I'm considering doing a small turbo for the Daewoo next year. I'm thinking of getting a junkyard 1.8L engine (interchangeable with my 1.5L), putting in two head gaskets, installing some nice rod bolts and then making it work with a junkyard sourced turbo and megasquirt. The only catch is that my junkyard turbo choices will be restricted to Bongo-style diesel trucks, Mercedes 2.9L diesel powered SUVs, and if I'm super lucky, the 1.5L turbo Hyundai Scoupe of the early 90s.

Is there anything special I should keep in mind using a diesel sourced turbo?

The Bongos/Porters use a d4bx engine. It might be an evolution of the 4d56 Mitsubishi.

The Mercedes derived engines are 0M602 5 cylinders.

The Scoupe uses a 1.5L Alpha with a Garret T15 Turbo.

I'm looking for 150-160 hp.

YaNi

Reader

9/6/10 8:01 a.m.

See if you can find the compressor maps for the turbos. Diesel's typically run at higher pressure ratios (atmospheric pressure + boost pressure/atmospheric pressure) than gas engines, so you will probably run it outside of its peak efficiency range. If they have an internal wastegate you will need to figure out what spring rate will get you the boost you want, or just block it off and go external.

1) Calculate pressure ratio needed to reach desired horsepower goal.

2) Calculate engine airflow at specific engine speeds. (CFM = (CID * RPM * VE)/3456)

3) Find compressor maps of sought after turbos and compare.

4) Compare 1 and 2 to compressor maps. See that you can reach the required pressure ratio with the airflow the engine makes at ~50% of max RPM. Also note the compressor operating efficiency.

Alot of guys run Holset turbos off of Dodge Cummins trucks.

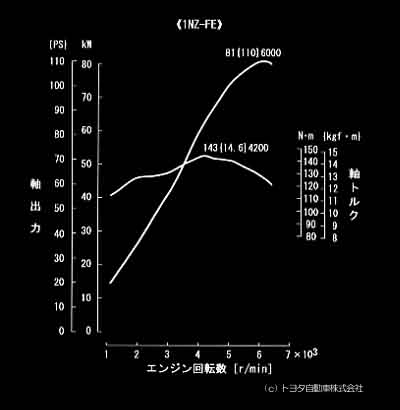

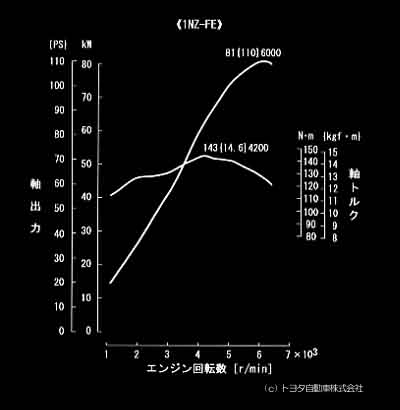

YaNi, I'm going to put a Garrett T25 from a JDM SR20DET on a 1NZFE (Scion xA). From what I understand, the SR20DET is 2L and about 200 HP stock. The 1NZFE is 1.5L and 108 HP at 6K and about 105 Ft*Lbs at 4200. I think the compression ratio is 10.5:1. This is purported to be the dyno:

The turbo needs a rebuild, so changing out the compressor at that time would be no problem. Uh, never look a gift turbo in the air intake. Would the stock wheels in there now work?

My goal is to have about 160 HP, certainly no more than 200 or less than 150. How do I calculate the pressure needed to reach 160HP? What about VE? Can I just guestimate VE at, say, 108 (actual HP) / 150 (ballpark theoretical HP at 100% efficiency for 1.5L)? Max RPM is only in the 6K range. Say 6500. I'm kinda think of about 6PSI as a SWAG pressure goal. The intake is plastic. Oh, and I'll have an air to air intercooler too.

YaNi wrote:

See if you can find the compressor maps for the turbos. Diesel's typically run at higher pressure ratios (atmospheric pressure + boost pressure/atmospheric pressure) than gas engines, so you will probably run it outside of its peak efficiency range. If they have an internal wastegate you will need to figure out what spring rate will get you the boost you want, or just block it off and go external.

1) Calculate pressure ratio needed to reach desired horsepower goal.

2) Calculate engine airflow at specific engine speeds. (CFM = (CID * RPM * VE)/3456)

3) Find compressor maps of sought after turbos and compare.

4) Compare 1 and 2 to compressor maps. See that you can reach the required pressure ratio with the airflow the engine makes at ~50% of max RPM. Also note the compressor operating efficiency.

Alot of guys run Holset turbos off of Dodge Cummins trucks.

Thanks for all the info. I've got a few questions though.

How do I calculate the needed pressure ratio for 160 hp? I'm thinking about 7 psi, which would be a pressure ratio of 1.5?

If I can't find a compressor map, can I make my own without huge expense? Is there any generic compressor map I could use to get things in the neighborhood?

I'm also curious about calculating VE. My engine seems incredibly similar to Dr. Hess's. 1.5L and 105 hp @ 6000 rpm. Fuel cut is 6600. The 1.8L has 120 hp @ 5800 rpm.

I think the Holset would be way too big. I've got a 1.5 liter engine. The next motor will be no bigger than 1.8.

Raze

Dork

9/6/10 8:17 p.m.

I run a Holset HY35 on a Ford 2.3L Turbo engine instead of the stock T3, I am proof it works, and well, but compressor map sizing is critical as has been pointed out.

Second, supporting mods make a huge difference and your ability to tune is also critical, the real reason being diesel turbos run lower temps, not orders of magnitudes but higher. For this precise reason most people don't want to use them because they think it's dangerous, and in many ways it can be depending on construction and application. We have at least 1000 miles now on our XR4's Holset and my rationale is that if I burn out a $200 JY Diesel turbo that's throwing down 30lbs of boost on a dedicated track/autoX car I'm not going to cry spending another $200 for another or a rebuild, $1000 turbos just don't do it for me on a car we paid $900 for, but that's just me.

That being said, you need to do flow calculations, our 2.3 flows crap, it's a SOHC, a DOHC could be smaller and still push a Holset, some of the DSM boys do it. Get the compressor map (again has been stated) then go to town. If you can't find one, call the company, see if they would give it to you, tell them you're doing a class project for your kids and need to teach them about flow and how to properly size a turbo to an engine just for demonstration purposes, maybe they'll help out.

Goodluck and keep us posted, very interested to see another oilburner turbo...

It doesn't need to be that complicated. Have a look at this

http://www.ihi-turbo.com/turbo_RHE-RHF.htm

Look at the sizes, and get an idea of what size turbo is good for the different applications.

The charts on the bottom shows the recommended turbos for gas, and diesel engines. Note the differences. Using this as a guidleine will put you in the ballpark (ie what size diesel motor uses a turbo suitable for what size gas). Since you only want to add a small amount of power, err on the side of small.

Okay, so let me run some math by you guys.

At approximately 10lb of air per 10 hp, 105 hp means that at 6000 rpm my car is ingesting 10.5 lb-air/minute. This converts to 152-ish cfm. 152 CFM converts to 4.03Meters cubed/minute.

Therefore I take my 4.03M^3/minute and compare it with the IHI graphs. So far so good since it looks like 4m^3/minute is around 100 hp. Reading the graph some more, it looks like 160 hp is around 7.5m^3/minute.

Once again going to the graph it looks like I could run an RHF5 at a pressure ratio of 1.5 and be right on the edge of the compressor's stall speed. I could run an RHF55 more comfortably. I don't want to run higher boost because I'm dealing with economy car cast pistons and a relatively high compression ratio. I'm also a first time megasquirter, so it's probably best to leave a margin for error.

So, my question comes to this, how big is an RHF55 and how can I compare it to what I find in the junkyard?

MrBenjamonkey wrote:

So, my question comes to this, how big is an RHF55 and how can I compare it to what I find in the junkyard?

Big enough to be on a 5-6L diesel, like on a 6-cylinder Isuzu.

The 5 would be fine. I have one on a 1.3 Swift GT motor and it's good at 9 psi. That motor probably flows better than your 1.5.

The 4 would also work, and lag would be minimal. If you look at the HP for a 4, they show 177 max. My buddy is making 230 with one on a 3 cylinder Geo motor, and it works really well.

The 55 would be way too big.

zomby woof wrote:

The 5 would be fine. I have one on a 1.3 Swift GT motor and it's good at 9 psi. That motor probably flows better than your 1.5.

The 4 would also work, and lag would be minimal. If you look at the HP for a 4, they show 177 max. My buddy is making 230 with one on a 3 cylinder Geo motor, and it works really well.

The 55 would be way too big.

Maybe I'm reading the charts incorrectly. A pressure ratio of 1.5 is a boost pressure of 7.35 psi at sea level, right? I don't want to go much higher than that because I've got crappy cast pistons and a high compression ratio. It's also hard to find premium fuel in Korea. My admittedly amateur intuition is telling me I need a relatively large turbo to make the right flow at the lower pressure. Am I off?

If I'm understanding this correctly, the 4 would be right on the edge of its potential at 7m^3/minute and a pressure ratio of 1.5. Being right on the edge means it's going to stall soon, right?

I've got the real strong feeling I'm missing something here.

Just did some more digging and it looks like the Mercedes Diesel runs a Garret GT25C. This turbo came on a wide variety of 150 hp diesels and has roller bearings. I also know where I can a good supply of them for super cheap.

AR is supposedly .46/.48. You think I should pull the trigger?

Similar Garret GT25^

So I thought of something else. If I have modest power goals and plan to use a tiny turbo, is there any point in swapping in a larger engine? Going from the 1.5 to the 1.8 should be a direct swap, but I'm dealing with Daewoos and the information out there isn't great. Should I just build another 1.5 so I am sure it will bolt in?