Whilst the majority of this forums readers (no doubt) rush to the phone, post-it note with local OPC number scrawled on it in hand, I'll stuck up some photographs of what I've been up to recently:

Starting position:

Thanks - I enjoyed wandering around with my camera.

Flow-bench news!

At 0.5" of lift with the 100mm bore (3.7) we get the following (what I'm going to describe as, knowing no better) path:

Intake* 247 CFM

Head (intake side) 277 CFM

Head (exhaust side) 197 CFM

Tubular manifold 168 CFM

So! Restrictions in both the intake and the exhaust, for the intake the only way forward that occurs (other than the ITB route) is the X51 alloy intake, but last time I tried to order that from Porsche they confirmed that it was available, but not when. On the exhaust side this was a huge surprise - it's an equal length, tubular manifold - similar to the FVD units. Does it simply need to have a larger diameter of primary? Or am I missing something obvious? (This is entirely possible).

* ie, all air entered through the 77.5mm plastic throttle body aperture complete with entry ring

I'm going to guess that the Official Porsche Centres of North America have not got back to anyone yet - still, plenty of time before the engine comes out for it's rebuild.

I'm wondering about intakes, as far as I see it I have a number of options, in escalating order of price and complexity:

- Standard plastic air distribution units with a larger plenum, and a larger throttle body on said plenum

- X51 alloy air distribution units with X51 plenum, larger throttle body (this is unlikely as I think the X51 parts are NLA)

- Jenvey ITB's in enclosures, fed from the existing airbox, via the existing MAF (close to the Porsche approach for the RSR etc)

- Jenvey ITB's wearing jaunty foam socks, management altered to run Alpha-N

I'm leaning toward option 3, but it would make much more financial sense to go with 1. But not such a good noise, of course.

In terms of exhaust I'm not entirely sure where to go here - the best I can think of is to ceramic coat the manifolds in question and hope that keeping exhaust gas temps high persuades said gas to scarper rapidly. There's really not a great deal of room for more gentle turns under the engine, which I imagine is why Porsche themselves seem to have kept to a more log-manifold type approach, rather than the equal length/nest of snakes that is the manifold tested.

I think a lot will come down to cam profile, which is the domain of the engine designer (who ran the flow bench tests), but I'm trying to think through all the options myself as it's a) a big part of the fun and b) I'm interested in understanding these things better than I do at present.

A chap who posts on some UK forums is making 370 BHP with the manifold seen in the test results, with a larger throttle body and plenum on the intake also seen in the test results - but the engine does rather fall on it's face at 6,250 rpm, if it revved out cleanly for another 500 rpm it'd be producing 400 bhp, and rather a nice noise I imagine - which is my goal.

I am aware that my choice of 911 is not what most would select for Ohlins coil-overs and a screaming, lumpy cam'd motor - but I quite like it.

Ok, I am a bit stuck- the stock intake won't support the cam profile we want to use.

So- a cry for help, if you will: if anyone has a lead on an M96 X51 intake I'd be extremely grateful. Long shots are fine.

Thanks in advance, chaps.

We're redesigning the tappet carrier to allow 12mm lift to be gained from the cams without FUBAR'ing everything, more of that to come.

In the meantime, stuff has been happening:

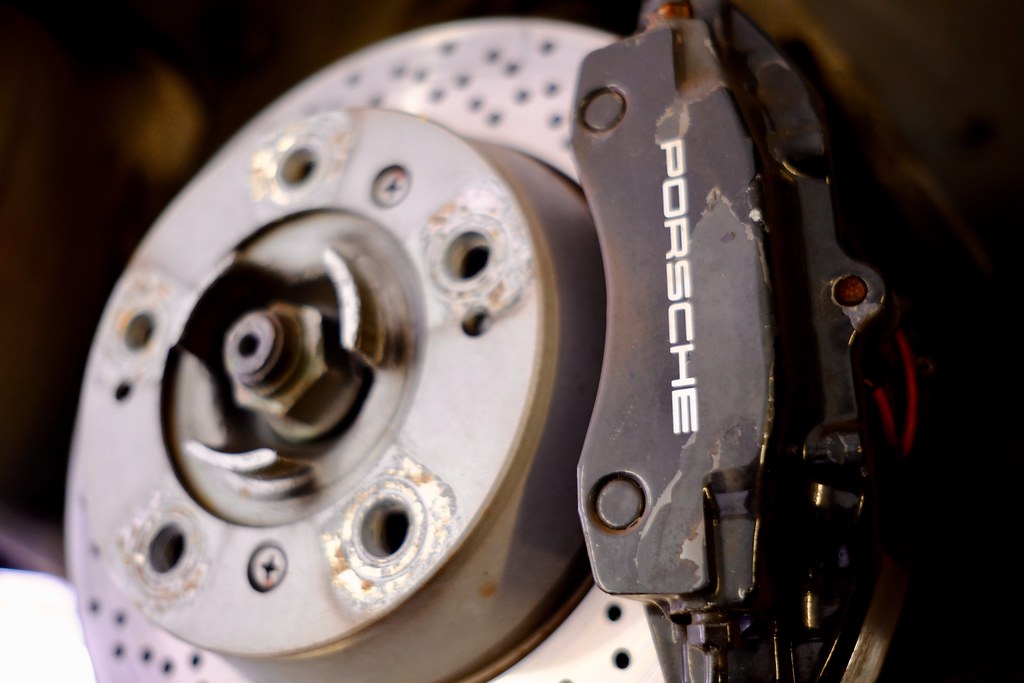

Thanks! I'm glad I chose to refurb the calipers at the same time, it's one of the details that would have really stood out (badly) if I'd left it.

I need some advice on seats.

I am 6’2” and 185lbs (or 187cm/84kg for the metric amongst us), and would say (without trying to sound too much like a Grindr profile) that I am athletically built- I run, cycle, lift.

With that in mind- would I fit in a Recaro Pole Position, or would a Profi-SPG be better?

Somewhat to my astonishment the trimmers claim to have found 2" of drop in the standard hardback sports seats - which if 100% accurate is fantastic news. Sneak peak of one of said chairs just cropped up on their Instagram:

New roof:

And we re-trimmed the roll-over hoops and the side flaps in matching fabric to the roof, so it matches when the roof is down:

And the chairs in the car now:

Looking great. Wonderful project. Probably not many among us that do these sorts of things on this sort of car.

I really like the look of the glossy silver back on your seats. Consider having the center console painted to match? Did the sport seats give you the drop you wanted for a better position?

Thanks - I think the seats look great, albeit I've only seen them in the photographs shared above.

I asked the bodyshop to do the handbrake console in body colour and he, well, he didn't quite refuse - but he made it clear that he thought it wouldn't look good, so he didn't want to. My thinking was that I could always do it later, so I said to skip it.

I'm in Corsica for a cycling holiday next week, then hopefully when I get back I can pick the car up - it'll have been over five months since I've driven it, and three months since I've seen it in person, which is not quite what I had expected when I dropped it off, but there you go.

Question - would it be insane to import this car to California?

California option is off the table - I didn't get the job.

We're slowly closing in on the engine specification, it's been evolving over time but I think we've got some conclusions on some parts now.

The M96 engine is slightly odd in that the crank, at the flywheel end, is unsupported - which had consequences.

Initially the crank was solid, which meant that as it flexed it transferred significant load into the closest main bearings, dramatically increasing the wear on those. Porsche decided to make the next generation of cranks hollow at the end - and machined out the centre. This made the crank more flexible, but the flex was contained within the hollow part of the crank, not transmitted straight into the bearings - but these cranks can crack.

So we're returning to a solid crank - forged from EN40B steel. We're also fitting an additional bearing that sits right behind the RMS, which requires said seal to stand slightly further out than stock. The only EN40B cranks available are for the 3.6 litre engines (when bore is 96mm) rather than the 3.4 which I currently have.

I'm in the process of sourcing a 3.6 litre crank carrier - the main bearings are usefully thicker than the 3.4 as well, so this is all good news. We'll use Carillo rods, and new pistons to fit into the 100mm Capricorn liners which will be fitted after the stock liners are machined out. We'll close the deck at this point, also. This will give us a swept capacity of 3.9 litres, so up 0.5 litres from my current engine.

The heads are being lightly ported, the tappet chests we are completely redesigning and will have machined from billet in order to address some issues that they suffer from as stock, and also allow for higher lift cams to be fitted - these will be specified and ground to match the new capacity and overall design of the engines. I believe we're sticking with stock valves as they flow (impressively) well.

Porsche motorsport provide the X51 kit for the 3.4 engine, and we're using some of their parts here - specifically the intake manifold, the extra oil scavenge pump fitted to one head and the additional radiator that fits beneath the number plate - with an additional thermostat inline to stop it opening too early.

Exhaust manifolds are likely to be Cargraphic long-tube, equal length items as they are the correct diameter for our predicted use.

Not sure on the throttle body at the moment, an 82mm unit of some description but I don't know which one, I'd prefer to stick with cable, but the Syvecs unit can support eGas and that might be easier.

With the new crank, ARP fasteners, Carillo rods and the revised tappet chest we should be ok to push the rev ceiling on the engine up a little, will be very interesting to see what the engine designer thinks is appropriate there - the 3.7 (which would be the result of using the 3.4 litre cranks) is over-square, the 3.9 has a longer stroke so is not as suited to a high revving application, but that said the engine is going to be pretty robust with the updates so we shall see.

Ok, I keep going round and round in circles here. Whilst there is no huge urgency I spoke with Hartech yesterday and am hoping to get a shortblock assembled toward the end of summer (I am aware that we are at the start of said period at the moment).

This requires decisions being made- or, rather, a decision.

Making this as simple as possible - 3.7 or 3.9?

The 3.7 would be a 100mm bore with a 78mm stroke

The 3.9 would be a 100mm bore with an 82.8mm stroke

We're making changes in the bottom and top end to mitigate issues that might limit revs, and whilst my instinctive reaction is "bigger is better" I can't help but return to "but a shorter stroke might be happier and faster to rev", and it's that high rev howl from the flat-6 that is such a part of the character of these cars for me.

So - which one, and why, GRM'rs?

You'll need to log in to post.