Over the week, I got the shut pillars welded in and started on the rockers. There's a gusset that connects the shut pillar to the rockers, so this is the next step that makes most sense. I was a bit tired and was just about the chop the rockers in half because they weren't fitting right. My adult brain prevailed and I went home.

I got back to the shop this weekend and spent some time with a clear head looking at the fitment of the rockers - they definitely need to be shortened. Not sure if this is because of the trimming of the door, the fact that it's a poor pressing or a combo of both. The driver's side was off by about 1/4".

I measured a number of times and then made my cuts.

Muuuuuuch better!

Then I welded the seam upt and got it mostly secured in place. Still need to weld the top edge.

NOHOME

UltimaDork

1/14/19 8:59 a.m.

Now sit back and count the hours you have into this door and rejoice in the fact you are not paying someone over $50/hour to to the work. I know someone who does restos on healeys for a living; and his builds are closer to $100k than not. As crazy as that sounds, he is booked for years.

This is moving along nicely.

If I go back to the start of this project I can see where you are getting a lot more confident in your solutions to making tin go where you want it to go.

Pete

Welcome to reproduction sheet metal. I have yet to buy a piece from any supplier that is a direct fit. Some are better than others, but none are perfect. I is not just the variation in Healeys, although that is a contributor.

NOHOME said:

Now sit back and count the hours you have into this door and rejoice in the fact you are not paying someone over $50/hour to to the work. I know someone who does restos on healeys for a living; and his builds are closer to $100k than not. As crazy as that sounds, he is booked for years.

This is moving along nicely.

If I go back to the start of this project I can see where you are getting a lot more confident in your solutions to making tin go where you want it to go.

Pete

Oh, I completely believe the six-figure mark. Before I started taking the car apart way back when, we priced out even base-line restorations that put the project in the realm of zero possibility. They would have also cost significantly more than this car would be worth finished (not a huge factor). At least in recent memory a numbers matching BJ8 could fetch $100k+.

I'm still far from what I consider to be competent but I do also feel that I've come a long way. I really should have taken on a smaller project to learn on first...

TurnerX19 said:

Welcome to reproduction sheet metal. I have yet to buy a piece from any supplier that is a direct fit. Some are better than others, but none are perfect. I is not just the variation in Healeys, although that is a contributor.

Yeah, it's really nuts how off the panels can be. The Kilmartin stuff for Healeys has been the best for me but even those required some massaging in most cases.

Just some more evidence that I'm a sub-par fabricator/welder with a Healey getting closer to being close.

NOHOME

UltimaDork

1/23/19 8:48 p.m.

Those welds are just fine! Remember, Healeys ( like most Brit cars) are really just parts traveling in close formation.

Pete

NOHOME said:

Healeys ( like most Brit cars) are really just parts traveling in close formation.

Hah!

Thanks. I suppose as long as the glue holds, it's sticky enough...

More of the same. Both sides have a couple more stitch welds to do once the doors are off again but more-or-less, both rockers are in.

Between temps in the teens and single digits (doesn't mix well with a garage that has no heat) and general busy-ness, I haven't been able to put as much time in recently. Hopefully in the coming weeks I'll have more opportunity to knock some stuff out.

dougie

Reader

1/28/19 11:30 p.m.

Looking really good Alex! What are your plans for the motor?

Hey Doug, thanks! (Andrew by the way) Since the focus is really on getting the Healey back on the road at this point, it'll just be new gaskets and a general clean-up / paint for the time being.

Last night was my only chance to work on the Healey this week and coming weekend so I forced myself out of the house to the shop. I finished up the welding on the shut pillar. Only thing left on both sides is the gusset that goes behind the door striker. That will have to wait until I actually have door strikers...

I've only been using about half of the mounting holes for the fenders/quarters because the other half don't line up. I started slotting the ones that don't line up and my Dremel ran out of juice. Time to dive into body panel rust repair. Remember how I've mentioned the metric ton of filler on this car..?

Behind that half dollar-sized mess of filler was almost no metal at all...

Fiberglass.

I think I can rest assured that no matter how poorly I view my skill set, this car will be in significantly better shape when I'm done with it than when the last guy "restored" it.

After much measuring (check all the various sharpie lines...there are more on the other side) I made my cut.

Some trimming later and it's fitting pretty well. At this point I was starting to feel myself fading so I called it quits.

My original plan was to use a flanging tool to make welding this patch panel in easier but I realized that wouldn't be any easier. New plan is butt weld the entire length - I'm hoping to be able to do most, if not all from the backside.

I'm to the point where I am 100% over metal work on this car but the fact that I can smell (not taste yet) the finish line is keeping me going. Tons of work still ahead though.

dougie

Reader

2/1/19 11:52 p.m.

Great work Andrew! My '57 lived in Cali all it's life, so the body condition is pretty good. I've had my share of repairs though, all cause by my on track exploits .....ugh.

NOHOME

UltimaDork

2/2/19 3:23 p.m.

Make sure you clean the rust off the backside when you go to weld the panel on. I myself would always weld from the outside, but now that I think about it, cant give you a compelling reason why other than easier to grind the weld?

By hammering on-dolly along the weld seam, ( after you grind most of the weld off) you should be able to get that panel to a near primer ready level of smooth.

Pete

Doug - I think I've told you this before but yours is easily in my top 5 Healeys ever and I haven't even seen it in person! I love the constant improvement that you put into it. It doesn't hurt that it's extremely pretty as well.

Pete - Yes, I've made that mistake before. That and leaving undercoating on the other side of a weld. My thinking in welding primarily from the back is having to grind less on the front allowing me to be less-good at the body work thing. What do I know...

Speaking of welding from the back. One of the 6 major rust repairs on the body is finished! Still needs some tidying, obviously.

Healey time has been hard to find but progress is being made. I've done as best I can with the repair panels but taking measurements from a heavily rusted/fixed with fiberglass panel is difficult. A hawk eye will notice that the dog leg of the rear quarter doesn't look quite right. That's because it's "short" by about 1/16-1/8 of an inch and the rocker will need to be...uh...clearanced.

Since I'm no professional and we all know direct replacement panels certainly aren't direct... the door(s) are going to need to be adjusted further. No problem. I've done it 20 times, what's another 20?

Door adjusted for the *final* time. Rocker and quarter massaged. Everything all together in a pretty-much final form. Exciting.

No time to sit back and relax, on to more rust repair.

I adjusted the patch panel, took careful measurements and made yet another nervous cut for the rear repair on the passenger quarter. No pictures but I think the fit is good.

NOHOME

UltimaDork

3/10/19 3:26 p.m.

You do realize that by the time you are done you are going to be confident enough in your tin skills that you will want to do it all over again just to see how perfect of a car you could build...right?

Pete

dougie

Reader

3/14/19 12:25 a.m.

Andrew -

Your work looks great, these cars were hand built in the time and none had the perfect panel gaps of the German cars.

Yours looks better then my factory fit 57 100-6 MM. Hope to see you on the track soon. Keep up the awesome work.

In reply to dougie :

Thanks Doug!

I hope to be able to finish up the passenger quarter this weekend but time will be tight with family in town for our daughter's 1st birthday.

dougie

Reader

3/16/19 10:45 a.m.

I understand those days, you can't miss out on the family events. You'll never get those days back. It's said over and over, but it's so true. They grow-up so fast.......

Great pics! We've already got a few of our daughter in various cars. This was in July at Schenley.

I was able to spend a couple hours this afternoon working on the Healey. First line of business was the rear patch panel on the passenger quarter. It took a good bit of fiddling and trimming and I'm not certain I got it strictly, right, but I think it'll do.

It looks great in the pictures but the angle is a little off. I do think it's workable though. Notice the door handle in place. The latch is also there! No striker yet but it makes things feel just that bit more real.

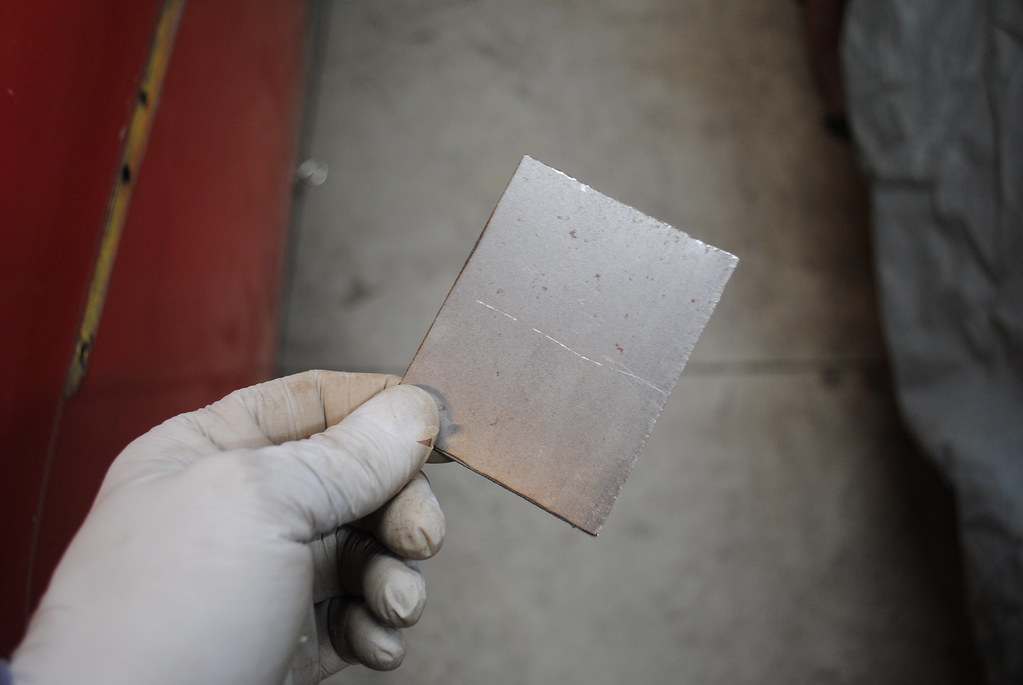

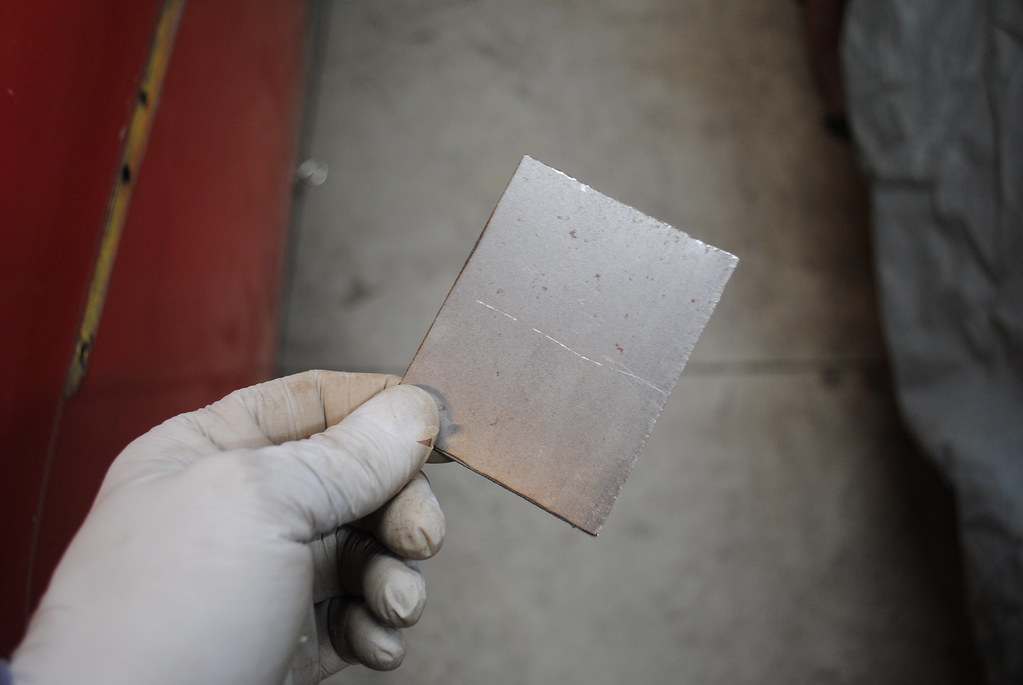

I didn't feel like jumping into the fenders so I decided to work on a patch that I've been avoiding. It started with a simple square...

I didn't feel like jumping into the fenders so I decided to work on a patch that I've been avoiding. It started with a simple square...

Then I put a little bend in it...

Then some slits...

Now we're getting somewhere.

Then welded it up.

Who needs a shrinker/stretcher, right? There's obviously a lot more cleanup needed but I hadn't had much to eat and my hands were shaking. Power tools and shaky hands is not a good combo. In hindsight, it makes more sense to do fewer cuts. I may start from the beginning but as a proof-of-concept, I'm pleased.

NOHOME

UltimaDork

3/17/19 8:14 p.m.

In reply to AxeHealey :

EVERYBODY needs a shrinker stretcher.

Funny enough, re-shapping a brand new Healey fender is where I discovered the value of the shinker.stretcher tools. But there is always a way to get it done if you can weld.

Pete

In reply to NOHOME :

Yeah, that comment was a bit tongue-in-cheek. It's doable but what a pain.

dougie

Reader

3/25/19 11:02 p.m.

Great work, keep it up. Love the checkered flags on your daughter's shirt, was that from you or mom?

I didn't feel like jumping into the fenders so I decided to work on a patch that I've been avoiding. It started with a simple square...

I didn't feel like jumping into the fenders so I decided to work on a patch that I've been avoiding. It started with a simple square...