If you follow my Rally RX7 thread, you know that we nearly beat it to death at Magnum Opus, and as such I've been looking for something a little more robust, a little safer, and probably a little faster as well. So I bought this:

It was only about 10 hours away, and I was planning to hit the road to pick up an RX7 engine anyway, so I made a weekend of it and picked it up.

The car is pretty well built, has a good cage in need of some small updates, came with a bunch of parts, and a fancy JVAB suspension with a lot more travel than the RX7's HotBits stuff. It also only has 6 rallies in the logbook, the last of which was Sandblast 2008, and it still wears the stickers from that event.

Since Sandblast 2008, not much has happened to the car. It has mostly been sitting and slowly leaking oil from the turbo drain line- running occasionally to keep everything alive. I am trying to have it ready for Black River Stages in September, although the RX7 is running and has been welded back together where needed so I have it as backup.

So what have we got? Inside it's a home made dashboard/gauges, nice seats, expired belts:

A 2.3t with a leaky turbo in the engine bay:

And fancy suspension at both ends:

I got it up in the air and started tearing it down:

The absolute minimum I need to do before Black River is:

-Weld in door bar gussets

-Install current belts

-Install intercom

-Make door panels

Wow! Nice short list, but I'm planning on more to help keep us from having any issues:

-Replace leaky turbo with (included) new Cosworth unit

-Remake exhaust to mate up to new turbo (also current exhaust sucks)

-Replace spongy brake MC with (included) better MC

-Replace open differential with (included) welded diff

-Flush all fluids

-Replace anything which looks suspect

-Make shields for fuel filter and other potentially rally ending weak points

Still, not too bad. Let's get started!

Am I just not seeing it, or does it not have an A-pillar support downbar?

Also, when you get a chance, take a pic of what the lower attachment point for the JVABs in the rear is. I'm starting to get dangerous ideas about the e30 suspension of the future....

I removed the skid plate and the exhaust. The skid plate seems OK, maybe a little thin, but the exhaust definitely needs a rework- it was one piece from the turbine to the tail end of the car, had a bunch of broken hangers, and ran under the diff.

The good news is that there's plenty of tubing for me to work with, and the cat/muffler seem to be OK. The bolts at the turbine came out pretty easily, but I'm spraying the ones holding the turbine to the manifold with PB blaster daily in the hopes that they'll break free when I go to remove that.

Next was yanking the seats out in preparation for door bar work:

The seats have these interesting welded subframe thingies under them, presumably to tie them to the cage so that you move with it instead of the floor, and possibly preventing an "up the ass of Timo" type incident ![]()

The belts are expired, but Sara already removed the ones from the RX7 in preparation to install them into this car- she, for good reason, is extra excited about us having a car with a somewhat modern cage in it.

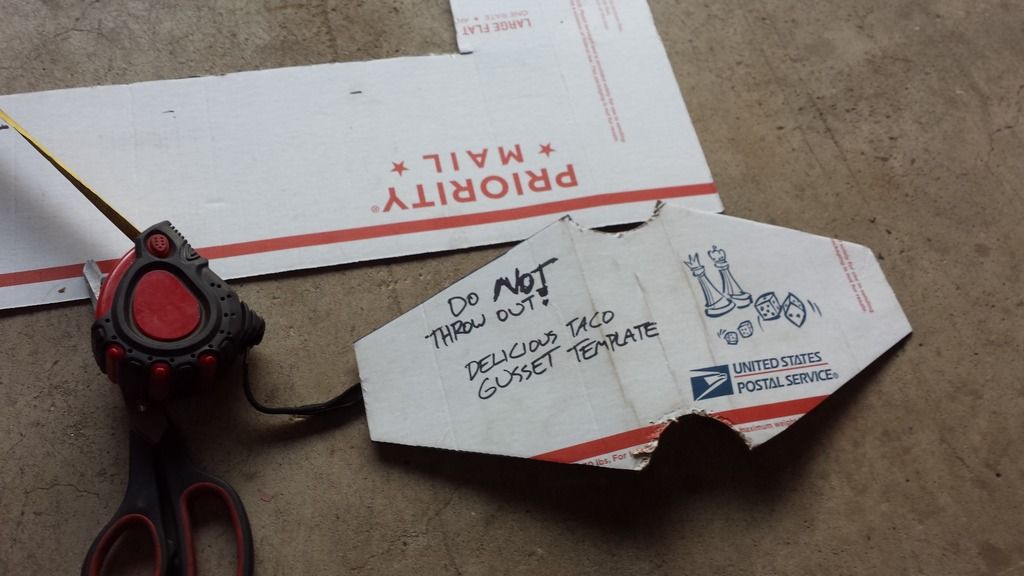

So, the biggest thing the car needs in order to pass tech is gussets tying the "X" in the door bars together- the idea being to keep the welded tube from breaking free and turning you into a kebab when you attempt to use the side of the car for forestry operations. The gussets need to look something like this:

But, steel instead of cardboard. They call this style a "taco" because it has to fold in the middle.

I'll be using .075" steel, which is nearly double the .040" minimum spec but should weld nicely to the .095" wall tubing. I wanted to cut it out on the laser at work, but it's running 24/7 right now so I had to make do with a cutoff wheel. Then I bent the tacos around one of the door bar tubes- they're not perfect, and initial fitup will probably involve a few tack welds here, a whack with a hammer there, but they should get the job done.

irish44j wrote: Am I just not seeing it, or does it not have an A-pillar support downbar? Also, when you get a chance, take a pic of what the lower attachment point for the JVABs in the rear is. I'm starting to get dangerous ideas about the e30 suspension of the future....

No secondary A-pillar bar, Toyota bar, whatever you want to call it, which is OK because this car was caged in the early 2000s and meets the grandfathering requirements. I may add one over the winter.

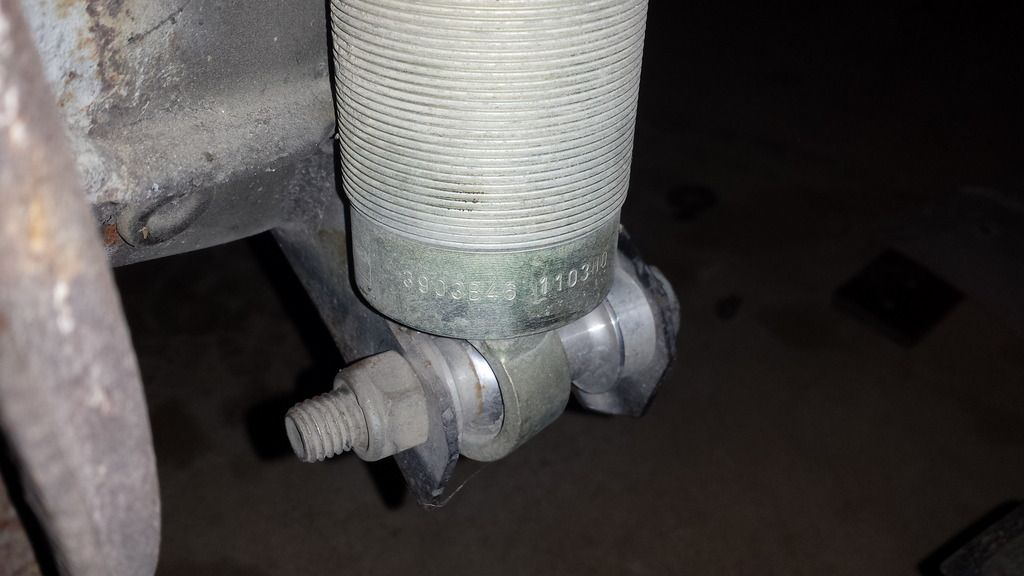

Lower attachments:

Pretty typical double shear mount and spherical bearings.

cool, thanks. Was curious to see how similar it was to an e30 mounting location. Is that car a stock coilover setup in the rear?

all of our gussets we cut with a jigsaw, using the same thickness steel as you used (IIRC). All of them looked sloppy when cut out and bent, but like you said - a big hammer and some tack welds and they straighten up and fit just fine. And the welds clean up any sloppy edges anyhow.

This car is like a 2x scale e30 out back- there is a spring perch on the trailing arm, in a similar spot to the e30, but the arms are much beefier. The upper shock mount is tied into the cage and has thick steel reinforcement over the top.

I've been eyeing the original spring location though, it looks like it could be a fun place to put a hydraulic bumpstop.

Yeah, my upper mount is tied to the cage as well and I'm further plating it this weekend probably and will eventually switch to a coilover setup back there I think.

Anyhow, looking forward to having a chance to check the Merkur out closer. Didn't really have much time to look at it when you were in Frostburg.

I have other obligations today so I'm not going to do the door bars just yet- I had a little time though, and I was told the car has a tendency to get hot towards the end of a stage, so I grabbed a hole saw and opened up some airflow for the radiator:

Well, just in case, CX racing makes full size radiators for our cars. It's enough to keep a 302 cool.

http://www.ebay.com/itm/CXRacing-Aluminum-Radiator-For-85-89-Ford-Merkur-Fits-Stock-Location-/161937754330

Granted, if you've got a Cosworth style intercooler it won't work since you need a shorty radiator

It has a cosworth intercooler, and a Saab radiator. This setup is supposed to be good enough to keep it cool on stage so I'll be refreshing the cooling system and trying it with this radiator.

Just another FYI, JVAB makes a kit to swap in a Supra diff too.

Running it in my car and works well.

In reply to GPz11:

Oh believe me I know, and I just so happen to have two Supra differentials sitting right here! That is on the rather large list of things to do for the off season.

In reply to t25torx:

Purchase price was $6k with a buttload of spares- I anticipate about $300 in total to have it ready for Black River, then a few hundred here and there for upgrades over the winter, unless I crash it, or break something major. The car is honestly not the most expensive part of a low budget rally operation, so if needed we can always skip an event and use the funds to fix the car instead.

¯\_(ツ)_/¯ wrote: unless I crash it, or break something major.

I have money on you going YUUUUUGE over the jumps at Goose Pond ![]()

Door gussets are in:

I'm confident the welds are stronger than the metal in the gussets, but I couldn't get the penetration I was looking for, even with the current cranked all the way up and no extension cord. I've had no problem with .125" plate to .120" wall tubing, and this is theoretically only sticking .075" to .095", so I'm not sure what the deal is ![]()

¯\_(ツ)_/¯ wrote: In reply to t25torx: The car is honestly not the most expensive part of a low budget rally operation, so if needed we can always skip an event and use the funds to fix the car instead.

What is the most expensive part?

EvanB wrote: In reply to lnlogauge: Entry fees/towing/hotel for crew etc.

That. We budget roughly $1k per day of rally, and seem to go over that on single day events and under on two day events. Figure an average of $1600 or so per event, provided the car doesn't suffer any major breakage- so at the cheap end of the spectrum, the car only costs a few events worth of money, and you easily burn more than the value of the car in a season.

If we were paying someone to do the work, that equation would get turned upside down in a hurry- lots of hours go into the car regardless of how many dollars are spent.

They say "treat any used rally car as if the seller is trying to kill you with it." First attempt: when I pulled the diff the driveshaft bolts were finger tight ![]()

The welded diff is waiting for RTV to cure before going in- open diffs are unpredictable and make me nervous on gravel.

The welded diff is waiting for RTV to cure before going in- open diffs are unpredictable and make me nervous on gravel.

Also yanked the leaking turbo and got the nice one with fancy Cosworth turbine housing and adjustable wastegate actuator ready to go in.

I mangled one of the water lines when I took it off. I have heard that the water cooling is not that important for a turbo on a race car, anyone have any thoughts on that?

Dusterbd13 wrote: Cooler bearings can never hurt. If it's an easy enough fix, why wouldn't you?

Extra leak points- you can finish a rally with a dying turbo, but not without any water in the engine.

Yes, the car came with an open diff installed, a welded diff uninstalled, and a Supra LSD which will need a rebuild and an adapter kit to put it in.

You'll need to log in to post.