Raze wrote:

What's up with your spark?

I've seen something like this due to one of three issues.

Fist is cold side leaks, build a pvc inlet and pressure tester from a cap and a compressor fitting, make sure to test with your throttle open and closed, also check crank case and head ventilation, shouldn't factor in if the engine is healthy but you never know...

Second is knock sensor, or in my case noise from the injector fly back circuit on our megasquirt leading to over rpm leading to massive timing regard, we found this after quite a bit of testing and logging...

Third is Watergate improperly set and too small for the volume of air leading to a bizarre surge, pressure drop roller coaster, get a manual boost controller, set it with your compressor at lower pressure and step up gradually. If it's consistent until higher pressures it could be the culprit...

As for fuel vs spark vs pressure...if the AFR is stable then it's not the fuel as in fuel pressure, and if the AFR is stable then spark isn't the issue because it would be maintaining AFR especially since this isn't happening in lower gears...leaving you with a boost leak...

We've run our 3 BAR map past its operating range and just filled in the targets based on nominal duty cycle and ARF targets and haven't seen anything weird but we only go over by 3psi

I don't understand what you mean by "what's up with your spark?" Are you saying there's something wrong? Spark timing is set by a 2D table with rpm and MAP as inputs and the log files show that it's tracking properly based upon those inputs. As said before, MAP goes haywire and drags every related variable with it, and spark timing is one of them. Referring to the logger plot referenced in the first post in this thread, right at the vertical blue line where the anomaly occurs, spark timing is 16 degrees, which is correct for the given MAP and rpm. 0.3 seconds later it's 19 degrees and the lookup table shows that at a MAP of 136 kpa and an rpm of 7600, spark timing should be 19 degrees, and it is, so spark timing is correct per the inputs to the table.

About one second later, the throttle is closed and the engine's slowing with an rpm of 6400 rpm. At that time, MAP is 17 kpa, and for those values, the spark lookup table specifies 37 degrees, which is exactly what it is. That's why I'm asking what's meant by "what's up with your spark", since it's where it's supposed to be - based on the values it's given.

Checking the intake for leaks is slightly more complicated than that, since with the throttle open, the air's free to flow through the engine and out. That said, it will still be done.

Crankcase and head ventilation is handled very well by the dry sump system, drawing approximately 10" vacuum.

Knock detection has been disabled until this issue is solved.

Wastegate sizing is good, and in fact the boost control duty necessary to bleed off pressure is lower than most other engines due to the free-flowing header and wastegate design.

Regarding the manual boost controller: Even without any boost control - running solely on the wastegate spring - the anomaly is still present, so regardless how the wastegate is controlled, the problem still exists.

Lambda is stable right through the anomaly, which seems to rule out fuel and spark. Fuel pressure is read by the ECU, allowing it to maintain a constant fuel delivery by monitoring the fuel pressure - MAP delta.

Sorry if I'm a bit testy, it's been a long day and I thought I'd explained much of this. I know you guys are trying to help and I appreciate it. It's just that you can't lob in a "what's with your timing" without explaining what's behind it

I obviously still have a problem, so something I'm claiming is "fine", simply isn't, apparently.

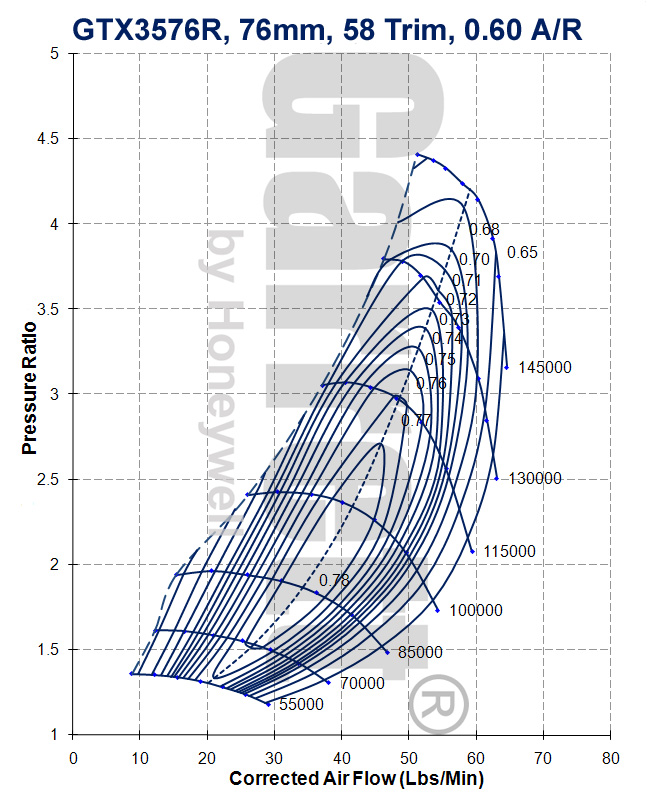

I talked to a well-versed turbo buddy who thinks the turbine housing might be a bit small due to it being a twin-scroll setup. However, he said that an undersized turbo will only gradually choke off flow over several 1000 rpm, not shut it off over 0.2 seconds and 200 rpm.