Starting off with a warning. This steering wheel is for off-road use only. Any pictures or accounts are for information only. If you chose to try something similar all liability is your own.

That said. I've decided to try to build a steering wheel. I have an old Nardi wood rim wheel that I've been using for my mockups that is ~14-15" OD. It's much to big. I nearly pulled the trigger on either a Kart wheel or a 10x9 Dshaped wheel but reviews of those wheels for regular cars are not favorable (too small and awkward). I owned a MKV GTI which has probably the best steering wheel I've ever used so I looked to it for my shape inspiration. The Nardi wheel provided my design inspiration.

The Nardi is basically a pice of aluminum with pieces of wood glued to the front and back of it. It has no fasteners/plugs and relys on glue to hold everything together. Mine has been through alot as it is at least 30 years old and has been completely submerged in a flood with very little ill effect. I would love to continue to use it but it's just to big and not very "sporty" feeling.

I like everyone like nice things and want the feel of a $300 aftermarket sport steering wheel but I'm decidedly low cost on this sort of thing. This post will take you through day 1 of this build. I am not done so you will be following along, however it is my intention to work on this until it is finished so it won't be but a week or so.

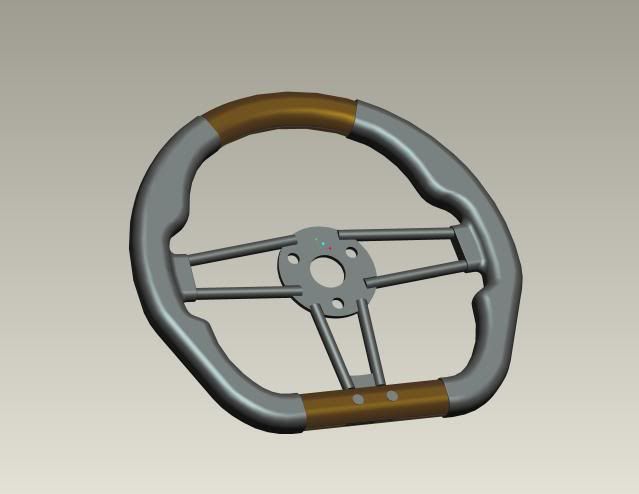

Step 1 was the concept.

I origionally had it designed to use a flat sheet of aluminum as the hub. I then costed that out and found that that sheet of aluminum would be ~$30 from Mcmaster and decided I would just weld up the hub.

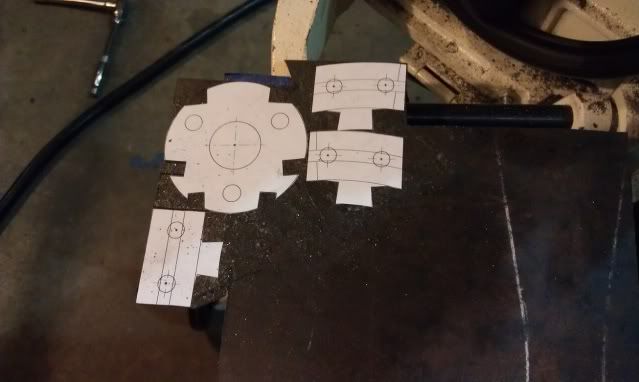

I built the hub up out of 5/16" rod and .125" steel plate. Total cost ~$6 as I had to buy the rod at Tractor supply. I am going to finish weld both sides but welded on 1 side the 3 prongs are in the right spot and flat.

I then Glued the templates for the wood forms which will be glued together clamping the hub in the middle. I will use hardwood dowels ($1) to go through the two pieces of wood ($Scrap from flooring project) and the holes in the 3 tabs creating hopefully a solid stiff sandwich.

I cut out 1 template thus far leaving 1/6" or so for finish sanding. This should allow me to glue the two together and still have enough space to sand to my final desired shape.

And here is the mockup. the gap between the botom bumps and the hub is a little small but I will enlarge is slightly when I get to the profile sanding phase.

Next steps are cut out the other template. Relieve the wood for the metal thickness (1/6" per side so the metal is centered between the wood). Glue/Clamp it together with dowels inserted. Assess overall strength to determine if I want to move forward. Then sand/file/plane down the shape I want on all of the parts. Once that is done I will varnish/seal it and decide if I want to try to leather wrap it or leave it wood.

If I leather wrap it it will be with leather from an old jacket for max cost effectiveness.

So there you go. This will either be a display of how to succesfully build a nice steerign wheel or it will serve as a leason to others of something they should not attempt. I'm hoping this goes over ok and people don't pile on me for how bad of an Idea this is. Realize that I'm building a CAR from scratch. I have fabricated things on this vehicle that a much more life threatening than a steering wheel.

Thanks for looking,

Daniel