We're way past due for an update. We've been slingin' lots of toobs over the last few weeks trying to get the engine attached to a cradle and a cradle attached to a chassis. I've also been jumping through some pretty stupid hoops trying to get decent trades on our few remaining Civic parts. This week I traded our complete Tanabe exhaust for a set of VX wheels, 440cc injectors, OBD2 engine harness, and a Delta regrind camshaft. My patience is definitely getting worn thin trying to trade Honda tuner parts on craigslist, but I guess that's how you have to play this game! We'll need the injectors for E85 and the harness to ditch our dual port setup for MPFI. The VX wheel trade allowed me to take the wheels out of the budget, the camshaft was just gravy.

A couple of weeks ago we got some used tires from jbracingtires.net that we're really happy with. They charged me more than they said they were going to, not sure if I was remembering wrong or if they were remembering wrong. Either way, we got some used Hoosier TDs, a 185/60 13 bias ply DOT rated tire. These are a touch smaller than the 185/60R13 A6/R6 type tires, which is better for us. These tires look GREAT on this wheel, we're really happy with the fitment, plus the tread pattern looks appropriate on the Honda. I'm still trying to drum up a set of these locally for cheaper for the challenge, but I had to pull the trigger on something for fitment so we could get the cradle stuff going. These tires and wheels aren't that common, so I've had to scour pretty hard to find good deals on used stuff. In the last six weeks I've compiled three sets of VX wheels (better deal each time!), a set of shaved 175/50R13 street tires for test and tune, and the Hoosiers..getting pretty silly! Here's the new tires during a test fit showing the suspension at anticipated full jounce:

So, on to toob slingin'. We started the base cradle assembly by copying our PVC mockup. Our PVC mockup was pretty accurate, we used it to dial in our cut angles and lengths so that we could pretty much recreate it in steel...way faster to dial in PVC than to dial in steel! For reference, almost everything is made from 1"x.065" round, .75x.065" round, 14 ga sheet, and 18 ga sheet.

A lot of our tube ends use this scheme, a couple of washers welded to the 1" tube. The local (awesome) hardware store "Park Rose Hardware" had these uncoated steel washers that made it a breeze. Here's some of Aaron's welding warmup, nice and easy to access to dial in the welder settings.

Our cradle uses a setup similar to the Fiero, which makes dropping the engine+suspension assembly a breeze. Here's our rear attachment area starting to form, which later gets more tube coming to it and some gussets.

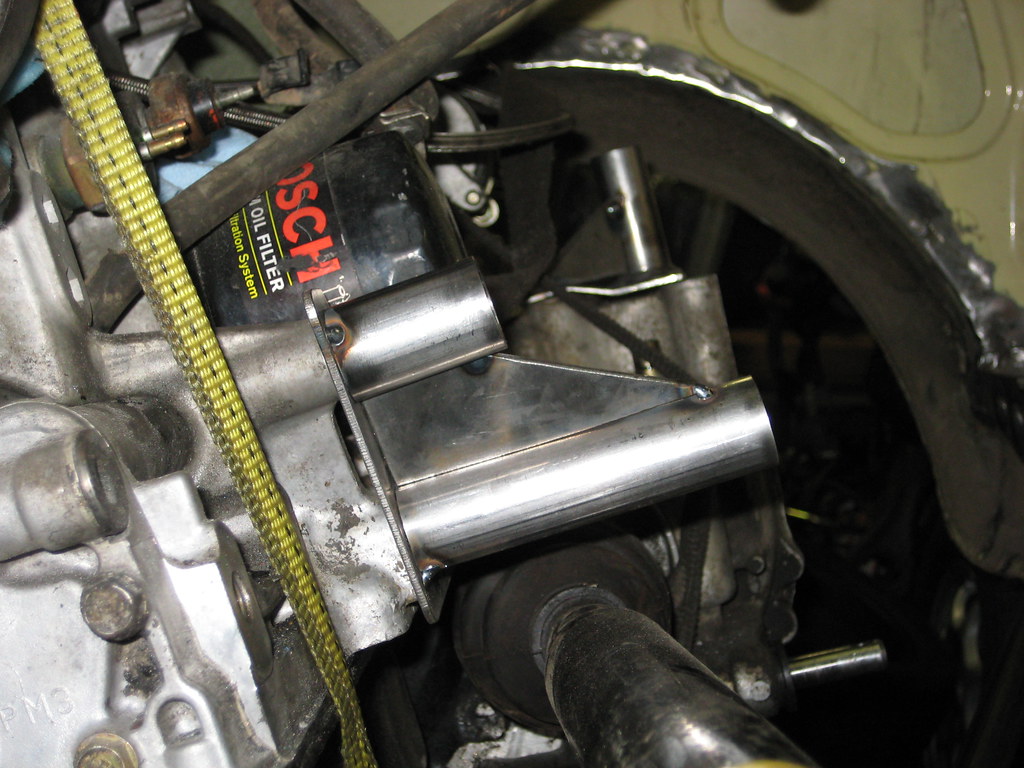

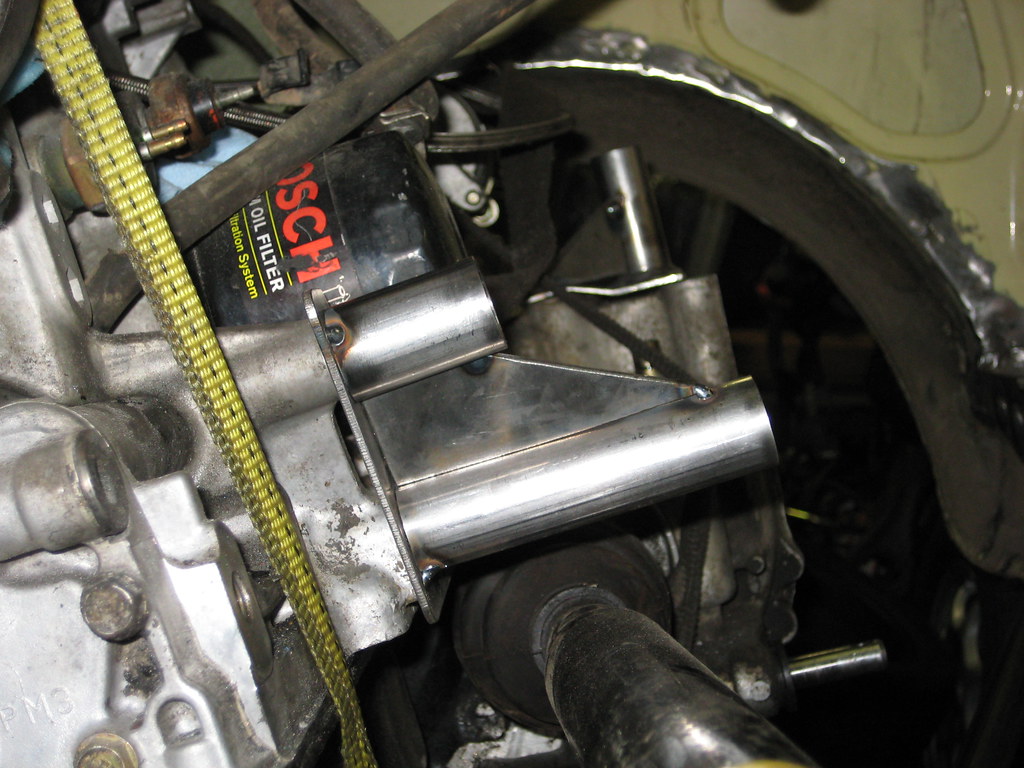

Here's the space wars bracket...I'm convinced this looks like something you'd see in a Star Trek prop. This one attaches near the oil filter and provides an attachment point for the tube coming from the rear cradle area that won't interfere with the axle shaft.

There were a few head scratchers, this was one of them. Trying to figure out how clear everything while also making it serviceable, strong, light, and manufacturable was a challenge on a couple of spots. Here's one where we had to get creative. All the pinched tubes have a short section of smaller tube pinched inside the larger tube, then they are welded on the end and a hole is drilled through the whole assembly. These are surprisingly strong and the secondary inner tube help to spread any bending loads that may end up in the tube.

Based on how much talk there was about alternators and batteries, you will all be relieved to hear that I figured out how to get an alternator on there without interfering with the tire/suspension/axle clearance. I got a free D15 crank pulley and cam pulley from a craigslist adventure a while back, apparently early D15 crank pulleys didn't have any damper at all, perfect for modifying! Unfortunately, the early D15 crank pulleys were made for a smaller crank snout than our D16A6 had, so it didn't fit right away. My buddy Jesse (who helped with my Fiero build as well) chucked the pulley up in the lathe and machined a couple millimeters out of the center bore to match the D16 pulley and also lopped off the extra ribs that used to stick out for power steering and AC. I made a bracket to locate the alternator in just the right spot out of some 1/4" steel we got for free out of a scrap bin. So, we now have a FREE crank pulley and bracket that allow the stock alternator to work with the stock belt! I also bought an ebay special $40 pulley that will work before I got the free stock pulley, but of course I was glad to get that $40 back out of the budget. It's hard to tell, but there's just enough room for the turbo downpipe to shoot over the alternator, then turn down to exit in front of the tire.

This was a pretty big moment for us...the engine is finally attached to the chassis without any crutches!

There are still some temporary struts between the cradle and engine; we could have removed them but figured that we'd leave them in as long as we can while we do suspension mock ups. Starting to see the details take shape is helping motivation, and we'll need all the motivation we can muster as we start to hash out the suspension mounting details!

That's all the build progress we have to show and things will probably be slow for the next week and a half or so. I'll be off the grid on a wedding location scouting trip with my fiance and Aaron will probably be distracted with his new toy:

Bryce