Hello Folks.

New here and wanted to get your expert input to something I’m still unsure about. I am attempting to build a coilover setup that offer weekend warrior handling yet offer good daily driving manners. I’d like to have the discussion on technical/measurable details and not focus on “brand” item. For starters, I’m using an affordable set of coil overs. Yes, it is not the best example but it is affordable and I am using this as a learning experience.

[B][The Setup][/B] My vehicle has a total weight of ~3500 lbs with a f/r 56/44 weight distribution, which would put it 1960 lbs front, divide by 2 = 980 lbs sprung weight per corner at rest. I don’t know the exact numbers but I would guestimate about 980 – 120 = 860 lbs un-sprung weight per corner at rest.

The coilover shocks are 33 way adjustable monotube cartages and has an internal bump stop build into the base. Set to the softest setting, I pressed the shaft all way the down and get a net shock travel value of ~3.5”. This is likely when it hits the bump stop so I would max it at 3.7”” before bad things happen…

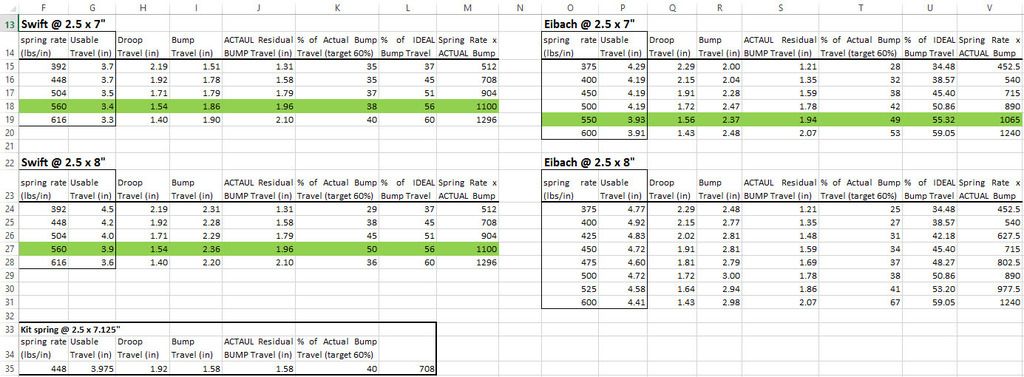

The kit springs are 2.5” diameter, rated 448 lbs/in, and measure 7.125” length at rest with a coil bind value of ~3.15”. 7.125 - 3.15 = ~3.975” total max spring travel (likely ~3.7”?).

[B][Questions][/B]

1) Is Bump or Droop more important for comfort? I’ve read that a good DD rate is 60% Bump / 40% Droop. Does that sound right?

2) Since the springs are 448 lbs/in and assuming the unspring weight is 860 lbs, does this mean at rest the spring has already lost (860/448 = 1.95”), 1.95” for droop travel?? I would only have 3.975-1.95= 2.025” of spring travel??

3) Since that shock only has 3.5” of travel, does this mean I would only have (3.5 – 1.95=1.45) 1.55” bump travel!?!? Am I looking at this right?

4) I image when at hwy speed and air pressure and down force in play, this would further compress both spring and shock travel down further by a little bit. Any I understating this correctly?

5) The standard kit spring seem to give me 40% Droop / 40% Bump.

The kit spring’s numbers seem off for my needs. It seems to strive for a 50/50 bump/droop. This is nice but the front end is just too heavy, it seems. Also, the 445 lbs/in spring rate x 1.58” remaining shock travel for a max bump of 708 lbs. Is there any correlation between this number vs the car’s unsprung weight of 860lbs? I an thinking of going with 560 lbs/in spring, which would net me 1.85" remaining shock travel for a max bump carring weight of 1036 lbs. 1036 seems much better than 708 when hitting a pot hole at HWY speeds. It would seem the spring is under rated for this car? In this instance, it seems it would benefit me to go up in spring rate (see green ones I’ve highlighted, yes one of the formulas is off in the pic). Based on my butt dyno, I get the feeling these coilover shocks can handle an extra few hundred lbs/in no problem, just need to adjust it for higher rate.

The kit spring’s numbers seem off for my needs. It seems to strive for a 50/50 bump/droop. This is nice but the front end is just too heavy, it seems. Also, the 445 lbs/in spring rate x 1.58” remaining shock travel for a max bump of 708 lbs. Is there any correlation between this number vs the car’s unsprung weight of 860lbs? I an thinking of going with 560 lbs/in spring, which would net me 1.85" remaining shock travel for a max bump carring weight of 1036 lbs. 1036 seems much better than 708 when hitting a pot hole at HWY speeds. It would seem the spring is under rated for this car? In this instance, it seems it would benefit me to go up in spring rate (see green ones I’ve highlighted, yes one of the formulas is off in the pic). Based on my butt dyno, I get the feeling these coilover shocks can handle an extra few hundred lbs/in no problem, just need to adjust it for higher rate.

It's another discussion on whether or not the coilover shocks, set to the stiffer setting, has the proper damping profile to handle a stiffer spring. It did not come with a shock dyno. In the end, I would end up with a more 'taught' travel but it is less likley to crash at HWY speeds, sound right? If so, that is exactly what I need.

Eibachs are more affordable but the Swifts have actualy number for Max vs Usable spring rate, whereas Eibach only has one number without reference what it measures. Any experience on this?

Appreciate any comment you can offer. Thanks!