Lol. Smart. I totally get it :)

In reply to SkinnyG (Forum Supporter) :

I so relate to this. You are not going slower, just dropping down a gear to get up a steeper climb. Like riding a bike... you aint gonna get up in 12th gear, so kick it down to 3rd and go slow but steady.

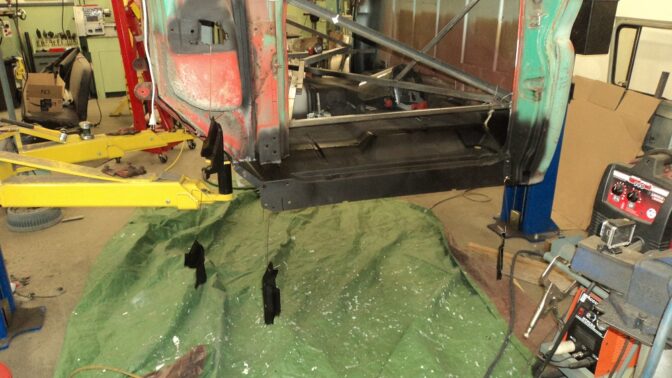

Fitted the passenger side inner-rocker/floor-section, also fitted the front and rear cab supports.

The panels needed the toe part cut and re-welded to fit the truck, as well as behind the seat to line up with the existing floor. The cab support holes needed to be moved as well. You need to just accept that the panels don't fit "out of the box," but it's still easier than fabricating your own from scratch. At least, that's what I keep telling myself.

Tomorrow, if it doesn't rain, I'll blast all the exposed metal so I can reassemble everything. If it does rain, I'll just epoxy prime the mounts and parts get get hidden in assembly. You can see the one I painted the other day - on it I also welded up the 63+ cab mounting hole, and added a bigger drain at the small end. I added a sleeve to the cab mount bolt hole, so it doesn't crush.

Ok, so I forgot another patch. But I did get blasted what I wanted to get blasted. Epoxy primer tomorrow. I learned watching "Bitchin' Boot Camp" that it's a good idea to have rounded corners on patches, so I thought I'd do that.

Killin' it, man. Beauty.

I love how you make your own patch panels from scratch. I'd like to get into those skills more.

I patched a section of the Toe board, as it was far more pitted than i wanted. The passenger side Inner rocker and cab supports got installed, and now that all that structure is back in and located, the A pillar bottom and kick is being replaced. I was a horrible judge of how long this would take. OMG.

Handy tip - use the appropriate sized end mill in a hand drill (lightly) to clean out your epoxy primer or weld-through primer prior to plug welding.

Handy tip - use sheet metal screws to suck the cab supports up to the floor for welding, then just plug weld the holes.

Driver's side rocker and floor done, and A-pillar bottoms are epoxy primered and drying, ready for welding tomorrow.

This side was just as annoying to do as the other side. I am losing my patience too easily.

In reply to SkinnyG (Forum Supporter) :

Man, I love what you are doing with the truck, and I enjoy all the progress/tips/tricks you post, it's a blast to follow. Lately, though, it seems as though the truck has got you frustrated for some reason. So, I gotta ask- Have you read your own signature lately? Seems as if it's pretty good advice. What if you work on a different part and give the sheet metal a break for a bit to freshen things up? If I have to fabricate too many days in a row at work, I get awfully wrench-throwy...

I think life it trying to tell me something. It might be "take a break," but I'm also back at work next week, so I'll be doing a whole lot less come Tuesday. My self-imposed and lofty "goal" is to have floors, rockers, and cab corners done before going back to work. I tend to set nigh unobtainable goals. I -do- often meet them, though.

My main frustration is just all the things that constantly go wrong. Just like when you are walking down residential street with your sweetie, and simultaneously two cars cross paths with you at exactly the same time whilst a jet crosses overhead. The comedy of timing is absurd.

I drag an extension cord to where I am, turn around once, and it's knotted itself to two other cords and an air line.

I put all the cords away, save one (doesn't matter which one), and it snags on e.v.e.r.y. s.i.n.g.l.e. t.h.i.n.g. it can possibly snag on, even things that should not be snaggable.

I have an air coupling that will pop undone if you tap it against something by accident (usually when it's snagging something), but danged if I can get the thing off by hand.

I put a power tool on the power tool shelf of my cart, and the zip disc falls onto the ground and breaks the newly installed disc. I put a new disc on and place it on the cart, and the air hose knocks over the camera. I replace the camera, and the safety glasses fall under the welding cart. I move the welding cart to get the glasses and the wheels hang up on a power cord. I move the power cord, and the angle grinder with the cutting disc falls off and breaks the new disc. Flap disks that send the first dust of abrasive right into my face (doesn't matter which way it's pointed), roloc discs that catch edges that aren't there and explode, requiring the twist lock nub to be ez-outed out of the adapter (I'm getting good at those).....

Hot metal chips down my shirt, burning into my chest. Hot welding sparks burning into my arms/chest/elbows/shoes. Burns. Cuts. Stuff to the face. I'm surprised I don't bleed as much as I get hit.

The braces in the door openings are a freaking monkey bar's revenge in trying to get my head in there to weld. I am old, so I have a cheater lens in my welding helmet so I can see. And progressive lenses in my glasses. except half-way down the floor patch I can't keep my head close enough to see, so I have to take out the cheater, until I get near the back of the floor and I'm too far away to see, so I have to put in the cheater, all the while catching the helmet on the bars, smacking my head on the bars, dropping the cheater, misplacing the cheater, forgetting that I needed/didn't-need the cheater.....

....and so on.

It's just a freaking comedy of hundreds of little things going wrong and going wrong and going wrong, and yeah - I totally mentioned to myself a few times today "I think life is asking me to take a break from this."

But I'm so close. SO close to my goal.

I could, of course, just keep my mouth shut and make y'all believe that it's all sunshine, lollipops, and rainbows, but sure as shooting someone else out there is going through the same thing and it's good to know they're not alone.

I also tend to be negative, so let's look at some positives:

I -thoroughly- enjoyed working the pressure-pot sandblaster. Money well spent. I am actually looking forward to doing more, especially the frame (though that will likely be next spring). I was nervous that it was going to be garbage, but man - it worked, and it was fun.

Things are going -reasonably- well. Not THIS-FREAKING-AWESOME-AND-I-SHOULDN'T-EVEN-BE-READING-THIS, but for the limited experience I think I have, it's going reasonably well. This ain't going to be a "show truck" - it's a driver, it will be my daily (sun, rain, snow, etc). It's coming along a lot better than other stuff I've seen, especially for a self-taught home hobbiest.

I really enjoyed building the motor. I like motors.

I really enjoyed figuring out the suspension. I'm looking forward to figuring out air ride.

I am super proud of figuring out how to shorten the X frame and keep the X.

I'm tickled that the bizarre collection of suspension and steering parts have worked out as well as it did.

I'm getting really good at shaping sheet metal.

The sheet metal brake I built works pretty good (not wicked awesome, but certainly -very- good).

I've been trying to apply what I've been learning about MIG welding panels: tack, planish the dot, grind to almost flush on both sides, tack the next one....

There is a ton of good going on. I need to remember that.

To quote one of my Canadian favourites: "Keep your stick on the ice; we're all in this together; if women don't find you handsome, they should at least find you handy."

The comedy of errors you describe sounds all too familiar.

I have recently stepped away from major rust repair/ surgery, and been engine building. My mood and competency have taken a drastic upturn. I recognize that this is not really something you can do on this project, due to your scheduling and pacing.

In short, sometimes you have to walk away, and sometimes you have to push on through. As long as the work doesn't suffer (as is clearly the case here-awesome!), nothing wrong with railing against adversity.

I'm anxious to follow along for the air-ride stuff. Please do carry on.

Oh yes. I've been there.

Yesterday I had a one-step-forward two-steps-back kind of day myself. Maybe didn't even got the step forward. Nothing fit right.

I'll often do a quick power clean of the shop when things get bad. A swept floor and empty work bench help me reset.

I hung the door to fit the outer rocker, which (after some significant adjustment) fit with gargantuan door gaps. The door already had the hinges as high as they would go, and the guide on the door also adjusted as high as it could go, and the gaps are freaking drunk. The build quality of these trucks betrays the golden age of no seatbelts, and bottle openers on the dashboard.

Since it appears that the door bottoms in and out should be replaced, I may "adjust" the gap at that time. Or ignore it completely.

I won't be making my self-imposed schedule of "done by school start (Sept 8)", so I slowed the hell down and just focused on the one side. Even if I had gotten just one rocker finished and sprayed in epoxy to dry over night, that would leave Monday to fit the cab corners and epoxy, and I'm back to work Tuesday. So, I backed off.

Oh, and with the doors up in the air, it looks like I -should- replace the door bottoms. They are not bad, but to really stop the rust, it really needs to be gotten rid of completely.

In reply to SkinnyG (Forum Supporter) :

I'm in denial about my door bottoms, the left door is completely rotten. I guess it's not a bad place to practice since it's not very visible...

I fabricated my own door bottom on one door in my '77 Silverado, but I did not deal with the rust properly, and it's all rotting out again. I have a much better plan for these doors.

Oh My Gosh - the body panel gods must be smiling. The back of this rocker panel fit perfectly, the front only needed two slits.

And two coats of epoxy primer, and that's it for my summer. Back to work tomorrow. My projects usually stall for close to two months at the start of the school year because work sucks all my energy away.

Rockers are welded in, and I welded a "tab" I bent back for the rear cab supports.

Hopefully, cab corners tomorrow.

Both cab corners are fitted. They both needed tweaking as the curve didn't match, and the beading at the bottom didn't match. Good think I have hammers.

The passenger cab corner was actually very solid. But I cut as little of it as I figured I could get away with, just to make sure that ALL the rust in the nooks and crannies are gone. I want to do my best to make this repair last as long as possible.

Sprayed epoxy over the rockers, and in and on the cab corners in preparation for welding whenever I get to them.

Oh, also filled the hole in the cowl.

In reply to SkinnyG (Forum Supporter) :

any chance you've got an industrial coatings place nearby that could dip the entire cab in an e-coat tank? if MonZora lives on post 2026 Challenge, i'm gonna spend the grand and have it dipped.

Not to my knowledge.

If it lasted 60 years with zero coatings inside, I'm sure it can last another 60 years with modern coatings inside and out, at which point I'll be WELL over 100 and probably shouldn't be driving.

Discovered last night that I forgot one tweak I had to do on the passenger cab corner. After it had been sprayed. Grrrr.

Today, I made the modification, but instead of mixing up a thimble of paint to spray and wasting a cup of lacquer thinner to clean up, I just mixed a wee bit of epoxy up in a tin, and brushed it over the repair. Should work just fine.

You'll need to log in to post.