A few weeks ago I let my 4 year old grandson ride on my mower with me and he drove around. He did not choose the most efficient path but he did have fun.

I started thinking that a zero turn toy would be really cool so last weekend I built him one.

First I create a 3D model.

I purchased a couple of Ryobi drills from our local hardware store and removed the speed controls.

Next I modeled a mechanism with cams that would depress the button when you move the handle forward or backward. It also has a lever that selects forward and reverse as you move the handles forward and reverse.

I then built the frame.

I machined all of the panels and glued them together.

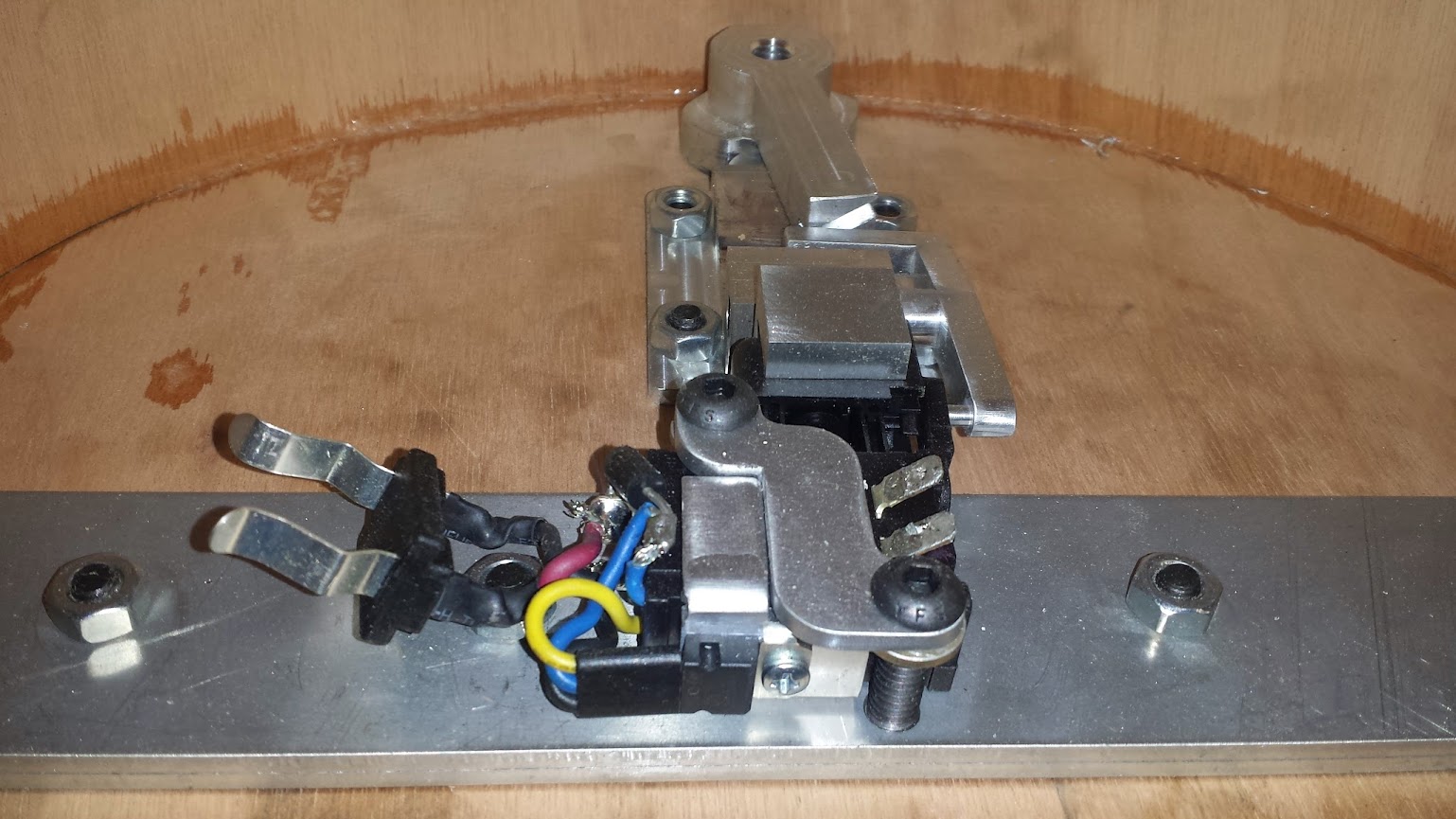

The speed control and handles were next.

I installed gear boxes from a Camaro ride on toy.

Installed a battery, wiring and a grandson.

Google created a montage of our videos and images so we thought we would share it. Just remember that google created this.

I am personally humbled by your skills!

Should you happen to be accepting additional grandkids...I have been a good boy.

Very cool. I am thinking about building a non battery powered car for my daughter using a similar approach (excluding steel, because no skill.) What width and type of wood did you use? What did you use to cut the curves in the wood - hand or power?

I can build one for $5000, it comes in green and says John Deere and I will even throw in a mower deck for free.

Here is a rough model I rendered so you can get a good feel for how it will look.

GTwannaB wrote: Very cool. I am thinking about building a non battery powered car for my daughter using a similar approach (excluding steel, because no skill.) What width and type of wood did you use? What did you use to cut the curves in the wood - hand or power?

I used some 1/4 inch material I got from Home Depot. It is too thin but I am planning on adding some doublers and fiberglass cloth in various places.

The frame was made from pre bent tubing elbows that I also got from the Home Depot. You could build the frame using these elbows and conduit without welding. Just slip the conduit into the elbows as far as you can and then use some self tapping screws to hold it together.

I machined the panels on a CNC mill but you could easily cut them out with a jig saw.

Hope this helps.

That throttle control bracketry and linkage is really cool!

What voltage are you running? I ask because my 4 year old's powerwheels is running 1 ryobi drill trigger/motor controller and the 18v battery and has a significantly higher top speed. With your 2 controllers that thing could be seriously nutty.

Again, very very cool build.

I have redesigned the way the motor are controlled.

As it is there is a dead space during movement while it switches from forward to reverse.

I am replacing what i have now with two rc boat ESCs and two servo testers.

The potentiometers on the servo testers will be attached to the handles. So when the handles are moved forward and reverse it will tell the ESCs to turn the motors forward and reverse.

This should improve vehicle control.

The new parts came in so I will be fitting them to Jackson's ride on toy soon.

The first new parts are the servo testers. They are usually used for checking the movement of your servos without using a transmitter and receiver. I'm going to connect the two levers of the ride on toy to the potentiometers of the testers.

The testers are going to send signals to two electronic speed controls. I first looked into using RC car ESCs but they have a reverse lock out that makes you have to push the trigger away from you once to brake, then return to neutral and then away again for reverse. This is alright for cars but for the toy, the transition needs to be seamless.

Unlike cars, RC boats switch from forward to reverse without a lockout, so I ordered two boat ESCs.

I've hooked all of this up temporarily and it looks like it is going to work well.

You'll need to log in to post.