Id love to clone the wing from the c5r. For a challenge car. Out of scrap.

I tried before, and failed. Not sure what i did wrong.

Shape

Then drilled a hole and pop rivited to a piece of conduit to keep an even spacing and all in the same plane

Dont have any pictures after this. Sorry.

I then started skinning with .030 aluminium by drilling holes into the pine and pop riveting the blind hole.

St some point it all fell apart. Pine started breaking at the rivets on the trailing edge, conduit didnt hold it rigid, and i never could figure out how to attach it to any uprights. Scrapped it all in disgust. Planned to buy a 55-60 inch wing on ebay. Then got TIGHT on challenge budget.

So, how should I do this? The .030 aluminium is $0.30 a sheet, sheets roughly 24x40. Wood is free from any construction dumpster. Budget needs to be LOW.

aero is not primaryconcern, this is mostly for visual effect. However, functional aero on this would not piss me off.

If you could make your wing innards a little more rigid you could probably skim it with that heat shrink film they cover RC airplanes with.

How about wood skeleton, expanding foam insulation and fiberglass?

The wood can be arranged to provide mounting pints, and the foam core can be shaped easily with wood working tools.

Fiberglass will add strength to the foam and give a nice surface to paint.

Mndsm

MegaDork

6/12/18 8:42 p.m.

Go get you a flap off a wing from an airplane. Add endplates.

I would use rigid foam insulation from one of the big box stores. Glue it together into a rough shape, dress up in your worst clothes, and go to town with a grinder/sander to get it to shape.. then 'glass it over

Driven5

SuperDork

6/12/18 9:02 p.m.

An alternate method is to cut a foam wing core similar to those from https://FlyingFoam.com (or buy if in budget) and glass over it

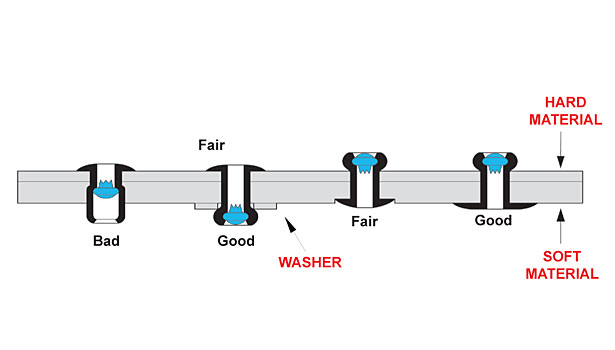

If I'm understanding you right, I think your use of rivets into the wood ribs was the cause of your failure. Screws fasten 'into', while rivets fasten 'through'. A 'blind' rivet still has a limited grip length (combined thickness of materials being riveted) and needs to have the full deformed side portion of the rivet exposed out of the opposite (blind) side of the hole. They are not intended to be used into blind holes of indiscriminate depth. Maybe try again with screws holding the skin on.

Here's a shot of the structure from the wing we built for UTCC in 2011. Pink foam insulation boards (found in the trash) were cut with a hot wire, and sandwiched between aluminum ribs we cut to the same profile. We skinned the whole thing in fiberglass, but packing tape (a favorite for foam RC airplane guys) might be a good lightweight alternative. You do want to give some thought to the backbone of the whole structure, we designed this thing to produce ~500 lbs of downforce and it needed to be built like it was going to. Your numbers may vary, but make sure it can take the pressure you intend.

Use the wood spars as a form to hammer the 0.30 aluminum sheet over, oak preferred tho w/ radius on top face. Allow enough flange to bond or rivet skin to, dimple die or makeshift hole w/ flange to bond/ rivet aluminum tubing (like the conduit). Fill between spars w/ wire cut foam like jysmonds said. Cover in aluminum skin riveted/ and or bonded, or fiberglass.

Mndsm said:

Go get you a flap off a wing from an airplane. Add endplates.

From where? This is intriguing based on price and availability.

Everyone else:

Good suggestions!

I hadn't thought about the rivets being the source of the last failure, but its absolutely right. Screws and this conversation wouldnt be happening. The foam in between the wood blocks for strength is another thing i hadn't thought of.

As far as fiberglass goes, i could. But its much more expensive than the aluminium sheets. Is there a compelling reason to go that way?

Also, the idea of expanding foam would be cheaper and easier than foam sheets. Is there a reason to choose one over the other?

Lastly, i wonder uf the conduit i used was too large a diameter, contributing to the failure. Would two pieces of smaller diameter be a better solution?

Thanks for all the feedback guys.

Mine is a pine buck with coroplast hot glued to it covered in fiberglass mat. It’s survived 115mph dragstrip passes with no signs of falling apart

In reply to Patrick :

Are you saying that im overthinking this?

I ran insulation-foam-and-fiberglass wings on my kart, and they performed just fine (2 seconds/lap).

You can build a hotwire with $5 worth of nichrome wire, a pair of drum sticks, and a dimmer switch. The hotter it gets, the better it cuts.

Limit your wing thickness to the 2" thickness of the foam, and make the hotwire wide enough to do the whole part. Gluing the foam together doesn't work. If you need more lift than that, build it as a multielement system.

Endplates and mounting can be plywood, but you need to make an optimistic estimate of the force generated by the wing and a pessimistic estimate of your bond strength. The plywood must be fully glassed to the ends of the wing and don't skimp.

Vacuum bagging produces prettier results. Epoxy resin is needed, because polyester dissolves the pink insulation foam.

Something like this? Just for an idea how to throw one together.

What about another t-shirt fiberglass experiment??

Or go totally hack as a carpenter.

Cactus

Reader

6/13/18 9:35 a.m.

Pop rivets work as clamps, you need a through hole to get them to work properly. You're trying to use them with the same principle as concrete anchors. Wood just doesn't have the strength to take that, which you found out. Rivets are more complicated than you'd think. They're still current aircraft technology for a lot of planes. (Not pop rivets specifically, but there's a bunch of riveted planes flying right now.)

Maybe attach pieces of angle iron to the wood so you can attach rivets in through-holes?

I think the screw and glue idea is a cheaper, and lighter option. Fill cavity with spray foam for stiffness, and additional binding agent. I could still use scrap wood for the ribs, and.....

Dirtydog: the aluminium one is kind of what im thinking. Only a hell of a lot more audacious. And wider. But that one just gave me what i couldn't figure out about how to do the uprights and angle adjustments!

As far as uprights: 1/2 inch plywood with guidewires in between be strong enough?

Dirtydog said:

Something like this? Just for an idea how to throw one together.

I know that wing well, because I built the mounts, took the picture and owned the Cadillac  That picture has to be at least 15 years old, possibly 16.

That picture has to be at least 15 years old, possibly 16.

It would be really easy to replicate using your wood technique as long as you used wood screws, that's basically how it was built only with aluminum ribs and rivets instead. Unlike airplane guys, weight isn't quite a critical for you.

Most of the spray foams I've used seem to continually expand for some time afterwards even past the time they're supposed to be fully cured. If it's the same amount of budget hit I'd probably go pink insulation board over spray foam personally.

Get some cheap fiberglass resin, super glue, and a spare bed sheet.

Get the wood aligned perfectly by whatever method you choose. On the other side, stretch and glue the sheet down to each of the pieces of wood to form the curved surface. Then get a brush and dab the resin into the sheet. Let it dry, flip it over and do the other side. You can leave it open on the ends and spray full of foam or whatever for rigidity. It'll form a cheap, somewhat stiff core to work with.

Dusterbd13 said:

Id love to clone the wing from the c5r. For a challenge car. Out of scrap.

Then drilled a hole and pop rivited to a piece of conduit to keep an even spacing and all in the same plane

I then started skinning with .030 aluminium by drilling holes into the pine and pop riveting the blind hole.

St some point it all fell apart. Pine started breaking at the rivets on the trailing edge, conduit didnt hold it rigid, and i never could figure out how to attach it to any uprights. Scrapped it all in disgust. Planned to buy a 55-60 inch wing on ebay. Then got TIGHT on challenge budget.

Your failure was the rivets. If you had used wood screws and washers instead it would have worked better, so I'd start there.

Uprights can be sorted out once you get the wing built. Think similar process to the wing, just vertical and smaller with allthread and some spacer tubing to hold it together and allow some adjustment.

Keith Tanner said:

Dirtydog said:

Something like this? Just for an idea how to throw one together.

I know that wing well, because I built the mounts, took the picture and owned the Cadillac  That picture has to be at least 15 years old, possibly 16.

That picture has to be at least 15 years old, possibly 16.

It would be really easy to replicate using your wood technique as long as you used wood screws, that's basically how it was built only with aluminum ribs and rivets instead. Unlike airplane guys, weight isn't quite a critical for you.

I'll be dogged. I guess good plans stick around a long time.