Really interesting motor. Geeking out on the build. Judging from the molds, would there be any value in massaging the valve pocket where the valve pokes through, especially on the exhaust side?

In reply to oldeskewltoy :

Terrific info and pics - thanks so much. So is that big cylinder below the table a mass flow meter of some sort? I'm guessing so. Does it take into account temperature?

Do you run the shop vac in "suck" mode for the intake valves, and "blow" mode for the exhaust?

So cool.

TVR Scott (Forum Supporter) said:In reply to oldeskewltoy :

Terrific info and pics - thanks so much. So is that big cylinder below the table a mass flow meter of some sort? I'm guessing so. Does it take into account temperature?

Do you run the shop vac in "suck" mode for the intake valves, and "blow" mode for the exhaust?

So cool.

Temp and barometric pressure inputs required

Yes... I also try to do exhaust first... less heated air(from vac) running through the head that way.

Jerry From LA said:Really interesting motor. Geeking out on the build. Judging from the molds, would there be any value in massaging the valve pocket where the valve pokes through, especially on the exhaust side?

The castings were done pre port work. The intake side is a much smoother transition from bowl to seat. On the exhaust side that was part of why I flowed the head. As long as exhaust flow is 65%, or greater of the intake flow, the exhaust side is usually good to go. In this heads case we are @ 180cfm on the intake, 65% would be 117cfm. In this heads case, with the exhaust flowing 136cfm(vs 180 for intake) we are at 75%... so no need to change the exhaust

oldeskewltoy said:Typically when you order new pistons, you plan for an overbore...

The cylinder liners are in very good condition, with no ridge at all, and only the very top of the bores no longer showing hone marks.... but the liners are likely a few ten thousandths different... so the intention at the shop now is to re-hone, and set all bores to within one ten thousandth (.0001"). With that final figure, I'll pass that along to Traum pistons so we can have the pistons made to the bores, instead of the other way around.

The cylinder liners were nominally under 87mm, so with final hone they will be 87mm dead... or more correctly 87.0008mm, or 3.4252"

In reply to oldeskewltoy :

So are you specifying what piston dimensions and features you want them to make?

In reply to TVR Scott (Forum Supporter) :

nope... showing the new piston being made for me by Traum Piston... Off-set wrist pin, essentially 2 sets of four.

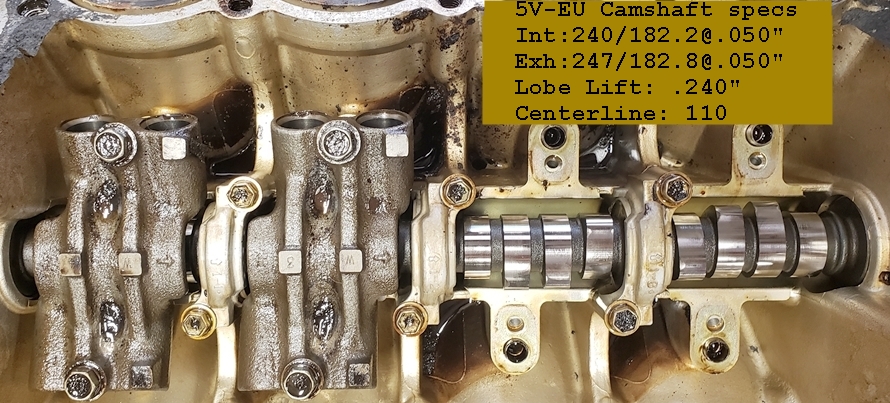

Spoke to the cam grinder this morning.. I have the specs on the stock 5V-EU cam.........

intake overall duration 240 (182.2@.050"), and exhaust 247(182.8@.050") lobe lift is .240", and as I said before 110 centers.

Hello oldeskewl, what do you plan to do to help the reground cam stay alive with modern oils? Tufftriding ? Joe Gibbs oil ? Lucas zinc additives?. I'm rebuilding a v8 myself that had a flat lobe now I'm getting paranoid.....

Agent98 said:Hello oldeskewl, what do you plan to do to help the reground cam stay alive with modern oils? Tufftriding ? Joe Gibbs oil ? Lucas zinc additives?. I'm rebuilding a v8 myself that had a flat lobe now I'm getting paranoid.....

I'll likely talk to my cam grinder, and the guys @ Portland Engine rebuilders... one thing is certain - I can't afford the wrong answer - as finding another 5V-EU cam wouldn't be easy....

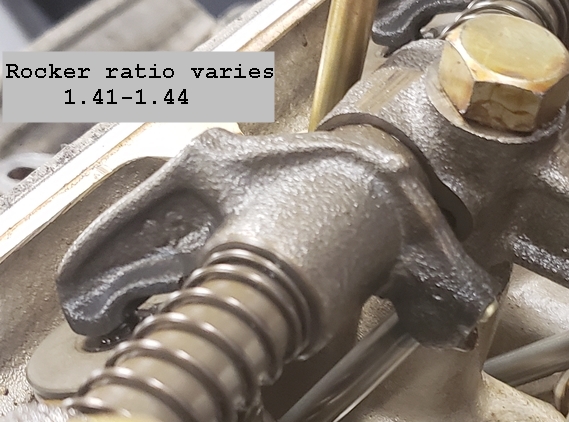

Here are the original cam specs... and now including the rocker ratio

more to come.... ![]()

A slightly better photo of the piston....

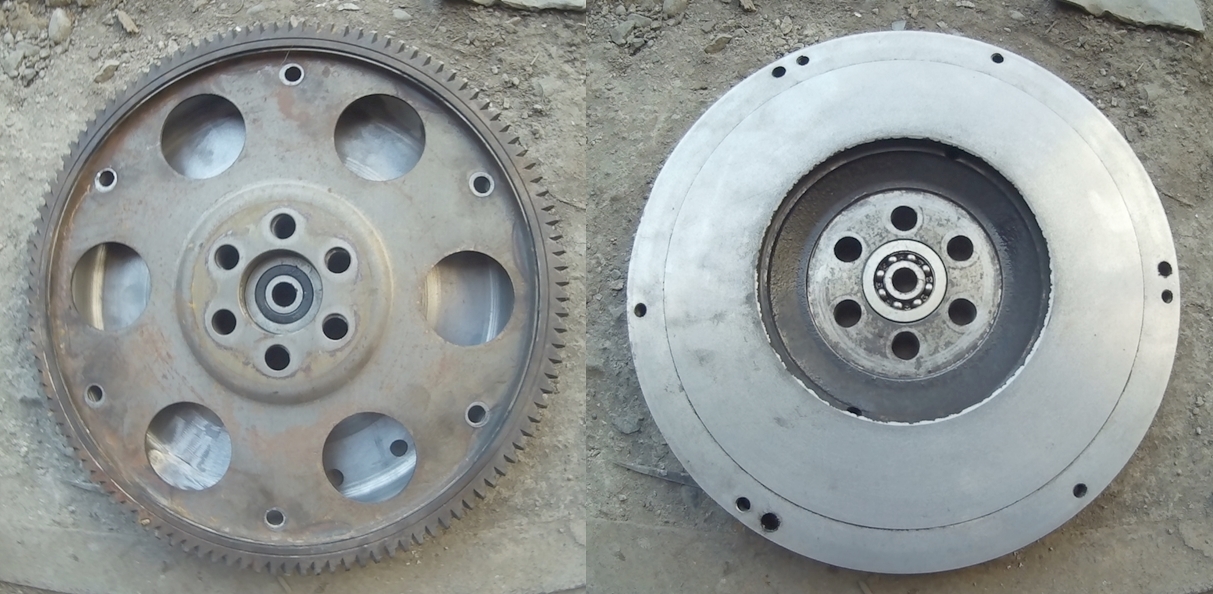

And.... I may have a line on a flywheel that can work... or be made to work.......

in another forum a Russian member spoke of a 1SU(2SU) Toyota engine - (predecessor to the 3S?) and its flywheel(SX70 chassis code, possibly SX60, and ST141 as well).... It seems to be VERY close in size to the 5V-EU flexplate.

Part number: 13405-69036, possibly also 13405-63010

Photos below show 5V flexplate and 1SU flywheel together...

Now for those that know Toyota... the 2S engine did make it to the USA in the 1st gen Camry(83-86). The Camry flywheel does have a different part#, but is also 6 bolt, and the ring gear (verified on Rockauto) is 11.588" (5V flexplate I measured @ 11.6")

I went on car-part and found a yard that had one available... sooo I'm shooting craps($70).... we shall see........................

edit - Camry flywheel....

more to come....... ![]()

Agent98 said:Hello oldeskewl, what do you plan to do to help the reground cam stay alive with modern oils? Tufftriding ? Joe Gibbs oil ? Lucas zinc additives?. I'm rebuilding a v8 myself that had a flat lobe now I'm getting paranoid.....

I'll be running Penn Grade Race oil... likely 10w-40. My cam grinder (Oregon Cam), recommended the Penn Grade as it has the zinc, and phosphorus that a flat tappet camshaft requires......

"New" camshaft specs have been decided.... 268 advertised, 218@.050" with a cam lift of .303" valve lift should be about .435"

Additionally... for my engine, I'll NOT be using over the counter motor oil... I'll be using a motor oil high in zinc and phosphorus - it uses a flat tappet cam, and we are making it more aggressive, so it'll need all the additive help it can get.

Alright... the 2S flywheel will "fit" the 5V crankshaft.... YES ![]()

The center hole fits the crank snout, and the bolt spacing is correct. What is still unknown is if we will need a step/shoulder type bolt or not, and what the back spacing is - we'll need the crank in the block, and the starter fitted to verify back spacing.

more to come.....

With 1.4:1 and relatively light valves compared to other pushrod engines, you are kind of a best case scenario.

What diameter are the lifters?

Pete. (l33t FS) said:With 1.4:1 and relatively light valves compared to other pushrod engines, you are kind of a best case scenario.

What diameter are the lifters?

Very close to SBF (.874), the 5V-EU lifters are about a thousandth, or 2 smaller - part of why the cam isn't much more aggressive, the lifter is only "moderately" sized (diameter)

Dan, your projects compelled me to sign up here just to follow along (also, I miss participating in a decent car forum). Let me know when you get that manifold scanned and I'll see if I can come up with a CAD pattern to get flanges cut for some headers.

DarkMonohue said:Dan, your projects compelled me to sign up here just to follow along (also, I miss participating in a decent car forum). Let me know when you get that manifold scanned and I'll see if I can come up with a CAD pattern to get flanges cut for some headers.

Welcome........

As mentioned above, OST let me draw up some header flange patterns. He shipped one of his exhaust manifolds down a couple of weeks ago and I finally made time tonight to get this done. There are two CAD models, one for individual port flanges and one for a common four-port flange. After I modeled them in CAD I exported them to STL, then imported the STL into Sketchup to create this image. It sounds convoluted but allowed for a better rendering than the CAD program was able to provide.

One interesting feature is that the stud holes on the two inboard cylinders measure 9mm in diameter, whereas the outboard cylinders' holes are 12mm. This is a fairly common approach to prevent breaking fasteners when manifolds get hot and expand, but I didn't expect to see that big a difference on this kind of application. Maybe Toyota was hedging their bets against the embarrassment of a bigwig schmaltzing around town with an exhaust leak ticking away under the hood. At any rate, the disparity you see in hole sizes is deliberate.

For reference, these flanges are modeled as 3/8" thick, which is pretty universal for header flanges. The port openings are 34mm diameter for the first round, but that is easily changed if you want something different. We can talk offline about how you want to proceed, and once we figure it out I'll email the files to you.

Anyway, here's what we have tonight.

In reply to oldeskewltoy :

I can't even imagine That precision on honing. I have a 5v engine in a t-buket not completed for many years. My engine was like new when I received it. The double deck distributer was broken too. I assumed it was for running on 4 cyl at lite loads and 8 cyl at speed. If you need a dist modified I can machine and weld on any top part of dist you want. I built a small open plenum manifold with front two cyl into the front and back to cyl in back and two runners on each side with a n edelbrock 4 barrel. the runners are aluminum tube welded to the stock manifold flanges and plenum. I made the same setup on a 928 porche that worked great.

I read but have not checked that 20r toyota pistons and head gaskets work.

I have ported and installed 2mm oversize valves in many 2tc and 3tc heads, but they work at very high rpm or high boost and I don't intend to use either on mine.

After the huricane blew away my shop I sold it and retired with a lathe, mill and welder. I still do a lot of race car work and welding was my speciality but at well over 70 years old my welding is not world class but I have a lot of experianc and am still very good If you need any speality work I am here to help

You may or may not be aware that Titan Speed Engineering makes roller tip rocker arms for the 2/3TC's at the request of some drag racing folks in Puerto Rico. Maybe these fit & help, and maybe not. Figured if you weren't aware of them then you couldn't make a decision.

https://www.titanspeed.com/content/rocker/rocker_toyota01.html

ntsqd said:You may or may not be aware that Titan Speed Engineering makes roller tip rocker arms for the 2/3TC's at the request of some drag racing folks in Puerto Rico. Maybe these fit & help, and maybe not. Figured if you weren't aware of them then you couldn't make a decision.

https://www.titanspeed.com/content/rocker/rocker_toyota01.html

Thank you!!!!

Called and spoke to Titan earlier today.... They took a look... and I'm back to fixing these rockers, and running adjustable pushrods. Cost would be astronomical... and there just isn't a market to make a custom rocker pay off........

You'll need to log in to post.