Im 30 pages late to this party but if you need something 3d printed out of metal (copper, stainless steels, aluminum, low alloy steel) I would love to help you out on some mini projects associated with this - I cannot print a wheel though but maybe some other features. I have a lot of catching up on this thread since I last left off and my jaw has not left the floor yet either. Nice job!

mke

Reader

7/25/19 7:00 p.m.

In reply to fidelity101 :

Thanks! We'll have to figure out something cool the can only be printed :)

mke

Reader

7/25/19 7:07 p.m.

They say when the gods wants to punish you they grant your wishes......

...today's punishment came in the form of an older but looking brand new go power engine dyno. I think it's a DA-512 which is rated to 750ftlb, 800hp, 10,000rpm. It might be a little low hp wise for my engine but I'm pretty sure that with a little work on the water feed it's a 1000-1200 hp unit....pretty sure.

Please Sir, may I have another :)

mke

Reader

7/25/19 8:05 p.m.

LOL

Sometimes things work out. I rarely look at Craig's list but there it was, on my way home from work, and I got it for $900.....just about the exact number the wheels came in under what i had planned to spend and had set aside for the car. I know I'll regret down the road it but today I'm pretty stoked.

mke

Reader

7/25/19 8:20 p.m.

In reply to Norma66-Brent :

Thanks, already downloaded it a couple days ago

....And the 516 version which the same actual dyno but newer/better load curves

...And the new 557 info

....and talked a bit to go-power tech

I know I'm going to regret it..

And don't forget the rollers a buddy found me on craigslist last year.... that I could mount the brake to sonehow.

mke

Reader

7/26/19 7:18 a.m.

They say you need about 1gpm of water per 10hp, so I'll need about 90gpm@45-60psi.....and I guess a pretty big tank close enough to the shop...I'll need to give that some thought.....solved :)

Don't forget that the water is going to come out of that dyno pretty hot. For low power applications, it's not unusual to run it through a truck radiator with a fan on it to cool it down, but 90 gpm would probably need something more elaborate than that.

mke

Reader

7/26/19 7:56 a.m.

pkingham said:

Don't forget that the water is going to come out of that dyno pretty hot. For low power applications, it's not unusual to run it through a truck radiator with a fan on it to cool it down, but 90 gpm would probably need something more elaborate than that.

I doubt I'll ever get to the point where Lana allows me to return water to the pool where the heat would be helpful most of the time and it would take an awful lot of dyno time to heat up a 36000 gallon tank ...but I'm pretty sure once water leaves the pool returns will never ever be accepted so hot water dumps down the driveway I guess.

mke

Reader

7/26/19 9:36 a.m.

Here's a funny story.

The 400i engine was from an automatic trans car. Ferrari used a GM auto trans so bolted to my engine was a trans adapter setup. I listed that stuff on ebay a few times then threw it out when it didn't sell thinking I don't need scrap metal cluttering up the shop......now I have no way to bolt a bellhousing that the dyno needs to the engine without tracking one down or making one.

DOH!

I guess the first step is call a around and see if any of the wreckers have one that I can afford.

mke

Reader

7/26/19 1:02 p.m.

mke said:

Here's a funny story.

The 400i engine was from an automatic trans car. Ferrari used a GM auto trans so bolted to my engine was a trans adapter setup. I listed that stuff on ebay a few times then threw it out when it didn't sell thinking I don't need scrap metal cluttering up the shop......now I have no way to bolt a bellhousing that the dyno needs to the engine without tracking one down or making one.

DOH!

I guess the first step is call a around and see if any of the wreckers have one that I can afford.

GT Parts says they think they have one, will see if they can dig it out for me....they didn't mention a price......

I usually buy most of my gaskets from them so I'll pull a list together this weekend and at least try to save a little shipping. That will officially mark the beginning of beginning the engine repair. I need to dig out the cylinder blank part number and see if those are still available, and the piston spec and see if I can get just 1....the pistons are probably 8-12 weeks or there about. Head gaskets too, those are custom so I need to dig that info out and get them ordered.

In reply to mke

Plumb a redirect valve into the pump outlet for the pool to use the pool pump as the initial feed to the dyno. Then in the winter, redirect the output from the dyno back to the pool. Should provide a very nice warming effect and more that enough volume... I think but I defer to you oh master of all engineering and fabrication.

mke

Reader

7/28/19 7:54 a.m.

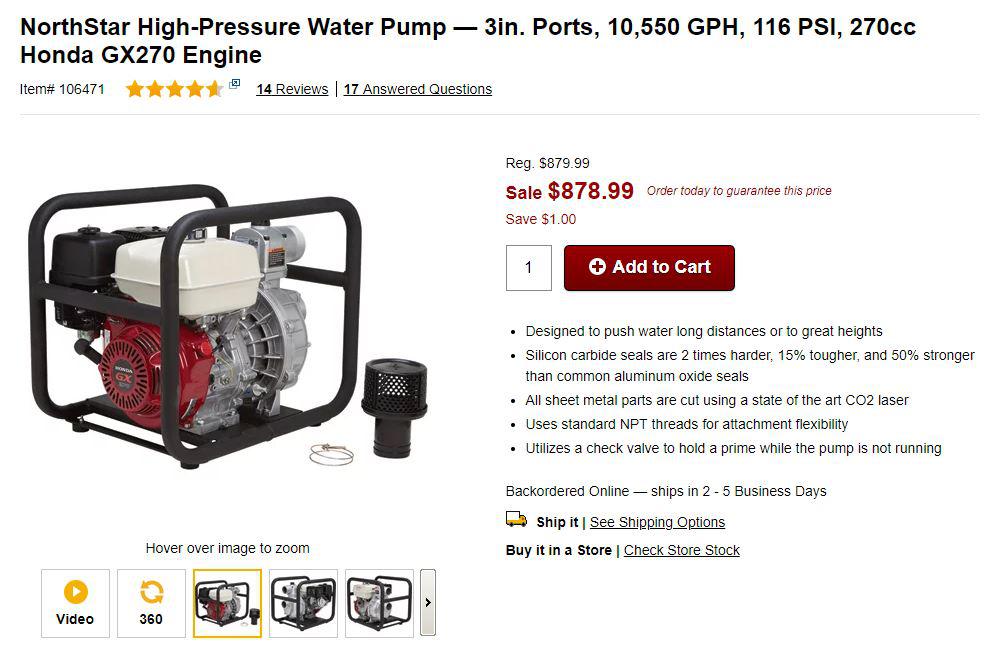

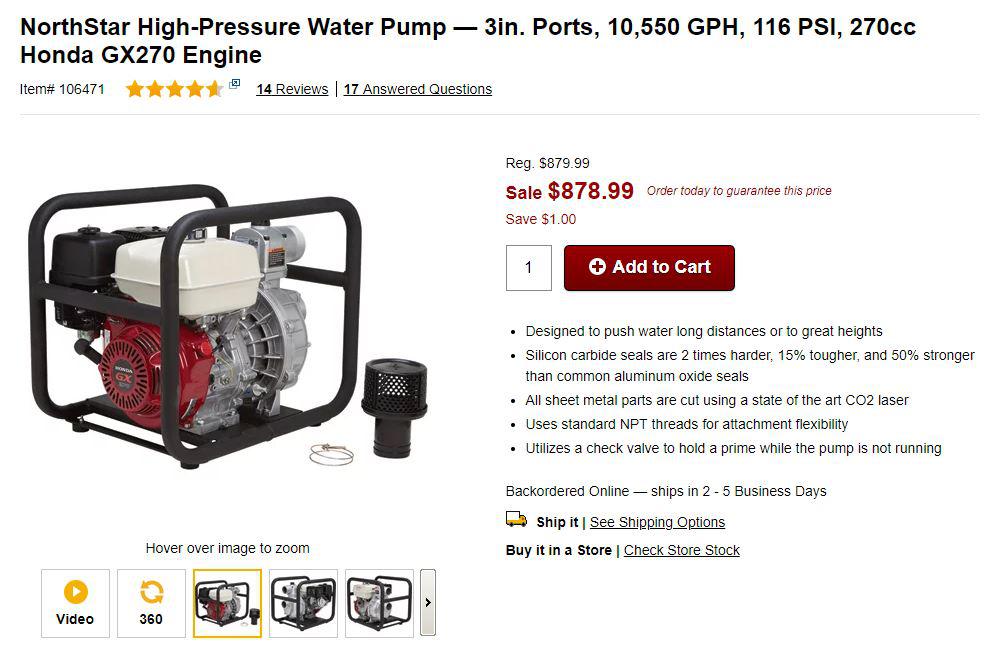

I THINK this will work for the water pump. I need about 90-100gpm, so 6000gph at about 45-60psi. They don't give a pump curve but i think this thing will be close....its got enough hp...end points seem about what I'd expect.....probably worth a try.

Northern high pressure pump

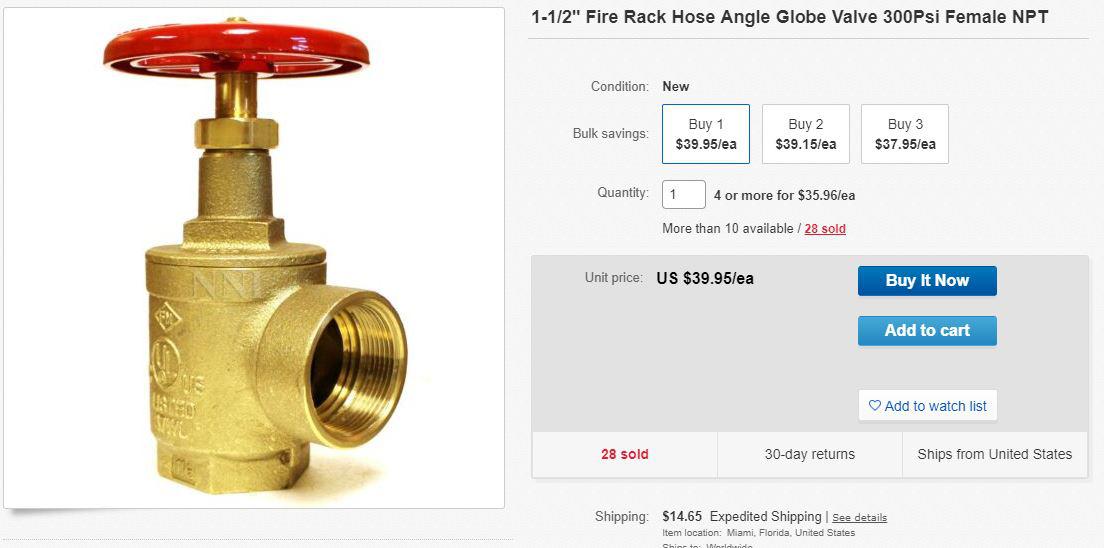

Right now I'm trying to figure out a new flow valve. The Dyno has a 1" valve and dyno connection fitting which is the same s the lower hp single rotor unit but then the 2 rotor has two 1" drains instead of 1 so the feed can't possibly keep up without flow restrictors in the outputs, which it has. I think is why the unit doesn't produce double the single rotor hp even though it uses 2 rotors identical to what;s in the 1 rotor unit.

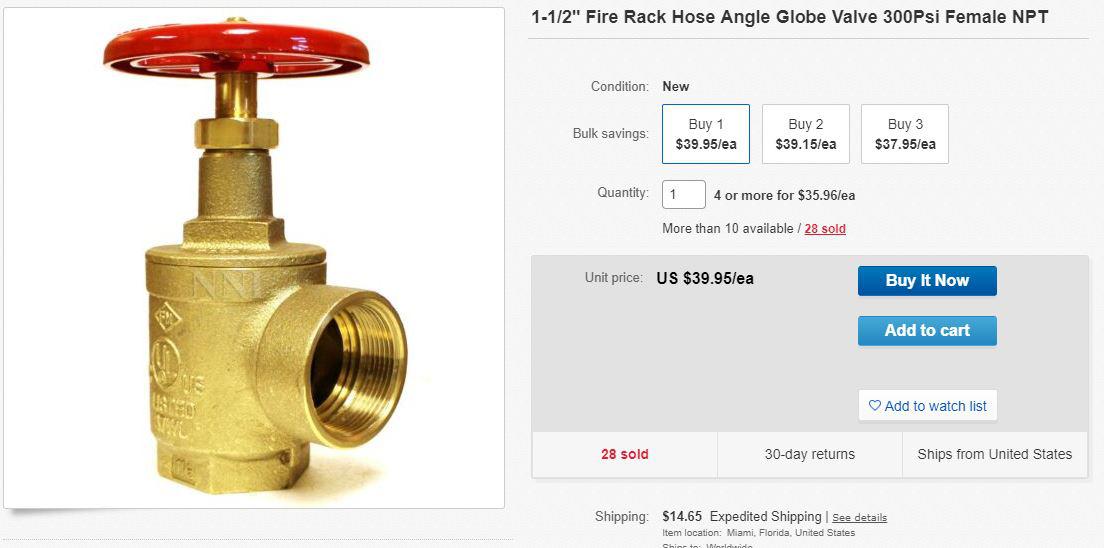

So I need to find or make a 1.5" servo operated flow valve and remachine the dyno for a 1.5" fitting...or maybe add 2 more 3/4" or 1? fittings.....need to look at it a bit, but it needs more water flow to be happy with my engine.

I also learned that the new units are rates at 6krpm with greased bearings and 10k with an oil feed bearing upgrade. My manual say 7500 continuous or 10k intermittent. I talked to teh tech and basically the bearings over heat so limited duty cycle above 6000 or so.....I think I can live with that and won't bother with trying to upgrade the bearing lube system.

You're a mad man. You just need a lab coat, some goggles, and Doc Brown hair...

Gingerbeardman said:

You're a mad man. You just need a lab coat, some goggles, and Doc Brown hair...

Without going back through all 30 pages, do we have any indication that mke is not already sporting this? I fully agree, regardless. I don't know if I've ever seen such an epic project with equally epic tangents!

In reply to mke :

I searched through the posting and can not find a reference to said rollers. I believe we will need to be enlightened as to that acquisition...

mke

Reader

7/29/19 9:49 a.m.

In reply to Samebutdifferent :

hmmm, maybe I neglected to post it. I found a set of 8.5" dyno rollers a couple hours drive for $100. They were off a low power emissions dyno but I think if I knurl them and space them on the wide side so the tire drops in a bit they should handle pretty decent power. The 8.5" dia means they should spin pretty close to crank rpm after diff reduction then tire to roller increase, which means the same dyno brake and controls and everything else can be used engine or chassis.

My basic plan is fix the engine, get the engine dyno working to test and tune. Put the engine in the car, get the chassis dyno working for fine tune and any changed I want to test.

....and this is why nothing is ever actually finished.

java230

UltraDork

7/29/19 9:54 a.m.

Does she need to know the water is going back to the pool?

I foresee much fabrication in your future...

For that, we are all thankful.

I for one am anxiously waiting the day when all 12 cylinders are firing, the new wheels are installed and this beast is on the dyno pumping out 900+ HP... and watching the pool temp jump up 10 degrees in less than 60 seconds!

Make sure you pull water from the deep end.

mke

Reader

7/29/19 11:45 a.m.

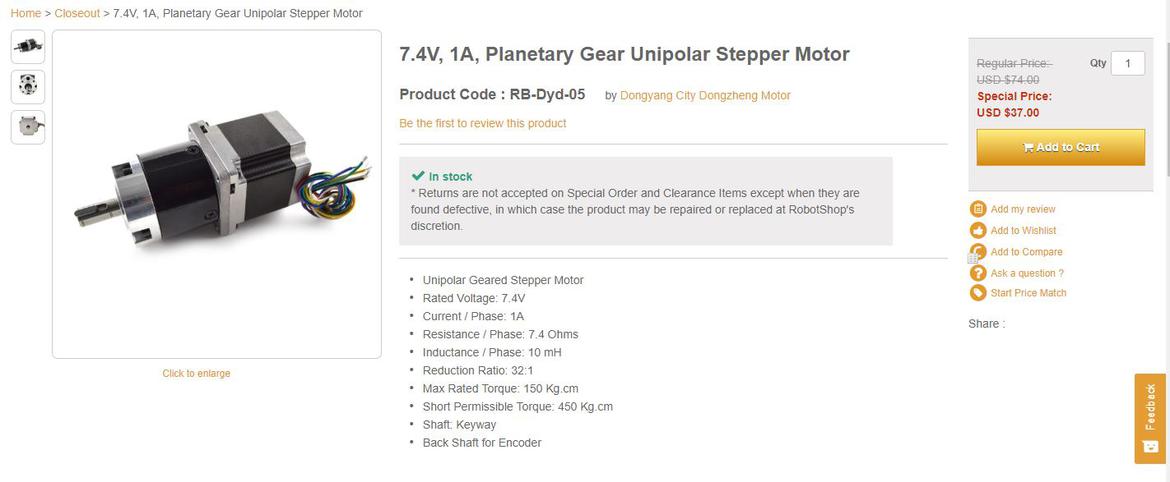

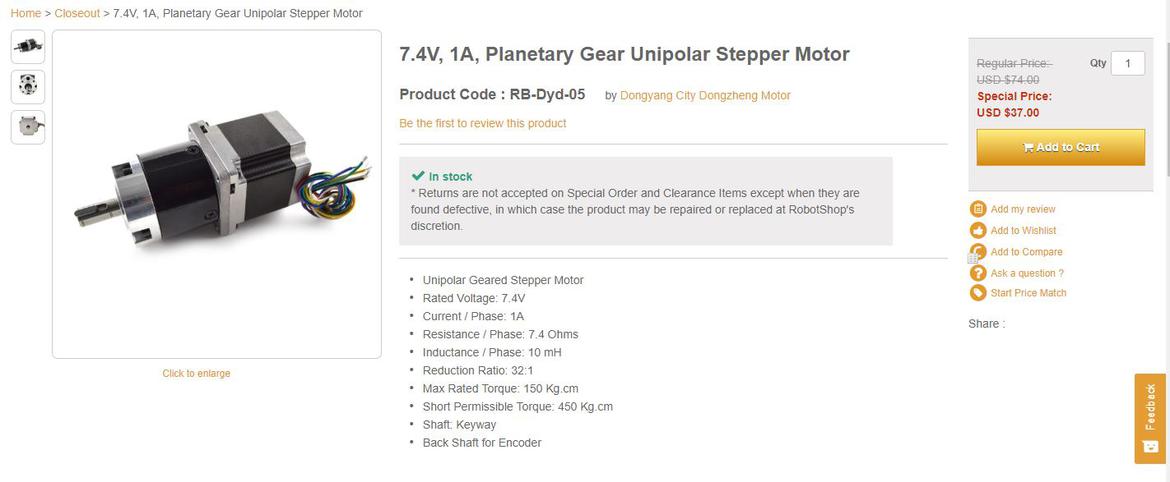

Bought a couple things to play with. The valve should have plenty of flow and the ECU should be able to drive this stepper....hopefully its fast enough and powerful enough to operate the valve properly. Hopefully I get it on my first try and have a working load valve for about $100.

mke

Reader

7/29/19 3:53 p.m.

I called and got the pump curve for the northern pump...looks about perfect. 60psi is about 140ft and 6000gpm is the point of interest and it looks like the pump delivers closer to 7000 so that should mean it can hold 60psi and handle flow for engine cooling too I think. Nice.