84FSP

Dork

12/29/16 10:19 a.m.

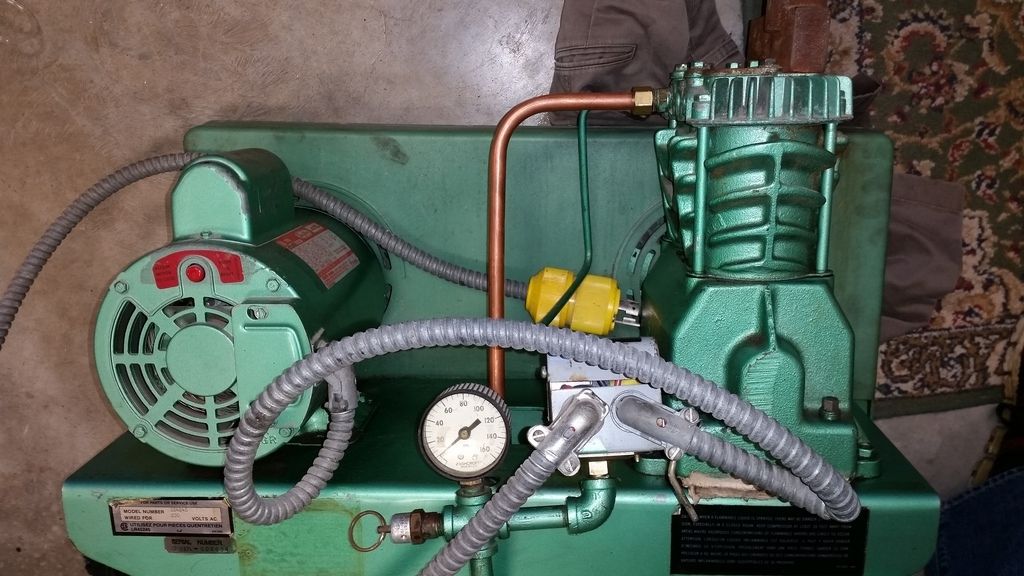

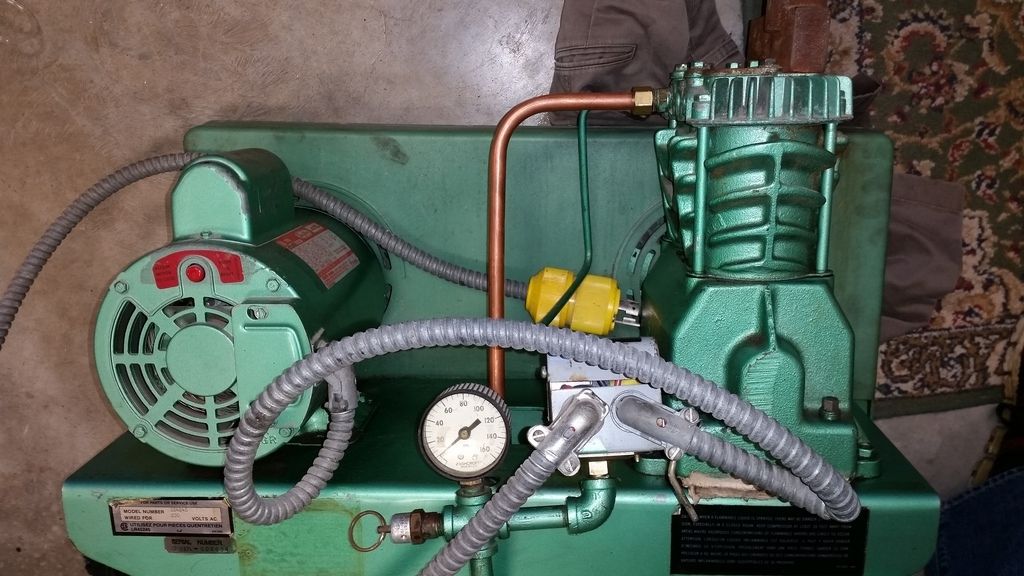

Need help from the Hive. I have an 80's Dayton Speedaire 220v Compressor that is very third hand but in seemingly good shape. This is the third house I have moved it to and in none of them did I ever get to the final steps to make it functional. This is even more ironic given that I have installed 220v service and outlets in two of the houses to run it. I'm attempting to turn over a new leaf and get my garage all sorted out for some mayhem which leads us to today.

I finally had a nice new line made up (the copper color one) and installed it yesterday. Ironically after avoiding doing it for years it was completed in 15min for $6.61 by Ohio Hydraulics here in Cincy (great folks).

With Mrs84FSP and the baby out for a few hours I decide to give her a shot and see if we have any leaks. You guessed it, I do have leaks. I dutifully made up my soapy water and came back out to see which was the offending fitting. Then I found this on the very bottom - seems to have been a hard line or drain line at some earlier point.

With Mrs84FSP and the baby out for a few hours I decide to give her a shot and see if we have any leaks. You guessed it, I do have leaks. I dutifully made up my soapy water and came back out to see which was the offending fitting. Then I found this on the very bottom - seems to have been a hard line or drain line at some earlier point.

It's 0.368" ID and you can see the hard line that was in this bung and was dutifully removed previous to showing up at my place...

It's 0.368" ID and you can see the hard line that was in this bung and was dutifully removed previous to showing up at my place...

Looking at it I'm wondering if I can easy out the hard line and either install a new hard line or tap it out? The pressure involved scares the hell out of me either way though...

Thoughts?

My guess is that this is a threaded in fitting for removing water.

I think you could probably use an easy out to get the remaining threads out.

84FSP

Dork

12/29/16 11:05 a.m.

In reply to wvumtnbkr:

Appreciate the input - was hoping the same thing but thought I would toss it out there before I dug into it. Gonna hunt my easy out selection but don't think I'll have anything that large...

If you put 200 psi in that thing, and you have a 1" square hole, that is only 200 pounds pushing on that spot. Since the hole is considerably smaller, It should only be about 60 to 100 pounds of force on that spot. I would not worry too much about force involved with the hole.

84FSP

Dork

12/29/16 11:12 a.m.

If I have threads I'm happy. If not, I still have concerns without a really good welder at the helm.

I think the part number is D1403 for that draincock. It seems like all of the Speedair's use the same part.

84FSP

Dork

12/29/16 11:34 a.m.

Whoa - building confidence and out researching me! Appreciate it sir. I have been dying to get this thing up and running. It should be more than enough compressor for any of my goofing around.

Seems your problem is solved and I don't mean to hijack, but I bought an 80 gallon Kobalt some years ago. They slid it into the back of my truck, waved good bye and I was excited.

Didn't work.

Brought it back and the Manager just shook his head, apologized and got me another one. He claimed these things can't be laid down.

YMMV.

FYI instead of using a radiator petcock I would thread the correct size pipe and run a length of it away from the compressor and then install a ball valve on the end. That way you can drain the water by just moving the lever of the ball valve 90 deg. to open. My laydown compressor is close to my overhead garage door and I have the end of the drain valve pointed to the outside. When I open it most of the water is shot outside on the driveway.

daeman

HalfDork

12/29/16 3:06 p.m.

If you're worried about pressure when replacing the broken drain cock, you should be able to yank on the ring to the left of the gauge as it looks like a manual override pressure relief valve.

Jimbbski raises a good point about possibly replacing the broken drain cock with a ball valve.

If it looks like you're going to make as mess of getting the old drain cock out it may be worth seeing the hydraulic guys to remove it and build a drain line with ball valve while you're there.

100% it used to be a drain cock and someone broke it off. It's a generic part and will have 1/4, 3/8 or 1/2 inch NPT threads. They're kind of a pain to get to and spray pressurized rusty water everywhere. I'd buy pre-tapped lengths of brass pipe and an elbow and a timer tank drain for $25.

To remove the stub of pipe thread in the bung, you can try a drive-in 4-sided type EZ-out, but I see an broken remover in your future. Possibly better to use a cut-down hacksaw blade to notch the remaining threaded pipe then use a small, sharp drift to push one side of the notch in, then carefully chisel and saw 'til you can twist it out.It's def possible to remove the broken-off bit while preserving the threads - they're pipe threads so they'll chase clean. Also, use a couple wraps of the thicker yellow PTFE tape that's spec'd for NG connections.

I strongly advise against welding on pressure vessels no matter how good a weldor you are or know. A failed 60 gallon tank can kill and will pretty much destroy a garage.

Agreed. Its for a draincock.

Skip the draincock. Use a reverse drill bit or other means of getting the old one out and you should have good 1/8" NPT threads there (If I'm judging the scale correctly).

What I do is go buy a 90 degree pipe fitting (usually a street elbow) and thread it in there, then a pipe nipple, then a 1/4 turn ball valve. Drain cocks get gunk in the o-ring and don't seal well, they are kinda fragile (as you're seeing) and you have to crawl under there to drain it. Plus, they seem to get boogered threads pretty easily and then you have to resort to vice grips every time you drain it.

But if you do it like I do, you just bump the valve with the toe of your shoe and bingo. Total investment of about $15.

One of each of these in the appropriate sizes:

84FSP

Dork

12/29/16 4:47 p.m.

Great input on the threaded pipe and a valve. It's all the way in the back of the garage so being able to direct the draining would be really nice. Another thing I would not have thought of...

Looks like an old sch40 steel pipe nipple that snapped off, common enough problem (in plumbing in general) that there are special extractor sets just for this purpose that you can buy just about anywhere, even HF sells them. If you install something other than a drain cock use a "street" elbow (stronger) and attach a hose to that to prevent stressing things, you don't want much weight hanging out and vibrating.

0.36" ID is Schedule 40- 1/4 NPT. EZ-out for that size oughta be available at any hardware store. Chase the threads after removal w/ a 1/4 NPT tap to clean it out. Street ell like others said or 1/4" NPT steel hydraulic street ell for greater strength like hanging a long nipple and valve from there. TSC has 'em. My old Sanborn sweat so bad in an unheated garage the condensation froze and broke the ell.

The new I-R came w/ the drain cock, PITA. Installed hydraulic street ell, Sch. 80 nipple w/ ball valve. Anchored as shown:

No wobbly

84FSP

Dork

12/31/16 10:03 p.m.

I like what you put together there. Did you just mount that bad boy to a skid and call it a day? Love the simplicity. I have some nice epoxy cartridges, all thread and rubber pads when it's ready to get bolted down.

Got a bit side tracked on the compressor as I've been under the V.

84FSP wrote:

I like what you put together there. Did you just mount that bad boy to a skid and call it a day? Love the simplicity. I have some nice epoxy cartridges, all thread and rubber pads when it's ready to get bolted down.

Got a bit side tracked on the compressor as I've been under the V.

That is the pallet it shipped in on. Although it's not recommended to leave it on the pallet I ran my old 5 hp Sanborn on it's pallet for over 15 years w/ no ill effects.

Plan w/ the I-R was to pour a concrete pad and Hilti bolt it but this pallet is pretty stout. At 600 lbs. the I-R ain't goin' nowhere plus it's easier to move if necessary while still on the pallet.

As someone said vibration would be a concern w/ that weight hangin' off the drain. Just some scrap angle pieces layin' around the shop welded up. Used a hydraulic hose after the filter/ separator for supply to the garage piping so no rigid pipe hookup.

With Mrs84FSP and the baby out for a few hours I decide to give her a shot and see if we have any leaks. You guessed it, I do have leaks. I dutifully made up my soapy water and came back out to see which was the offending fitting. Then I found this on the very bottom - seems to have been a hard line or drain line at some earlier point.

With Mrs84FSP and the baby out for a few hours I decide to give her a shot and see if we have any leaks. You guessed it, I do have leaks. I dutifully made up my soapy water and came back out to see which was the offending fitting. Then I found this on the very bottom - seems to have been a hard line or drain line at some earlier point.

It's 0.368" ID and you can see the hard line that was in this bung and was dutifully removed previous to showing up at my place...

It's 0.368" ID and you can see the hard line that was in this bung and was dutifully removed previous to showing up at my place...