Quick test this morning on non metalic scraping options. We have an old switch plate (free), a new hard plastic switch plate ($0.28) a new nylon switch plate ($0.48) and a package of plastic scraper blades ($5.49).

The old switch plate works well though I did have to bring it back to an edge with some fine sandpaper, it's the hardest of the scrapers. The new hard plastic one worked 95% as well though the edge may be dulling a bit faster. The nylon one was worthless but I honestly only bought that to replace the one I stole out of the kitchen. Surprisingly, the plastic blades designed just for this job were only marginally better than the nylon plate and way way worse than either of the hard switch plates. Baiscally junk.

The old switch plate works well though I did have to bring it back to an edge with some fine sandpaper, it's the hardest of the scrapers. The new hard plastic one worked 95% as well though the edge may be dulling a bit faster. The nylon one was worthless but I honestly only bought that to replace the one I stole out of the kitchen. Surprisingly, the plastic blades designed just for this job were only marginally better than the nylon plate and way way worse than either of the hard switch plates. Baiscally junk.

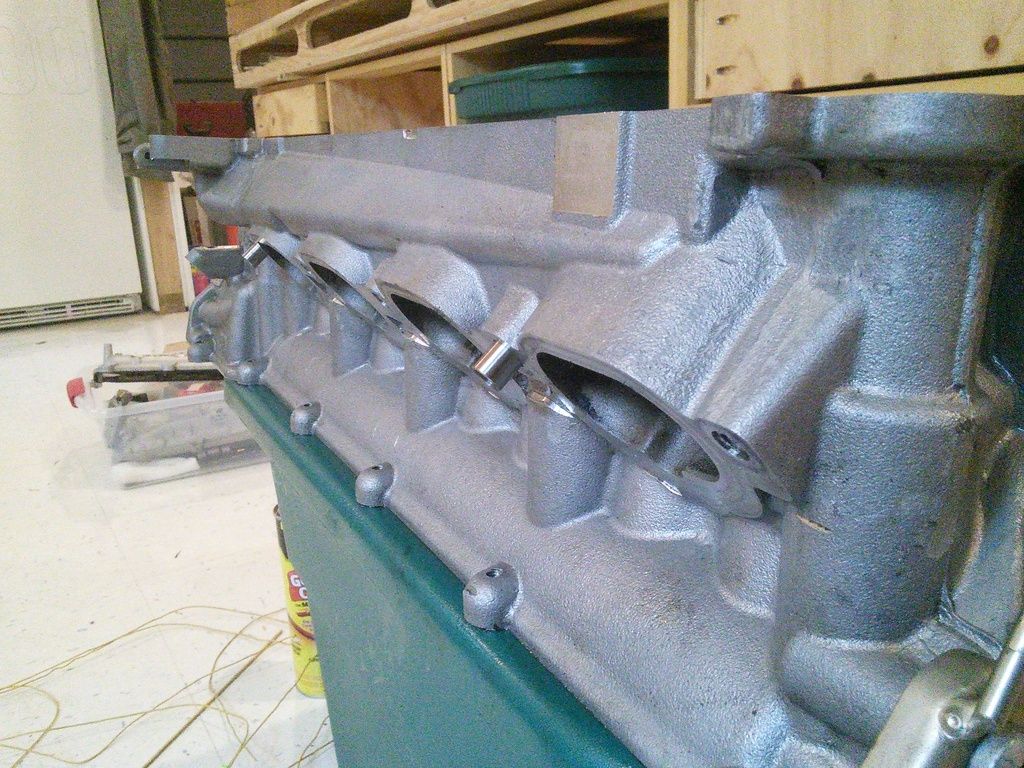

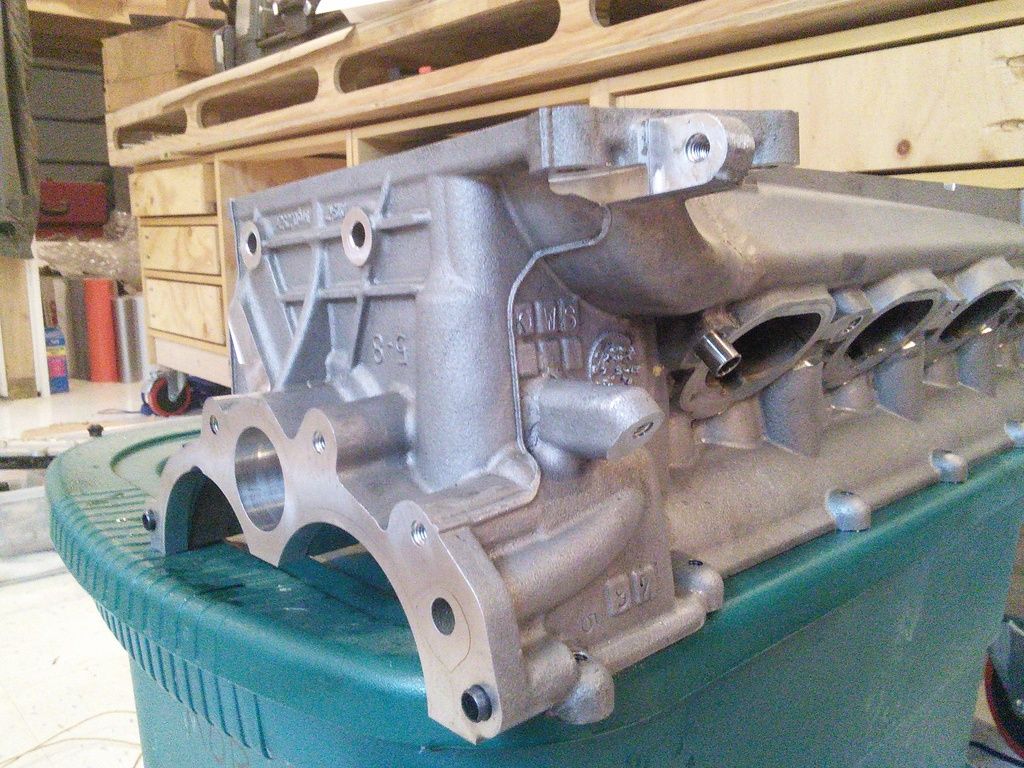

The chambers and surface on this one are clean. My wife has tomorrow off so I need to get the housework done today so we can go on a date tomorrow. We'll see if I have time to finish cleaning the outside of the head before it's kid pickup time.

hhaase

Reader

1/19/17 1:28 p.m.

Adrian_Thompson wrote:

mazdeuce wrote:

Proper lube. Duly noted.

ALways use proper lube, especially on rear, err engines.

And in all seriousness, find out what MB recommends as an initial startup procedure. Can always go back and correct any assembly issues as you work on things now. But that first 30-60 seconds of the first startup are a one shot deal for some components. Since your crank bearings and piston rings haven't been disturbed you won't have to worry much about them. But definitely want to still follow the process.

Is there any reason you didnt drop the head off at a machine shop? They can take it all apart, clean, lap the valves and put it all back together (with new valve stem seals, etc) Probably not terribly expensive either. At 100K, I'd certainly lap the valves & change the stem seals...

In reply to Kendall_Jones:

No big reason other than you have to draw the line somewhere. If you start looking around and what you can replace instead of what you need to replace then you'll drive yourself crazy. At it's core this job is simply bolts and gaskets. In out and done. I'm doing lifters because they should be done and timing stuff because changing the guides requires pulling the heads and they really are a wear item.

When you look at the job it's not complex at all and had I decided to do head bolts in advance this is exactly what the job would entail. I'm trying not to over think it.

In reply to hhaase:

I believe it's all in that big huge manual on the computer but I'll be asking many many more questions before I even think of pushing the start button.

In reply to SStrife:

Thank you for taking the time to type all of that out. The biggest scary part of this job is that the information isn't just laying around like it is for a Chevy 350. I literally saw a "how to rebuild your small block Chevy" book at Barnes & Noble two weeks ago and was more than a little jealous.

I'll read your post more than a couple of times.

Read it anyway, there are some things that won't apply or be totally wrong but it will give you some general things you need to think about as you go through the process.

bluej

UltraDork

1/20/17 1:45 p.m.

Thoughts from the hive on using vaseline (generic petroleum jelly) as assembly lube? I used it for reassembling a pair of aluminum dohc v6 heads that have ~150k on them since then. The thought back then was that it helped hold stuff in place like valve keepers (it did), and as the engine began to warm, it "melted out" easily w/out harming the oil or flow. This was over 12 years ago when I was less automotively educated and I'm curious if that experience and thought process holds up.

Good question. The last time I used Vaseline (on a car) was to pack the oil pump on a Range Rover prior to startup. It worked. I assume lubricstion has progressed since then.

mazdeuce wrote:

In reply to SStrife:

Thank you for taking the time to type all of that out. The biggest scary part of this job is that the information isn't just laying around like it is for a Chevy 350. I literally saw a "how to rebuild your small block Chevy" book at Barnes & Noble two weeks ago and was more than a little jealous.

I'll read your post more than a couple of times.

I was doing some research for a future project and i found about as many windsor small block books on amazon as there are parts in a windsor engine.

i do not envy you, but i do respect your bravery!

hhaase

Reader

1/20/17 3:25 p.m.

bluej wrote:

Thoughts from the hive on using vaseline (generic petroleum jelly) as assembly lube? I used it for reassembling a pair of aluminum dohc v6 heads that have ~150k on them since then. The thought back then was that it helped hold stuff in place like valve keepers (it did), and as the engine began to warm, it "melted out" easily w/out harming the oil or flow. This was over 12 years ago when I was less automotively educated and I'm curious if that experience and thought process holds up.

For new internal engine parts? I wouldn't. To hold things in place you're fine, and like you said it essentially washes away as long as there isn't too much. But I'd never use it as a replacement for a proper startup lube on valvetrain and bearings. I don't think petroleum jelly can withstand the higher contact pressures.

The big reason it's used on external geared oil pumps is to generate suction and prime the pump, but they don't see anywhere near the wear and friction.

-Hans

Thoughts from the hive on using vaseline (generic petroleum jelly) as assembly lube?

I've always used Lubriplate when rebuilding a motor, other than on cams and tappets. For valve train bits I use Federal Mogul brand assembly lube, it's stickier than Lubriplate.

Galane

New Reader

1/21/17 3:53 p.m.

I'd have a look at the cam lobes under as high of magnification as you can. If the ones for the valves where the lifters weren't rotating don't look as good as the lobes where the lifters were rotating, then you have more to think about.

Perhaps the cams can be ground just a little and shims put between the springs and lifters? Done properly the valve lift and motion profile won't be changed. Call Weistec and ask their opinion on that.

Seeing that picture of the lifter with the wear line it, my first thought was you're lucky the head bolt broke. If it hadn't, it would soon have gone on to some nasty valvetrain damage.

Edit: The hard switchplate cover is Phenolic. Nice and hard stuff.

Galane wrote:

Seeing that picture of the lifter with the wear line it, my first thought was you're lucky the head bolt broke. If it hadn't, it would soon have gone on to some nasty valvetrain damage.

I have thought about that. What made them stop rotating? Is it permanent when it happens? How long does it take to blow through a lifter? Did this happen when the oil turned to goo? It's not on all of the lifters so that would be odd.

I would love it if someone could find a discussion about this somewhere.

I wouldn't think too hard about it. We see that all the time on engines that were running fine, sometimes a lifter just stops rotating for a little while. Put it back together with the old parts, it continues to run fine for a long time.

It takes very little time to go from okay to failed, you're not going to see an impending failure unless your timing is perfect. If you only see a few little scratches, it's a non issue. If you see pits/spalled-out chunks on the lifter or severe wear over the nose of the cam, then you know you had a problem.

Spall is one of my favorite words and a neat concept.

It's my understanding that the rotation is caused by the center of the lobe being offset from the center of the lifter to some extent. If they don't rotate while hand cranking the engine you're in trouble.

The lifters are one of the parts 'improved' by MB. The word is that they don't bleed down like the stock lifters. Clicking on startup was one of the major warranty issues MB had with these and the new lifter design solved that, mostly.

And that won't have jack to do with rotation  And you won't really be able to "see" that kind of failure, it's either quiet or it ain't, you know?

And you won't really be able to "see" that kind of failure, it's either quiet or it ain't, you know?

Well then, let's put it back together and see what happens.

Galane

New Reader

1/21/17 9:29 p.m.

The base circle on camshaft lobes for flat tappets is ground to a slight angle. When the valve is closed and loaded to the least tension, the tappet/bucket/lifter gets turned a bit.

The rotation is so that the non-angled nose and ramps of the lobes rub across in a different direction each time.

The two exceptions to this design are cam lobes for roller lifters and valvetrains that use pivoting followers, such as the Ford 1600CC straight 4 and its descendants.

Crud buildup around the lifters can make them stop spinning. Base circle wear on the lobes can do it too. If the hydraulic parts of the lifters get stuck partway collapsed so there's not enough pressure when the valves are closed, the base circle angle may not be able to spin them.

What you don't want to do is put that worn lifter back in. New lifters all around and I'd get the cams looked at by Weistec or at least by a good rebuilding shop, preferably one that does in-house cam and crank grinding.

mazdeuce wrote:

The lifters are one of the parts 'improved' by MB. The word is that they don't bleed down like the stock lifters. Clicking on startup was one of the major warranty issues MB had with these and the new lifter design solved that, mostly.

In other words, it's exactly like a 1990 Miata engine

In reply to Keith Tanner:

If you took that Miata engine and doubled it's size and then stuck it to another one so now it made five times the power, pretty much.

I'm trying to get myself psychologically comfortable with the idea that actually driving this means I'm going to need a new engine someday. Even if this one goes back together perfectly, I was putting enough miles on it that I'm going to end up back inside it. My truck has 173k on the stock engine and transmission. The 911 is at 114k. I'm starting to feel like taking engines all the way apart is going to become part of my life.

Do plan to sell this or keep it once you get it running again?

The old switch plate works well though I did have to bring it back to an edge with some fine sandpaper, it's the hardest of the scrapers. The new hard plastic one worked 95% as well though the edge may be dulling a bit faster. The nylon one was worthless but I honestly only bought that to replace the one I stole out of the kitchen. Surprisingly, the plastic blades designed just for this job were only marginally better than the nylon plate and way way worse than either of the hard switch plates. Baiscally junk.

The old switch plate works well though I did have to bring it back to an edge with some fine sandpaper, it's the hardest of the scrapers. The new hard plastic one worked 95% as well though the edge may be dulling a bit faster. The nylon one was worthless but I honestly only bought that to replace the one I stole out of the kitchen. Surprisingly, the plastic blades designed just for this job were only marginally better than the nylon plate and way way worse than either of the hard switch plates. Baiscally junk.

The old switch plate works well though I did have to bring it back to an edge with some fine sandpaper, it's the hardest of the scrapers. The new hard plastic one worked 95% as well though the edge may be dulling a bit faster. The nylon one was worthless but I honestly only bought that to replace the one I stole out of the kitchen. Surprisingly, the plastic blades designed just for this job were only marginally better than the nylon plate and way way worse than either of the hard switch plates. Baiscally junk.

The chambers and surface on this one are clean. My wife has tomorrow off so I need to get the housework done today so we can go on a date tomorrow. We'll see if I have time to finish cleaning the outside of the head before it's kid pickup time.

The old switch plate works well though I did have to bring it back to an edge with some fine sandpaper, it's the hardest of the scrapers. The new hard plastic one worked 95% as well though the edge may be dulling a bit faster. The nylon one was worthless but I honestly only bought that to replace the one I stole out of the kitchen. Surprisingly, the plastic blades designed just for this job were only marginally better than the nylon plate and way way worse than either of the hard switch plates. Baiscally junk.

The chambers and surface on this one are clean. My wife has tomorrow off so I need to get the housework done today so we can go on a date tomorrow. We'll see if I have time to finish cleaning the outside of the head before it's kid pickup time.