This, in theory, is going to be my way of trying to motivate myself to finally get around to finishing this project. I've been lurking around the GRM forums now for about a year following a couple of builds (Mazduece, SkinnyG, and maschinenbau's rice rod) and sort of gotten a feeling for the community. I feel this is a place where my methodology is most at home, not on the individual forums for my eclectic collection of projects.

So here goes:

In March of 2013 (Christ has it really almost been 5 years?!) I was a freshmen in college, like a moron I had just wrecked my first car, and was searching craigslist looking for a replacement (like a moron). It was on that ever dangerous search I found what would become the demise of my wallet and spare time for many months and years to come.

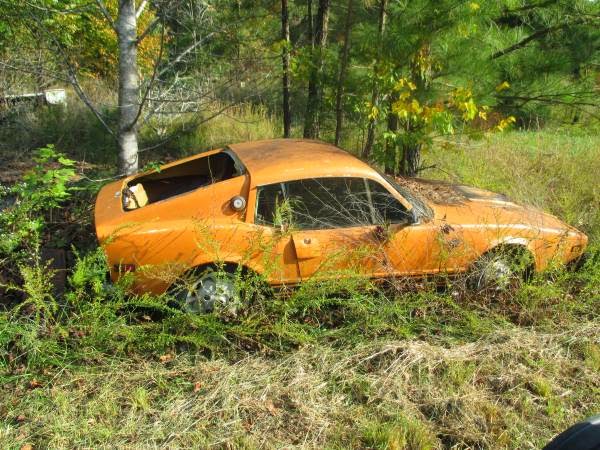

There she is as I first met her. I won't go into explicit details on EVERYTHING I've done in the past 4 years but I will give a quick run-down of the major milestones.

It's worth mentioning at this point that I'm not a mechanic. My father isn't a mechanic. Nor is my mother, or as far as I know any relative that I've actually met. I've got an uncle who always wears mechanics cover-alls, but I think that's just a fashion choice. My father had some tools and know-how, but mostly geared towards home-maintenance and minor wood-working. It is fair however to say he is above the average "Dad Handyman" and was still a tremendous help during the early stages of my learning during this project. Everything I did on this project I learned how to do myself from videos or written guides online, including I'm sure a few from GRM. The SAAB Sonett III was not a great choice as a first project because in almost every way it is not normal, and every part is more or less bespoke and made of unobtainium. I'm not making excuses, I'm just trying to show others that embarking on insane projects like this while not necessarily wise, aren't impossible. Even with next to no expertise or tools.

First order of business was getting the car running. Of course it wasn't when I bought it. All it took was a battery, some carb tuning, and some starting spray to get it to cough over. I then had to have to clutch master cylinder rebuilt so I could get the car in gear (one of the only things I outsourced). After that and a bodged gas tank the car could drive around the back yard. Re-did the brake lines and wiring from scratch through the whole car, pulled out the interior to be cleaned or replaced, did some rust repair, and then decided to embark down the rabbit-hole of paint and body work.

Normally it would be at this point the doors fall off the project, as soon as there is the expectation of something looking "nice" just getting it done will no longer suffice. However in my case that some how didn't happen. I did all the paint and body myself, with no formal training beyond YouTube. I think it came out pretty well and is one of my proudest accomplishments on this project.

I got the rear/main body back on without too much damage to the paint (there was a little, I still need to fix that) and it was at this point the wheels fell off.

Before putting the front body back on I felt it pertinent to test drive the car around the parking lot to make sure everything was in working mechanical order.

It was not.

First problem was after a blast around the parking lot the car wouldn't drop into gear. Then the next day out of gear there was a horrid knocking noise coming from the engine that wasn't there the previous day. Then next weekend when I had time to work again the gas tank had rusted into a colander. This wave of bad news, coupled with increased time commitments from work and school the project fell by the wayside as the car was shuffled from storage unit, to friends garage, to now the small garage I rent at my apartment.

I've finally got some time on weekends and after work to get things done in the garage. The past few months of working around but never on the SAAB has started to drive me insane. So this is going to be my accountability check-off to finally get back to finishing the car. Maybe if others are at the very least asking whats going on with the car I'll guilt myself back into working on it.

In retrospect I think I've traced the knocking noise to (hopefully) not the engine itself. The V4 Ford Taunus, like many ford engines, has torque-to-spec flywheel bolts. Well when I had the engine out I took the flywheel off and like a moron re-used the bolts. So I suspect (read: really hope) that the only problem is the flywheel working its way off the back of the engine. I've got new bolts, a new pressure plate, and carrier bearing, and am out of excuses to not pull the motor and confirm my suspicions. Or cry when it's something else.

If you want a chronological, more in-depth, write-up of all the stuff I've done to the car since I bought it I did make a blogspot to chronicle the process. Here: http://saabsonett3.blogspot.com/

If it tells you anything I haven't updated that blog since May 2016 and since then: sold that Fiero, got my next car (Volvo 242, sorry to ruin the weird cliffhanger I left there for almost 2 years), then got ANOTHER daily driver cause' the Volvo was trying to kill me.