In reply to dean1484 :

Wow, my thoughts exactly. I go in thinking it's a joke, only to be overwhelmed with knowledge and skill.

In reply to dean1484 :

Wow, my thoughts exactly. I go in thinking it's a joke, only to be overwhelmed with knowledge and skill.

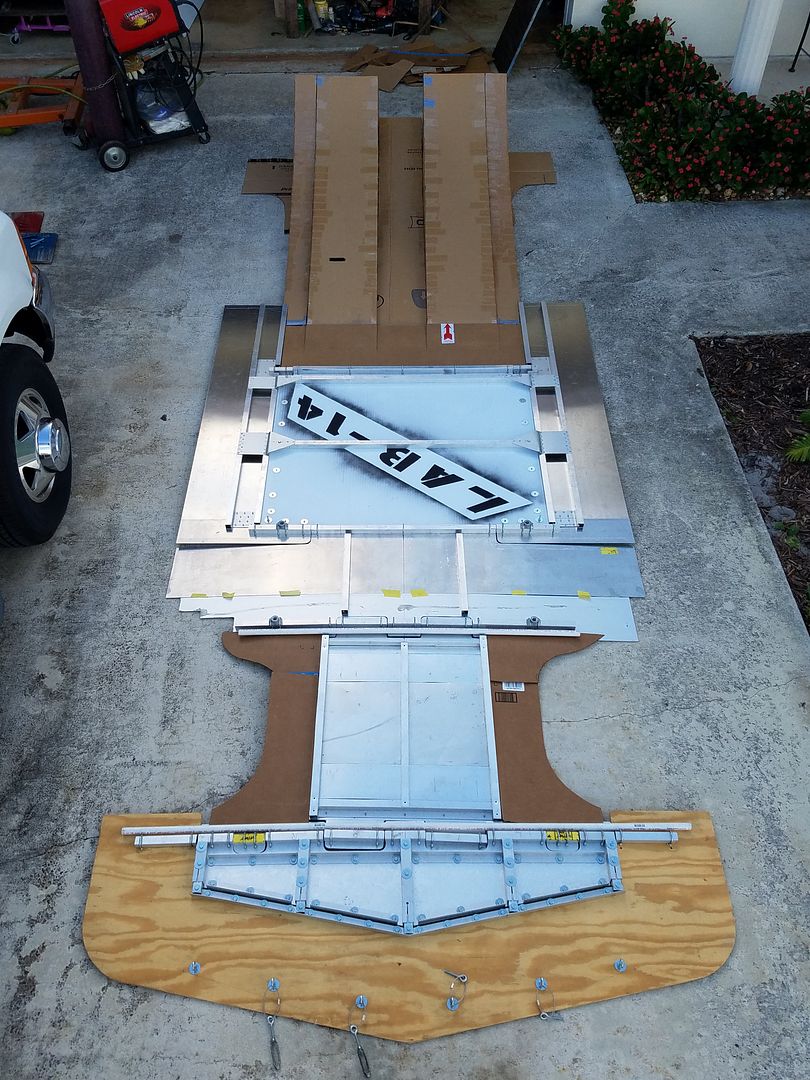

Here's the one I've been working on. It's just one part of a combination of modifications I'm hoping will reduce lift as a package.

[URL=https://app.photobucket.com/u/NOTATA/a/ac949837-2452-4f6a-b3a7-1455f6a2f0b0/p/d11e461d-33f5-4340-ae70-108b33397a54] [/URL]

[/URL]

[URL=https://app.photobucket.com/u/NOTATA/a/ac949837-2452-4f6a-b3a7-1455f6a2f0b0/p/b306c2e6-f818-4b50-9191-8af8efe123af] [/URL]

[/URL]

In reply to NOT A TA :

you can use about 1/16 of the mounting points you have on that splitter and it will be just as strong.

Crackers said:What considerations need to be made if I want to add a diffuser later?

It looks like some kind of side skirt is needed to funnel/guide air under the car, but how deep?

Are skirts necessary, period, or does that only apply to when using a diffuser?

Can a flat bottom make a car worse if done wrong? Any examples, I can learn from?

Thanks all!

hit these questions in order.

1, you'll want a diffuser. even a very simple one would benefit you. don't go nuts as with a flat floor a diffuser will be happy to work. just make sure you include strifes (vortex generators) as they help keep the air attached.

2 Side skirts aren't needed. most GT3 cars add them to do 2 things. 1 that's usually where they put the side pipes to keep heat away. 2 they make the floor wider and that helps speed air under the car. remember downforce is made by "fast air under, slow air over". so make them as wide as you can stand.

3 Skirts, like real skirts that touch the ground. those mythical things used and outlawed in F1. help formula cars a lot by stopping turbulent air caused by the tires from messing with the ground effects. unfortunately, on GT cars the wheel wake is substantially less and the skirts are outboard, meaning they won't control the wheel wake the way they do on F! cars. so don't worry

4 not really, they are almost always good.

In reply to Johnny_at_NineLives :

I've got a lot more going on there than would appear at a quick glance. There are 10 points where the splitter section connects to the vehicle. As seen in the pic it's over built only for testing to allow quick changes to different length plywood sections of the splitter. I can stand on the splitter when it's attached to the car. For me it's a learning tool, I have nothing to win.

In reply to GameboyRMH :

They still are naca ducts. In this direction they exhaust hot air built up from the exhaust, trans& diff

Evander said:In reply to GameboyRMH :

They still are naca ducts. In this direction they exhaust hot air built up from the exhaust, trans& diff

N.A.C.A. ducts (aka submerged inlets) work because of the vortices they generate, that's why they have a very specific shape.

Turned around backwards like that, they're just holes. They could be shaped like Hello Kitty and they'd work the same.

The lowest part of my Volvo 1800 is the front cross member, by a lot (4 inches above ground). It is also a licensed road car and I want to build a tapered under body tray attached with Z channel shaped like the below diagram with curb clearance at the front splitter. Good, Bad, Ugly? Ignore the front conveyor belt air dam.

In reply to VolvoHeretic :

The location of the lowest point (throat) will be the center of the downforce generated by the floor. If the car tends to understeer put the throat closer to the front. Loose? put the throat further aft of center. The offset from center-ish to the throat does not need to be much more than front or rear of door opening bottom corners. You don't want to push the balance too far in one direction.

As an idea this is pretty common. The downsides are getting cooling flow out of the underbody and potentially allowing some cooling air in for things like the exhaust and rear axle. Height will be a big question and since it is a street car, you will want som reasonable clearance. It does provide a good foundation for a fully developed diffuser.

CAM/XS now allow a functional diffuser, I think it's the only class that does? It's pretty limited in size.

"A rear diffuser may be added but the aerodynamic surface may not extend forward past the vertical centerline of the rear wheels and may not extend rearward more than 6” from the original body, as viewed from above."

Actually, that is pretty decent now that I think about it. At least, there should be enough area to make measurable downforce. Right?

Measureable will be relative to the weight of the car and the speeds involved. The shape can be pretty wild and manage to do some real work, but the side effect is going to be limited ground clearance to make the most downforce over the distance allowed. The roof angle can be fairly agressive (upwards of 15 degrees to the ground) and the diffuser can expand side to side after the tires to get a bit more expansion. For extreme expansions you will need to include fences to separate the flow into distinct channels. Keeping the bottom edges of the outer walls as close to the ground as possible will also help. You may even want to use some creativity to help channel some air in front of the rear tires into the throat of the diffuser (under the rear axle).

In reply to stafford1500 :

Thanks for the reply and insight. Right now as it sits in the below photo and only on public roads, at low speeds around 40 mph, it understeers like a pig. At 65 mph or so (the fastest I have ever played with its limits of traction), it is pretty neutral, oversteering with throttle and understeering with coasting.

Rear tires are 2" wider than the front. I figured that I would balance it all out with the new rear wing.

(edit: sorry, this next sentence doesn't make any sense. The hood swings forward with the hinges at the front.) The last time I had it out for a top speed run, I had the rearwards opening hood unlatched because it wouldn't close if I use a 3" thick air cleaner and I haven't modified the latches to cinch down with a 1/2" rear gap (It does with a 2.5" filter). At 120 mph, the net air pressure was so negative that the hood was open about 8" and it was hard to see over the hood. I would like to build a new hood with multiple louvers hinged so that they could let air in or out depending on the pressure sitting over each individual louver.

Good or bad, anything has to be better than a flat floor, right? ![]()

I also never finished and blocked off the top of the bumper to body gap.

The passive louver idea is one that could be used more if there are not rules against active aero. The hood lift you experienced is due to the low pressures on the front end of the hood. If there is room, and you are willing to do some body work, the front end of the hood could be rolled down under the front fascia edge to create a decent hood extractor vent. The core support and other stuff above the radiator might have to be adjusted to help get some of the hot air to the hood vent without too many twists and turns.

Flat floors are a good foundation for other things. Adding diffusers behind a messy underbody reduces the effectiveness. Flat also has the side effect of being the least stiff in regards to buffeting and oil-canning under load. Adding shape can add strength and stiffness to reduce the underbody vibrations caused by unexpected aero effects.

Is the picture you posted on Ortega highway?

You'll need to log in to post.