Split Lock Washer

Description: Split lock washers are the most common type of locking device. They’re also one of the least effective, but they’re easy to produce and readily available. Split lock washers are flat washers that have been cut and “twisted” so that they create tension under the bolt head. In theory, this tension applies additional load to the threads and makes them less likely to back out. Typically, however, it takes far less torque to completely compress the washer flat than the fastener needs for proper hold.

Pros: Readily available, inexpensive and ubiquitous.

Cons: Doesn’t really do much.

Should be used when: Loads are light and non-critical and nothing better is available.

Wave Washers

Description: Wave washers are similar in principal to the split washer, but this is a continuous loop with a “wave” shape that applies tension as the bolt is tightened. Drawbacks are very similar to the split washer, but the wave washer is kinder to the surface and will not leave burrs.

Pros: Does not require a flat washer. Looks neat.

Cons: Similar to split washers. Looks weird.

Should be used when: You have a very light load and don’t want to use an additional flat washer.

Serrated Washers

Description: Serrated washers are also referred to as “star” washers, which rather accurately describes their appearance. These are available with the “teeth” on either the inner or outside diameter of the washer, and work by physically digging into the underside of the bolt head as well as the (hopefully soft) surface against which they are used.

Pros: Simple. Nice, direct mechanical operation.

Cons: Not terribly strong. Not good on hard surfaces.

Should be used when: You’re putting small fasteners into soft materials (aluminum, plastic, etc.).

Tab Washers

Description: A tab washer is a flat plate that is installed under a bolt head or nut, affixed to another fastener, then bent up to keep the primary fastener from rotating. Cool idea, but there’s an inherent weakness: Any material soft enough to bend will be soft enough to crush under the fastener’s tension. Good thing the tab washer is there to keep the bolt tight, because that tab washer is crushing under the bolt head and trying to make it looser.

Pros: Easy to improvise. Ease of visual inspection.

Cons: Inherently flawed, much like modern country music.

Should be used when: You have nothing left to lose.

Nylon Collar Lock Nuts

Description: Commonly referred to as “nyloks,” these nuts feature a nylon collar insert that is a smaller diameter than the threads. When the nylon is engaged with the male threads, it forms a compression interface that keeps the fastener from turning on its own.

Pros: Readily available, inexpensive, does not require additional bits of hardware.

Cons: Still somewhat susceptible to vibration loosening, although will rarely back out past the point where initial bolt tension is lost. Should not be heavily reused. Heat can melt the nylon insert.

Should be used when: Whenever you can. Good all-around performer from an effectiveness/ cost/availability standpoint. Everyone’s hardware assortment should include nylon locking fasteners.

Prevailing Torque Nuts

Description: Picture a regular nut, with regular threads for most of its length, but with an end that has been distorted into (usually) a more triangular shape, or “teeth” that are angled inward. When the nut is applied to the male threads, the force distorts the nut into a round shape, but the inherent tension creates a strong mechanical friction.

Pros: Strong and very vibration resistant. The good ones (mil-spec) are surprisingly reusable and won’t damage the bolt’s male threads.

Cons: This is a kind of specialized bit of hardware, so availability isn’t wide. Cheap ones will be one-time use and could mess up male threads when removed.

Should be used when: You’re rich and can afford the mil-spec stuff. Use prevailing torque nuts when you’d usually use a nylok nut, but high temperatures won’t allow it.

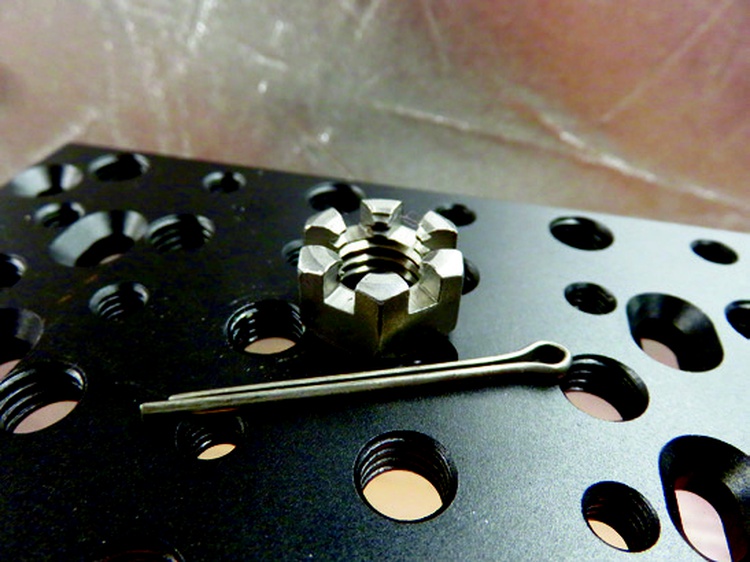

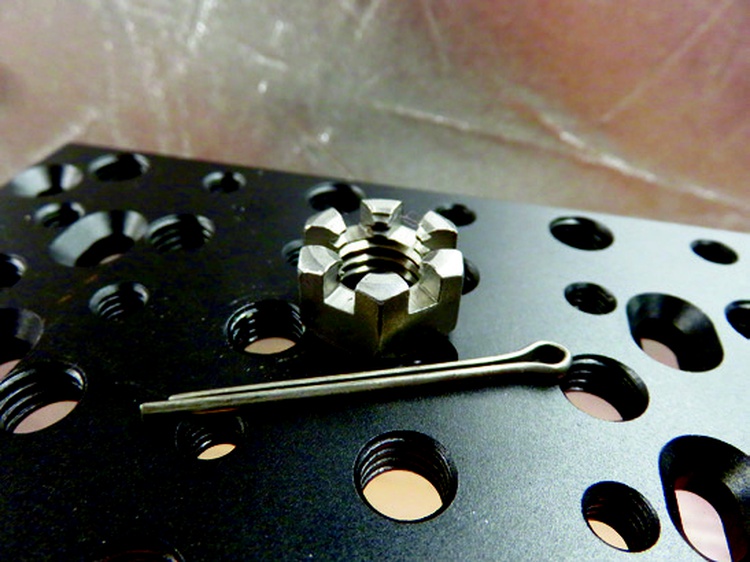

Slotted Beam Stop Nuts

Description: Commonly called castle nuts, these feature a segmented top section through which a cotter pin can be inserted for use on a cross-drilled bolt. A similar-looking arrangement also works like the elastic stop nuts. In this version, the slotted parts are angled inward and create mechanical friction on the fastener when tightened.

Pros: Very positive and visually identifiable locking.

Cons: In some applications, aligning the slots with the hole may result in the application of either too much or not enough torque.

Should be used when: Specific torque isn’t critically important, but retention is.

Wedge-Locking Washers

Description: Most commonly referred to as “Nord-Locks,” which is actually a brand name of one of the more common versions, these wedge-locking washers actually feature a two-washer system that uses interlocking plates to create additional friction that prevents rotation. The washers have two toothed surfaces that fit together and provide torque counter to the direction of rotation. Serrated outer surfaces grip the bolt head and surface plate.

Pros: Most vibration-resistant system that doesn’t use an external force (such as safety wire). Can be installed with common tools, just like a regular washer.

Cons: Many times more expensive than regular washers. Serrations will mark surface it mates against.

Should be used when: When you really need resistance to both vibration and rotation and don’t mind the extra cost. Wedge-locking washers are what we chose to lock down our Mustang’s Watts link; for mission-critical fasteners, they’re likely worth the cost.

Diamond-Embedded Friction Washers

Description: As the name implies, and the microscopic closeup shows, these washers are embedded with crushed diamonds, which creates an extremely high-friction mechanical connection. The hardness of diamonds means these work very well on hard surfaces. Most widely used in the aerospace industry and among OEMs for stuff like cam bolts and crankshaft bolts.

Pros: Strong mechanical connection. Works great for hardened surfaces, or surfaces without a lot of inherent friction.

Cons: You’re not going to find these at Ace Hardware. This is specialized stuff with a price to match.

Should be used when: Your ruby washers just don’t have the same panache anymore. Seriously, this is a good product for when you need a high-friction connection, but don’t want to introduce additional pieces as required by the wedge-locks.

Safety Wire

Description: A wire is passed through a drilled hole in the fastener and attached to another hard point to prevent loosening.

Pros: Probably the safest overall solution, both structurally and for ease of visual inspection. Even a mediocre job of safety wiring is stronger than most other things on this list.

Cons: Complex and time consuming. Requires additional specialized equipment and knowledge. Not good for anything that requires frequent removal.

Should be used when: You don’t want something to come off, and you don’t intend to take it off any time soon. See also: every bolt on a helicopter.

Jam Nuts

Description: Besides sounding like that party band your uncle was in during college that he just won’t shut up about (no, Randy, you never “almost got signed”-let it go already) jam nuts are one of the best “conventional” locking methods around. A jam nut is a second nut that is applied to a bolt’s male threads and then tightened against the first fastener. This produces opposing stresses and increases friction on the threads.

Pros: Easy, cheap and reliable. Jam nuts are a go-to solution that’s easy to implement in the field. Use a nylok jam nut for even more reliability.

Cons: Requires additional male threads to implement, so not suitable for some tight quarters.

Should be used when: You need a reliable solution, but have limited stuff in your box. Or when you have the space available.

Chemical Thread Locking Methods

Description: As the most prolific brand, Loctite has become synonymous with chemical thread lockers, but it’s just one of many high-quality brands out there. Thread locking compounds are anaerobic (meaning they cure in the absence of air) liquids or gels that effectively act as glue between the male and female threads. Books can and have been written about their use and properties.

Pros: Easy to use, readily available and highly effective. Available in varying strengths and heat resistances.

Cons: The joint is only as strong as the surface is clean. You always run out right when you need just a little more.

Should be used when: Whenever possible. Lots of specific formulations for different applications means lots of options.

Of course there are more solutions out there, and you’re ultimately limited only by cost, complexity and possibly access to secret government files. This should get you headed toward making good decisions about how to keep your fasteners in place. We highly recommend Carroll Smith’s “Nuts, Bolts, Fasteners and Plumbing Handbook” for in-depth discussions of many of the solutions we mentioned here.

As for us, as we mentioned, we’re going with the wedge-locking washer system for now, coupled with a dab of medium-strength thread locker. We’ve also put a splash of paint on our Watts pivot and many other critical fastener connections, so we can easily see if there’s been any movement in these fasteners since they were last torqued.