Work day today. And I didn't get anywhere near as much done as I wanted due to running errands and a missing tool.

The first set of shelves went up quickly. I had to knock about 2" off the top of the uprights so they could tuck under the 6' high crossbar on the wall, but the sawzall took care of that in short order. These things are not built as well as the full on pallet shelves, but that's not really surprising. They're a big step up from the usual dross.

Second set of shelves was different. More front-rear members so more even support across the shelf. The wire was a bit thinner. Same packaging, though. It also had a mangled upright, but since I'm siamesing these that's not an issue.

Third set of shelves was like the first. And in order to make them fit, I need to shorten the lateral bars by 2.125". No worries, I wired up the welder plug and got ready to stick metal together.

Well, that was the plan. I could not, for the life of me, find my angle grinder. Spent all day searching and trying to think of where it was, but to no avail. I tried to clean off the powdercoat with the belt sander, but it didn't do a good enough job. So the shelf building exercise got put on hold until I can borrow an angle grinder from work. I don't want to load up the shelves I have because I'll need to keep them out from the wall just a little bit to assemble the last ones, and they'll be no fun to move when they're loaded.

Poop.

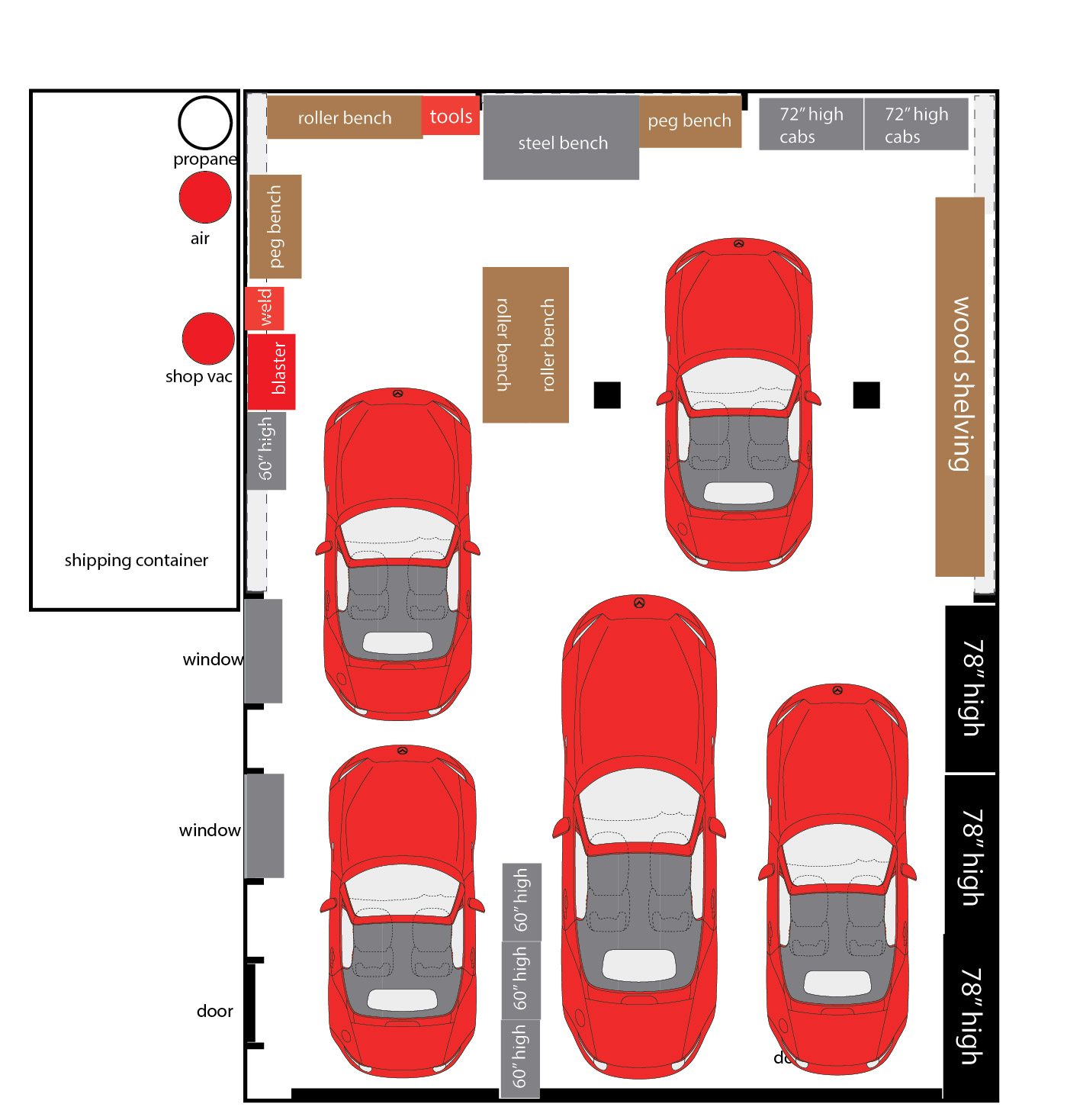

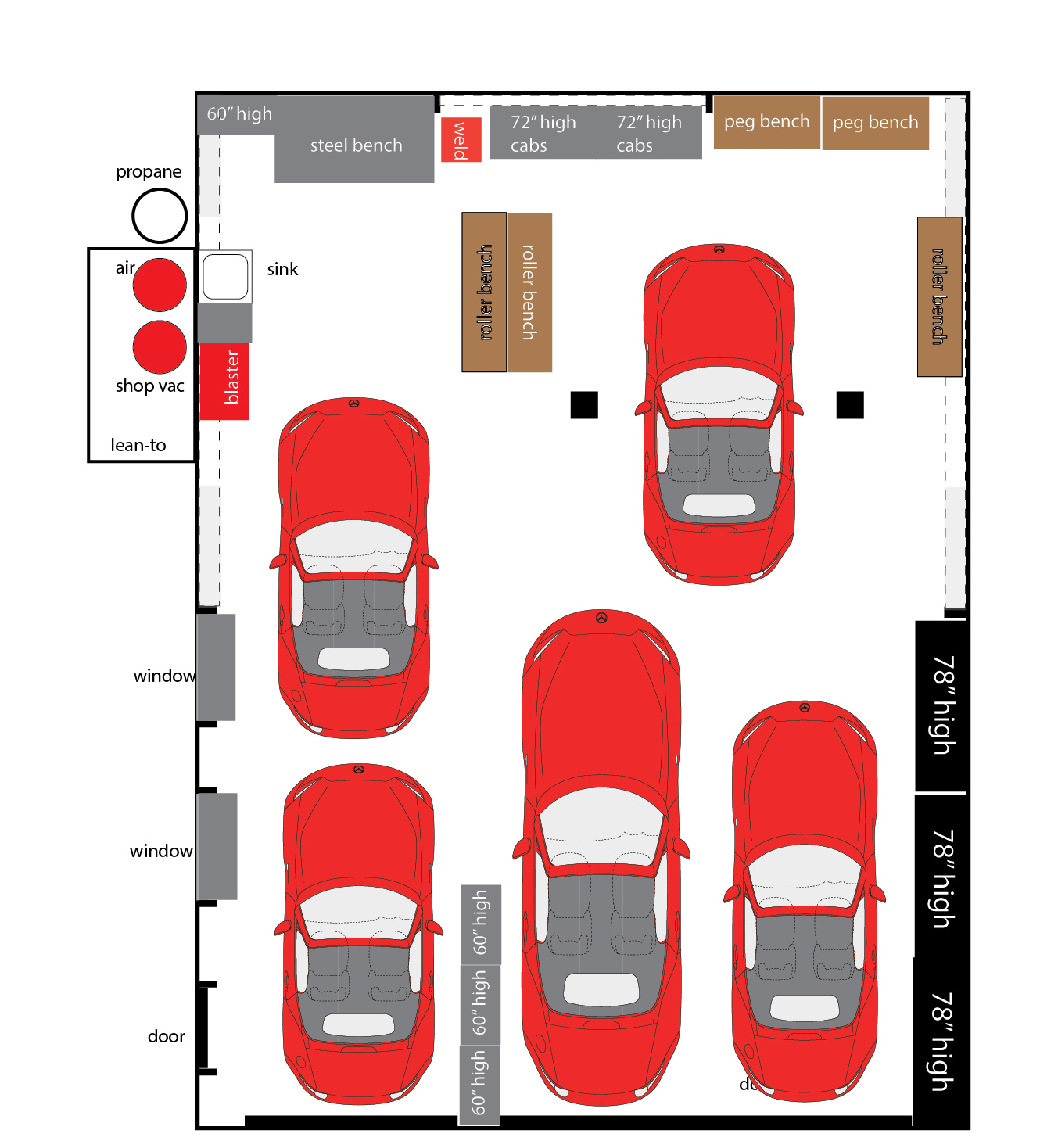

So I moved on to other things. First, I need space. Cleared some cars out, probably terrifying the neighbors that this was their future.

The MG was stuck at the back of the garage in the middle, right where I wanted to go. I put it up on dollies, dragged it sideways, cleared out a path and manhandled my big 2x4 cabinets to the back.

These have adjustable legs so they can be cornerweighed. I satisfied myself with just leveling them instead.

I learned when unloading them that these cabinets can swallow an immense amount of stuff. For the time being, I just started throwing boxes of their future contents on the shelves. The one on the left will be small parts for the fleet, the one on the right is fluids and painting stuff. A trio of seats went on top. And all of a sudden, the garage started to develop floor space of a sort. That's 60 square feet of shelf space if you include the top.

I learned when unloading them that these cabinets can swallow an immense amount of stuff. For the time being, I just started throwing boxes of their future contents on the shelves. The one on the left will be small parts for the fleet, the one on the right is fluids and painting stuff. A trio of seats went on top. And all of a sudden, the garage started to develop floor space of a sort. That's 60 square feet of shelf space if you include the top.

I also installed the 60" high shelves between the two doors. Just two of them. We'll see if they prove to be in the way, but so far they seem to be good. I had a set of shelves that fit so well they seemed to be custom built and it would be a shame to not use them. It's also a good place for the garage stereo, which has now been installed temporarily. They're also a good temporary working area.

So, some progress today. Not quite the progress I'd originally planned, but it's something. The monster cabinets are in place. The welder is wired and functional. 2/3 of the new 78" shelves are in place. Tunes have been achieved.

I learned when unloading them that these cabinets can swallow an immense amount of stuff. For the time being, I just started throwing boxes of their future contents on the shelves. The one on the left will be small parts for the fleet, the one on the right is fluids and painting stuff. A trio of seats went on top. And all of a sudden, the garage started to develop floor space of a sort. That's 60 square feet of shelf space if you include the top.

I learned when unloading them that these cabinets can swallow an immense amount of stuff. For the time being, I just started throwing boxes of their future contents on the shelves. The one on the left will be small parts for the fleet, the one on the right is fluids and painting stuff. A trio of seats went on top. And all of a sudden, the garage started to develop floor space of a sort. That's 60 square feet of shelf space if you include the top.