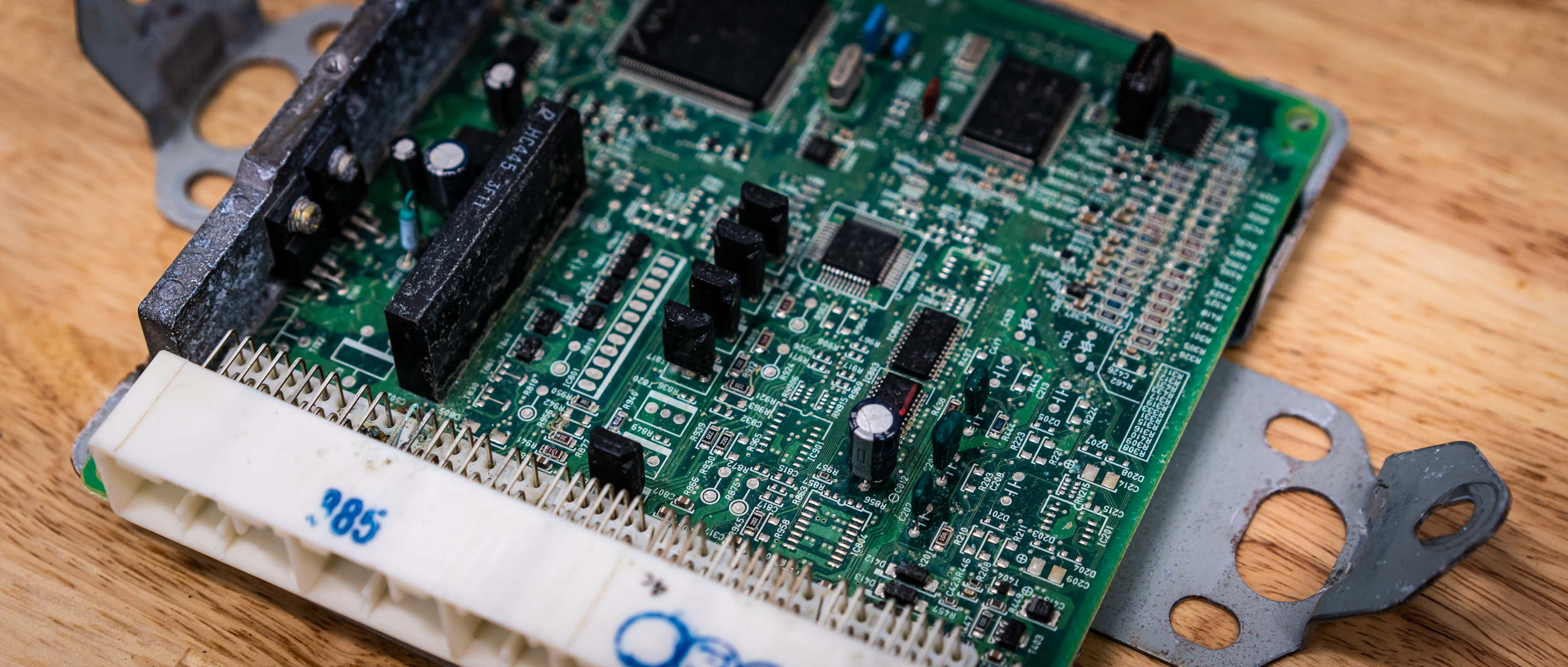

Not sure if you can tell here, but the ECU circuit board definitely went swimming. In very dirty water.

But that wasn't the worst of it.

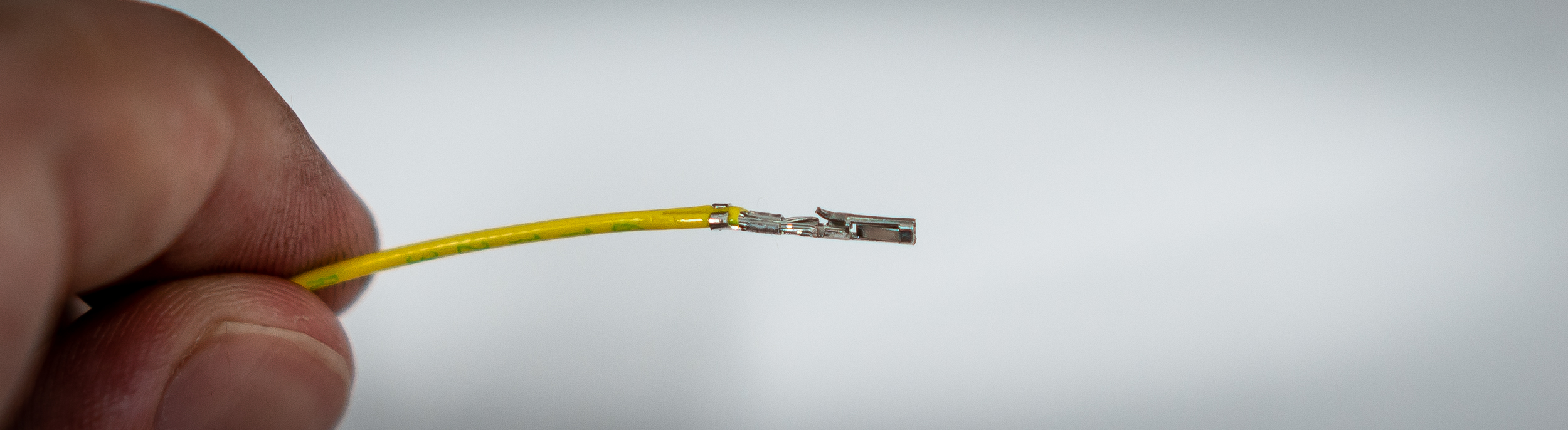

Sorry for the overly soft and zoomed photo here, but I don't have a macro lens that would get this just right.

That mess on the backside of the connector is where the pin used to be.

Used to be! The entire pin is just totally gone, all the way to the circuit board! I did some serious head-scratching for quite awhile. What happened here?!

My best guess is electrolytic dissolution? +12V on this pin while it took a nice long soak in some loaded water. What do you guys think?

Anyhow, I'm thinking this might also explain why I couldn't pull codes. As soon as I pull the key out after running, the ECU doesn't have the backup power and gets cleared?

Who knows what else is going on with this ECU; I'm amazed that I could drive the car at all.

I found a used ECU online for $100 and ordered it immediately. It should be here sometime next week; supposedly this will be a plug and play operation, but I'll find out.

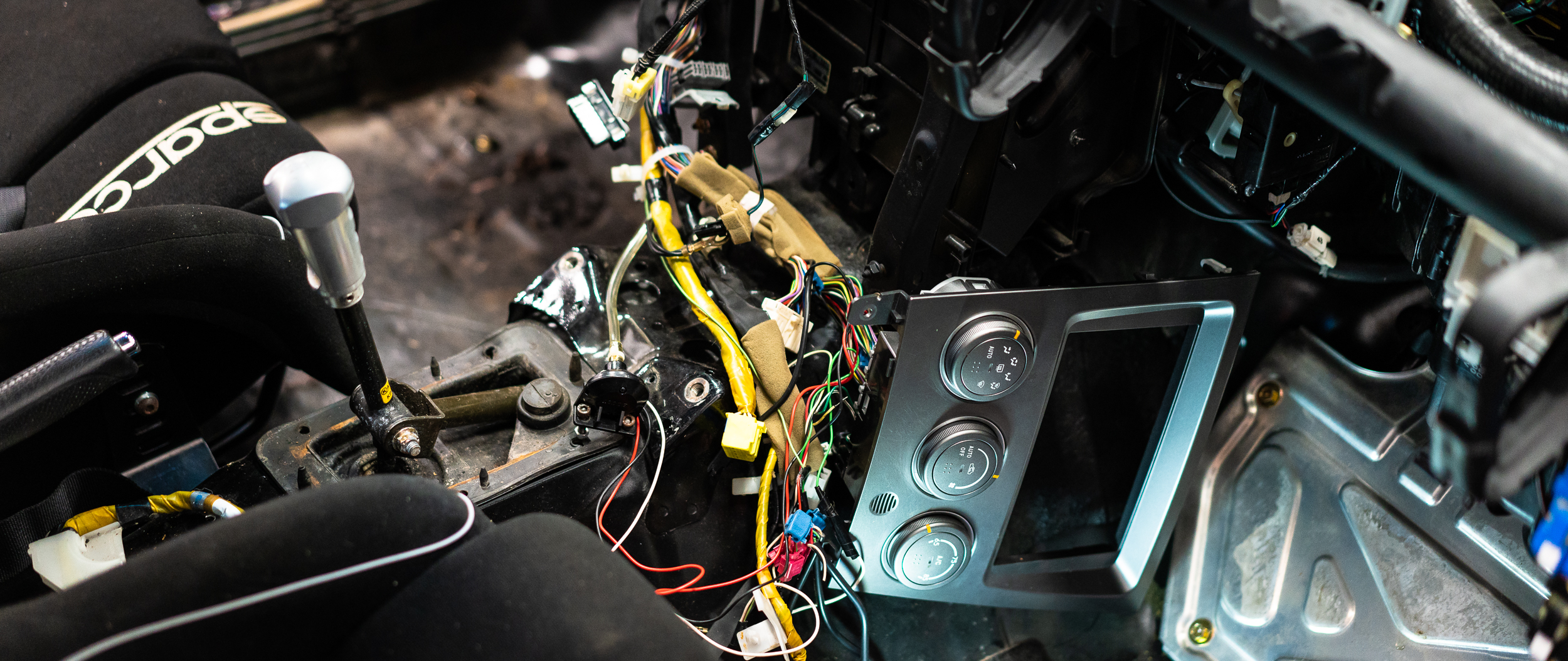

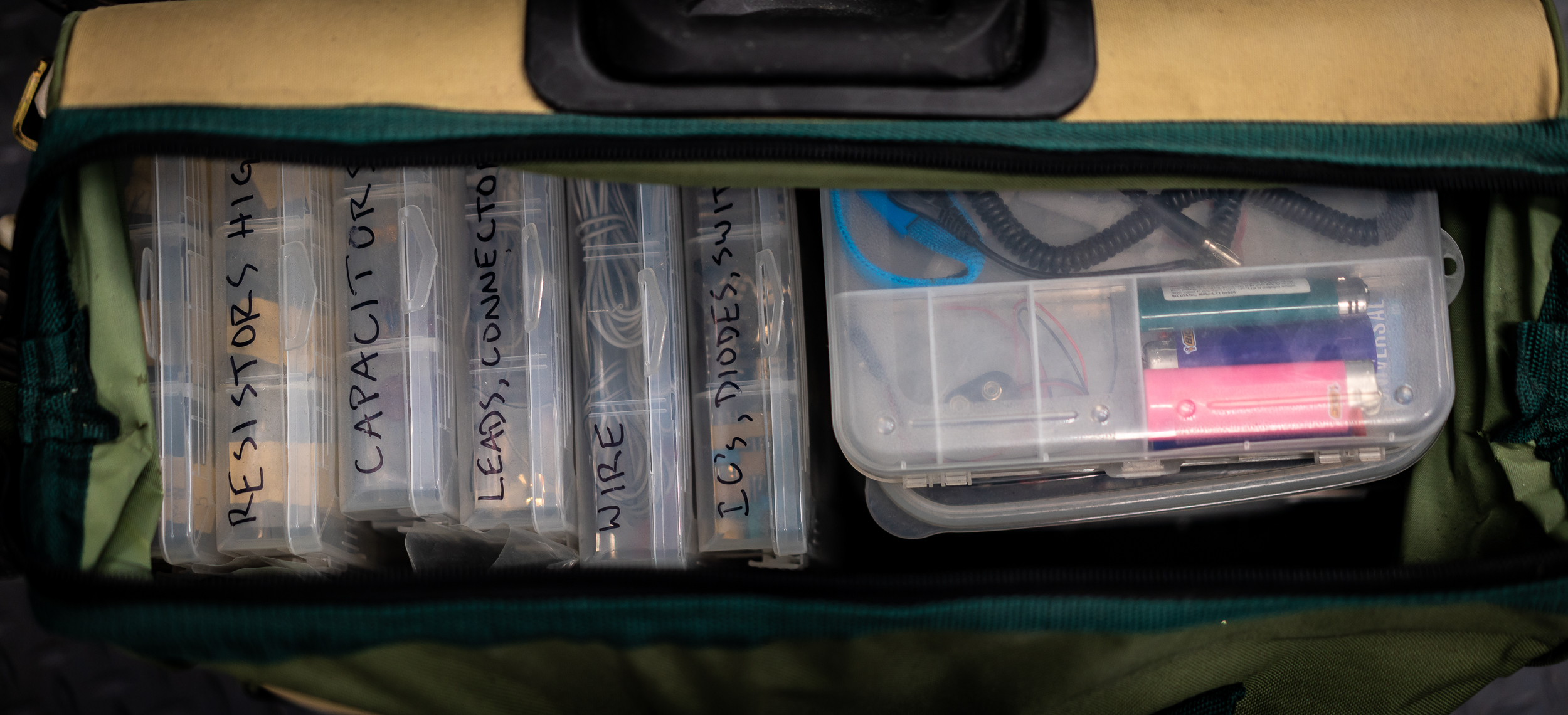

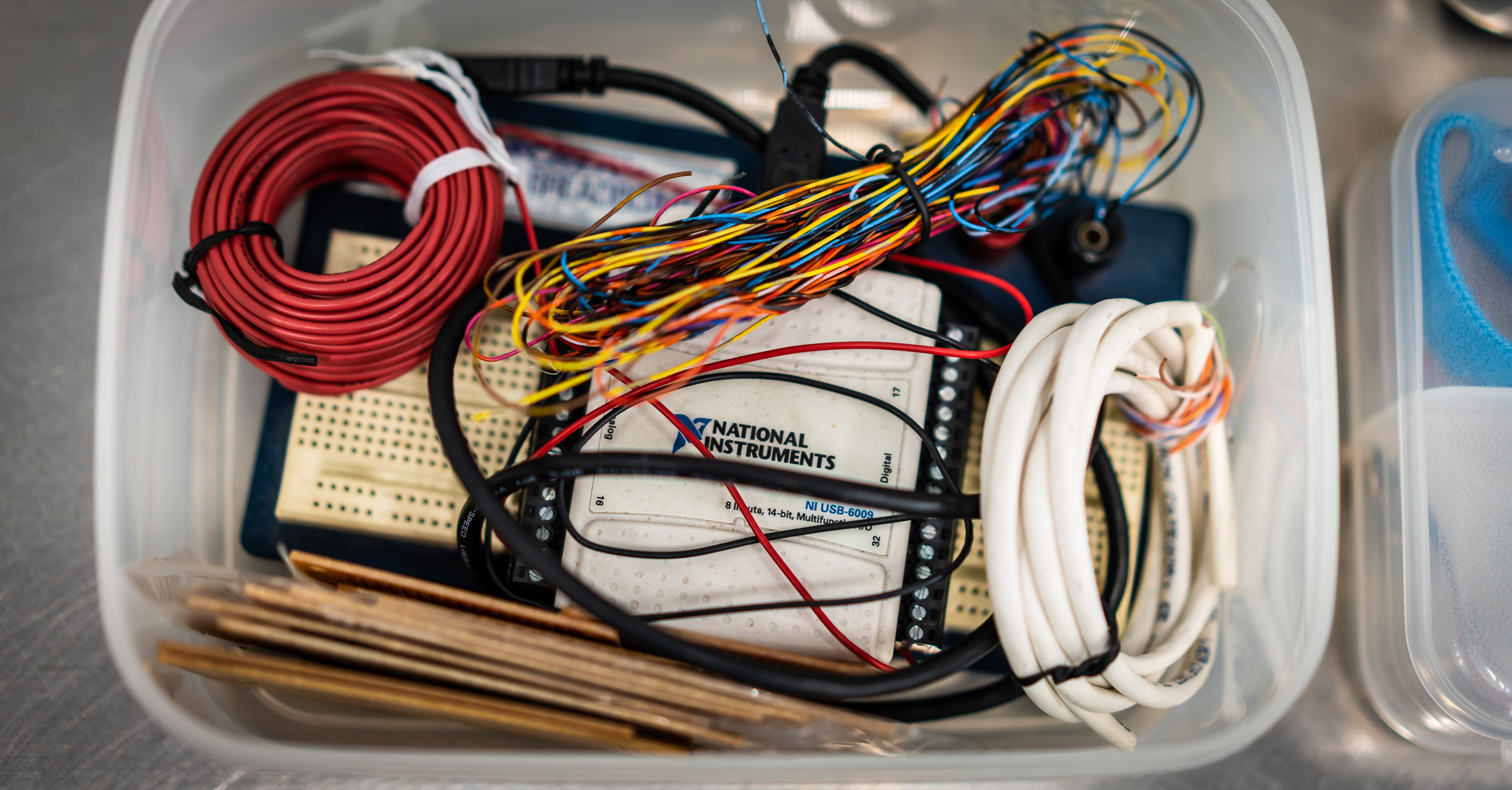

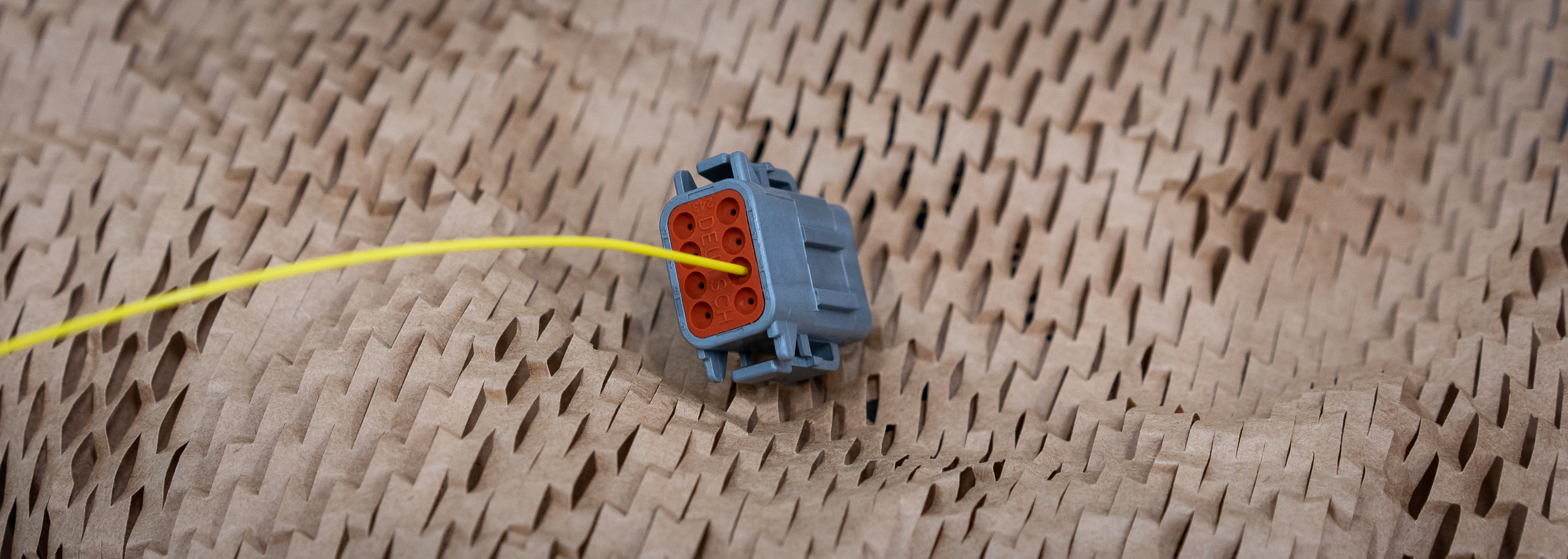

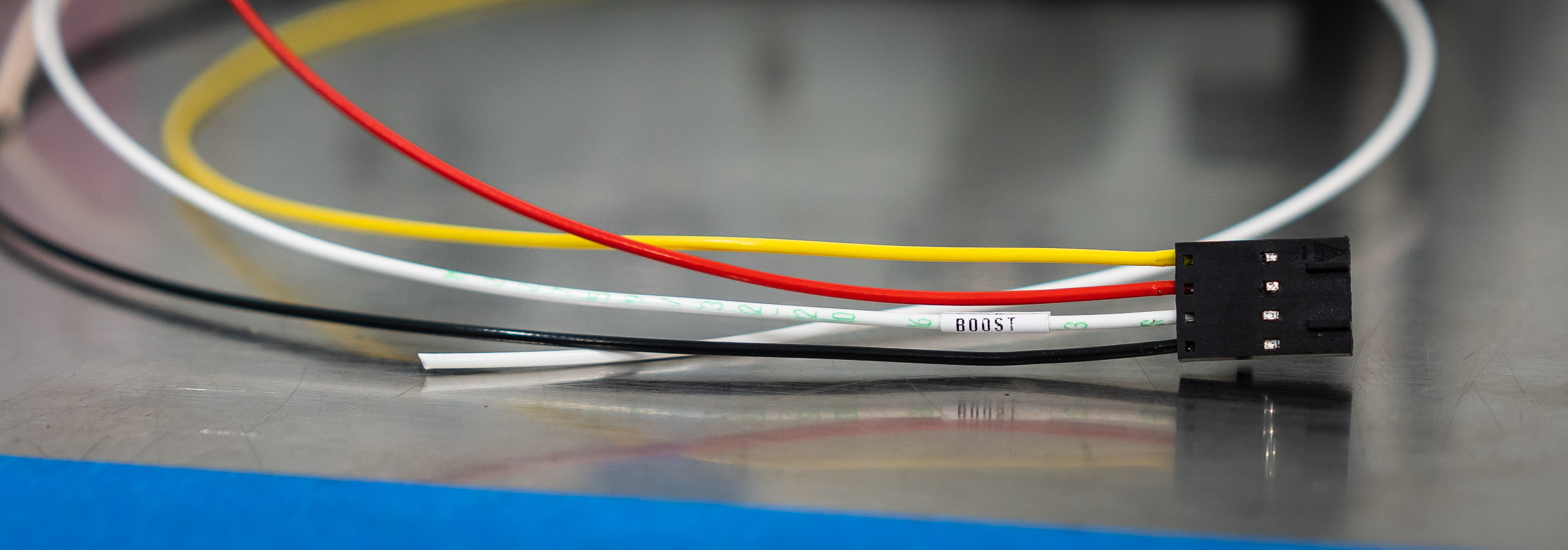

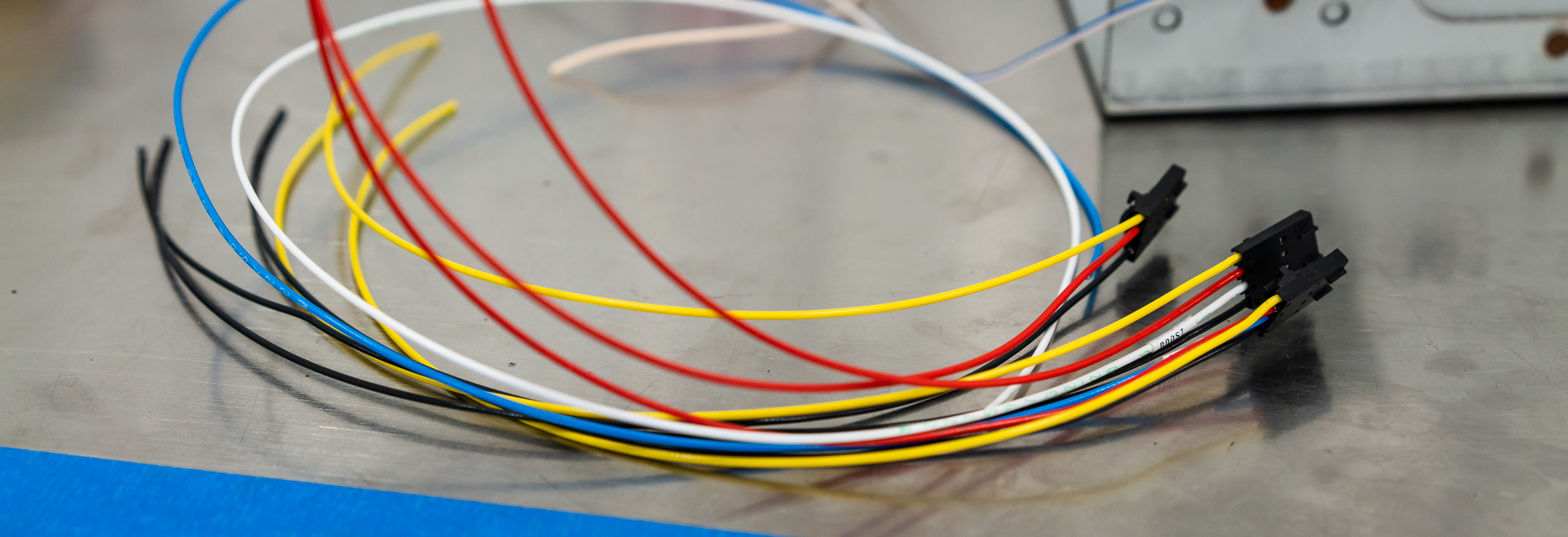

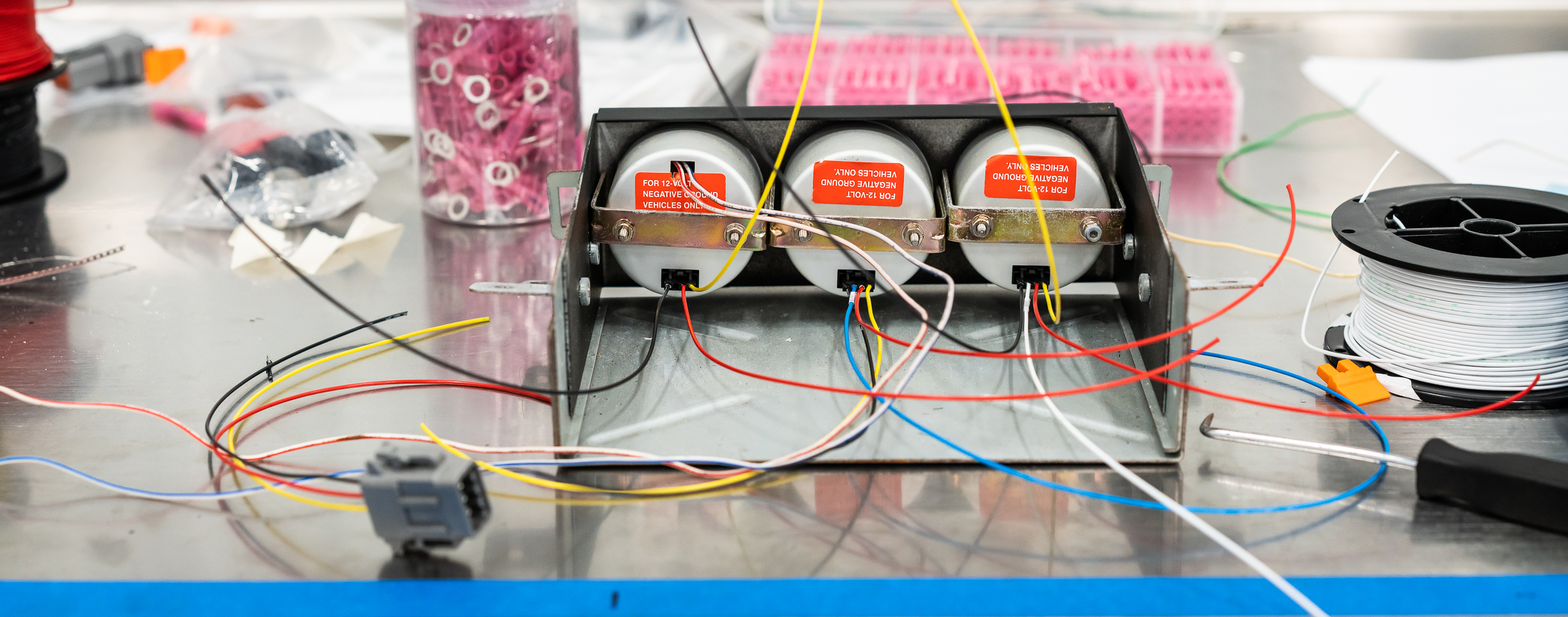

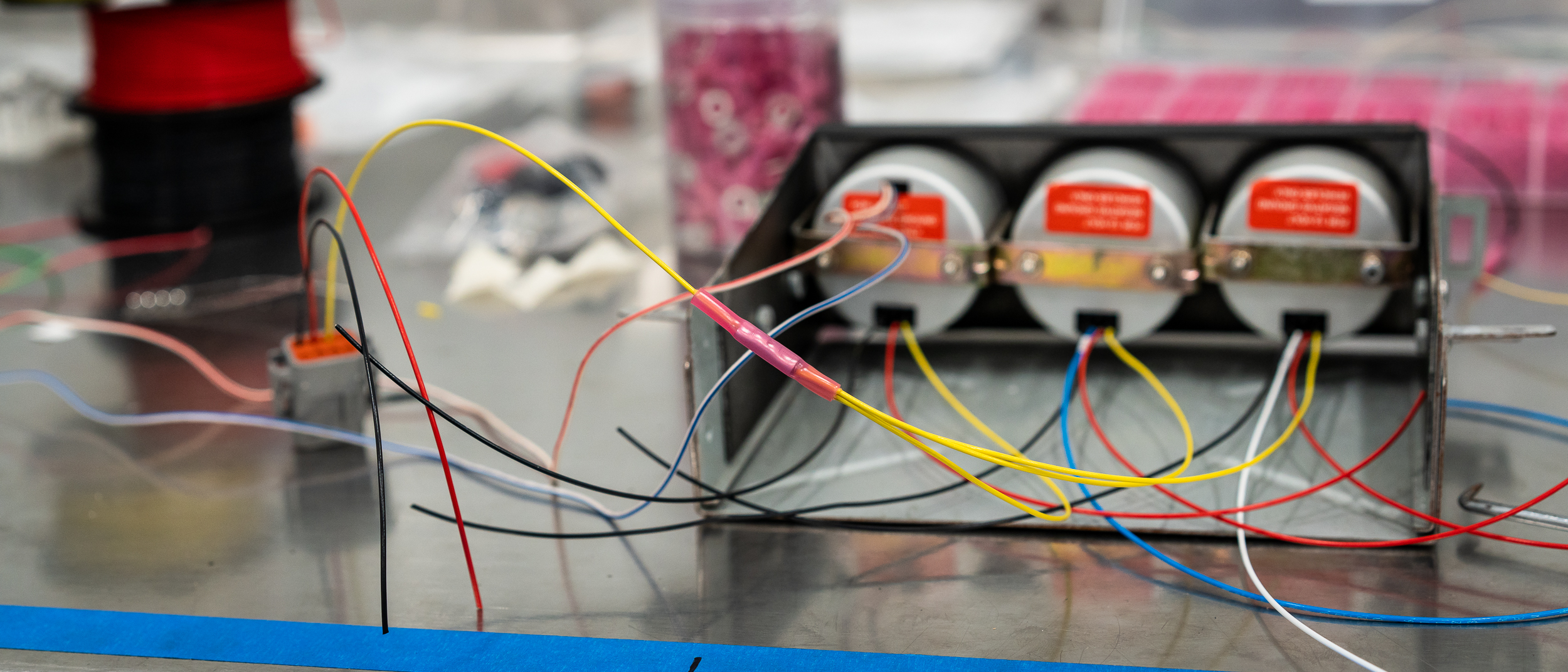

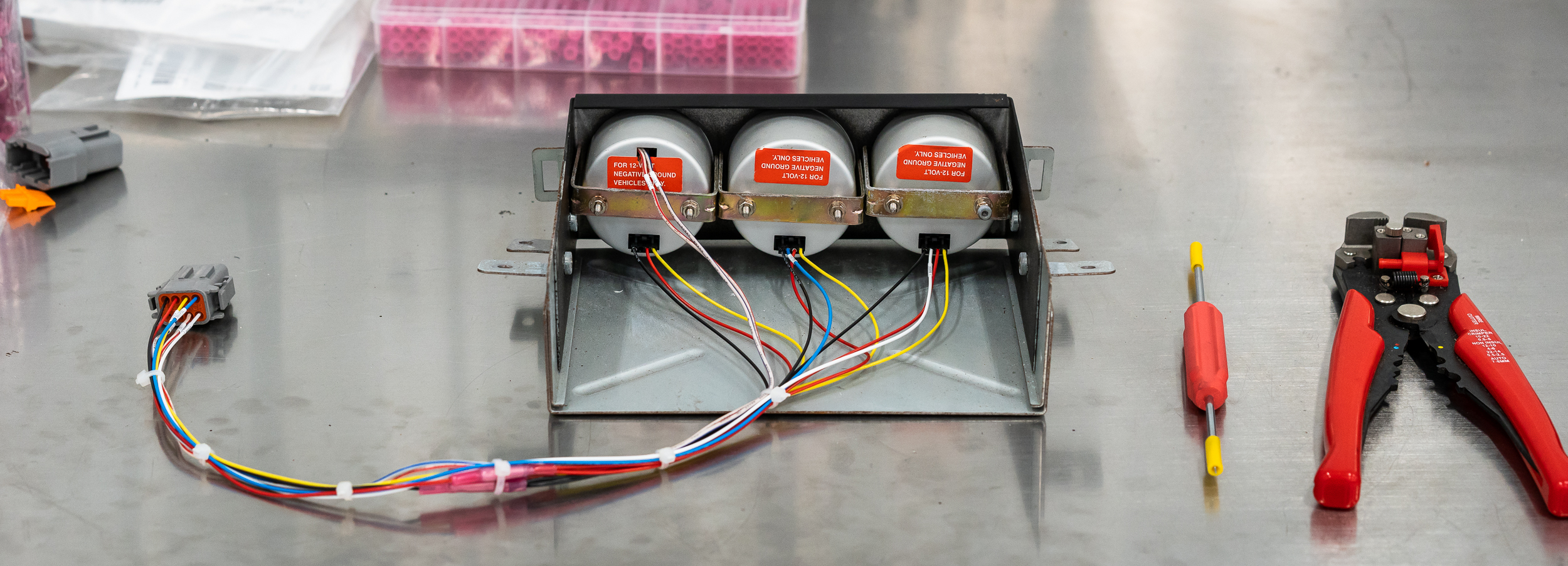

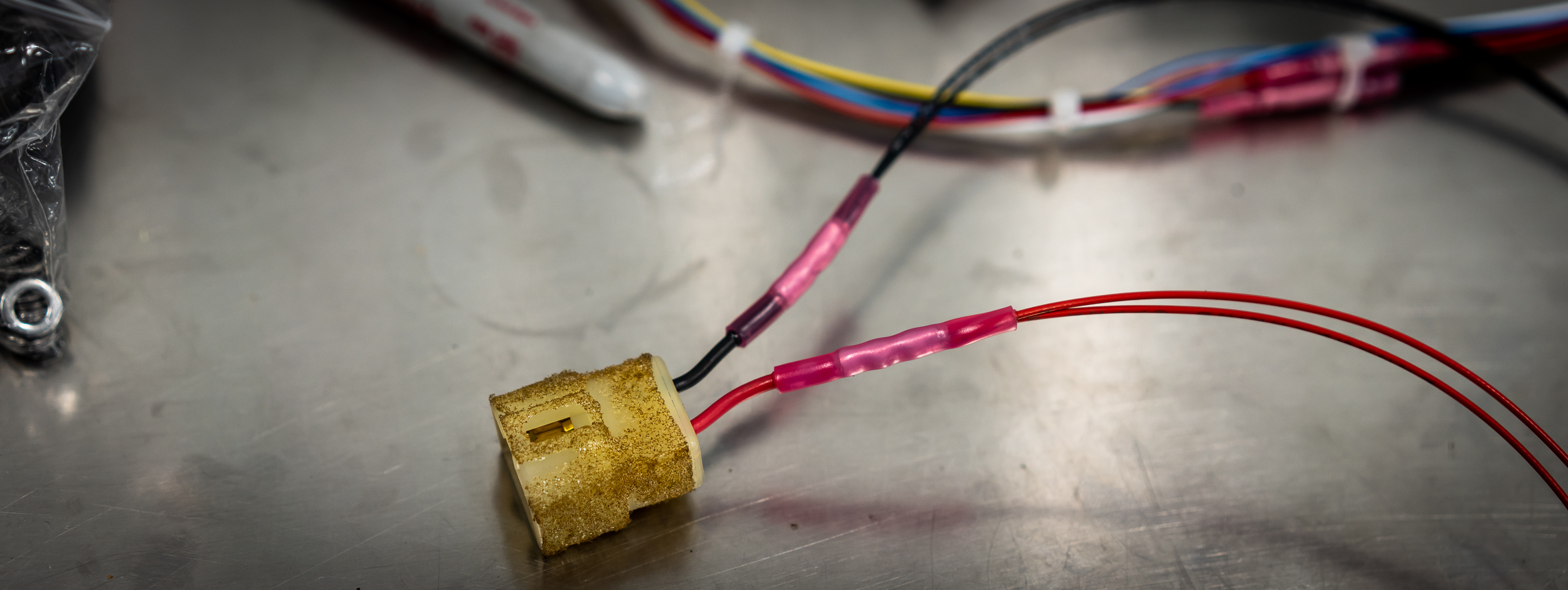

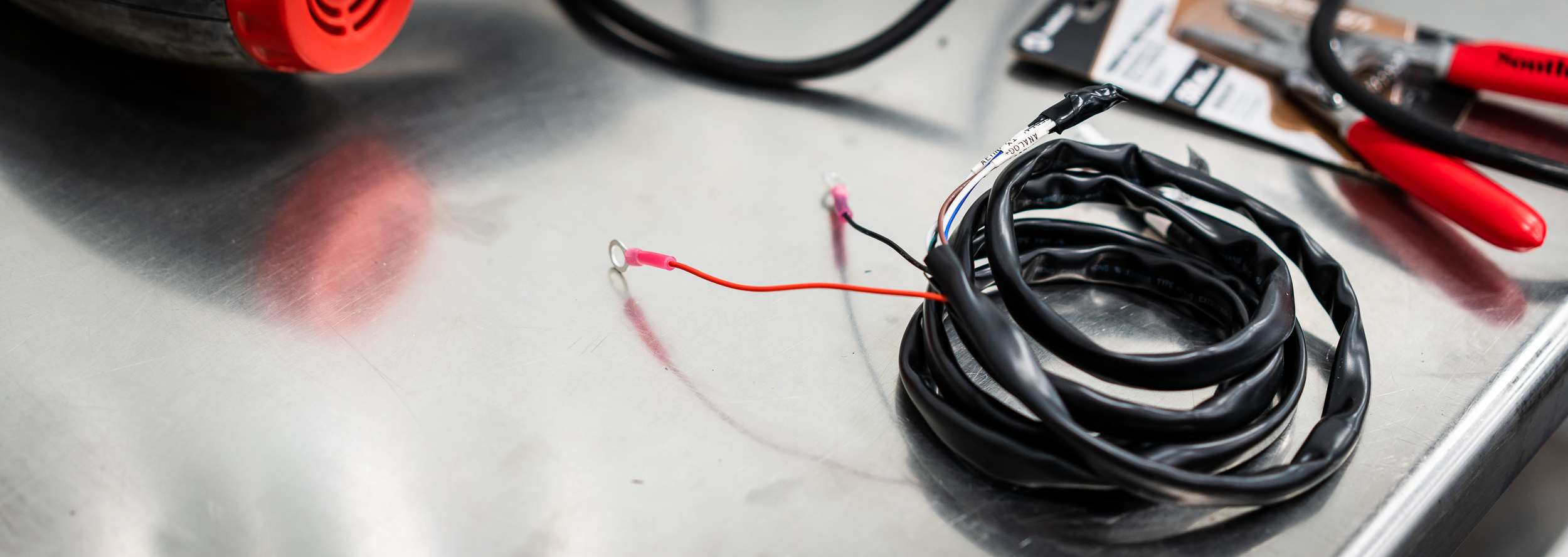

This event has given me pause, though. I was shooting for a September track weekend (HPDE), but I've decided to cancel that idea. I now want to get the dash cleared of lights and codes, get the boost, EGT, oil pressure, and wideband O2 gauges (that I already have) hooked up, and drive the car for a bit. I want to make sure this thing is still viable before I spend a bunch more money on go-fast bits like tires, brakes, aos, oil pickups, big turbos, 2.5L blocks, 6 spd transmissions, etc etc.

damen