This is of great interest to me. I'm maintaining four bikes with different hangers, and I like to have a spare or two around.

This is of great interest to me. I'm maintaining four bikes with different hangers, and I like to have a spare or two around.

Turbo_Rev said:I'm thinking this guy is gonna be a little off. The drawing I used to trace it wasn't the highest resolution. I might just trace the one I have, upload it, and use it as a template if this one isn't jiving with reality.

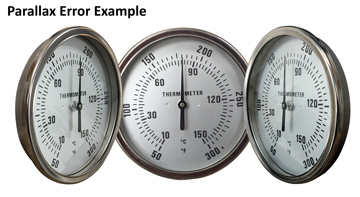

You have to be careful with drawings and pictures. Even if they are straight dead on you can still get what is called parallax error. Something as small and flat as this is not that prone to it, but you can find it in other things. Flat and wide is bad about it as well, such as a gasket. An example:

In reply to Mr_Asa :

Yeah, that was truly bizarre. I'll have to post another picture to show how off it was. Lesson learned there.

So, an update:

First off, we have a successful final product.

Tasty (except where I clipped it taking it off the build plate). A couple of notes:

1. It's not as rigid as a metal arm. That's probably obvious. I doubt this will factor much into shifting performance; I didn't notice any flexing while shifting. Even after everything you read below, it shifted reasonably well for all the other problems. You do need to be a little bit more careful when taking the wheel off/on.

2. It will probably break before it bends. This is probably a wash over a metal arm. A bent metal arm still has to be straightened. Alternatively, you could print another PLA arm. Print a few spares or buy a straightening tool. Potato, tomato.

3. 4 prototypes and the final product are WAAAAAY cheaper than a new arm. $34 dollars is almost two 1 kg spools. All of this took maybe a tenth of one spool. Maybe less.

4. It's all moot, in this case, becaaaaaaause.......

I'm pretty sure the cage on the derailleur is bent. Remember, I'm doing all this because the bike landed on the derailleur. Additionally, all the adjusting and screwing around pretty much hosed what little was left of the shift cable. It's frayed to all hell and has such little slack that it's still putting a bit of tension on the derailleur with both barrel nuts fully loosened. So, I'm going to go ahead and replace shifter cables.

And this is the real kicker: I realized the derailleur on it isn't the factory one. Somebody replaced the Shimano Acera with a MicroShift and BOY, does it look like a cheap piece of crap. I figured this out while I was entertaining replacing the derailleur because of the cage. Who knows if the MicroShift is compatible but I'm not gonna' struggle with it anymore. A replacement Acera is $50 and has the correct specs, so it's been ordered.

All of that combined probably explains why the bike has never shifted right since I bought it (used). I've tuned it a countless number of times and replaced the hanger arm one other time in the past. I've also replaced cables and housings as a matter of course. We'll see how everything comes together but I'm going to call the arm sorted. I'll update after everything is installed and we've got a road test under our belts (about a week).

In reply to Mr_Asa :

It's possible. I don't know how rigid a given epoxy would be over solid PLA but I'm sure there's something out there. I'd really like to be printing it in nylon or PETG, ultimately. If it turns into a problem, I'll probably try that.

I think just about any plastic is going to lose out over metal hear because of the 4mm thickness of the thing part of the hanger. A simple fix might be to just print the whole thing a few milimeters thicker than it needs to be.

That reminds me: the B screw does not like PLA and vice versa. It digs into the hanger a couple of millimeters before it starts adjusting. I'll probably change the shape from the ducktail it has now to something flatter.

I have made the model 2mm T H I C K E R:

This should help with rigidity. I also got rid of the little teardrop tail shape that the B-Screw pushed against. PLA is a little too soft for that kind of force, it looks like, so the extra material should allow a divot to form while maintaining the level of adjustability.

That is all. Derailleur and cables gets here tomorrow.

I've used the Thread feature on Solidworks for 3d prints, and it works out just fine. A chase with a tap will clean them out. I've done as big as 3/4-10 and as small as 1/4-20.

If I really want to keep something bolted, I'll run a helicoil into the printed part. This makes for a super strong joint.

Definitely use the stiffest filament you can find - there's actually quite a lot of force on one of those little hangers. The carbon-filled nylon sounds like the right idea.

Ah, that's a good tip about the helicoil.

When the derailleur gets here, I'm probably gonna' print two or three spares just in case the installed hanger decides to poop.

Do ya'll have an enclosure (DIY or not) that you like for printing nylon? I don't think I'll be able to vent it out a window, since there's just not a good place to do it in this apartment.

stratasys is sending me some new fancy rolls of ultra rigid that require thermal heating and cooling to activate.

Send me the STL and let me print one up and I can put it in the mail if you want.

Another thing I've done is print a hole in the part and then press a steel rod into the hole. Makes the length of the part much stiffer.

I don't have any enclosure, but my machine runs in the detached garage.

In reply to Turbo_Rev :

Look into embedding an actual nut into the print. Its fairly easy to do if you plan it.

As I was typing this, I actually looked over at my work shelf and remembered I have a bunch of those press-in threaded inserts. The kind you use a soldering iron to embed and they have the knurled face along the circumference.

If the hanger fails due to the threads of the PLA near the hardware, I'll definitely start looking at those as a fix. Just remove the small threaded holes and make some blanks big enough to accommodate the press-ins.

Derailleur and cables got here. Good news and bad news:

Good:

Thicker hanger fits fine with wheel installed. Is waaaaay more rigid but it's also the absolute widest it could possibly be.

Thread in the hanger matches mounting hardware for derailleur. No changes needed.

Bad:

Someone tightened the cable retention screw in the shifter like they were trying to drive it into a chunk of marble. Tried every screwdriver I have, the Phillip's head is stripped. It'll probably have to be drilled out and will definitely need to be replaced. Thanks, whoever, you kept the screw in there, no matter the cost.

The new derailleur has this:

The b-screw mount ring thing has a gap where the allen is pointing and a raised lip everywhere else. This gap is meant to be wide enough to allow whatever hanger through but, since Norco didn't travel into the future and see this, the factory hanger is too wide to fit in that gap. This means the lip keeps the derailleur from mounting flush against the hanger. Lovely.

The b-screw mount ring thing has a gap where the allen is pointing and a raised lip everywhere else. This gap is meant to be wide enough to allow whatever hanger through but, since Norco didn't travel into the future and see this, the factory hanger is too wide to fit in that gap. This means the lip keeps the derailleur from mounting flush against the hanger. Lovely.

So, back to the drawing board to add a recess that allows for that little ring so the derailleur fits flush. Hrngh.

I just want to ride.

P.S.- I checked with Shapeways and they can print this in glass-bead reinforced nylon for $11, which is nice if you want cheaper replacements.

You can also have them print it in platinum for $12,000.

https://drive.google.com/file/d/12NfaLrf8SViZ4zqm5VB8433JLAghxQ5g/view?usp=sharing

We have lift off. I can tell you right away this is the absolute best this bike has ever shifted. It really didn't like that Shimano/MicroShift abomination the PO was rockin'.

Also, I'm not a bike mechanic, so if you see anything blatantly wrong, feel free to let me know.

Only downside is that c-shaped groove I modeled for the derailleur prevents the hanger from contacting the b-screw ring thing from earlier. This means the ring has no leverage to lift the derailleur and it's now effectively non-operable. I'll make a V2.5 today that fills in some of that cut ("half-moon" instead of a full circle) and gives the ring something to push against. There's a tiny, tiny bit of chain rumble in low gears and I think that's the culprit. The gap between the g-pulley and cassette is a little less than a pencil-width. Also, shiny new cable and housing and a new Missing Link.

It survived a nice, hard sprint from home to campus earlier. Jumped some curbs, pedaled as hard as I could, shifted often. Sat in the sun for about 1.5 hours then did it again. No hang-ups or hesitation. No visible deformation or cracking on the derailleur.

Take-aways:

-definitely cheaper than a new derailleur. This would make an excellent spare and may make a good replacement. Time will tell. A ShapeWays print would be even better (and still 1/3 the cost). Print one and keep it in your roadside kit.

-it may be worth it to just by a new one if your time is valuable enough. This took a few days, if you exclude waiting on shipping.

-PETG/Nylon is probably better than PLA.

-Makes updating derailleurs on older frames waaaaaay easier. I think it would just be dremel time if I had to make a metal hanger fit the new derailleur. And then it would look like garbage and what if you eff up your new $34 hanger? Beats hoping there's enough of your old derailleur out there to keep your bike on the road.

-possible upgrades are nylon, helicoil threads and/or threaded inserts.

Thanks for watching. I'll update if it breaks. Any questions, don't hesitate to ask.

So, this is a somewhat inelegant-but-who-cares change to give back b-screw functionality. I'll prototype it tonight and print a solid one if it works. I won't update beyond this except to say "it worked".

You'll need to log in to post.