I spent the first 4 months of 2016 living in an apartment so no progress was made. We closed on our house and moved in the first week in May but I really didn't get back to work on the car until August. I finished up the chassis wiring I posted out of order on the previous page but that was about it for 2016. Why did I get no work done in late 2016? This happened:

I found this for sale in Nebraska (I might have even made a post here about it) and it was just to good to pass up. It's an all-original '79 (made in March '78) GS with less than 30k miles on it. It's nearly immaculate but did require some work since the previous owner basically drove it a handful of times every 10 years since getting it from his brother in the early '80's. I spent late Summer through the end of 2016 fixing small things here and there.

Back to the subject car. Finally in Spring 2017 I started throwing the interior back together.

The shiny stuff is that "EZ-Cool" thermal/sound barrier you can pick up at your local hardware store. It weighs next to nothing and I figured it couldn't hurt. I can't remember if I posted this before or not but I made a simple battery tray/tie-down to hold the ETX18L battery behind the passenger's seat. I also relocated the main fuse box along side it.

Interior all buttoned up:

One of the issues I ran into with the roll bar was it interfered with the storage bin lids. Not a huge deal but it made installing and removing the battery difficult. My not-so-elegant solution was to cut the lids in half and add small hinges for a sort of bi-fold setup. It works...

To this day I still don't have a passenger's seat.

I'll be picking up another OMP WRC seat and G-Force 5-point harness shortly. I bothers me to no end that OMP changed the look of their seats in 2014. Now I'm going to have mismatched seats because I'm not spending another $800 just to have matching seats...

The good news is I hooked up the battery and most everything worked. At least the magic smoke stayed inside the wires. I had one small issue with the factory alarm being triggered. It's integrated into the OEM CPU, which also contains the horn and indicator/hazard relays. To avoid rewiring those I kept the CPU and severed all the alarm connections. The problem was I also removed the ground on the ONLY circuit that switches to open when triggered. This caused the horn to go off (because they're internally connected in the CPU) at random times. One quick jumper to ground and that problem was solved.

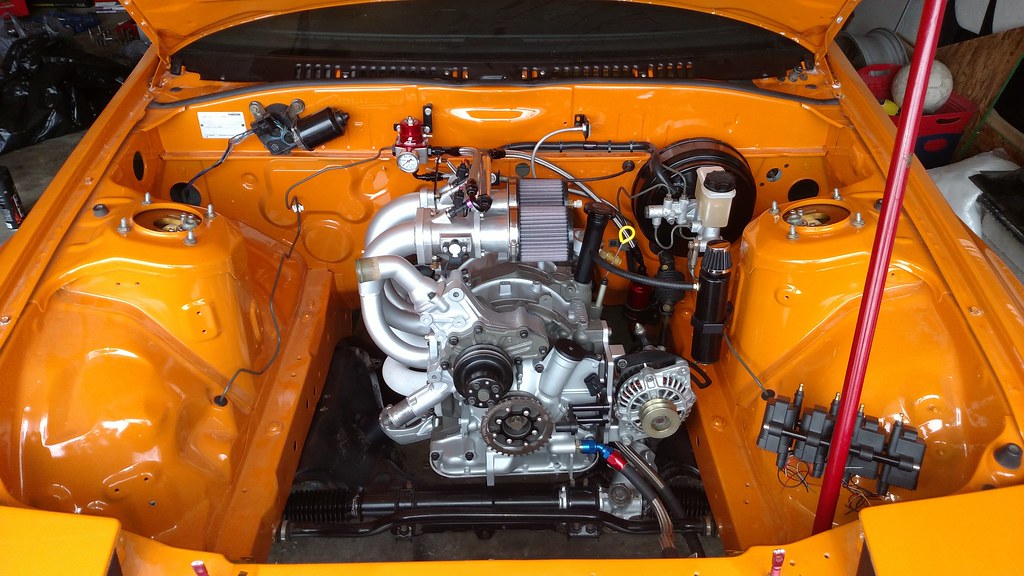

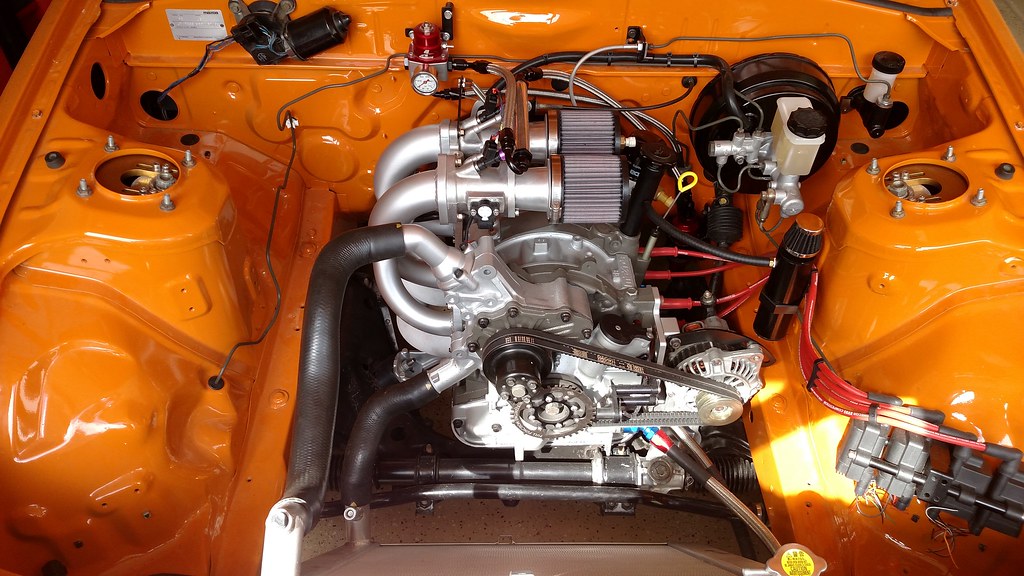

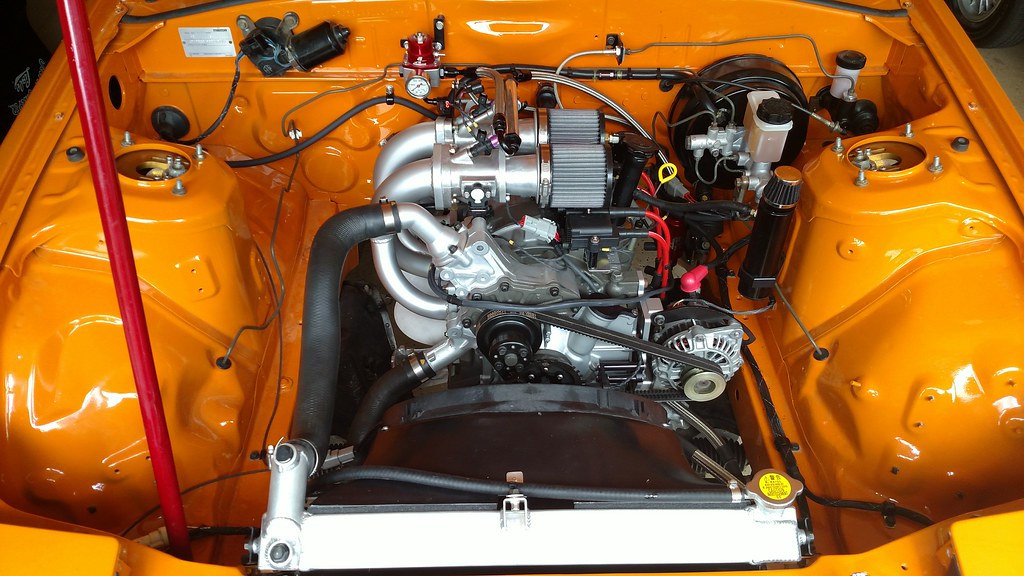

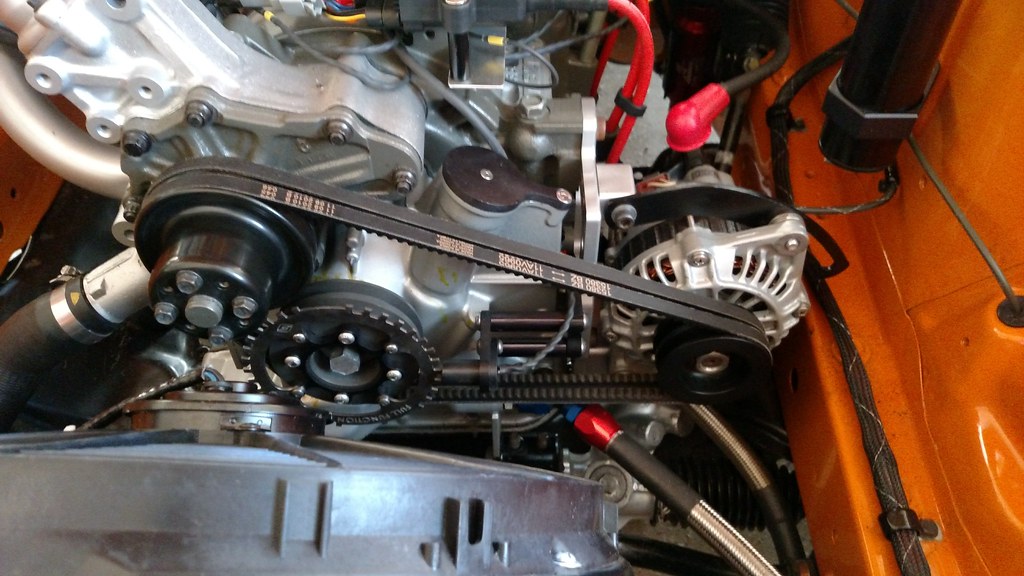

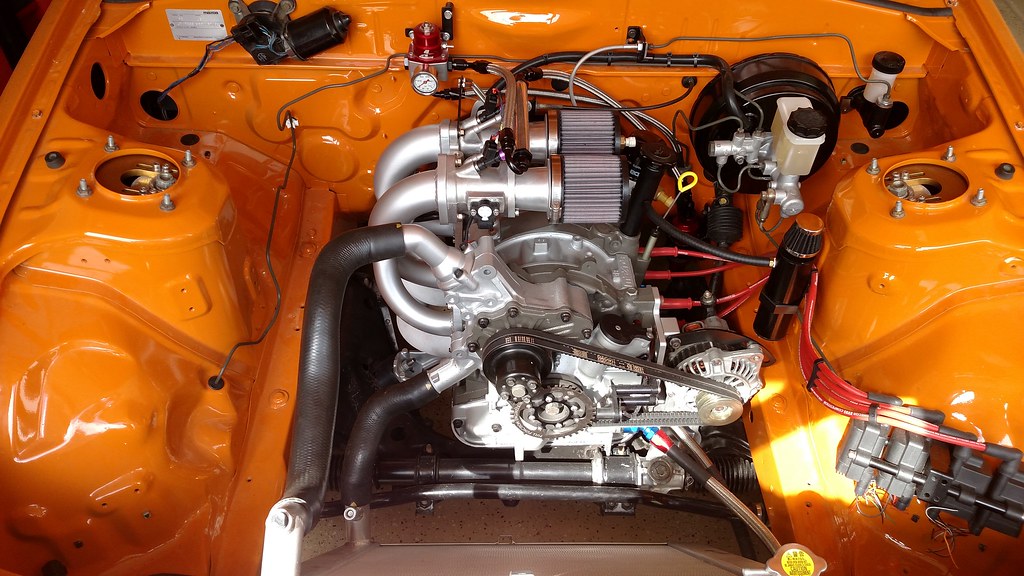

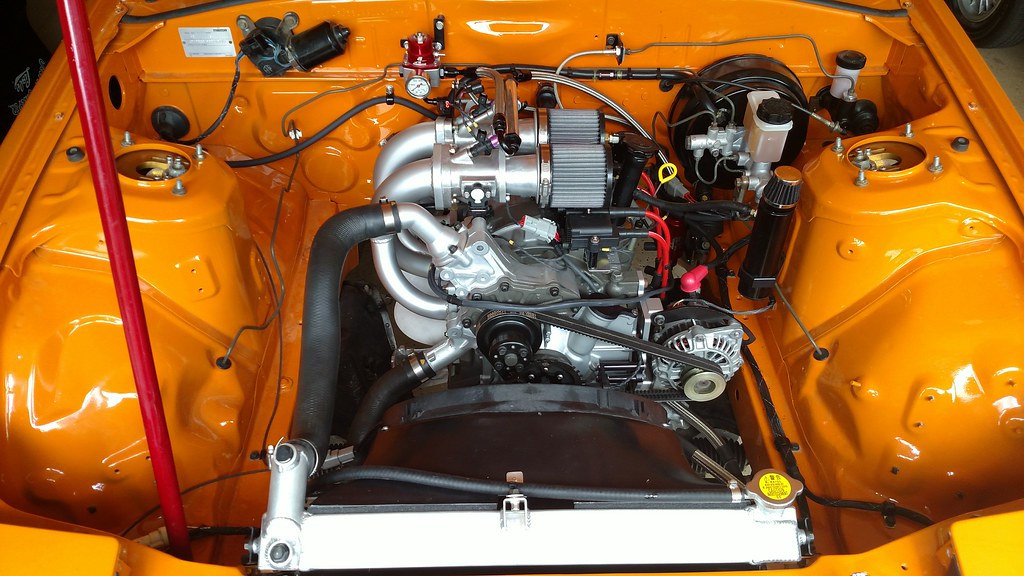

Back to the engine. Test-mounted the radiator. Installed the clutch master cylinder and ran the spark plug leads.

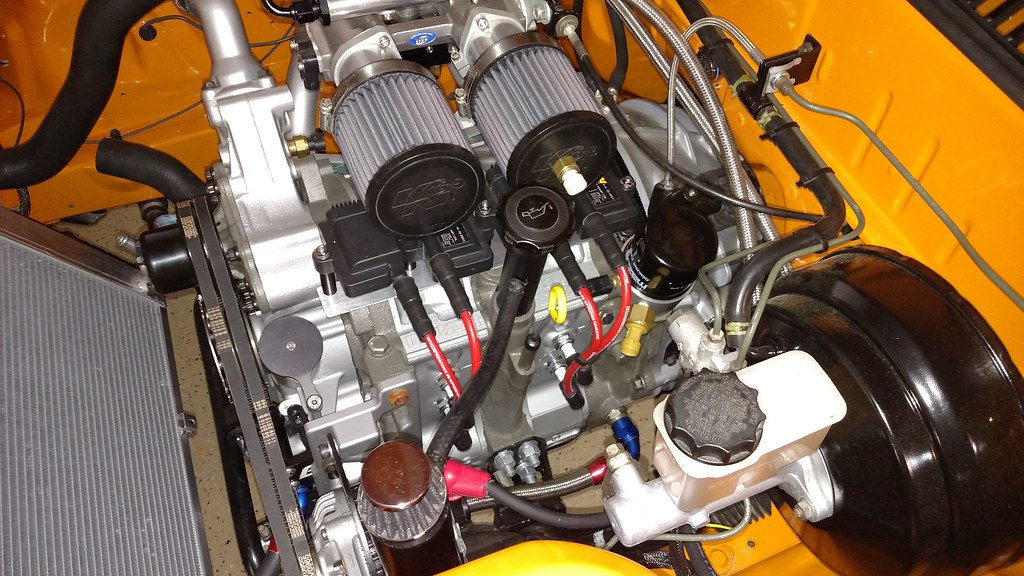

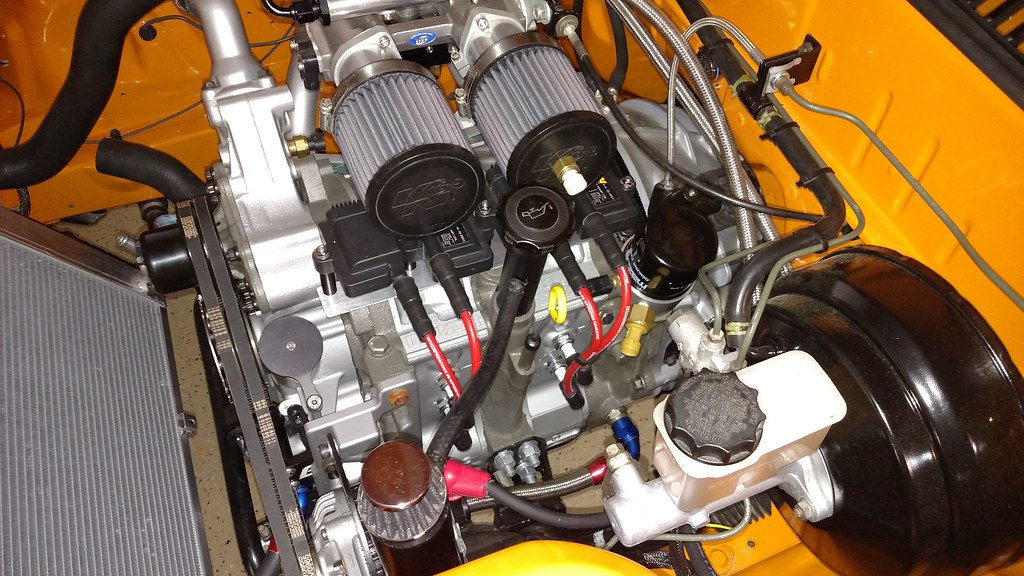

I decided I didn't like the leads snaking around the engine so I made a new bracket the mounted the coils on top of the engine.

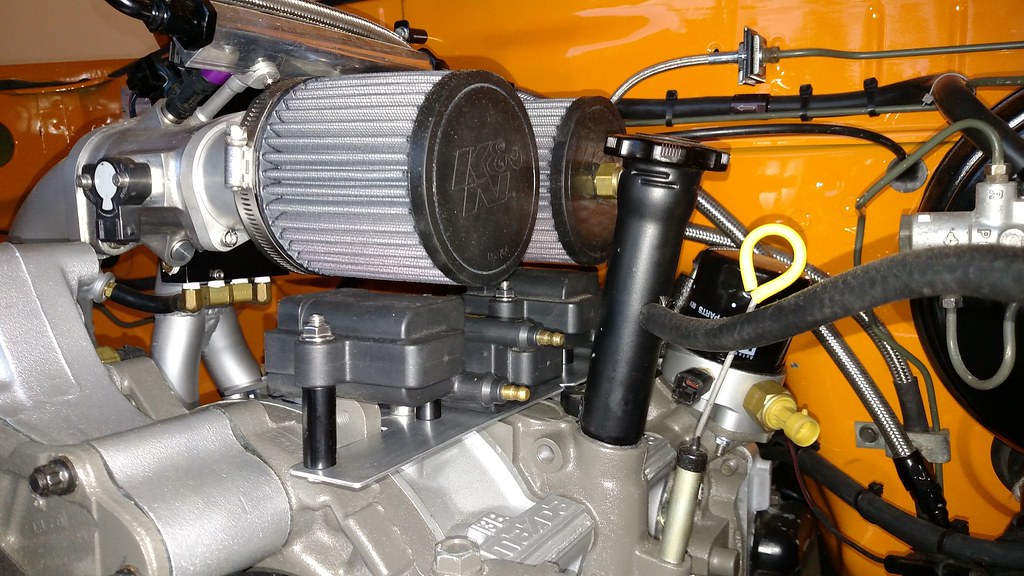

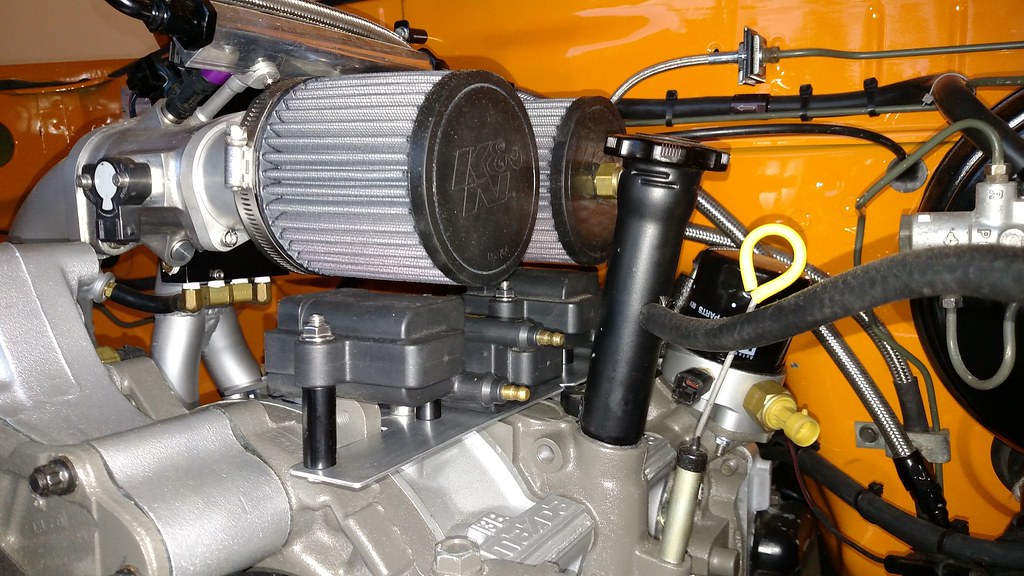

They're a close fit with the filters installed.

Hit up Magnecor for another set of custom leads. Much better:

Unfortunately this wrought havok on my engine harness since it was designed with the coils mounted behind the driver's side headlight. I still made it work. The ignition subharness just spirals around the engine for the moment.

Here's what it looks like under the filters:

I definitely need to clean up the harness at some point (later).

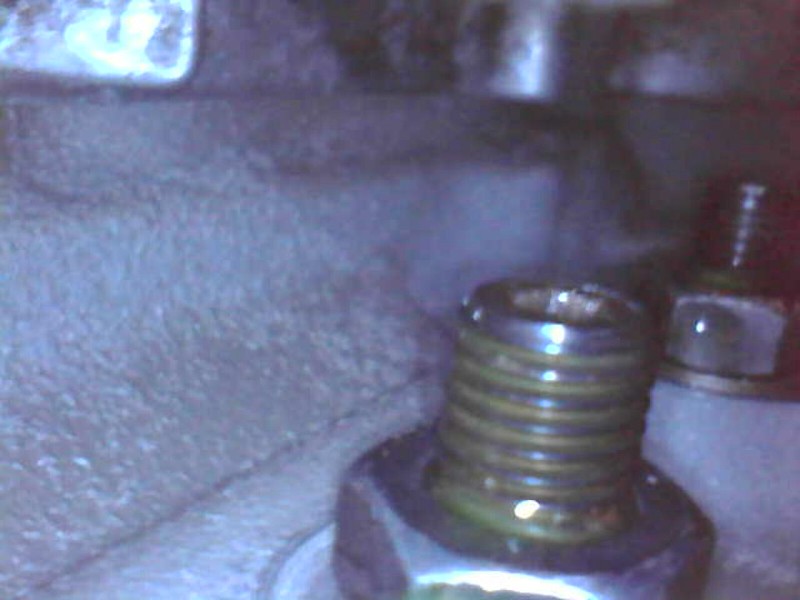

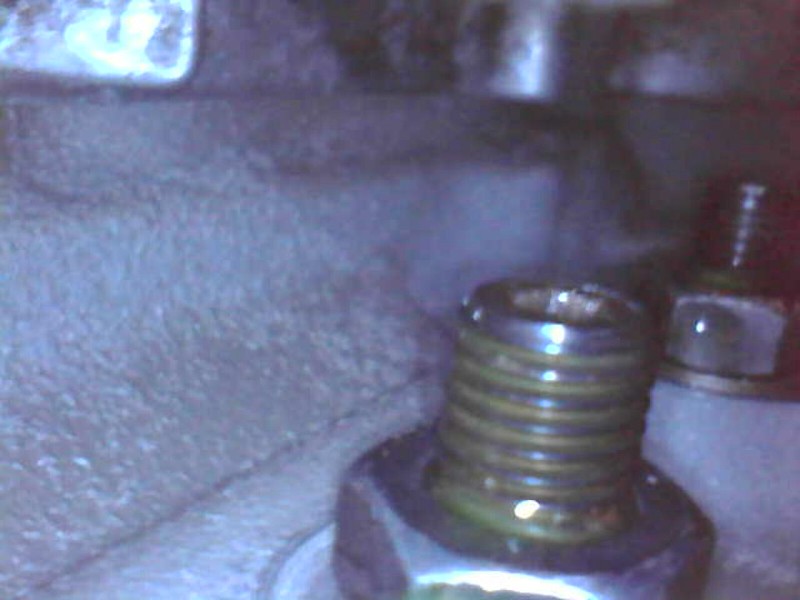

So... that's it, right? Engine built. Harnesses completed and installed. Time to add oil and coolant! Oil goes in as expected. Just as I'm finishing topping off the coolant I see a small puddle on the floor under the transmission bellhouding. Please don't be coolant. PLEASE DON'T BE COOLANT! ...it's coolant. CRAP! My heart sank. Pretty much the only reason coolant would be leaking is a failed coolant seal, which means I screwed up something in the rebuild and would have to take it all apart. Before I admitted defeat I figured I'd try to at least see where the coolant was coming from. I had received an endoscope for Christmas the previous year and figured now was a good time to use it. I popped off one of the inspection covers, plugged the endoscope into my phone and started probing (ha). This is what I see immediately:

and

Okay, so coolant is leaking around the threads of the tension studs. Yes, studs. I replaced the OEM bolts with studs because reasons! This is good news. It's not leaking from the block so the seals should be intact. I drain the oil to make sure and fortunately it's devoid of coolant. The studs run between the inner and outer coolant seals and are exposed to coolant so somehow it's finding its way around the threads. I used the OEM sealing washers so what gives. Oh, wait. The sealing washers are designed to be crushed under a bolt head. Mine are still crushed but there's still a leakage path around the threads. I did use sealant like the instructions said, right? WRONG. Turns out I skipped over that part. Well the good news is I didn't completely botch the rebuild. The bad news is the engine still has to come out.

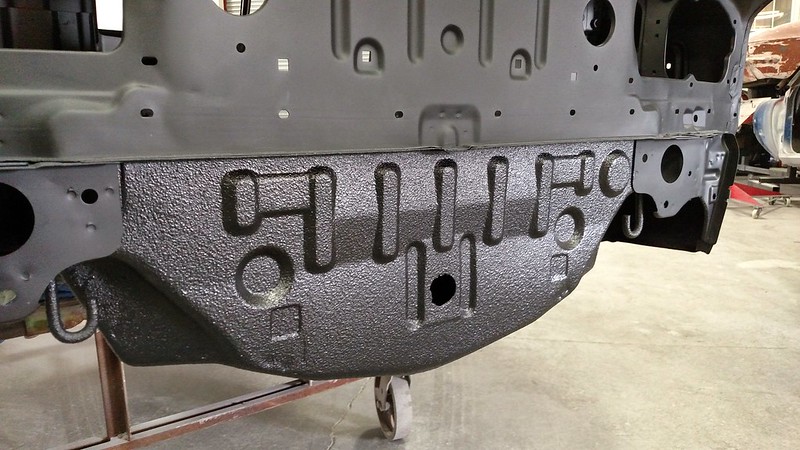

If I recall correctly I had all the fluids drained and the peripherals drained that evening (a Friday). By noon Saturday the engine was out.

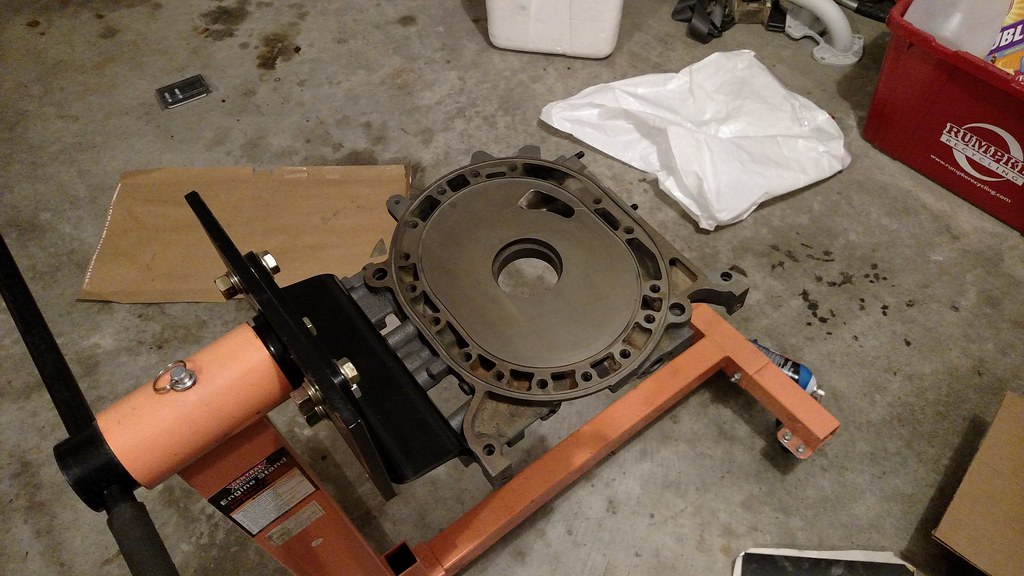

Off goes the clutch and flywheel:

I spent the rest of the afternoon slowly loosening each nut, then cleaning each one, applying a pea-sized dab of Permatex black to the threads of the stud, and then slowly re-torquing each nut down again. I let the silicone cure overnight and reinstalled the flywheel and clutch on Sunday. This time I would make sure the engine was watertight before reinstalling it. I flipped it upside down on the stand and filled it with coolant and let it sit for a week. I did find one more leak at a loose NPT fitting:

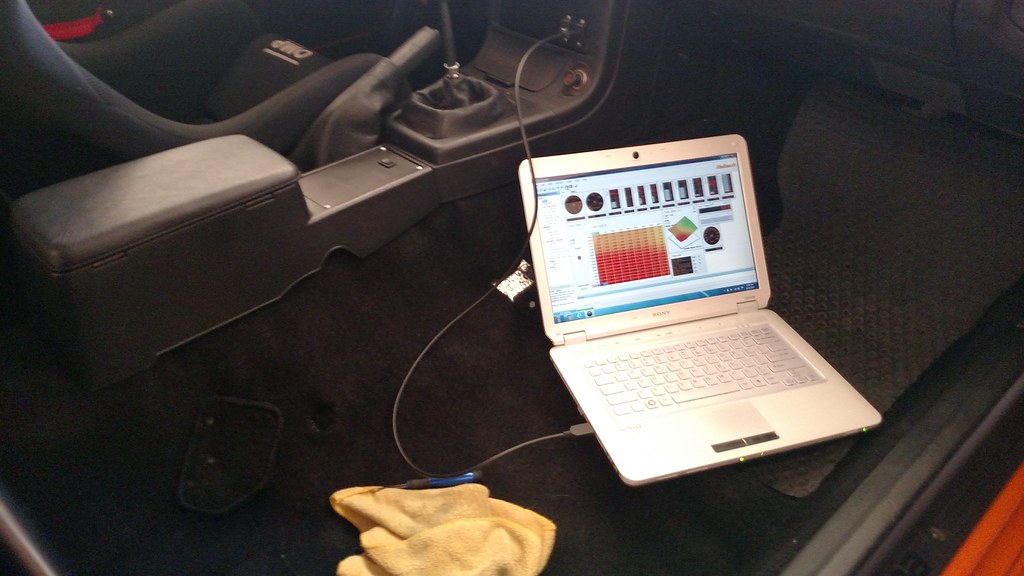

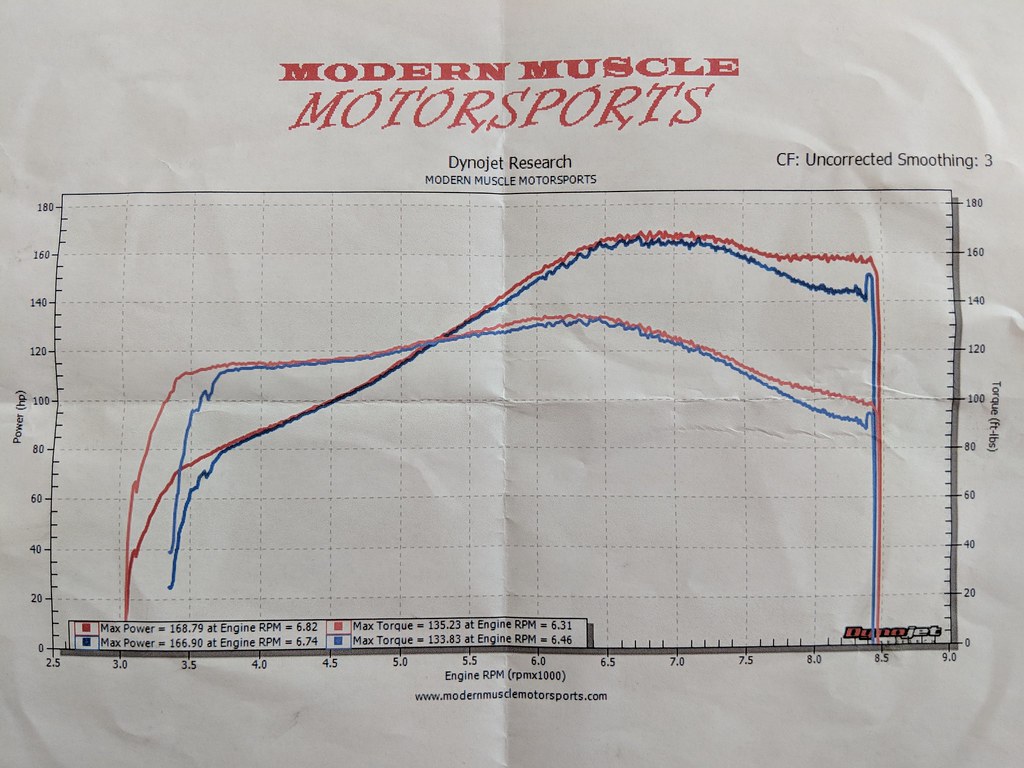

After torquing that a bit deeper the engine was leak free and I reinstalled it the next weekend. Fluids were added once again and I completed the painful process that was calibrating the fuel level sensor: note empty voltage, add 2 gal, wait for sender to equalize and note voltage again. Repeat up to 16 gal. The last piece of the puzzle was a start-up tune. Fortunately, Chris Ludwig at LMS-EFI came through once again and provided me with a TPS-based map to get it running.

Next up: let's get this party started