6/5/21

Well I gotta bunch of stuff done since the last update.

Engine is in and all plumbed, wired.. It runs and drives - clutch is adjusted and feels good; Custom exhaust routing allows for breeze easy clutch adjustments.

I really cannot believe that there are no Leaks at the front or rear of the oil pan. I found when I went to Bolt the thing down that it was warped quite a bit around the Cast Aluminum Rear Main seal Retainer and at the Front Near the bottom of the timing cover. I put a lot of sealer in those locations on the outside of the rubber oil pan gaskets and let them set up for 2-3 weeks. I did have a valve cover leak that was easily fixed with a new gasket and a quick straightening of the bolt holes with hammer and piece of wood.

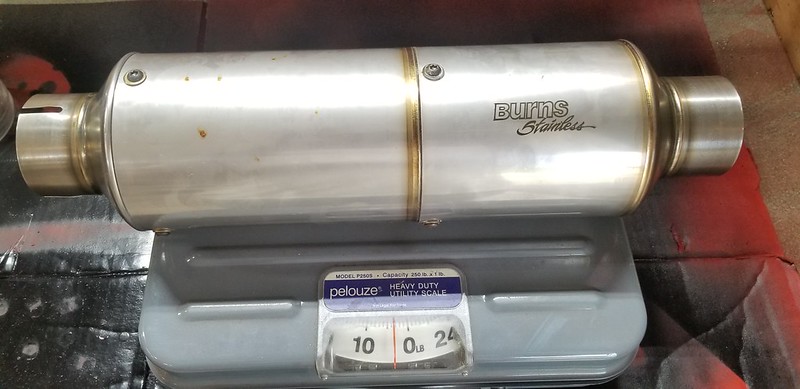

Exhaust is loud... The Burns Stainless 2 Stage Quiet muffler is still pushing the loudness limit for the street.- Might have to add a resonator.

Found that on this Cam which is an Oregon Cams Regrind that there is no Fuel Pump eccentric.. Which Made firing it off for the first time a 6 hour affair as I had planned on just using a stock mechanical fuel pump.. I never thought to check the cam for a functioning eccentric... it should just be there...but it was not.

After figuring out that the 2 Mechanical fuel pumps were good but the eccentric was just a boring on center circle, I had to get and Mount an electric Pusher Pump with all the associated switches, relay wiring, etc.

I got that all done. After Driving the Thing 100 or so miles it's time to lash the valves and rejet the carb. It is very rich on the primary circuit and a touch lean on the secondaries.

Also Put Hatted Rotors on the Rear. Does not save much Weight :( - Maybe 1.5# per rotor.. At least it's unsprung and rotating mass.

Pictorial:

"Lighter Rotors"

Stock Chinese Rotors - Non Hatted @ 11#

Plumbed, Wired, Ready to go..

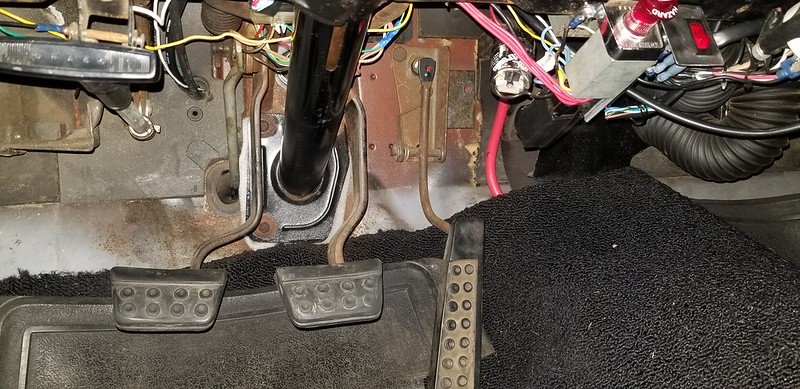

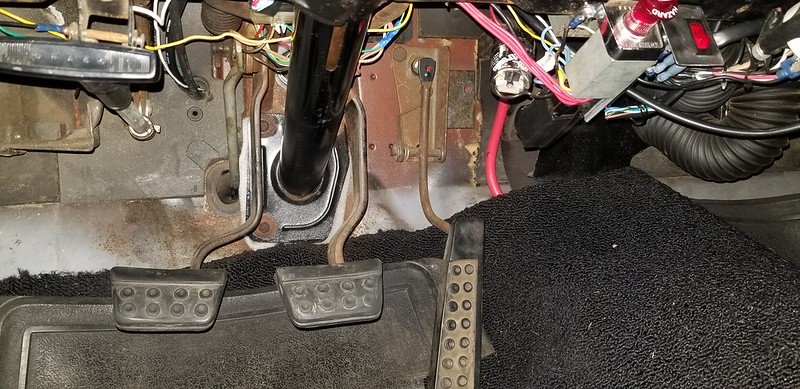

Another Item of interest is that stock with a 6 cylinder from the factory this generation of car does not have a throttle cable; they have a sort of convoluted twisty linkage system from the gas pedal to the carb.

I wanted to keep the stock pedal, but also use a cable for the future carbs / throttle bodies.. Some folks like to find the 1964-66 273 V8 Factory cable setup (expensive and Hard to find)... I just used a 72-80 D series truck Pedal pivot with a lokar cable... So I can keep the stock pedal and it works great.

Future Plans include a seat upgrade:

Stock Factory Buckets: Cool for restoration and heavy:

This behemoth weighs in at:

56#

Until I can get some Proper Race seats these 3rd Hand Mazda Seats will do:

I will have to make some bracketery for them, and Had done some lightening, removing brackets, air bags , etc.

They come in at probably not a svelte, but lighter...41#

Greg