Great thread-is that a two door Tahoe in your collection? Really wanted one, settled for a four door due to condition.

Great thread-is that a two door Tahoe in your collection? Really wanted one, settled for a four door due to condition.

It's actually a full size Blazer before they made the Blazer S10 size and made the full size the Tahoe. The good side.  The ugly side.

The ugly side.  The bondo over expanding foam.

The bondo over expanding foam.  This is the one I bought with the missing body ground and sold within a couple of hours of putting it on CL. I've always wanted one also. I was in college when they came out and I thought they were the coolest. Unfortunately it's was one of those things I was more in love with the idea than the actual vehicle once I got it. Nothing wrong with them just I guess I crossed it off my bucket list and moved on. They still catch my eye though.

This is the one I bought with the missing body ground and sold within a couple of hours of putting it on CL. I've always wanted one also. I was in college when they came out and I thought they were the coolest. Unfortunately it's was one of those things I was more in love with the idea than the actual vehicle once I got it. Nothing wrong with them just I guess I crossed it off my bucket list and moved on. They still catch my eye though.

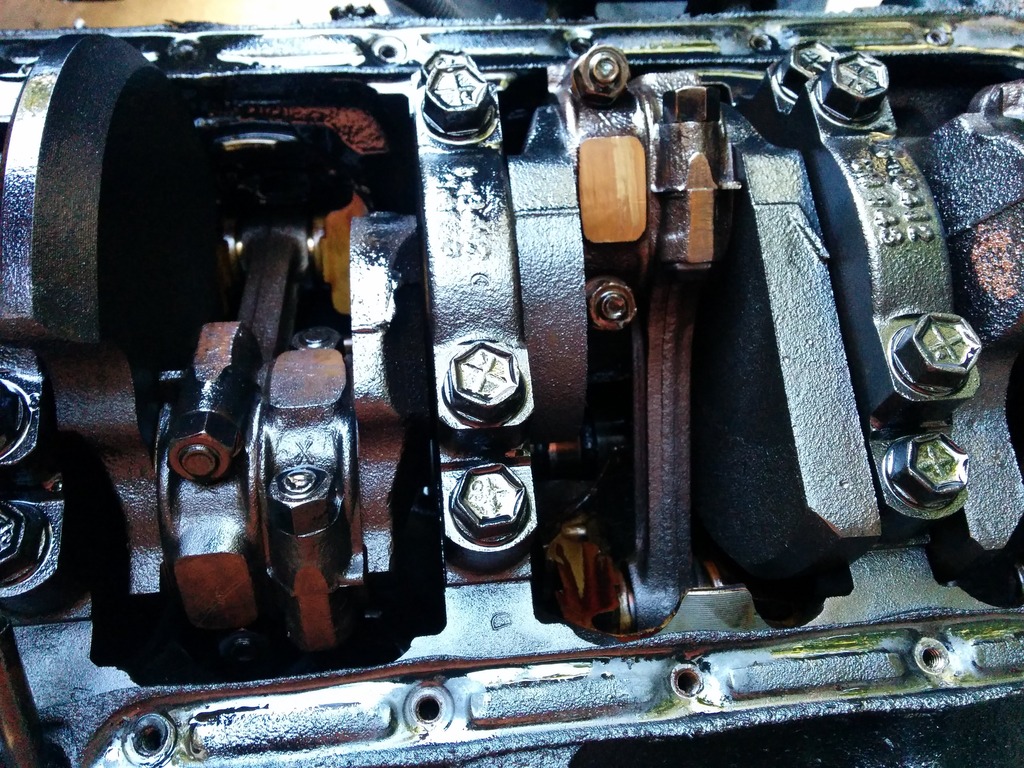

A little update while I wait for Costco to open up. You may have noticed that we're no petegossett or mazdeuce. At this point I've had the K30 for 6 months and all we've really done is put in a starter and break the block. A lot of donuts gave their lives for this progress. I agree with the kid that I'll give him everything he needs for the 6.2 including the hydroboost brakes and fuel filter system. We pull it all and swap the engines. Now I'm a little picky about a running engine that's pulled. I leave everything together and "sealed". Well the kid isn't me. He's pulled the valve covers and somehow lost the original carb but finds another one in his barn. Anyway we decide to go through it all. Here's some of us starting on pulling the 6.2 out.  And after a compression test showed it was good (well goodish for a cold unrunned engine) we confirm four bolt mains while replacing the oil pan gasket.

And after a compression test showed it was good (well goodish for a cold unrunned engine) we confirm four bolt mains while replacing the oil pan gasket.  Also it was Chris's great idea to just let the air out of the front tires to make it easier to get the 6.2 out. That of course meant they came off the beads so we had a little fun with starter fluid. https://www.youtube.com/embed/dY7unMGW-CM Only other issue really was somebody decided to fill up both tanks with diesel right after we got it running the first time. I came up with the bright (for me at least) idea to use air pressure to drain them. I hooked an air nozzle to the return fuel line. That pressurized the tank slightly and forced the diesel out the fuel feed line which we drained into buckets. If you put to much pressure the gas cap would vent the excess. Only special thing we had to do was hook up a battery in the middle to switch from the right tank to the left one. 31 gallons took about 2 hours this way. I should probably put in a don't try this at home your results may vary including rupturing your tank warning at this point. But hey it worked for us. That gets us up to last weekend. We're doing all the little things before we get the 350 in. Chris and I spent an hour or so going through the wiring harness cutting out the diesel stuff we didn't need but identifying wiring we could keep like oil pressure, coolant temp, and switched power for the HEI. We had put in the vacuum brake booster a few weeks ago but didn't hook up the brake pedal because well it's was up under the dash. That's why we have kids right? Asa gets under the but says he can't get the arm to fit on the pin.

Also it was Chris's great idea to just let the air out of the front tires to make it easier to get the 6.2 out. That of course meant they came off the beads so we had a little fun with starter fluid. https://www.youtube.com/embed/dY7unMGW-CM Only other issue really was somebody decided to fill up both tanks with diesel right after we got it running the first time. I came up with the bright (for me at least) idea to use air pressure to drain them. I hooked an air nozzle to the return fuel line. That pressurized the tank slightly and forced the diesel out the fuel feed line which we drained into buckets. If you put to much pressure the gas cap would vent the excess. Only special thing we had to do was hook up a battery in the middle to switch from the right tank to the left one. 31 gallons took about 2 hours this way. I should probably put in a don't try this at home your results may vary including rupturing your tank warning at this point. But hey it worked for us. That gets us up to last weekend. We're doing all the little things before we get the 350 in. Chris and I spent an hour or so going through the wiring harness cutting out the diesel stuff we didn't need but identifying wiring we could keep like oil pressure, coolant temp, and switched power for the HEI. We had put in the vacuum brake booster a few weeks ago but didn't hook up the brake pedal because well it's was up under the dash. That's why we have kids right? Asa gets under the but says he can't get the arm to fit on the pin.  Chris gets under and he says the pin is to big.

Chris gets under and he says the pin is to big.  I call bullE36 M3 so I get under there to show them how it's done.

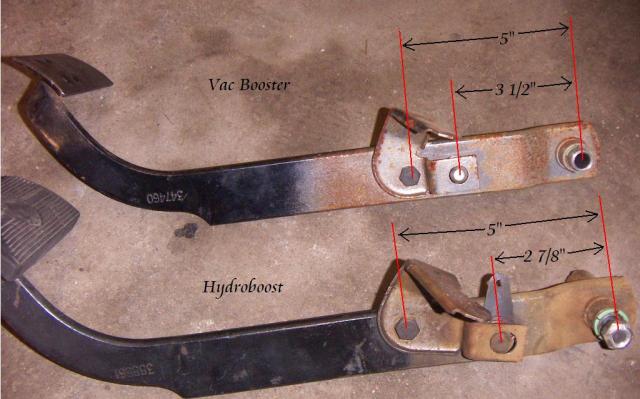

I call bullE36 M3 so I get under there to show them how it's done.  Sure enough they're right and the pin is to big for the hole. Little quick googling shows we need to swap out the pedal also. So there we are all caught up on a typical Stampie project.

Sure enough they're right and the pin is to big for the hole. Little quick googling shows we need to swap out the pedal also. So there we are all caught up on a typical Stampie project.

Triple verified. Good work.

Dumb question, can you just pull the current pedal and drill it out?

Dig the C30 on those wheels an tires!

Well the pin is on the pedal arm so I'd have to drill out the booster rod. There is also a leverage difference. Here's a picture I stole of the differences. They made it hard to steal so strangely I don't feel as guilty about stealing it.

Dusterbd13 wrote: Is this the one for the vortec heads?

So now I can say yes this is the one I got the vortec heads from you for. For those that don't remember John aka Q45 Godfather picked up a set of heads on the way to the Challenge last year. Dusterdb13 was cool enough to sell them to me for a great price and it all came together in typical GRM fashion.

Unfortunately this build is where I'm really learning how to avoid the rabbit holes. Right now the heads aren't on the engine. I was going to but then I started adding up the vortec carb intake, plus, well might as well cam it for the better heads, oh and hmmm I wonder what a basic rebuild with some 10:1 pistons would cost. So in a very untypical moment for me I stepped back and said let's get the running engine in and decide where we want to go from there.

Today's goal was to find a brake pedal in the junkyard for her. Struck out. Wasn't that long ago that I pulled the booster in the same yard but that truck and all the square body Chevy's are gone now. The search is on.

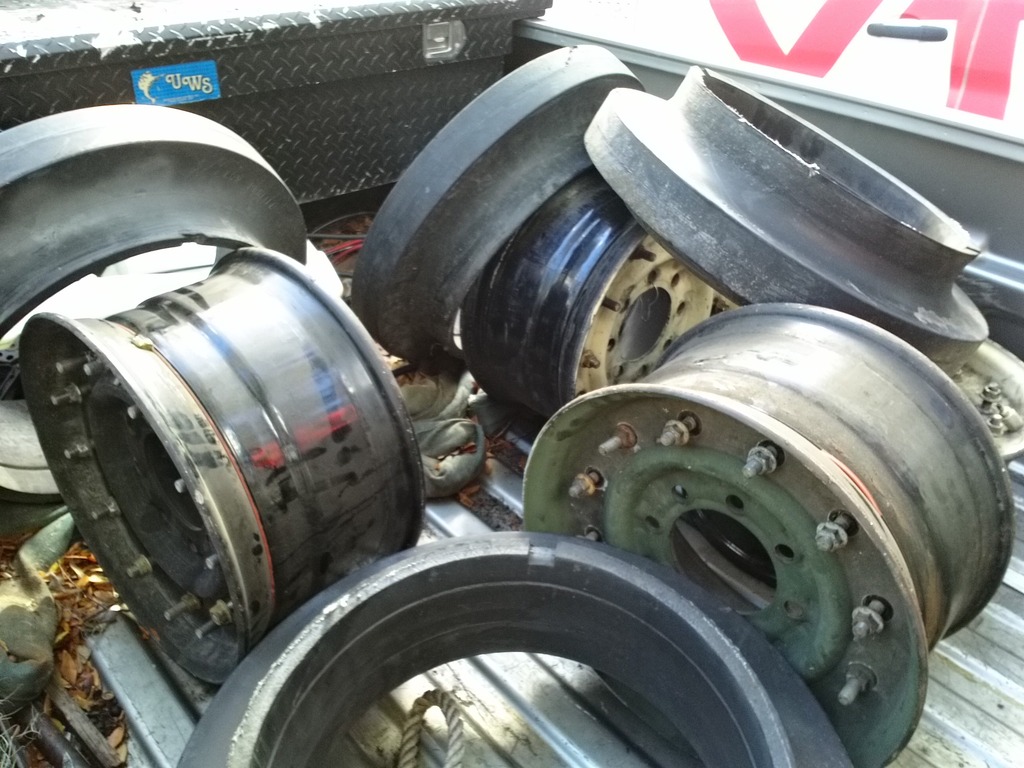

Almost forgot we picked up four H1 Humvee wheels yesterday. Yes the offset is wrong but we're working on some stuff.

In reply to Stampie:

Army surplus wheels? Finally the military-industrial complex is doing something for us, the little guy.

In reply to Billy_Bottle_Caps:

Thanks.

In reply to ssswitch:

Yes. The guy I got my tires from gets them mounted on the rims with the run flats inside. Since the offset won't work for most (any?) trucks the rims are a byproduct of his business. I got those for $25 each and when I asked about the rubber run flats he threw them in free.

Im impressed that the 37s fit your truck without any lift. They look awesome. What's your plan for the backspacing on the H1 wheels?

In reply to 2002maniac:

"Fit" is a very loose term. I had to sawzall a lot of the lower corners of the fenders and about a foot up on the inner fenders. Otherwise pulling out of the driveway was a 8 point turn. I wouldn't off road with the rears as is but they're fine for road use.

As for the wheels I've been talking to a GRMer about cutting some new centers to be welded in the proper position.

In never seriously considered swapping from Hydroboost setup in my Suburban project to Vacuum assist. After reading this thread, I'm very happy I didn't ![]()

Awesome project. We've got a couple of squarebodies around here (at the moment...could be more at any time). Looking forward to following along!

In reply to ClemSparks:

Yes as I read your thread the other day I was telling myself that maybe we should have keep ours. Oh well at least we are learning something new each day.

Stampie wrote: In reply to ClemSparks: Oh well at least we are learning something new each day.

Absolutely! I had to learn about the hydraulic end of the system...you had to learn about the pedal end.

It was K30 day today. Chris and Carol had to work so Asa and I were left to ensure the donut shop stayed in business.  So once Chris got done with work we went over to his house to begin the day. We needed to put the oil dipstick tube in. The kid I got the engine from broke the old one off. Just in case I picked heavy grease down it so that when I used an extractor no chance of shavings getting down the hole. Time to suck out the grease. A McDonald's straw, zip lock bag, and electrical tape made a custom adapter for the vacuum.

So once Chris got done with work we went over to his house to begin the day. We needed to put the oil dipstick tube in. The kid I got the engine from broke the old one off. Just in case I picked heavy grease down it so that when I used an extractor no chance of shavings getting down the hole. Time to suck out the grease. A McDonald's straw, zip lock bag, and electrical tape made a custom adapter for the vacuum.  This of course turned into a long discussion of who's anatomy was better suited for the new tool. OK so grease out. We go to insert the tube. It's not going on by hand and I seem to remember there's a tool to slide over it to make it easier. OK so I really just wanted an excuse to buy a new tool that I'd only use once. Run down to the local parts store and nope. So head back find a piece of angle iron and wack it in with a rubber mallet. Damn that was hard work. Carol has her lunch hour at noon so we head out to meet her for lunch. After lunch we stop at a yard sale and score Asa a nerf gun tripod for 25¢. We then go to a antique/junk store and I see what looks like Qbert with legs.

This of course turned into a long discussion of who's anatomy was better suited for the new tool. OK so grease out. We go to insert the tube. It's not going on by hand and I seem to remember there's a tool to slide over it to make it easier. OK so I really just wanted an excuse to buy a new tool that I'd only use once. Run down to the local parts store and nope. So head back find a piece of angle iron and wack it in with a rubber mallet. Damn that was hard work. Carol has her lunch hour at noon so we head out to meet her for lunch. After lunch we stop at a yard sale and score Asa a nerf gun tripod for 25¢. We then go to a antique/junk store and I see what looks like Qbert with legs.  So yea that had to come home with me. On the way back we picked up an oil filter for the 350 and put it on. Here's what we accomplished today.

So yea that had to come home with me. On the way back we picked up an oil filter for the 350 and put it on. Here's what we accomplished today.  Some days you just don't get much done.

Some days you just don't get much done.

Today was supposed to be Q45 day but since Asa wasn't with me and we needed to junkyard for a brake pedal it became K30 day. The normal you pull its around town didn't have any square bodies. I hit CL and found a you pull it I didn't even know about adverting a C10. We walk in and tell them what we're looking for and ask they say is ya they think they have a couple of C10s. There's no map, no rows, no print out, just a go out and look. Carol's not digging it and we're about to leave when I see a C10. Brake pedal is still there but this truck hit a pole hard on the driver's front. You can see where the steering wheel and lower dash is caved in from the driver hitting them. We decide that removing the whole bracket is the best way. Here's Chris starting on the pedal assembly.  I couldn't let him have all the fun so I joined him.

I couldn't let him have all the fun so I joined him.  For some reason he felt the need to get out of there but I don't know why he did this.

For some reason he felt the need to get out of there but I don't know why he did this.  But after pulling the booster we finally had success.

But after pulling the booster we finally had success.  So then we go to a late lunch at 2:45. Right as we order Chris's wife calls to remind him that they're going out to dinner at 4. Oops. That left Carol and I to put it in the K30. We decide it's easier to just swap the pedals instead of the whole bracket since our dash isn't caved in and we have the room. Here's the two pedals side by side. The vacuum on bottom has a longer leverage with the pin further away from the pivot. Hard to tell in the picture but the pin is smaller which means a vacuum booster won't go onto the hydroboost pedal.

So then we go to a late lunch at 2:45. Right as we order Chris's wife calls to remind him that they're going out to dinner at 4. Oops. That left Carol and I to put it in the K30. We decide it's easier to just swap the pedals instead of the whole bracket since our dash isn't caved in and we have the room. Here's the two pedals side by side. The vacuum on bottom has a longer leverage with the pin further away from the pivot. Hard to tell in the picture but the pin is smaller which means a vacuum booster won't go onto the hydroboost pedal.  Not many pictures of it going in since it was just Carol and I but here's one.

Not many pictures of it going in since it was just Carol and I but here's one.  The pedal return spring about kicked my behind but finally we got it all done. We don't know how well she'll run once done but at least she can stop.

The pedal return spring about kicked my behind but finally we got it all done. We don't know how well she'll run once done but at least she can stop.

So real life and building a deck for Chris got in the way of working on the K30 for a bit. Oh yeah also something about me trying to show Asa how a 44 year old can still skateboard. That resulted in said 44 year old fat ass hitting the ramp so hard it sounded like the MOAB. Let's just say I was sore for a few days. So this morning at a bright and early 10am we hit the donut shop and made a list of things to do over donuts. List wasn't that long but as we started working I think we added two things for every one we crossed off. We got the little things out of the way and head to lunch. Getting back on it after lunch we realized the torque bolts and the bellhousing to engine bolts on the diesel were metric. The SBC is standard. Then after 4 trips to Ace hardware we end up with 9 bolts. Our normal picture taker had to work today so the following pictures were taken from a 9 year old's perspective. Here's the engine going up and over the radiator.  Now I'm holding the fender down while Chris maneuvers the engine into place.

Now I'm holding the fender down while Chris maneuvers the engine into place.  Isn't she pretty and simple?

Isn't she pretty and simple?  And finally she's in with some sexy legs in the background.

And finally she's in with some sexy legs in the background.  At this point we've got the motor mounts bolted in and two temp bolts holding the engine to the trans. Seems 6 of the 9 bolts we got on our 4 trips to Ace are too short. We say berk it and call it a day.

At this point we've got the motor mounts bolted in and two temp bolts holding the engine to the trans. Seems 6 of the 9 bolts we got on our 4 trips to Ace are too short. We say berk it and call it a day.

I've only read the first post so far (I will continue) so I don't know how this is going to turn out but the Crew Cab pickup looks like it would make an awesome 4x4 no-nonsense war wagon. Forget about the Blazer! :)

I'm going to keep reading now....

It always feels very good when an engine sets into place. For me, that always sets into motion the series of events that brings the next big milestone...hearing it run!

Looking good!

Yes and it was a nice milestone. Still a lot of little things to do. I looked last night and we started the engine swap June 4th last year. Hopefully we'll be done by the one year mark.

Last Saturday was supposed to be K30 day but we picked up the BMW instead. So today we worked on the K30. Plan was to do a bunch of little stuff. First on the list was plugging the heater hose coming off the water pump. That took 10 minutes an now the heater hoses are routed correctly. Next we went to replace the front universal joint at the Dana 60. Should have been a quick one also but ended up kicking our behind. Here's us trying to get it apart under the truck.  After that we said berk it and pulled the driveshaft to replace it outside the truck. We got done and then noticed that it's backwards preventing us from getting to the zerk fitting. Made the executive decision to flip it the first time we needed to grease it and called it a day.

After that we said berk it and pulled the driveshaft to replace it outside the truck. We got done and then noticed that it's backwards preventing us from getting to the zerk fitting. Made the executive decision to flip it the first time we needed to grease it and called it a day.

You'll need to log in to post.