mazdeuce wrote:

I'm going to spend the rest of my life wondering if I should have sent in an oil sample from that first oil change.......

I would assume the bolt would go quick though.

How many oil changes did you do on it before it went? Like 3 or 4? Would you send samples off every second oil change for each of your cars?

How likely is it that it could test fine and then self destruct 6k or 8k miles later?

Dont beat yourself up over it, crap happens sometimes.

In this case it at least happened to someone talented enough to rebuild it on their own.

An R63 was featured on the German cars for sale blog yesterday.

$50k ask with 126k miles!

qued

New Reader

1/5/17 8:29 a.m.

This video came up in my youtube feed.

https://www.youtube.com/watch?v=wvilUHyUyGo

How to check for bent rods, but for a tractor. Thought it might be interesting for those following along.

In reply to qued:

Thanks for the video. That's the same general procedure MB outlines in their head bolt failure memo. They're even nice enough to give spec for what is bent and not bent.

NGTD

UberDork

1/5/17 4:12 p.m.

Missing updates on the RSX, or has it moved on to the co-owners place?

In reply to NGTD:

Actually outside right now getting it up to temperature just because. Still needs a lot. Still in title limbo hell. Runs great though, so that's nice.

The Mercedes M104 doesn't have a cam sprocket idler like your 63 does, but they obviously didn't stray far from past methods. In the M104, the FSM calls for a slide hammer trick to pull out a chain guide pin at the timing cover very similar to what you've described here.

For the M104, we skip the slide hammer direction and just use a few sockets as spacers and thread a long bolt into the pin to be extracted. Add spacers and tighten bolt until it bottoms out, then back it out and add more spacers. Repeat. I'm not sure if this is the same sort of arrangement you're dealing with here, but it sure sounds similar.

Are you able to thread anything into the part to be extracted?

I don't have anything that size, no. It's big and very fine thread and not in a great spot to measure. I'll be the guinea pig for everyone waiting to tear apart their M156's and measure things once I get it apart.

Looks like you should be able to sneak a thread gauge in there, though if it's a real fine thread the bolt for it probably doesn't exist outside of the special MB tool or a lathe with metric threading capabilities.

NGTD

UberDork

1/5/17 11:47 p.m.

mazdeuce wrote:

In reply to NGTD:

Actually outside right now getting it up to temperature just because. Still needs a lot. Still in title limbo hell. Runs great though, so that's nice.

I'm trying to line up a local bodyshop to do a structural inspection on mine so I can get the salvage title converted over to a Rebuilt, so I understand your pain!

BrokenYugo wrote:

Looks like you should be able to sneak a thread gauge in there, though if it's a real fine thread the bolt for it probably doesn't exist outside of the special MB tool or a lathe with metric threading capabilities.

BLASPHEMY!

Mcmaster Carr has it. They have EVERTHING!

This one worked on the M117 V8 the W126 I had:

Guide pin puller

The threaded portion appears much larger than any of the threaded parts on that tool. You really only need to purchase this piece that threads into the shoulder and then you can pull it with a bolt or whatever. It's only $15. I'll measure it when it comes.

Mad_Ratel wrote:

BrokenYugo wrote:

Looks like you should be able to sneak a thread gauge in there, though if it's a real fine thread the bolt for it probably doesn't exist outside of the special MB tool or a lathe with metric threading capabilities.

BLASPHEMY!

Mcmaster Carr has it. They have EVERTHING!

They have everything in the realm of industrial maintenance type commercial off the shelf parts, and always in stock too, they lack plenty of oddball hardware you'll find on a car. The super long (I think M12) bolts that hold the rear control arms on a 128/Yugo come to mind, they aso didn't have some really oddball (but standard) sealed ball bearings I needed a couple times. They might be able to track some of that stuff down for you if you really need it, for a price I'm not sure of, but we aren't really their target demographic.

In reply to mazdeuce:

And I'm excited to see it on someone else's dime!

I just cannot believe how much of their engine and ancillary design language hasn't changed. There are so many components in your photos that could have been pulled straight from '90s Mercedes!

Glad to see the head off. Keep up the great work!

Awesome job. We are all rooting for you.

RossD

UltimaDork

1/11/17 12:23 p.m.

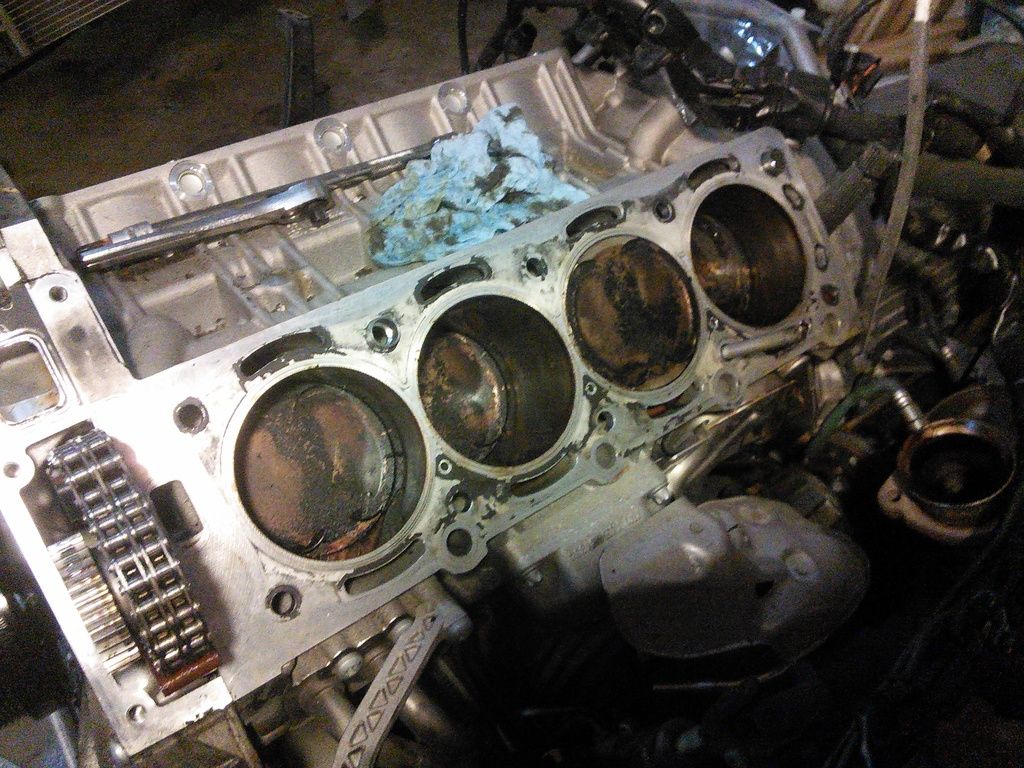

I can't imagine you didn't do enough of the ol' Italian tune up on this thing to burn up the carbon!?!? What gives? Gasoline quality? PCV? or is it just because of the Head bolt?

klb67

Reader

1/11/17 12:26 p.m.

So when service managers suggest a carbon deposit treatment to be done, maybe they aren't lying to us?

I suspect PCV. The intake manifold is gross. I'll do a bit more poking around on stuff. Still kind of want to reassemble with a supercharger.

NOHOME

PowerDork

1/11/17 12:31 p.m.

I have to say that I was surprised that there was any significant carbon build up. Is it possible the antifreeze messed with the O2 sensors to the point where the ECU added more fuel to the game?

I did find a perfectly sized box to hold the cams. It's time to do another big cleaning and maybe build a wooden subframe so I can roll the van to a different parking spot and free up the lift.

I did find a perfectly sized box to hold the cams. It's time to do another big cleaning and maybe build a wooden subframe so I can roll the van to a different parking spot and free up the lift.

Then I had these two pins to pull. They're M6x1.0. I used the bolt with washers and socket trick mentioned earlier.

Then I had these two pins to pull. They're M6x1.0. I used the bolt with washers and socket trick mentioned earlier.

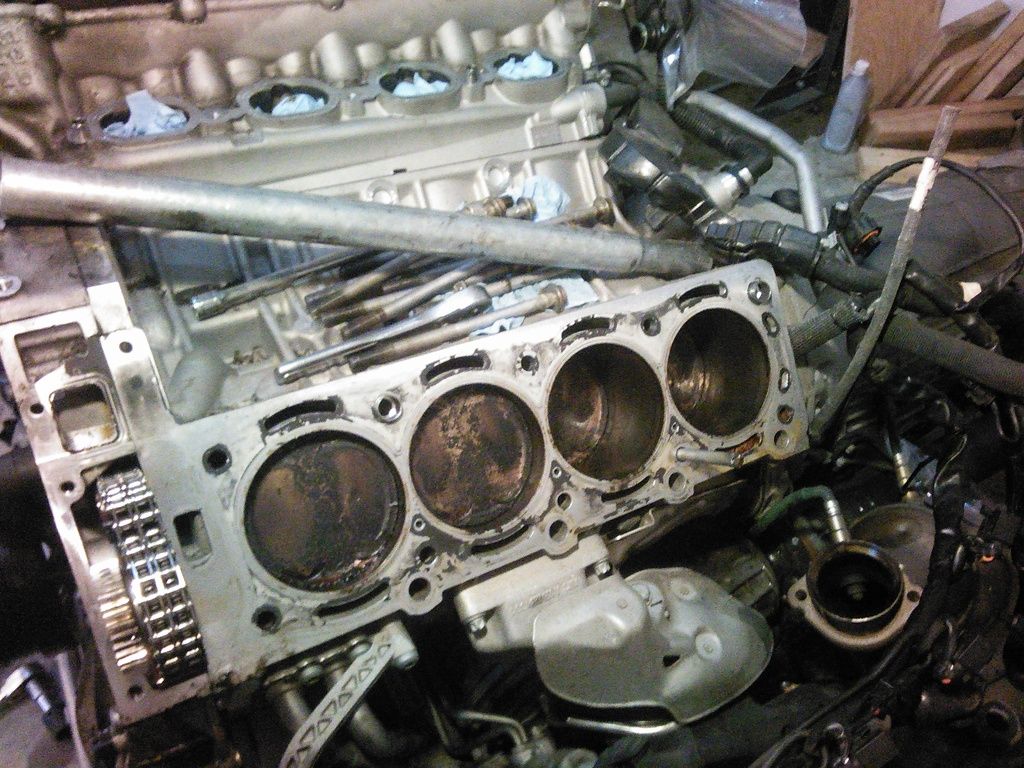

Everything came apart and..... one head off!

Everything came apart and..... one head off!

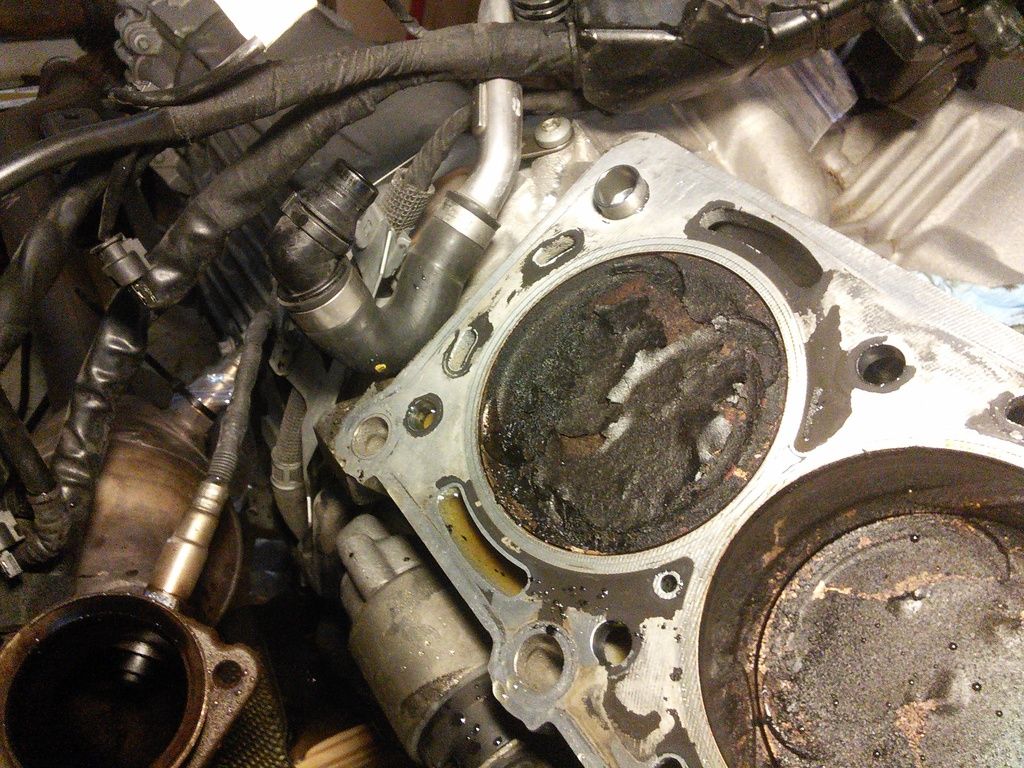

Nothing obviously broken here. (Terrible picture, sorry,working on a time limit here)

Nothing obviously broken here. (Terrible picture, sorry,working on a time limit here) And the bores all feel good, lots of carbon that has been shaken loose. But it's quite lovely.

And the bores all feel good, lots of carbon that has been shaken loose. But it's quite lovely.

The head gasket is three layers and it really looks like the layers separated and everything went between them leaving the head and block alone. I need to investigate more and take better pictures for your opinions, but so far so good to me.

The head gasket is three layers and it really looks like the layers separated and everything went between them leaving the head and block alone. I need to investigate more and take better pictures for your opinions, but so far so good to me. Need to pull the other head and measure for bent rods and lots of stuff. I need to make dinner first. More to come! I'm pretty excited by what I've seen so far.

Need to pull the other head and measure for bent rods and lots of stuff. I need to make dinner first. More to come! I'm pretty excited by what I've seen so far.

All of the bores feel good. Cross hatching in all of them. No corrosion at all that I can see. There is kind of a LOT of carbon build up on the pistons and heads. Most of is soft enough I can scrape it off with a fingernail. Is that something I should do? This is far and away the heaviest. It's pretty gross.

All of the bores feel good. Cross hatching in all of them. No corrosion at all that I can see. There is kind of a LOT of carbon build up on the pistons and heads. Most of is soft enough I can scrape it off with a fingernail. Is that something I should do? This is far and away the heaviest. It's pretty gross.