so, im apparently not that bright. or im a glutton for punishment. or both. regardless, there is definitely something wrong with me.

I have a thing for vintage tools. specifically late 40's-late 50's tools. they just do it for me.

my friends have started referring to my garage as "Crawford's home for wayward power tools". its not far off.

in October, a friend of mine was helping clear out the last barn of his departed grandfather. he couldn't bring himself to throw out the tools that none of the family wanted. he wanted them, but had no way to get them back home with him. so he showed up out of the blue to drop them off with me. I didn't even know he was in town.

the only tool he actually seemed to care about was his grandfather table saw. told me quite a few stories about him and his grandfather and that saw. he was a little teary eyed unloading it from the trailer.

now, im working in a 27x17 basement shop, that restores cars, does woodworking, fixes house stuff, etc. not a lot of spare space, especially when the 70 duster takes a full bay, and the other one is usually filled with something im building a wiring harness on. I have a 58 AMF dewalt radial arm that I also use for ripping, as its a truly superb radial arm. have not needed a table saw in years, and had no plans to get one. until this one shows up.

still didn't want it, but I hatched a plan to restore it and deliver it to his home. he has that many memories tied up with it, it deserves a place of honor in his shop.

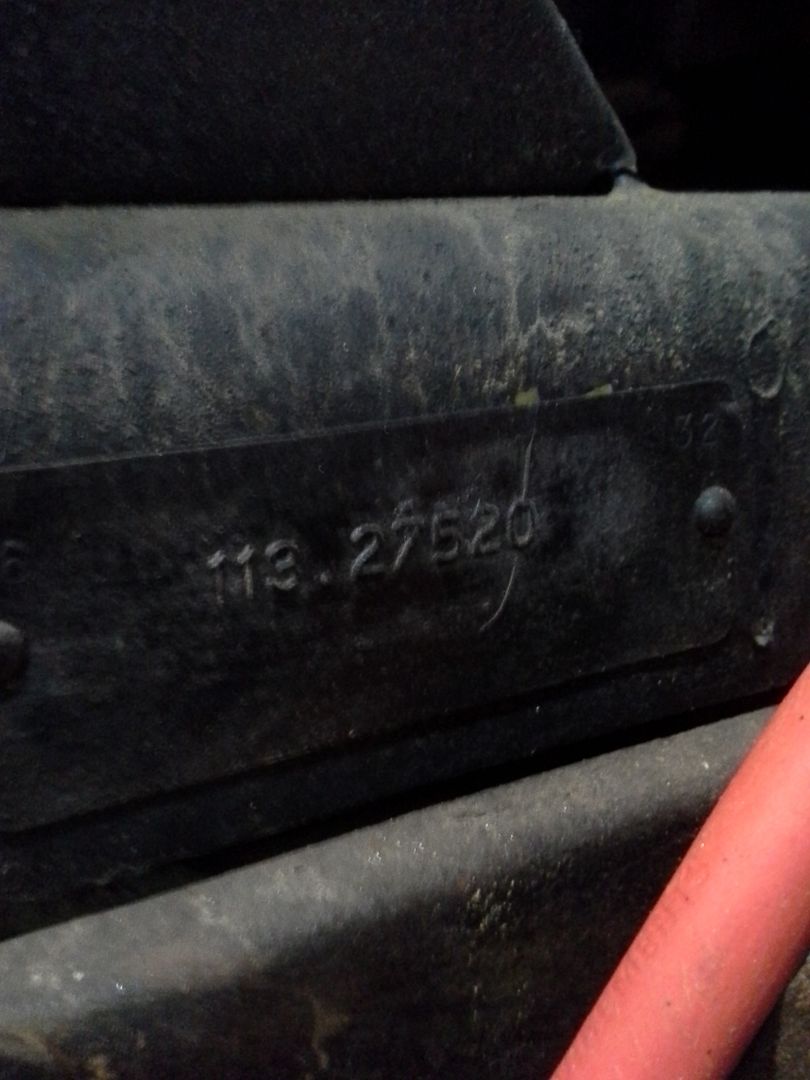

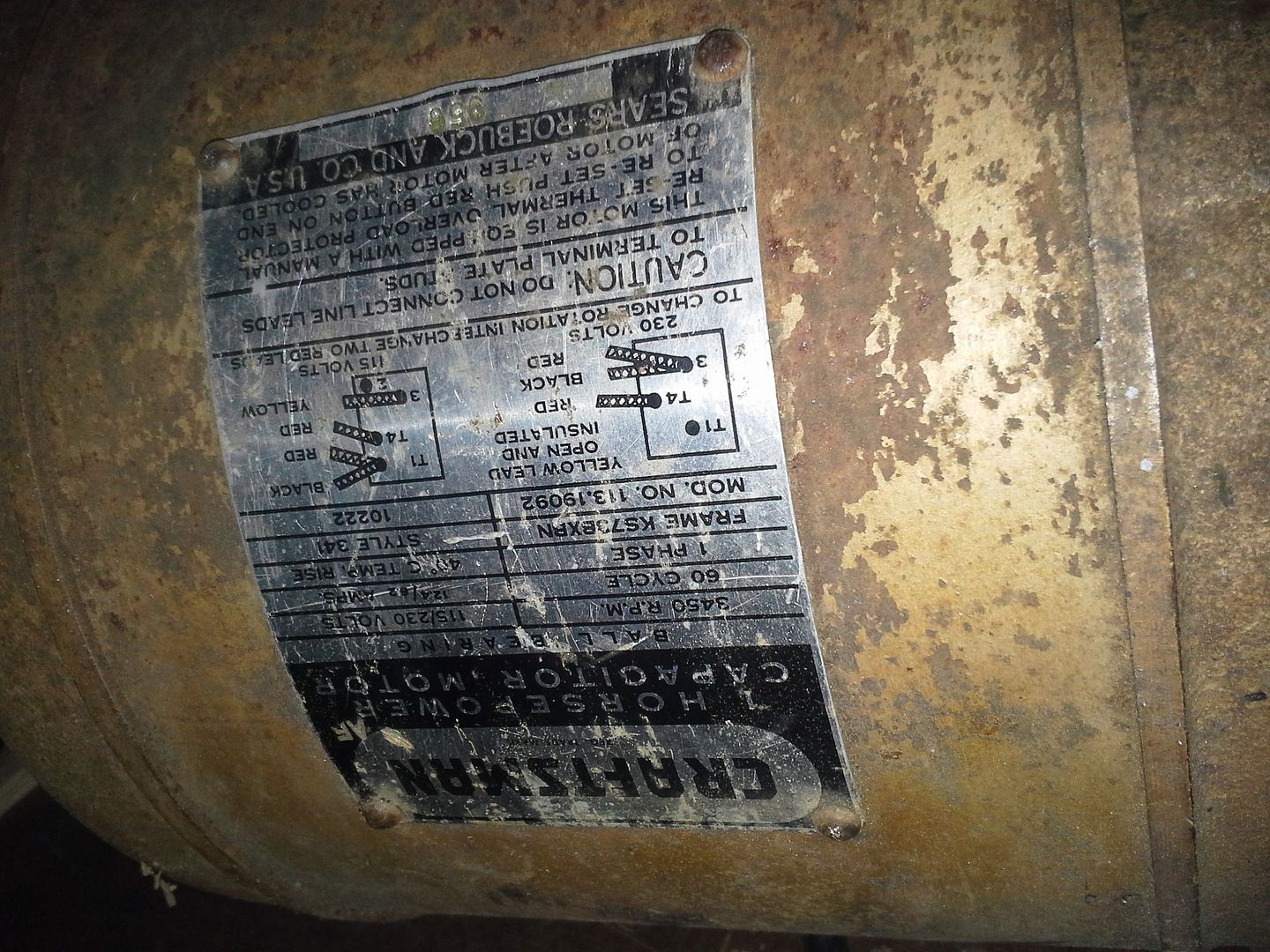

only problem is, the saw is TRASHED. multiple coats of paint on everything, top included. loaded with crap and debris, making adjustments and use very difficult. And someone equipped it with a different motor that trips breakers, and a 7 1/4 blade. this happened sometime after his grandfathers death. he speculated one of the cousins....

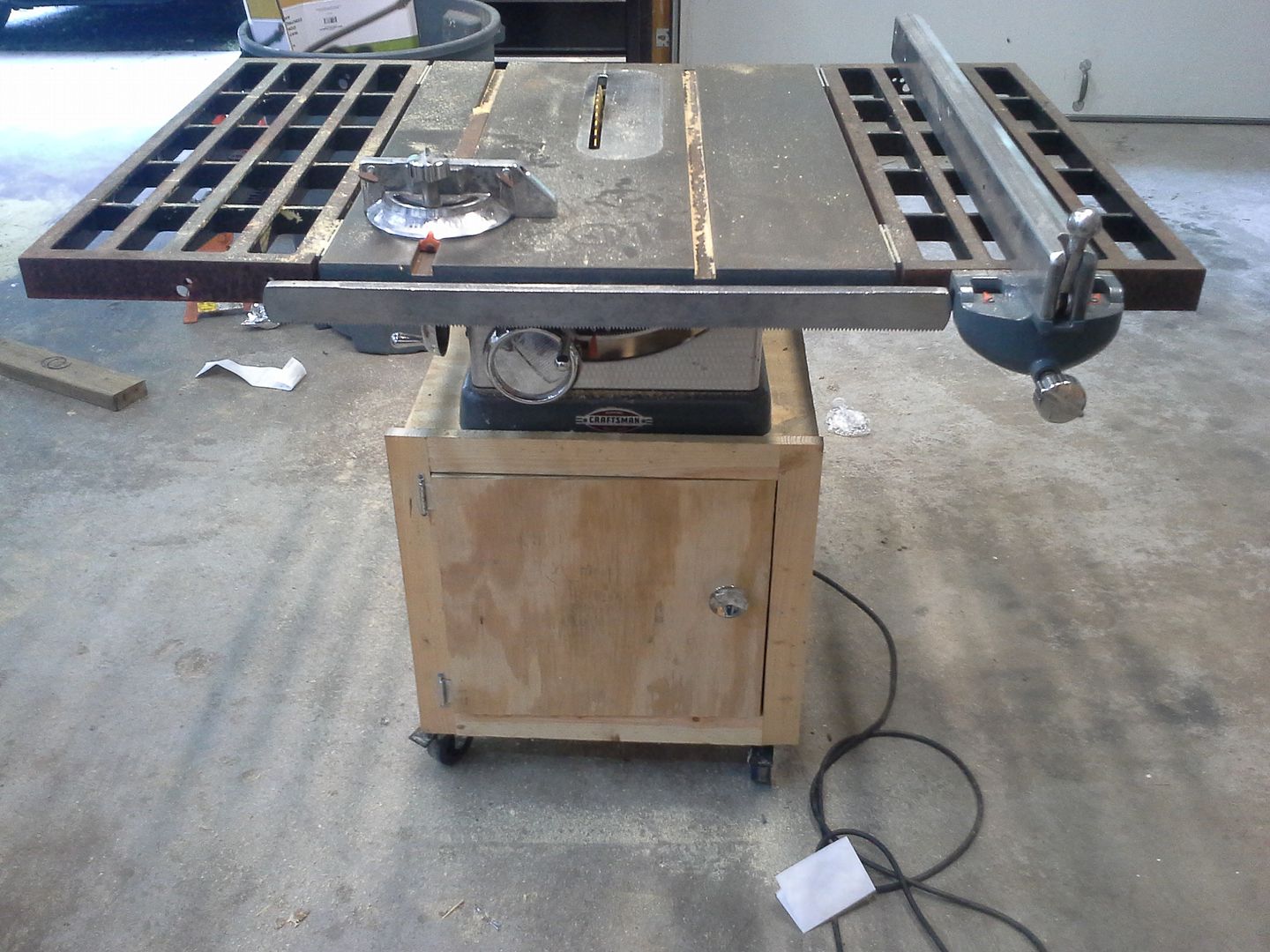

anyway, here's some pics of his saw.

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150427_191650_zpsz8lcxsi3.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150427_191641_zpsbpozxdph.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150427_191641_zpsbpozxdph.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150427_191621_zpsnndg20fl.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150427_191621_zpsnndg20fl.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150427_191606_zps4jvrinhn.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150427_191606_zps4jvrinhn.jpg.html] [/URL]

[/URL]

pretty rough, right?

so in December, I was at a mower junkyard getting some pieces for my rider. came across a forlorn, crusty and rusty 113 just like his. with perfect aluminum pieces. for 20. so I bought it as a parts saw. only to find out it was in better shape than his.

here's what 20 will buy you. this is after a lot of cleaning, replacing the cord and checking out the motor, and managing to un-seize the miter gauge with a BFH and liberal use of MAPP gas.

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150422_081209_zpsv5haq68q.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150422_081217_zpseznzpdt2.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150422_081217_zpseznzpdt2.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150422_081225_zpslis4gp2a.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150422_081225_zpslis4gp2a.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150422_081318_zpsp73fevpf.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150422_081318_zpsp73fevpf.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150422_081324_zps515ypxv1.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150422_081324_zps515ypxv1.jpg.html] [/URL]

[/URL]

and this is where things go sideways.

I decided I like the idea of having a table saw, and figured out how I could make one the appropriate use of floor space. since I had two that could theoretically be brought back, why not just restore them both?

mine will be the former parts saw. going for a correct restoration (to a point. im going to mirror polish all the chrome and aluminum bits, as well as polish the top to as shiny as I can). his will be a much less correct restoration. pretty much restoring it to his childhood memories.

so I got started on mine tonight. it was cosmetically rougher, with a REALLY bad top. id read over on the GRM forum about evapo-rust, so I decided to try it. decided electrolysis was just too much hassle.

first step was to get it cleaned up real good and brought inside. Castrol super clean and some hot water took care of that.

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150427_184800_zps79s3kaj1.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150427_184807_zpsfjwtpzc3.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150427_184807_zpsfjwtpzc3.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150427_184815_zpsmhkpvecg.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150427_184815_zpsmhkpvecg.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150427_184826_zpsyol7uwwv.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150427_184826_zpsyol7uwwv.jpg.html] [/URL]

[/URL]

next, wire brush the worst of the rust out of the miter slots, insert for the insert, and the top.

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150427_190030_zpsszlpjfpf.jpg.html] [/URL]

[/URL]

I really think this saw was well cared for and well maintained before it wound up outside under a pine tree at the mower junkyard. top is cleaning up way too easily for it to be otherwise, and all the bearings are still rock steady and quiet.

so now were up to evaporust. according to the jug, im supposed to spread paper towels, soak them, and cover with plastic overnight.

paper towels was easy.

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150427_190046_zpsmckqirtd.jpg.html] [/URL]

[/URL]

to soak the paper towels:

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150427_190107_zpsdlvea8u6.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150427_190111_zpscbwges6m.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150427_190111_zpscbwges6m.jpg.html] [/URL]

[/URL]

after soaking and working out the air bubbles:

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150427_190730_zpsbaauxunp.jpg.html] [/URL]

[/URL]

and wrapped for the night:

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150427_191430_zpsbyvaagac.jpg.html] [/URL]

[/URL]

next time I get shop time, ill continue on the tear down and reworking the top.

I like this! Half way through, I was thinking that it would be a good candidate for Naval Jelly, but I'm curious to see how the Evaporust works.

Same here. I was planning naval jelly, but wanted to try something new. This stuff got rave reviews here. We'll see what I think tomorrow. Just checked it after two hours, and so far i am not impressed

EvapoRust is the E36 M3, but it really works best when you immerse the part. If you can find a tub big enough, you might just have enough juice there to make it work. Look on the EvapoRust site for the guy who did his undercarriage with it, he used some very specific techniques and got decent results.

So, update time as I have a minute.

First off, the evapo-rust: not impressed with the paper towel method. I actually think it made things worse, not better. Ill try it again on the hardware by dunking, but I aint holding my breath.

Anyway, this is what it looked like the next morning after I removed the bag, towels, and wiped it down according to directions:

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150428_072114_zpsvp0yoevj.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150428_073632_zpspqmi3dfr.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150428_073632_zpspqmi3dfr.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150428_073734_zpsaw0sekay.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150428_073734_zpsaw0sekay.jpg.html] [/URL]

[/URL]

I attacked it with a knotted wire cup brush and 80 grit on a block. It’ll come out ok at the end. But I got a lot more to go before I worry about that.

Had to disassemble for cleaning and refinishing, so I started to attack it. Surprisingly, everything came apart with absolutely no issues. Well, other than the tilt adjusting wheel. That took a BUNH of effort to remove. Took it as far down as I could, other than the trundle assembly. The trundle was just cleaned up and relubricated, as there was no play, no nothing. No need to take it the whole way down.

Pics from the tear down.

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150429_182101_zpsoo1vmu83.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150429_182109_zpssjckzfit.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150429_182109_zpssjckzfit.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150429_182115_zpsky40bkxr.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150429_182115_zpsky40bkxr.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150430_164117_zpsssavlrh9.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150430_164117_zpsssavlrh9.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150430_164124_zpsgbjjaawt.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150430_164124_zpsgbjjaawt.jpg.html] [/URL]

Then we spent a long time with wire brushes, 80 grit, and degreaser. Didn’t see a need to remove the old finish that was still sticking well, just the rust and loose stuff.

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150501_125207_zpsz6g6tvtr.jpg.html]

[/URL]

Then we spent a long time with wire brushes, 80 grit, and degreaser. Didn’t see a need to remove the old finish that was still sticking well, just the rust and loose stuff.

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150501_125207_zpsz6g6tvtr.jpg.html] [/URL]

Grabbed the Valspar rust proofing paint that I got matched to the old craftsman color and my brushes.

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150501_125211_zpsvx3qzdle.jpg.html]

[/URL]

Grabbed the Valspar rust proofing paint that I got matched to the old craftsman color and my brushes.

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150501_125211_zpsvx3qzdle.jpg.html] [/URL]

That was enjoyable. Turned out great, with the right amount of gloss for me. I also took this opportunity to start cleaning up and polishing all the aluminum and chrome bits. The engine turned aluminum turned out to be quite a challenge. Mothers mag and aluminum wheel polish worked too well, polishing out the turning on a few spots. Best combo was mothers California gold wax after cleaning with a coarse rag/soap water, followed by buffing with newspaper and lacquer thinner. It aint perfect, but neither is anything else ive built.

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150503_155042_zpsvap8b0zb.jpg.html]

[/URL]

That was enjoyable. Turned out great, with the right amount of gloss for me. I also took this opportunity to start cleaning up and polishing all the aluminum and chrome bits. The engine turned aluminum turned out to be quite a challenge. Mothers mag and aluminum wheel polish worked too well, polishing out the turning on a few spots. Best combo was mothers California gold wax after cleaning with a coarse rag/soap water, followed by buffing with newspaper and lacquer thinner. It aint perfect, but neither is anything else ive built.

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150503_155042_zpsvap8b0zb.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150503_155033_zpssuwxm5gs.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150503_155033_zpssuwxm5gs.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150503_155051_zpsjkteqrm8.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150503_155051_zpsjkteqrm8.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150503_155444_zpsgdhy5ru0.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150503_155444_zpsgdhy5ru0.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150503_155449_zpstsiljtip.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150503_155449_zpstsiljtip.jpg.html] [/URL]

The chrome knobs turned out great. Slight pitting. But definitely good enough. Put the better of the two as the lift knob, as it’s on the front where it will be visible at all times. The worse of the two went as the tilt, where it will be hidden by the extension table. I also went ahead and cleaned, lubed, and adjusted the entire mechanism in the trunion assembly. But it back in. still need to align it to the table.

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150503_162302_zps42wnvv9u.jpg.html]

[/URL]

The chrome knobs turned out great. Slight pitting. But definitely good enough. Put the better of the two as the lift knob, as it’s on the front where it will be visible at all times. The worse of the two went as the tilt, where it will be hidden by the extension table. I also went ahead and cleaned, lubed, and adjusted the entire mechanism in the trunion assembly. But it back in. still need to align it to the table.

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150503_162302_zps42wnvv9u.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150503_165804_zpskebuxtfa.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150503_165804_zpskebuxtfa.jpg.html] [/URL]

The fence rail is turning out good. You can tell in the picture which part of it I have started polishing and which I haven’t. the aluminum has some sort of grain pattern to it, which I am doing my best to leave because it looks cool. The polishing is also making the engraved measurement markings stand out very well. So I’m happy about that.

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150503_164058_zps52o4b92n.jpg.html]

[/URL]

The fence rail is turning out good. You can tell in the picture which part of it I have started polishing and which I haven’t. the aluminum has some sort of grain pattern to it, which I am doing my best to leave because it looks cool. The polishing is also making the engraved measurement markings stand out very well. So I’m happy about that.

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150503_164058_zps52o4b92n.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150503_164107_zpsm5qpcory.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150503_164107_zpsm5qpcory.jpg.html] [/URL]

So that’s it for now. More polishing, more tweaking adjustments, cleaning/painting/motor maintenance. That’s next! Then adding accessories.

[/URL]

So that’s it for now. More polishing, more tweaking adjustments, cleaning/painting/motor maintenance. That’s next! Then adding accessories.

Thanks guys. Im almost more excited about my table saw than my elky. This thing is turning out bitching.

sorry for the long delay in updates, guys. got a little distracted.

first, by this: http://grassrootsmotorsports.com/forum/build-projects-and-project-cars/project-drivabeater-20-64-el-camino-this-time/60101/page1/

then, by these:

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150508_144629_zpscxxl7nep.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150508_192258_zpsiwgcqk3d.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150508_192258_zpsiwgcqk3d.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150514_175302_zpskbq9uhx4.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150514_175302_zpskbq9uhx4.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150524_160615_zpsendadq6f.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150524_160615_zpsendadq6f.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150524_160604_zps5zszudnc.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150524_160604_zps5zszudnc.jpg.html] [/URL]

[/URL]

but fear not!! im finally back on this thing.

when we left off, I was starting to polish things. I may have gotten a little carried away.

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150506_143814_zpsztg7kcrl.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150506_171831_zpsscfbmqfw.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150506_171831_zpsscfbmqfw.jpg.html] [/URL]

[/URL]

I got the fence rebuilt, all the parts polished, and the saw assembled. got the rest of my pieces painted too. all that's left is to paint my pointers bright orange, mount the motor, do a fine tuning, and use it to build its stand. then, on to the next one.

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150524_160637_zpsmruynb8j.jpg.html] [/URL]

[/URL]

hopefully ill get better at documenting....

Duster,

I know this might sound a little to easy, but try WD40, a Scotchbrite pad, and some elbow grease on the top. It works surprisingly well. I'm slowly doing a similar rebuild on a Delta saw. My top was/is in a similar condition. I'll post some pics of the test I did a little later. But this is the cleanup tip on the Old Woodworking Machines forum for rusty tops.

The rusty part is how it started. The cleaned part is just the wd40/scotchbrite section I tried

long overdue, poorly documented update, version 2.0. its version 2, as the nice, detailed, well written version was just deleted by my computer. I hate technology.

anyway, when we left off, the saw was a pile of parts on the floor, that took the general appearance of what could possible be a table saw.

first step of turning it into a table saw is a blade. when I was doing furniture and cabinetry for a living (4 years since I've even touched a woodworking tool) I always ran CMT or Freud blades. this time, I tried something cheaper, as I have never even used one of these saws, so I didn't know if it would work for my style. the dewalt trim blade had good reviews, meaty carbide, and a thin kerf. I decided to try it. after a few cuts, I can say that I like the blade (not QUITE a CMT, but half the cost) and that the saw needs much more table than what craftsman gave it.

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150613_144156_zpsueivcxnq.jpg.html] [/URL]

[/URL]

anyway, I had to finish putting my saw back together. the needles were originally bare steel, near as I can tell. I painted them orange for better visibility, and got the saw dialed in to within a few thousandths. .002 on the blade to miter slot, and .1 degree on the stops. damn saw cuts nice!

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150613_144106_zpsmiixtt5h.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150613_144113_zpsiemnppqh.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150613_144113_zpsiemnppqh.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150613_144119_zpsdnusamfl.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150613_144119_zpsdnusamfl.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150613_144126_zpshz947qfs.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150613_144126_zpshz947qfs.jpg.html] [/URL]

[/URL]

so the saw needed to earn its keep. and have a rolling stand made. the constraints of my 500 sq ft shop make things a Tetris game of amazing proportions. the saw, for storage, needs to be torn down. that means miter gauge, motor, and rip fence all have to come off. and go somewhere. as well as feather boards, extra blades, push sticks, etc. so I designed a cabinet that will hold most of those things inside, while allowing the saw to just slide under my workbench top for storage, hard up against the wall. maximizing floor space. due to the lack of area on the saw top, the carcass of the cabinet was built entirely with my handheld circular saw. I will tell you now, it aint square...

but the concept works!

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150613_181840_zps2rjve1u1.jpg.html] [/URL]

[/URL]

to correct my top size problem, I decided I needed a set of extension wings. I was able to find a late 80's dunlap saw with a knackered trunion for $30. the 1 1/2 motor went into my spares pile, the wings went to my saw, and the sheetmetal base went into my daughters go kart. rest was scrapped.

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150613_144205_zpsbmhkdzbh.jpg.html] [/URL]

[/URL]

to make these work, I decided to have them hinged. this is not as easy as I thought it was. not by a long shot. had to mill part of the flange for hinge pin clearance, drill precise holes, shim and align everything, etc. but they're on there and done, tripling my table capacity.

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150627_141401_zpsrcbkihmo.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150627_141408_zpsyj8tkptl.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150627_141408_zpsyj8tkptl.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150627_142526_zpspeknkje7.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150627_142526_zpspeknkje7.jpg.html] [/URL]

[/URL]

then I used the saw to finish the stand. well, after making a safety addition. you see, the only on/off switch from the factory s a toggle on the motor. not safe at all. so I bought a harbor freight foot switch. makes it much more safer. anyway, I built a face frame, and using some 50's NOS hinges and knob, hung a door. cabinet still needs painted, and door needs routing, but its done enough for now to get started on my shop renovation.

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150627_164627_zpsj5td1rxs.jpg.html] [/URL]

[/URL]

folded up[ for storage (except for rip fence. I clamp it to the underside of the wing by the saw body)

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150627_172407_zpsx2serkst.jpg.html] [/URL]

[/URL]

I have the same table saw, inherited from my grandfather. Mine only has one extension, but the extension has a rack for the rip fence. Mine wasn't in such bad shape, so I've been just using it as-is for the last 20 years. The only missing piece is the spinner on the blade lift knob. The only work I've done to it is to rewire it and add a switch in a box on the front of the stand. Runs like a top after ~60 years.

Someday I'd like to take it apart and do a full restoration like you've done. I like the idea of adding hinges to the table extension! Now I end up having to bolt/unbolt it as needed.

I have a couple of wood storage cabinets my grandfather made with this saw, as well as a few other tools from him and my great uncle; I like having the connection to the past and all of the things they created in their shops over the years.

I looked into the rack for the rip fence. Near as I can tell, other than an auxiliary guide, it doesn't do much on the wings. Not toothed for micro adjustment, and the fence is squared to the table top, not the rack. So I saved $50 and just threw a tape measure in the bottom cabinet.

Im really digging this old saw. Glad to see you are still using your grandfathers. Ive got my grandfathers lathe I still use.

In reply to AngryCorvair:

That I would like to see!

Duster, always look forward to getting an update. Awesome to see you able to use it finally!

in reply to Duster and CJ, i will post a couple pix here tomorrow.

to Duster, because you inspire me so much with the Driveabeater series, i will sell it to you super cheap. like, trade you for those C5 wheels you took off the elky.

And thank you for the compliment that the drivabeater series is inspirational. I try to show others that realistically, anyone can do what I do. I'm not all that bright or educated, I just do lot's of research and guessing.

What kind of lathe? When you say horizontal, I think metal. Any idea what year?

And were back to the table saws. First one I did is still going strong. Great tool. May not be the latest and greatest saw, but has done everything I’ve asked of it so far.

Im now on to the first saw. Confusing, right? This is the one that initiated this thread. It was a friend of mines grandfathers.

I believe every tool has a story, as well as every family. This tool belongs in his family’s story, as it has been part of it all along. Im restoring it the best I can with what it is, and giving it back to him for Christmas. So….

We started here:

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150427_191606_zps4jvrinhn.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150427_191641_zpsbpozxdph.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150427_191641_zpsbpozxdph.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150427_191650_zpsz8lcxsi3.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20150427_191650_zpsz8lcxsi3.jpg.html] [/URL]

[/URL]

Heavy, heavy pitting and rust on all the steel casing, incredible oxidation on the aluminum, many different coats and colors of paint overspray, wrong blade, dead motor, top covered in rust, grime, and paint, and a long history of being a “man eater”. Looking at it, there was no way it was safe to use any time in recent history. So, doing what I do, I decided Sunday that it was time to get this thing done. Dove right in. hit it with superclean and the pressure washer to knock some of the crap off, and moved it back inside. Started tearing it down without pictures. Found one of the knobs will not come off, as the set screw is shattered and in a spot I can’t drill it out. Also, there’s no pointers on the rip fence. Screws and pointers are gone. Throat plate is steel on this one, and there’s a gauge on how high the blade is lifted. Half the fasteners needed cut off for disassembly. If this was a car, id think it had spent a few winters in NW PA. since it’s a tool, I’m beginning to wonder if this built his family’s beach house. I just have no idea how it would get this rusty.

Anyway, here’s some pictures of where I got to.

[URL=http://s54.photobucket.com/user/dusterbd13/media/20151127_153854_zps5ipyq28z.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20151127_153901_zps5chmmtyd.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20151127_153901_zps5chmmtyd.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20151127_153907_zpsme93kkxz.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20151127_153907_zpsme93kkxz.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20151127_153910_zpstekvqit5.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20151127_153910_zpstekvqit5.jpg.html] [/URL]

After wire wheeling all the loose stuff off, I got the base painted. The craftsman badge has been being worked on for a long time with paper towels, lacquer thinner, acetone, paint thinner, mineral spirits, and brake clean. Pretty much whatever was on a paper towel for another project, got wiped on the paint on the badges. You’ll see how far I was able to bring it back. But the badge is part of this saws story, so it doesn’t bother me.

[URL=http://s54.photobucket.com/user/dusterbd13/media/20151130_173543_zpspf6dli1a.jpg.html]

[/URL]

After wire wheeling all the loose stuff off, I got the base painted. The craftsman badge has been being worked on for a long time with paper towels, lacquer thinner, acetone, paint thinner, mineral spirits, and brake clean. Pretty much whatever was on a paper towel for another project, got wiped on the paint on the badges. You’ll see how far I was able to bring it back. But the badge is part of this saws story, so it doesn’t bother me.

[URL=http://s54.photobucket.com/user/dusterbd13/media/20151130_173543_zpspf6dli1a.jpg.html] [/URL]

I also started on the polished trim. This stuff was SO bad that I had to get aggressive. Sanded down with 320, 400, and 600 before buffing. Unfortunately, I lost all the engine turnd detail in the process. That bothers me.

[URL=http://s54.photobucket.com/user/dusterbd13/media/20151130_173557_zpsgpe788fs.jpg.html]

[/URL]

I also started on the polished trim. This stuff was SO bad that I had to get aggressive. Sanded down with 320, 400, and 600 before buffing. Unfortunately, I lost all the engine turnd detail in the process. That bothers me.

[URL=http://s54.photobucket.com/user/dusterbd13/media/20151130_173557_zpsgpe788fs.jpg.html] [/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20151130_173656_zpslgeciddl.jpg.html]

[/URL]

[URL=http://s54.photobucket.com/user/dusterbd13/media/20151130_173656_zpslgeciddl.jpg.html] [/URL]

[/URL]

Tonight will be buying hardware, seeing what I can do with the heavily corroded knobs, reinstalling the trim to base, and pulling the trunnion from the table top. Hopefully clean the top and get it painted tonight as well.

You'll need to log in to post.