If you don't have the piston (or a bladder, which is effectively the same thing), then you'll lose the air pressure if the cylinder ever gets completely emptied of oil.

To see why an Accusump is beneficial go watch the video in the "Daytona coupe reborn" thread. Pay close attention to the oil pressure telemetry.

Rather than treat the symptom, treat the cause.

Oil accumulating in the top of a motor will cause it to starve.

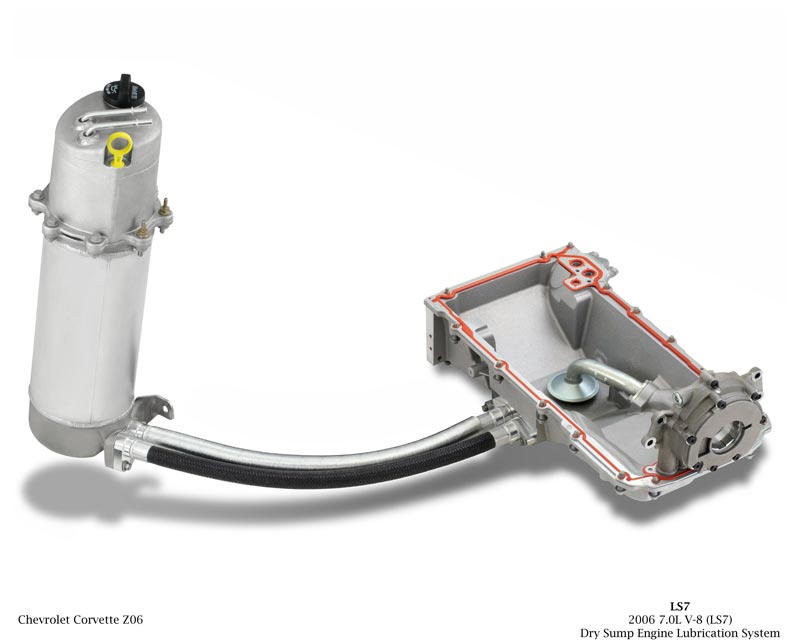

petegossett wrote:mr2peak wrote: Is this type of system totally absent from all OEM vehicles?It's used on at least one of the LS variants in the Vette.

Any idea on years? This might be the easy button

In reply to mr2peak:

The C6 Z06, ZR1, and Grand Sport had a factory dry sump setup, not an accumulator, might be what he's thinking of. I think many C7s have a similar setup.

Dunno what kind of 'budget' but when a new, name brand 3 quart accumulator is less than $200, used ones should be less than half of that. Check out roundy-round or RR used parts. Typical piston type rebuild is teardown and thorough parts wash. Bore gauge the cylinder ID and replace two O-rings on piston. Top and bottom flange O-rings can be reused.

A lot of nonsensical things were said here. Learning opportunities! All the right things were said too, so i hope ppl knew who to listen to.

I dont have a lot to add other than that it is possible to build a check valve with an orifice in it so that, while it never completely blocks flow and thus isn't truly a check valve anymore, it will allow much more rapid flow in one direction than the other. Might be useful to address the issue of the sump leeching too much oil flow from the pump and causing slow pressure rise when accelerating.

Then again, im not sure how much is really required. I think the 10psi per 1000 rpm rule is more an indicator of a generally healthy oiling system than a reflection of actual requirements. I suspect that pressure over a certain point is superfluous regardless of rpm/load and that any pressure over that only exists because the oil pump isn't 'throttled' or controlled in any way other than a pressure relief valve set at a very high pressure. Although i hear that new cars have a PWM dump valve that lowers pressure to reduce pumping losses from the pump. Therefore some factory engineers somewhere know what i'm talking about, but unless they post here it won't help me. ![]()

I expect that many know this, but we use a similar contraption on some turbo builds. You can run full synthetic oil or use dino oil and one of these.

The problem is that in a turbo, when it stops spinning on shut down, particularly after a hard bout of acceleration, the now static oil inside the turbo bearing is likely to be ashed by the tremendous heat which causes damage to the bearings.

Solution - use a small oil reservoir (bottle from a hand held propane torch is the usual size). Put it in the turbo oil supply line and put a one way valve right before it. The bottle fills up when the engine runs and when you shut down it bleeds oil through a calibrated orifice though the hot bearing, usually for several minutes.

The reason for the one way valve is the same reason as I like to use that sort of check valve with an Accusump - oil that gets forced down the main supply tube toward the oil pump (that is temporarily churning air) is wasted - you want it to all go into the main oil gallery to supply the bearings.

If you're too cheap/lazy for a check valve, wire a starter switch independent of the ignition switch. Crank the engine until oil pressure starts to come up and then hit the ignition.

This is a starting tactic you need anyway for large, high compression engines if you don't want to risk the engine kicking back at the starter and breaking its nose off. This is why the aftermarket racing switch panels have the starter switch and ignition switch right next to each other, and the starter gets its power from battery, not ignition feed.

You'll need to log in to post.