Well I have to say, its so incredibly frustrating trying to save up for this Corolla when my family vehicle needs a complete front suspension overhaul due to a minor accident and/or when this past Monday my daily driver wouldn't start when I get in to go to work. In a frantic rush to find and borrow a car so I could get to work I came to the conclusion that it was my starter solenoid. The starter would spin super easy and free and not engage. Great. After work I swing by an auto parts store looking for a starter. $187...... that's a lot of nope. I get home and start poking and prodding just to make sure it is the starter. I jack up the car and take off the wheel and the plastic bits for the service area. Had my wife try to start the car for a split second and the crank pulley is turning over. Hmmm. OK. I know it has air, so I start to look into the spark area. While I was pulling the silly coil pack bar thing over my engine I had this bad feeling.... the worst feeling. I should just take a look at the timing while I am already so close to it. To check the timing, the whole valve cover needs to come off. And lo and behold.....

Loosey Goosey

well at least I didn't buy a starter. Rush order from the Rock and then lots of research on how to do a timing job on a 2.2 ecotec engine. Having done a timing belt job on an old Dodge Stratus and it being horrible, I was not looking forward to this one at all. I had 4 days to stew, think, whine and complaine. Friday comes around and parts and tools bought. Half day at work then the real work begins. Boy o boy was I surprised! 6 hours of just moving easy nothing really hard and for a transverse engine not super tight. Moral stayed high the whole time.

Done!

Now you might see something strange between the two pictures. The chain guide in the middle of the two gears looks really different. Yea.... So apparently my engine had an old style chain tensioner that is prone to failing. It apparently had failed long ago and the chain rubbed through the original guide and little bits of metal.... everywhere. Every. Where.

Going to give it oil changes and such as long as I can. Not going to bother about it too much at this point, maybe throw in some magnets or something but I wont have my hopes up. Pretty sure damage is already done and its only a matter of time. Maybe then the Corolla will be my daily driver then. Who knows. But good news! No sign of a bent valve. The engine started up super duper easy, it runs smooth and doesn't rock like its missing or anything. Drove it to the auto parts store to return a socket I never needed ( who knew I already had a 32mm socket because I didn't) and it drove great!

Until next time. Working on the doors of the Corolla, the door sag is real and the passenger side doesn't open from the outside.

You can put a few magnets on the outside of the oil pan. It will trap some debris and is quick and easy. I would put them above the drain bolt and pull off when changing the oil so the pieces can drain out.

jfryjfry said:You can put a few magnets on the outside of the oil pan. It will trap some debris and is quick and easy. I would put them above the drain bolt and pull off when changing the oil so the pieces can drain out.

Ecotec has a cast aluminum oil pan. And, if I am not mistaken, all GM drain plugs from that era are magnetic.

Life. Life finds a way..... to annoy me. Several months of driving "White Fang" (2003 Saturn) and flushing the oil system several times, it was not enough. 9/26/19 on my way home from work, I accelerate to pass a person, and, well I am not accelerating like I would normally do and there is a strange noise coming from the engine. Sounds like an airplane under my hood. Ohh no. Rod knock big time. It is time to put White Fang out to pasture because, due to some extra ordinary expenses that have happened lately, my family cannot afford to fix it. So sell it we must. After thinking about what would be most cost effective, good ol Rusty to the rescue! I have periodically driving Rusty around the block a few times just to fiddle with it and such. Nothing major has changed at all. Until tonight. (sorry for bad pics, my phone is messed up too)

I noticed that driving around creates an oil puddle underneath the car that is concerning. I jacked it up and looked around for any clues.

the dirtiest transmission on the planet. I am pretty sure that the main seal is bad and 100% the output shaft seal is bad too. Going to drop the transmission and replace all the seals I can because I'll need to drive this as is for an unknown amount of time. I started by taking off the exhaust from header to right after the cat. The piping is bent and there is a nice hole from where an old EGR pipe used to be blowing a nice black spot on the underside of the car.

after that I worked on the drive shaft. It is a two piece design, no problem. I clean off an area on the driveshaft where it bolts together and use a marker to line up again. I unbolt it fairley easily and drop the back half.... then a heart attack!!!

I couldn't see them at all with the driveshaft in the way! Raid to the rescue and problem solved.

and finally the shifter. Tomorrow I will drop the transmission as I wait for parts to come in the mail. I ordered rear main seal, input shaft seal, output shaft seal and a water pump because I think I see water coming from the weep hole. Hopefully by Friday this will be on the road to get new tires and inspection and all that legal jazz.

Also some very dear friends are letting me use their Jeep as my family gets back into shape.... I must say Jeep life is not for me, at least not a soft top that flaps in the wind and death wobble.... I am still blessed though. Until tomorrow.

In reply to oldeskewltoy :

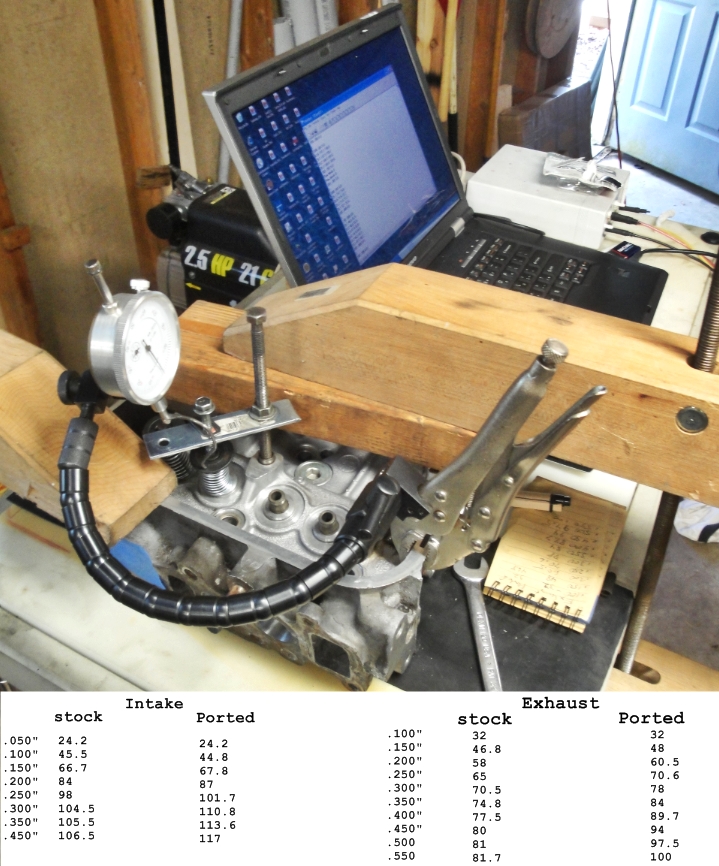

That is some port and polish! are you force inducing it? or just making it way better than it is.

Rishme said:In reply to oldeskewltoy :

That is some port and polish! are you force inducing it? or just making it way better than it is.

Looking for improvement....

In reply to oldeskewltoy :

Man thats pretty cool. Im pretty interested to see what you come up with!

Well time past and I have been working at it. (sorry for the blurry pictures. I have been having trouble with my phone so some of the pictures are blurry then others not and this makes me sad)

Crazy dirty transmission is out! Pro tip #38. make sure you jack up a car high enough to use a transmission jack.

You can see all that oil on the inside of the bell housing and that's why I think the main seal is out. Working with a transmission this dirty is pretty awful. Gets on your hands and impossible to get off and your clothes, and your eyes just looking at the thing. So promptly pressure washed. I sprayed a degreaser on it over night and that helped quite a bit.

Pressure washing it, I made sure to stay away from seams and the shifter and seals. I didn't want to ruin anything by making it cleaner. With that out of the way the clutch, flywheel and dust shield came off. The whole area is covered in oil and just awful as well.

You cant see it in this terrible photo but there is oil coming out from the bottom of the seal. Mission confirmed so that makes me feel better about this endeavor. I started working on taking out the seal and it is attached to an aluminum plate that is bolted to the block but also the oil pan. ...... I was pretty frustrated with this news because getting a good seal on the oil pan might prove to be pretty difficult. I left it for the night and slept on it. I came to the conclusion pulling the engine would be the best bet and would make working on it much easier. So everything connecting the engine to the chassis came off or apart.

And bam!

And she is out of there.

Dirt dobber nest under the engine next to the steering rack left for good luck. And off to the pressure washer.

It wasn't near as bad as the transmission but there were areas so full of grime that it completely hid a bolt or two. Mostly near the front of the engine with pulleys. As I let that dry I attempted my hand at welding. Its been over 10+ years since I last welded anything, what could go wrong?! The culprit: a hole formed on a nub from the cat from prior EGR stuff that was moved by an owner from the past.

I cleaned the area and started to weld with a trash heap of a flux core welder..... Oh my it was awful. It was bad, oh so bad. I kept burning through and making more holes that it originally had. A new idea need to happen. So a scrap metal piece cut into a square for a round hole.... yep. I hammered off the 90 degree bend and started welding. And grinding, and welding some more and grinding a lot more, until!

Ugh I hope it works. To tell the truth its pretty bad. But a mushroom weld plug gives at least 2hp so Im going for it!

With the engine dry I start work on cleaning and scraping and cleaning and scraping. My oh my did that take way longer to get off and clean that aluminum plate than one would think, but the end results are not bad and that puts to rest any doubt of a bad seal.

This "almost" looks new - said no one.

and with all the parts cleaned and ready, RTV was put on with a paper gasket and put on. The new rear main seal went on pretty easy, I just took it slow and a block of wood and hammer gently tapped it in going in as much as a star pattern as I could. The new rear main seal feels great and I have no doubt this is a quality part.

The oil pan was next and I cheated and used a wire wheel angled out so no or little to no debris would fall into the pan. Then gave the inside a gentle wipe down just to make sure.

(this camera focus thing is driving me nuts)

RTV and put it on (no pic) and just waiting over night before putting the engine back into its home.

You'll need to log in to post.