Another Update:

My nephew, who is a budding gearhead, has been begging me all summer to come down and help me turn wrenches on the Trans Am. With all the health issues going on with the wife, yesterday was the first time I had the chance to go get him for the day. So, we wrenched!

First, we went to the parts store and got a new battery. The old one wasn't cutting it and would mostly discharge after a few cranks, as I was mentioning earlier in the thread. I also picked up some Marvel Mystery Oil and some starting fluid to help un-stick the rings, just in case. I mean,I did pull about 5 QUARTS OF WATER out of the engine...

We pulled all the plugs, poured a little Marvel down the holes, and let it sit while I checked the connections for the starter and all of the grounds. I re-did all the connections at the battery, and cleaned everything for fresh contacts.

With that done, we tossed the battery in and cranked it over with the plugs out. It cranked freely and without issue, which was a good sign. After we put the plugs back in, but they kept oil fouling due to the remnants of the Marvel in the bores. We took the plugs out about 5 times, cleaned them, and tossed them back in. After a while, with the assist of some starting fluid, it showed signs of life, but wouldn't run off of gas. It took a while, but it FINALLY ran on its own!

It sounded good, so we let it run for 10-15 minutes before shutting it down to change out the oil I put in last week.

It still looks horrible, but there was no water this time. Most of the sludge that was in there plopped out. It was disgusting to watch.

After putting the new oil in, I let it run another 15 minutes and called it a day, because I had to take my nephew home.

Thoughts:

-Well, it runs! That's a good thing. Sounds fine, so the water in the engine thing should be behind me now. That's a relief.

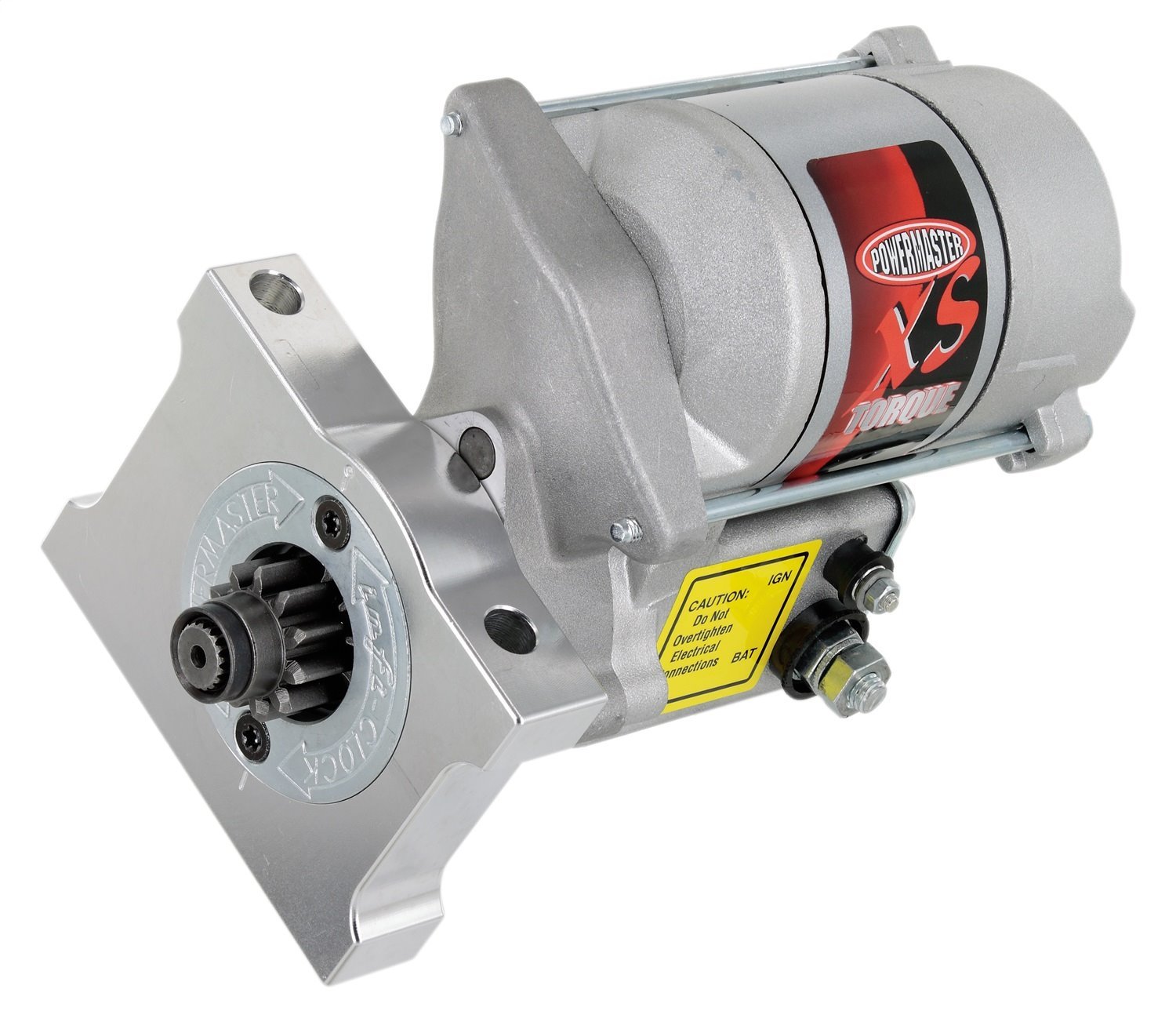

-Starting issues are still there, but slightly better with a fresh battery. I double checked everything, too. Everything is as it should be, but it still doesn't like starting sometimes. Hot starts are still an issue.

What's next? The floors need to get done, so that will be the big focus. Hoping to finish up the passenger side and getting the driver's side started soon.