Air goes in and out.

Coolant and oil go round and round.

Anything else is a problem.

dean1484 said:I have built a bunch of engines over the years and the number one thing that I see people screw up is not being realistic about the real needs they have for the motor that they are building. Truck/tractor motors are not sexy but most peoples needs are much closer to the truck side of things and yet they seem to think a high reving race car type motor is what they need.

I use a computer program that once you are familiar with it really makes your point valid. If it's a driver and not a race motor. You want power from idle to about 3000rpm. That's where most engines make their best power stock.

Making extra power above that 3000 rpm area is where camshafts, porting, bigger stuff etc comes in. But as you seek that added power your fuel mileage goes down, reliability goes down civilized driving goes down etc.

preach (fs) said:Mo cylinders mo money.

to each their own.

Not always. What does a Chevy, Ford, etc cost for a good used engine? You'll spend less than 1/2 of that for a JaguarV12.

Nelson's are making really impressive power from the GM Atlas engine. Without going into it. Just adding a turbo and rethinking engine management.

That approach is what is needed to make the Jaguar a screamer.

Again I apologize for my constant references. It's what I know. If I'd been interested in Merced's Benz or BMW they are equally underrated and overburdened with engine management issues.

ShawnG said:Air goes in and out.

Coolant and oil go round and round.

Anything else is a problem.

While true I was hoping for something a little more geared towards GRM. Something about how to make that process faster.

Pete. (l33t FS) said:A thousand times no!

You can move all the air in the world through an engine and not make an ounce of horsepower.

It's like I told you an elephant is gray and you're arguing that its trunk is long and flexible.

You're not wrong.

preach (fs) said:Mo cylinders mo money.

to each their own.

You see, I'm a man of simple taste. I enjoy 87, and 2 stroke oil, and ROTARIES

...And you know the thing that they have in common? They're cheap.

(SOMEONE watched The Dark Knight again last night)

frenchyd said:CrustyRedXpress (Forum Supporter) said:Once you get down to the physics involved there are a bunch.

Stoich is 14.7, your engine is actually an air pump, and your aluminum pistons will melt at 1.2k degrees F regardless of how much you spent on them.

Most of the really good tuners or builders I read sound like physics majors.

On Gas stoich is 14.7 E85 it's, 9.85-10.7

E10 is what you get at the pump and it's 14.5, 14.7 is the olden days.

CrustyRedXpress (Forum Supporter) saidIt's like I told you an elephant is gray and you're arguing that its trunk is long and flexible.

You're not wrong.

That happens a lot!!!!

There are two kinds of people: ones that are full of E36 M3 and others that want to sell you something. Sometimes they are the same person, selling race engine parts, it's quite often. Trying to find the ones that aren't full of E36 M3 are hard, and usually it's hard won information that isn't broadcast all over the internet.

Also, stoich is lambda = 1 /thread

More questions than answers because every engine is different on a core design level. Always a self driven air pump but never perfect little "this is the answer".

Even the 80% exhaust "rule" is extremely generalized. Leading guys in the industry will point out the at the exhaust flows "enough". Enough being the reality that most of the Exhaust flow happens before the valve ever reaches peak lift. The flow bench cant mimic what happens when the cylinder is at post combustion pressures. Now things that will play into just the exhaust cycle are: Bore, Stroke, cam (both int and exh profiles), head design, head flow, piston crown, header, exhaust, muffler, valve size, anti reversion, cylinder pressure, and rpm. Probable more too.

A great example here is Good port vs. Bad port Big Block Chevy. Good port intake flows more air, IIRC when Darin Morgan was testing this stuff 20+ years ago (its on VHS) the good port was around 20 cfm better than the bad port. However on the Dyno the Bad Port heads made more power. Since then he as been a proponent of the Dyno is king because the engine will tell you what works better and what doesn't. Flow bench is a good tool but by no means a guarantee of improved performance. Another example here is putting heads with flow"capable of 1000+hp" an engine only to have it barely outperform a smaller cubic inch and significantly lower flowing head. IIRC it was 390ish CFM on a 565 Pontiac vs 330ish CFM on a 525 Pontiac. 565 made 870hp and the 525 made 840hp. Same head castings by the way.

When working from an older "stock" engine, just about anything can be an improvement. New engines are much more optimized and gains are harder to come by. Example here is a K series Honda. The Head is so good it that porting nets almost no gains. Most of the gains to be had are in the valve job.

So given just these few examples its easy to see that a one size fits all answer will never be. I takes enormous amounts of testing and data collection (especially on the dyno) to even reach a well informed answer...which only applies to a specific engine design, size, bore/stroke, cam, head, etc. For example I can say that Oldsmobile engines make best power with 35 degrees of total timing. I can only say that because I have built 50+ and dyno'd over half of them. 350ci to 496ci, Iron heads, aluminum heads, ported and unported, different headers/intakes/cams, 350hp to 700hp....all made best power with 35 degrees of total timing. Now jump over to a Small Block Mopar for example and one made best power at 37 degrees of timing, the next needed no more than 28 degrees of timing.

Beware of generalizations, especially on anything built since the mid 90s. Most of the go-to books and info out there is based on a SBC of various configurations. Check the dates while you're at it. Some of the books still used are based on testing and research from over 20 years ago...some of it 30+. Tech being used nowadays was not even in existence back then.

In reply to asphalt_gundam :

Great comments. Absolutely valid. I liked your points. ( and experiance )

I've used engine analyzer computer program to try various components. Much cheaper than building, tuning, trying.

Accuracy of data is critical. But still doesn't give me answers. For example. A small block Chevy's crankshaft is about 22-23 pounds. The forging is 4-5 pounds heavier. Yet I've held NASCAR crankshafts as light as 18 pounds.

OK weight is hyper critical at 9000 rpm. With the relatively long stroke they use.

But Group 44 raced LeMans with what appeared to be a stock crankshaft in their V12. ( that weighs 78.7 pounds.) But I can't figure out how to value that on the computer program.

Then there are endless questions about flow versus swirl, chamber shape and turbulence etc. is the heron head design dead? I can't imagine any better shape for flow. And the easily modified piston can create whatever design is the current rage for combustion shape.

Heron can be good for flow if the ports are steep enough, but that is hard to do well in most castings. Chamber in piston can be a pita as you have to actually thing about that when you design the piston instead of just hitting the easy button and making it flat or with a slight dish/dome to hit the desired compression. The best thing we have done with our 2v heron style heads is throw them into the garbage for 4v pent roof ones. Valve area rules the rest follows.

Regarding flow test supersonic ports: Instead of using a fan to flow test an exhaust port, use compressed air... and hearing protection!

Paul_VR6 (Forum Supporter) said:Heron can be good for flow if the ports are steep enough, but that is hard to do well in most castings. Chamber in piston can be a pita as you have to actually thing about that when you design the piston instead of just hitting the easy button and making it flat or with a slight dish/dome to hit the desired compression. The best thing we have done with our 2v heron style heads is throw them into the garbage for 4v pent roof ones. Valve area rules the rest follows.

That's probably best if you have the choice. But gets real complex on V engines One side of a V 12 is just bolt the head of the 4.0 in line six with 4 valves per cylinder. The other side gets hopelessly complex. You've got to cut off the cam drive, then make the intake on the exhaust side and the exhaust on the intake side. Then weld everything back together.

Paul_VR6 (Forum Supporter) said:Heron can be good for flow if the ports are steep enough, but that is hard to do well in most castings. Chamber in piston can be a pita as you have to actually thing about that when you design the piston instead of just hitting the easy button and making it flat or with a slight dish/dome to hit the desired compression. The best thing we have done with our 2v heron style heads is throw them into the garbage for 4v pent roof ones. Valve area rules the rest follows.

One thing Heron type heads have going for them is the valves are inherently not restricted by the chamber.

Modern head think (speaking of 2v here) is the chamber is really an extension of the ports, so the chambers get shaped for flow first and combustion second. Or combustion first but in ways that do not actively hurt flow. That way you get excellent flow in the chamber, and you don't wind up with pistons that weigh two pounds each with a hugely tall compression height, the other problem with Heron heads. (Why the Chevy 409 never did well as a race engine, even though Chevy tried fairly hard)

In reply to frenchyd :

In regards to the heron (flat chamber) head. While being a completely unshrouded valve and should be good for flow it fails to do one very important job in a performance application. Support the air once it gets past the valve. There is a point when opening up the camber around a valve where you will begin to loose flow by continuing to cut away material near the valve. This characteristic gets more evident with steeper valve seat angles. A 50 degree seat cares very much about this vs a 30 degree seat wouldn't much care at all. Think about it like pouring water onto a flat surface with a hole in it vs. into a funnel into that same hole (like an exh port). The reverse of this on the intake side also affects flow by keeping the air supported and controlled flow vs it tumbling out of control (slowing down and loosing fuel suspension).

Crank weight is real wild one to tie down. Several factors play here: weight, material, journal overlap, stroke, rotating weight, number and size of mains, the strength of the block, stud and main cap. For example a ford 460 crank is cast and very heavy with a relatively short stroke. Bad is heavy and cast. Good is a decent journal overlap between mains and rods. If you get one IPN'd (Ion Plasma Nitride) it makes the stiff cast crank (forged cranks flex easier and more before cracking) incredibly stiff and can be used in 900hp+ pull truck engines. What makes sense to me here is the incredible stiffness (resistance to bending) does a better job at spreading the load to all 5 mains vs loading the 2 nearest during a power stroke. That stiffness also reduces HP losses that get used up flexing the crank. Getting deeper into this...There are some applications where a cast crank will hold an engine together at higher HP because the cast crank being stiffer than a forged one will spread the load to the bearings and block more uniformally. The forged crank is stronger on it's own...but it flexes more to be stronger and that can lead to bearings getting touched or cranking a main in the block.

Reduced weight is almost always good in the rotating assembly. But the real heavy crank that has a large portion of its mass at the mains....probably isn't causing much increase in stress because of the near zero leverage. On the other hand, taking 1/2 lb out of the piston and rod (realistic on old engines) had a massive effect on the stresses involved as the leverage is much larger and then exponential increase to to rpm. This means that a heavy crank with lots of meat on the mains and overlap onto the journal will be much stronger without being as big of a downside as you might think. Conversely a light weight crank with gun drilled mains is going to be a little lighter at the cost of strength without much gains beyond the weight reduction. Its still rotating weight but 2-3lbs at the center of rotation is much less benefit than a 2-3lbs reduction on the flywheel near the ring gear diameter. Pistons, rods, pins, rings, bearings are all much more significant (effective) by reducing weight here it reduces the stress put into that crank by an exponential amount. Double rpm is quadruple the stress forces. For example lets say the force on the rod throw at 2000rpm is 100lbs. That means at 4000rpm the force is 400lbs. At 8000rpm its 1600lbs.

The performance value most affected by the weight of the crank (and entire rotating assembly) is acceleration rate and rpm recovery. Seen best on the dyno. Two engines make the same Hp and TQ with all things identical but one has a light weight rotating assemble and the other heavy. The light weight rotating assemble will be the faster engine at the track because it can climb rpm faster because its rotating assembly is easier to accellerate. This shows itself being measured by the dyno but also by how the engine free revs. Heavy engine at idle and I snap the throttle to Wide Open for 1 sec and let it snap closed. The engine revs to 4000 and takes 3 seconds to decend back to idle. Now I do the same thing with the light weight rotating assembly engine. It snap revs to 7000 and take 1 second to drop back to idle. They both make the same power and curve but the light engine will be faster on track.

Now the complete opposite of this would be an application where rpm "hang" is desired. Most obvious one is Truck/tractor pulls. A heavy rotating assemble will have the inertia to get a few more inches or feet by resisting the drag down of the heavy sled at the end of a pull. In a leman car perhaps the desired affect was better engine braking off throttle...just a wild guess (if was even something considered).

In reply to asphalt_gundam :

On the Jaguar the port starts the swirl and aims it at the cylinder wall to keep it in effect. The flaw with that design is it works best at higher RPM so fuel mileage is hurt at low engine speed for exactly the reason you mentioned. Since the valves are flat to the top of the piston it's unlike a combustion chamber in the head with the need to change direction of the flow 3 times before entering the bore.

With the spark plug almost dead center in the combustion chamber a bowl centered in the piston produces the desire hemisphereical combustion chamber. And the squish around the flat edge of the piston provides the desired turbulence.

To meet the proposed California emission rules In 1981 Jaguar eliminated that design and copied the old Buick fireball design of the 1930's and used into the 1960's on chevy 6 cylinders.

To retain the same power as previously compression was increased to 11.5-1 in America and 12.5-1 for the rest of the world. ( from 7.8-1 for America and 9.0-1 for the rest of the world) They eliminated "pinging" by limiting advance. Going from 38 degrees down to 17 total.

Racers still used the earlier "Flathead" design for power. With timing as much as 41 degrees.

Power was the same with the new HE ( trade Mark for the fireball combustion chamber ) but part throttle driving increased fuel mileage by 4-8 mpg.

The response rate of light is well understood but the question becomes how strong is strong enough. The factory took the stock crankshaft up to 8300 rpm and held it there just short of valve bounce.

The temptation is to grab one of my engines reduce the counter weights and bore the rod journals ( stock pin diameter is 2.30 ) and rev it until it destroys itself. The crankshaft is forged EN 40 steel and when finished machining the crank is then hardened ( process unknown )

In theory a V12 is naturally balanced. Why then is so much counterweight used? That and the heavy factory vibration dampner. Could it be to deal with the torque converter?

Need for drastic amounts of timing is a sign of poor combustion performance. Anything of 36 is above average. The required reduction in timing is also a red flag for the newer head.

Swirl/flow at the cylinder wall is another problem. It can't flow through the wall and more importantly it can cause fuel wash leading to ring wear and poor combustion.

Valves are exactly flat to the pistons??? This causes harmonic problems in the valve train too as the vibrations of the piston movement can travel directly into the valve.

Have any pics of these heads?

My guess is some deliberate shape changes by porting (ports and chamber) along with possible valve shape change can fix/significantly improve the newer head to perform. Limiting factors being casting thickness and overall design.

In reply to frenchyd :

More counterweights get the harmonics balanced out closest to where they are caused. Even on a V8 adding the center 2 counterweights is an upgrade over the less weight of not having them. You could cut all the counterweights off an Inline 6 but its going to stress the crank by forcing the "balance" to take place all the way accross the crank at the opposite rod throw. Counterweights balance the crank as close as possible to the source of inbalance.

In my opinion (and in practice on my own engines) you'd be much better off grinding that rod pin down to a SBC 2.100...or hell go Honda journal (I have before). Then lighten the rod/piston/rings/bearings/pin/locks. Once that is done you'll probably be able to cut the counterweights down in the lathe by a significant amount on the OD, either to balance or without risk of bad results.

If you go through all that then IPN the crank it'll be very strong and a big upgrade. I took a stock 330 olds crank from 64 to 56lbs with Honda rod, counter weight cut to balance, some smoothing, IPN, and stroke increase. The pistons/rods etc all dropped around 250grams (over 1/2lb per cylinder), then add in a light weight balancer and there was over 20lbs shaved off the rotating weight.

The heavy damper isn't for the torque converter. Most factor dampers are very heavy. Mass is the easiest way to cut down harmonics. That's why CNCs and other machines and Jigs are built so heavy. Aftermarket dampers employ better tech to take care of vibration by canceling them out over just absorbing them with rubber and weight.

My Question ,

How do you clean the block/ crankcase so that tiny bits of junk does not get into the oil and pumped to the bearings at start-up ?

Yes I know you have an oil filter ( except my aircooled VWs) , but the grit is in the oil galleys , and in the nooks and crannies and seems to find its way to the soft bearing surfaces......

The VW trick is to drill out the oil plugs so you can run a wire brush all the way thru and put a treaded plug as the oil plug.

that helps but there is still "stuff" in there....

DISCUSS :)

In reply to californiamilleghia :

That's exactly how you do it.... You remove all the plugs before you clean the block. Then you do the machining. Then you clean the block again. Then you remember to put ALL the plugs back in ![]()

Removing all the oil plugs was the part I really did not look forward to when I'd strip engines down for rebuild at the machine shop.

The block should be clean to bare metal, no leftover bits of gunk anywhere, before you do any machine work. That way the swarf cleans right out because it has nothing to get stuck in.

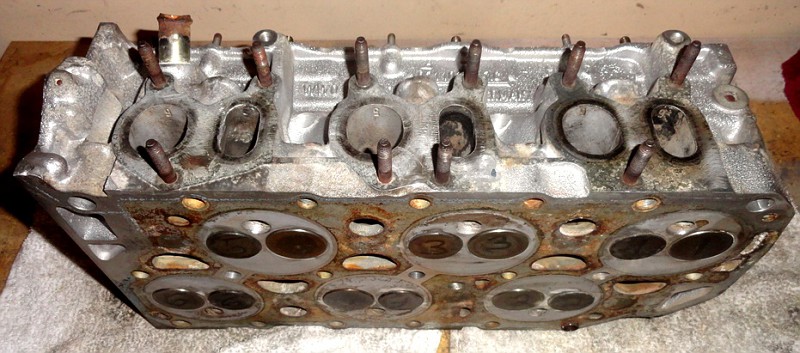

asphalt_gundam said:Have any pics of these heads?

2v boat anchor:

4v slightly better boat anchor

It's a 15 (or 10.6deg) v angle, and the piston top quench are parallel to deck on the 2v with the chamber cut into a pseudo bowl/wedge. The 4v just has a slight dish as it goes to pent roof.

The only worthwhile thing to do to that top one is throw it 40+psi of boost.

In reply to Paul_VR6 (Forum Supporter) :

Flow doesn't matter as much when you start talking about forced induction, bottom end strength does ![]()

I've never played with them, but I've heard head porters cringe at the ports in the 2JZ. Apparently they are kind of like big block Chevys in that there are three (!) different port shapes in the same head. But people make power with them just fine, just keep adding turbo...

asphalt_gundam said:Need for drastic amounts of timing is a sign of poor combustion performance. Anything of 36 is above average. The required reduction in timing is also a red flag for the newer head.

Swirl/flow at the cylinder wall is another problem. It can't flow through the wall and more importantly it can cause fuel wash leading to ring wear and poor combustion.

Valves are exactly flat to the pistons??? This causes harmonic problems in the valve train too as the vibrations of the piston movement can travel directly into the valve.

Have any pics of these heads?

My guess is some deliberate shape changes by porting (ports and chamber) along with possible valve shape change can fix/significantly improve the newer head to perform. Limiting factors being casting thickness and overall design.

Yes, I'll try to get to them tonight. I've been moving stuff trying to clear out a space to work on the Jaguar .  But I've got to move about 20 things to find space to store one.

But I've got to move about 20 things to find space to store one.

As far as fuel wash it really isn't an issue. The piston squish prevents that. I've pulled engines apart with well over 100,000 miles on them and there is no measurable wear!!!! You can still see honing marks in the cylinder wall.

The combustion chamber is in the piston not the head. The head is completely flat. In fact the valves sit on top of the head surface. You can see how free air flows from the intake valve. Without the intake valve in place you can see how the port swirls the intake around the cylinder wall.

The valves don't exhibit any issue with float or harmonics up to about 8300 rpm. That's because the cam activates the valve directly with a simple cup shape lifter to open the valves. No push rods, no rocker arms, and relatively light supple springs. 8300 RPM before float.

the newest design. The HE heads with the combustion chamber in the head are limited to about 450 horsepower ( Net DIN) yet the oldest design made 815 horsepower on 87 octane French pump gas for the 24 hours of LeMans.

Excuse the lousy photos. Dark corner of the shop where storage is. That pair of heads came off an engine 30+ years ago and has never been cleaned.

One of the cheap tricks with The Jaguar V12 is how cheap and easy it is to increase the engine size.

Because the rod journals are 2.30 and the stroke is so short (2.75) if you offset grind the crankshaft to chevy small block size (2.10) you pick up .400 stroke for the cost of grinding the crankshaft. Then you buy Chevy 283 pistons. (3.75 stock Jag is 3.50 ) And get aftermarket 6.00 Chevy rods. For about $1000 you increase the engine from 326 cu in to 418 cu in.

You'll need to log in to post.