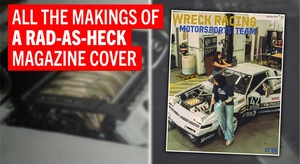

I got a late start Sunday but managed to get some work done.

Before I can install the gas tank again I need to weld up a torn tank mount. This required removing the fresh air box stuff which kinda snowballed into removing the dash cap and lower dash pad. I still have some of the old harness that needs pulled out as well.

So the tank mount got welded along with some random holes I found throughout the frunk. I also opened up the coolant hose passage so I could have a rubber grommet and still fit the hoses through.

I broke both sides of the vent flapper things due to a half dozen pens and pencils that found their way into the defrost vents. Hopefully I can extract the ones from the parts car without issue.

Almost forgot I welded up this cut in the frunk floor.

I spent some time trying to clean up the dust that's been dormant for decades while the air box stuff is out. This is AFTER some nylon brush and shop vac work. More to be done but it's way better.

The trunk bolt strap thing got welded up with some holes.

And more in the frunk.

The mess was starting to get out of hand.

The dash work sucks but hey, the frunk has some good progress going on.

I kinda needed something to really wrap up the progress for the weekend and make me feel like I accomplished something. A while back I found that Gates makes these heat sleeves used on coolant hoses. I thought they would be perfect for the splices I have in the system so I won't need a half dozen hose clamps. RockAuto had them for around $3 each so I bought enough to do the whole system other than the actual connection points that will be serviced.

Let me tell you boys and girls, these things are worth every penny!

They cover the splices while also clamping them together. It's a thing of beauty.

I also added a splice with an 1/8 NPT port to drain the system. This is located on the thermostat side high enough to not snag on stuff. Once again the miracle clamps were used.

Last but not least was the splice made on the water neck coming off of the head. So for the whole 1 1/4" hose system I will need only 4 clamps to secure it all but still be able to remove everything or service all sides without issue. It's brilliant.