Started figuring out how to raise the bed floor, but what I put together warped all to hell, so I need a different approach. I have a new plan up my sleeve to reduce warping, but still do the deep.

Off to Metal Supermarket tomorrow.

Started figuring out how to raise the bed floor, but what I put together warped all to hell, so I need a different approach. I have a new plan up my sleeve to reduce warping, but still do the deep.

Off to Metal Supermarket tomorrow.

The bed header is bound to be stretched from object bashing into it over the years.

Are there "Oilcans" in the panel?

Regardless, you are going to have to shrink spots in the panel if you want to make it flat. And "perfectly flat" with zero filler is a lofty goal.

Pete

I got the header panel pretty acceptably good.

I wailed on the round end of my toe dolly to use the flat edge to "sharpen" the edges of the existing beads.

I raised the bottom fold for the boards 4" and then used the shrinker to bring it back into parallel.

I heak-shrank all the "dents" which improved it considerably as well.

I think it's good enough - I can make it flatter with filler, but then it will look like trash as -I- start using the truck and bow the header again. I -am- going to use the truck; can't make it -too- nice.

I got it pretty close to straight. I'm not going to chase this panel to perfection - it's just going to get dinged up as -I- use the truck.

First, some brainstorming, because people don't seem to have a lot of detail in their builds to follow. That, and maybe I'm a little fussy:

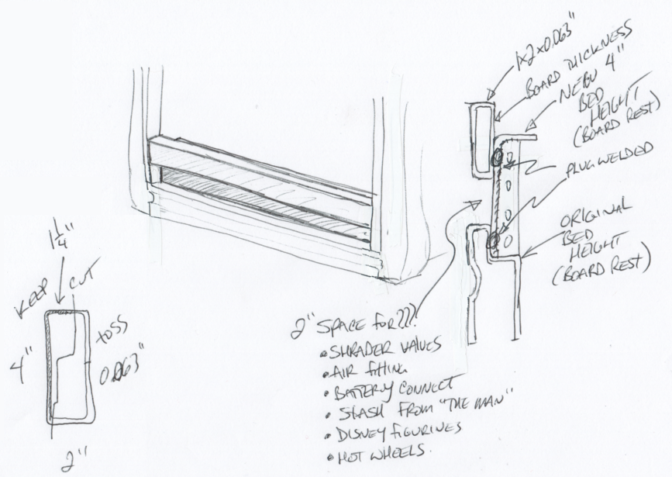

I sliced the 2x4x0.063" rectangular tubing to an "L" that is 1-1/4"x4", and welded some flats on the ends so I can plug weld them to the bed. This is a LONG stretch to weld, and it's going to warp all the heck, so plug welds are a good idea.

I will place a length of 1x2" to create a new "back" to this, to recreate the raised stop at deck height. Should all look like this:

Then I cleaned and scrubbed all the skid strips, angle strips, and blasted bits and epoxy primer. I'll give that a few days, and then weld the front and back back on.

Sprayed some more epoxy on parts/spots I missed.

Measured the old angle strips (1" tall) and the new angle strips (1-1/8" tall), then did some math for the raised bed floor, plus the thickness of the composite boards (15/16" vs 3/4" pine) to figure out where the new strips need to be mounted.

Drilled holes for plug welding the new strips.

Removed one offending fender bolt (offender?) which is right where the strip needs to go.

Hung the doors on the cab, and sat on some lumber to make some vroom vroom noises.

Placed the inner fenders and front fenders just to gaze once again at the awesome hard park height. Hoping to get the bed on soon.

General tidying of the shop.

Ahhhhh ......visions of sugarplums dancing in their heads .....thank you and Merry Christmas to you and yours

AngryCorvair (Forum Supporter) said:SkinnyG (Forum Supporter) said:

Is it inappropriate to pop a boner from this picture? Asking for a friend....

Home Depot called yesterday saying my Trex boards are in, but when I got there they couldn't find the boards, so I went home. I called this morning to see if they found them, and they had, so I went down again.

Looks like forklift operator tagged something immobile, and chipped two boards and broke another, so another length is ordered, but I brought what would work home. Be a couple weeks for the replacement to come in.

And, it seems my '77 is now stuck on "turn right" mode. Not sure what's up with that - steering box issue?

Started welding it back together today.

Added my 4" floor riser at the rear. Turns out the Trex decking is 0.850". Spot welds mean less warping.

Nothing photo-worthy of today's adventure in the shop.

I dressed up some pin holes and welds, epoxy primed over the shiny metal area, attached the bed header and wire-wheeled the fasteners.

Also dragged out the gas tank (S10 EFI Blazer tank), contemplated how to attach it, and braced the rear frame ends together in anticipation of cutting out a crossmember.

Also primered the welds on the floor patch.

Bed supports now located at their new height:

4" Bed risers, made of 2x4" rectangular tubing:

I need to lower the step braces 4" as well. Thank you GM, for being drunk and disorderly on the assembly line:

I remember reading a story from a guy who worked doing the body drop on B-body Pontiacs in the 70s.

He said "We stand there with a 3/4 drive impact gun and the body bolt ready to go. Even if it goes in cross-threaded, it still goes in all the way"

It's a purpose bolt to hold the step bracket to the forward bed crossmember. It appears to have been cross-threaded and then left.

This truck has no evidence of having been apart before - not even a clutch.

I lengthened the Step Brackets by adding a 4" length of 2x4" box tubing, with one end cut off. I then transposed the mounting holes 4" down.

I also fully welded the bottom "stand" of the bed brace since I want to hide the bed mounting bolts. These are merely spot welded from the factory, as the whole shebang is clamped down by carriage bolts - but I don't want that.

The step was shortened by removing the box brace underneath, and I cut 14.5" out, removing some stress-fractured holes.

The undercoating was wire-wheeled off (knotted wheel on an angle-grinder), and the step was clamped to my welding table (1/2" plate steel), washed with lacquer thinner and TIG welded with zero filler (though I kept a length of 0.023" MIG wire in my hand for the three spots that needed it).

I went TIG on this, because TIG welds are so much more malleable than MIG welded, and if I needed to correct any misalignment of the "beads" I wanted it to be easy. MIG tends to crack as you beat on it. I went -against- Oxy-Acetylene, as I'm finding it harder to work with such a large Heat Affected Zone. With TIG I set it on pulse to keep the heat down.

And the driver's side step is done. I had some measurement irregularities, so this one didn't weld up as tastily. I know you just buy reman ones of these, but they are $150CDN each - I save $300 cutting them down myself.

In reply to SkinnyG (Forum Supporter) :

Really nice work there.

I found it interesting following your progress thru these panels - first with the MIG, then the gas rig, and finally on to TIG. Thanks for passing on the knowledge.

I wasn't happy with the first version of the upper straps, so I made new ones out of 1-1/4" square tubing sliced to 3/8". The top straps had to be removable, because the back panel had to be removable, because the hitch had to be removable, and this arrangement made sense to me. Which, of course, required finishing the trailer hitch (yes, the chain loop thingies are not on yet). Truck is only rated to pull 6000lbs.

You'll need to log in to post.