Anybody know how to build a chain drive rear differential?

I have access to a Bridgeport mill and a lathe, but I need some help with the design.

Anybody know how to build a chain drive rear differential?

I have access to a Bridgeport mill and a lathe, but I need some help with the design.

Search for the bike engined Geo. The website had a pretty good writeup. IIRC he built 2 bearing holders to mount sealed bearings to hold the pumpkin in place and then mounted a sprocket where the ring gear once lived.

Remove tapered side bearings and replace with ball bearings. Mount bearings into hangers that locate it in the vehicle. Bolt sprocket where ring gear usually lives.

Oiling has a few options.

1. Build a "cup" that houses the diff. Oil with gear oil.

2. Weld openings shut. Add plugs to drain / fill now solid housing.

3. Leave it open to the environment. Spray with grease / oil.

This site has some articles on the Metrognome that might be helpful.

http://www.motoiq.com/magazine_articles/articletype/articleview/articleid/1367/the-best-engineered-lemons--2-the-metrognome.aspx

Forgive my ignorance, as I've never messed about with diffs before. The ring gear mounts outboard of the bearings?

Hahahaha-love it!

Crazy lemons people:

"did anyone see the winner of the 24 hours of lemons rave at thunder hill on 12/28/08?it was a 90 geo metro that was converted to a front engine cbr 900.this thing was fast around the track.they even got 20 bonus laps because if the chain came off they thought it would take the drivers foot off from a small hole in the fire wall.the car used the geo diff with carriers built from steel to hold it just behind the bike motor.the diff was open and they used toilet plunjers to keep grease in it.very simple to do.it was also very reliable it ran 17 hours and no break down.its also very easy to add reverse with a ring gear and a starter motor from a toyota truck.if you google 24 hours of lemons geo metro nome you will see pics of it.i have also wanted to build a bike powered car.i had thought about getting a composit mini shell that i would have done a hyabusa in the back mid engine.tube frame.but i just didnt feel like building a whole new car."

MrJoshua wrote: Nope, inboard. Crappy pics here

That's what I thought. I'd like to figure out a better way to keep the diff lubed.

I'm wondering if I can add a drive sprocket to the outside flange of an IRS rear, where it mounts to one of the drive axles and drive the other axle across the differential.

Does that make any sense?

You dont like the toilet plunger method used by the lemons guys? ![]() I have seen ones built using a steel can around the diff guts but not out to the diameter of the sprocket. It was on Locostusa.com I think.

I have seen ones built using a steel can around the diff guts but not out to the diameter of the sprocket. It was on Locostusa.com I think.

MrJoshua wrote: LocostUSA link

Wow. Thank you.

Woody wrote:MrJoshua wrote: LocostUSA linkWow. Thank you.

No problem, all this time spent dreaming and researching has to be of use to someone. ![]()

There is one apart in my the Formula SAE cage at my school I can take some pictures if you want me to. It uses Eaton internals.

96DXCivic wrote: There is one apart in my the Formula SAE cage at my school I can take some pictures if you want me to. It uses Eaton internals.

Please! Any details would be appreciated.

aren't both the DP1 and the DPLite at dennis palatovs site chain driven diffs? dpcars.net

OOo oo oo oo I got this.

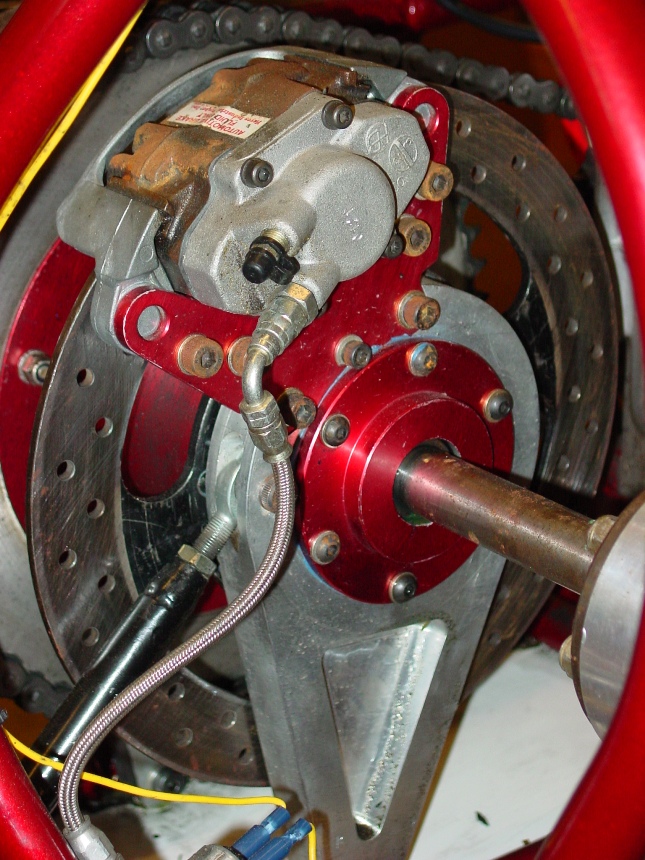

I built this in 2001

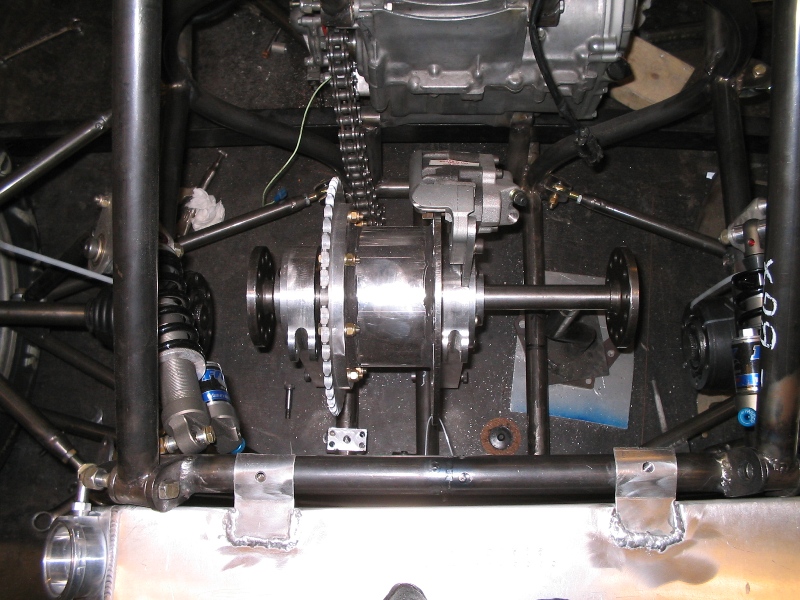

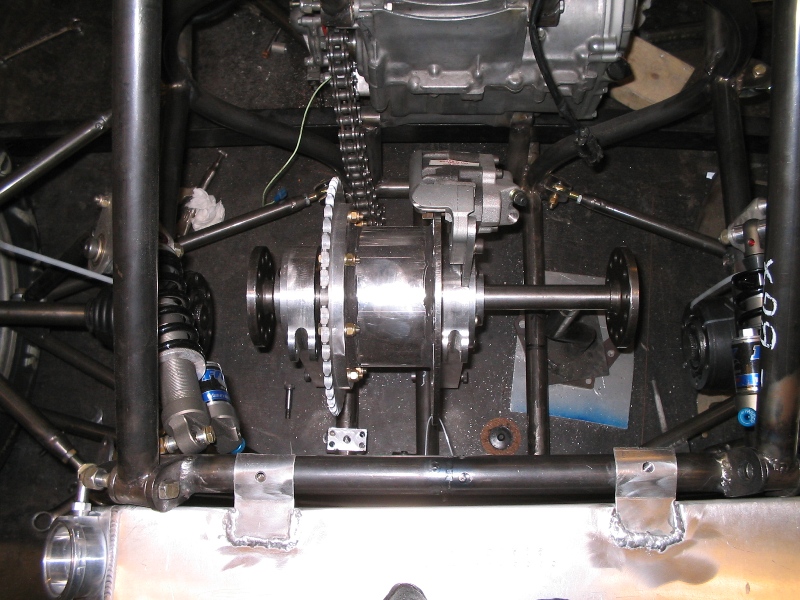

Then in 2003 / 04 I built this

From this pile of parts:

Using one of these (though the 2001 version was almost entirely manually machined)

So if you have any questions fire away. I will add some CAD model images when I get some time later.

Basically, sprocket on one side, brake on the other, both bolted directly to the diff. That aluminum housing around the diff is there only to contain oil. The carriers that hold it all contain the bearings and brake caliper mounts. Also, another cap mounts to them that hold a support bearing for the stub axle. On top of that the carriers pivot to adjust the chain and alignment.....

That being said that carrier design is kinda crappy. Plenty strong but getting it aligned just right is an epic pain in the ass. There are much better designs that do the same thing, better and lighter.

That diff is an LSD from an old Audi gearbox. Any diff will work really, as long as you can drill and tap the case. Hell, instead of a aluminum fancy machined housing, a piece of carbon fiber tube can be used.

This guy went the super minimalist approach with his geo and i really like the results:

http://psiman.net/index.php/finished_projects/geo/

That's a work of art!

I guess that I need to get my hands on an LSD to help me visualize the layout. Did you have any issues keeping the lube inside the case?

In reply to Woody:

Oh lord yes. Eventually we settled on a high density orange o-ring on the diff case itself, and rotary seals on the stub axles. The key though is having a vent for the diff case. The 2001 version was so well sealed it built up pressure and spewed oil at a very bad time. The 2004 had a brass fitting mounted to the carrier that was exposed to the pressure. We just ran a plastic hose to the catch can.

jpaturzo wrote: OOo oo oo oo I got this. Then in 2003 / 04 I built this

I keep looking at this photo for inspiration and it got me thinking about the single inboard disc. Unless you were using a spool, wouldn't that just apply braking force to a single rear wheel?

I saw a Honda four-wheeler last weekend that made me think of this thread. It looked like a racing quad (sort of) but it had IRS. The chain didn't just drive a sprocket either. It was a differential. Could you use one from something like that? It might be cheap and it might stand up to the power you will be making.

You'll need to log in to post.