5/24/20:

So painting. Uhg, what a GD sh!t show. I have a massive amount of respect for people that paint well. The part I can't stand is that nothing is ever done perfectly. The sandpaper doesn't reach, or the filler shrinks just a touch too much, etc. The most important skill a painter has is the ability to say "well, that should be good enough" and be right about it.

The weather turned in MI a few weeks ago so I was ready for frame painting. I was going to just do that in the driveway but wasn't thrilled about it. It dawned on me at some point that with nobody throwing any parties that party tents might be pretty cheap. Turns out they are. 10x20 for $145.

This thing works great, I cut a hole for a big box fan in one corner and three furnace filters on the opposite wall. It moves a ton of air with the seams taped up. While not an HOA, our neighborhood definitely will not welcome my garage addition for long so I'm busting ass to get everything done. (There's a creek along our whole back lot line so you can only see a tiny corner of the tent from the road) My ultra tolerant wife is not loving this part either so that's double the motivation.

Frame pre-view!

[/url]

[/url]

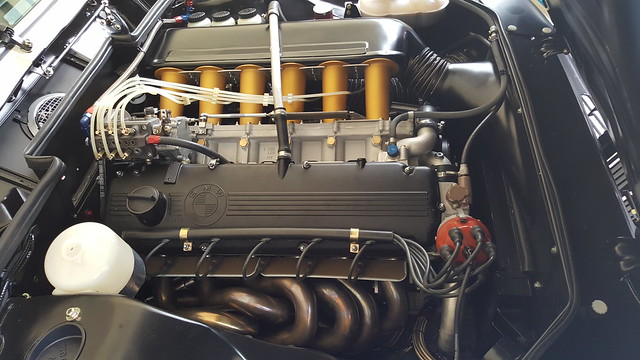

I'm new to 2 stage painting. I did a 40' long city bus for my wife in single stage (long story) so I own a fair amount of the equipment and I'm comfortable spraying, just new to the timing of getting all the coats on in one session. I wanted the frame to match the bodywork in Corvette Watkins Glen Grey but have red accents on the trans tunnel so the two tone is another new thing for me. Went to a really great paint shop in Clarkston, MI (Wiltse's) and they set me up with epoxy primer, both base colors, and clear. I went with the higher end paint since I knew it would help with my amateur mistakes.

That was one of the hardest garage days of my life. From start to finish was between 9-13 coats with the two tone situation and I vastly underestimated the amount of gun time to paint something like this frame. I had a nice detail gun so it gave me the best shot at getting in the tight spaces but took FOREVER. About an hour and half of actual trigger pulling. I thrifted some coats since it was clear that as you paint a square toob you really put on a couple coats. Last clear went on as the light was totally gone, Lisa was gathering flashlights in case I didn't finish but I did make it.

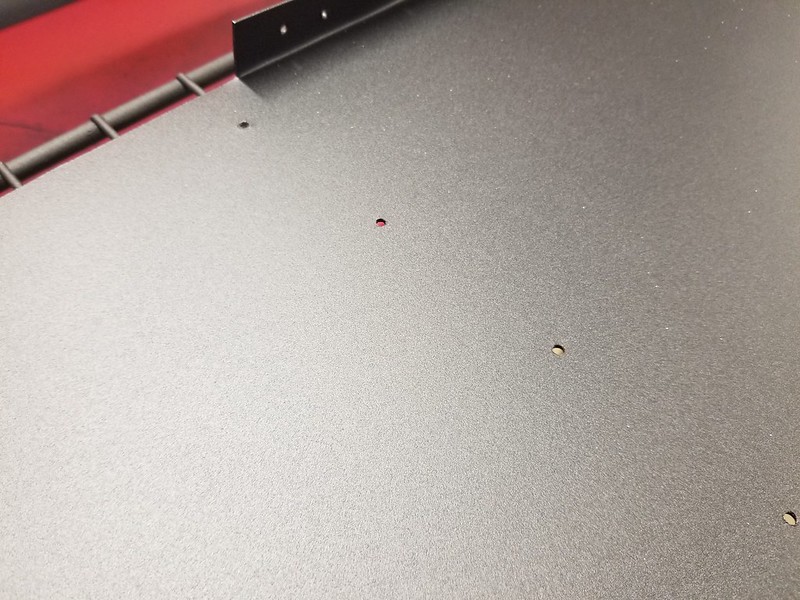

Result is a solid B which is about what I went in expecting for my first try and the reason I did the frame first. It's about twice as good as I expected mid-day while painting that SOB. There are a couple dry over-spray spots of clear and a few areas where the WGG didn't cover enough. None in any place that you can see, all issues will get covered by aluminum panels, had good luck on that.

The only real problem is that I hadn't looked at a WGG Corvette in a while and it's a lot darker than I want the body. I went back and got some Blade Silver for the body. They go well together and you really can't see both at the same time anyway. Bummed that I don't have it matching but small potatoes in the end.

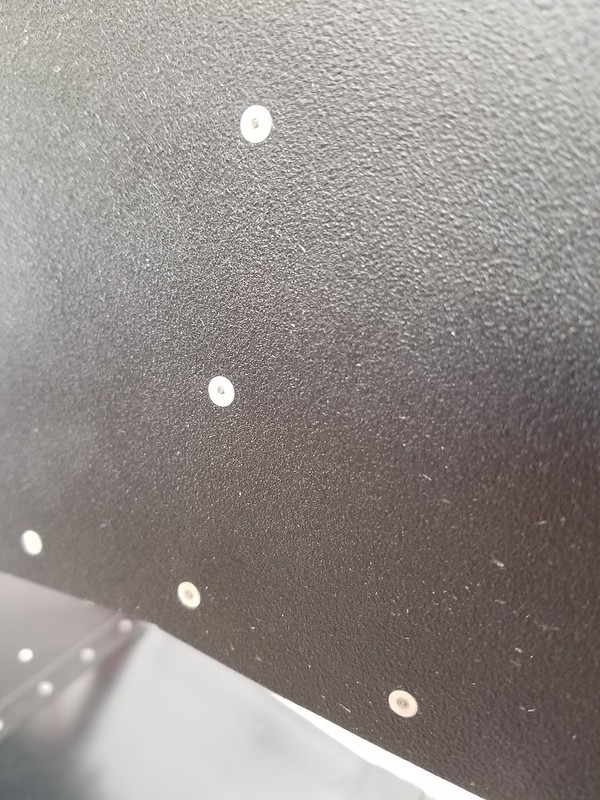

Roll cage got a texture black the next day, ready to bolt parts on now!

The red will 90% disappear under black aluminum panels, it will just be an accent to bring the outside stripe into the interior a bit.

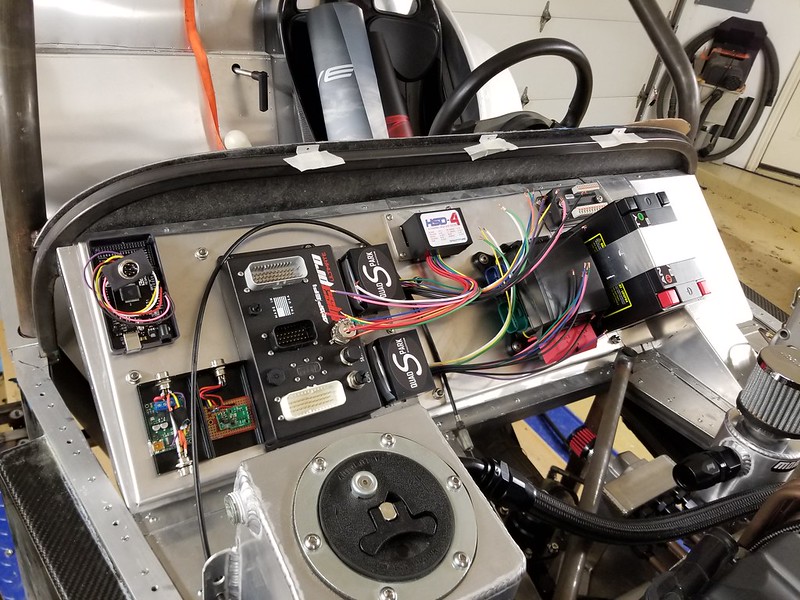

I'm now cranking through the prep for painting the body. Trying to get the tent down next weekend if possible. Everything is body-worked, sanded, painted black on the B-side, and ready for primer except the front fenders which I'll do tomorrow. Then I need to mask the backside of the hood and rear shell, move everything into the booth and clean, clean, clean. Depending on the forecast I'll then prime tomorrow night or the next day I find with 36 hrs of good weather.

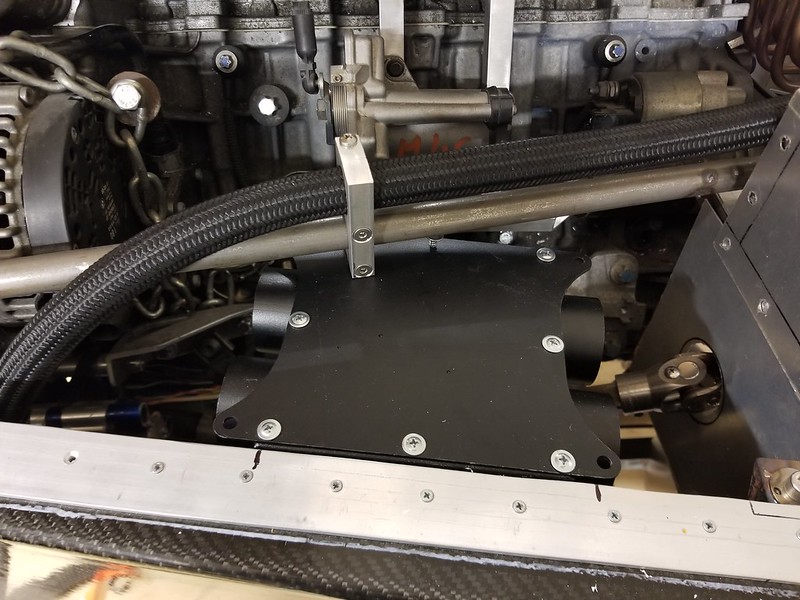

I also have a confession that I'm quite ashamed of. I feel like I've sunk to the level of a Civic Type R engineer. I've made a fake vent. It's just there to expand the footwell so I don't want any more water than normal getting in there. The same vent on the other side of the car is real, I swear! At least I gave it some depth. With that aluminum piece painted flat black it should look pretty real.

Those side panels were the first body panels totally ready for paint. Masked for the exposed carbon stripe and ready to go.

Not looking past a finished paint job at this point, fingers crossed that will be next weekend.

Alex

![]()

[/url]

[/url] [/url]

[/url]

[/url]

[/url]