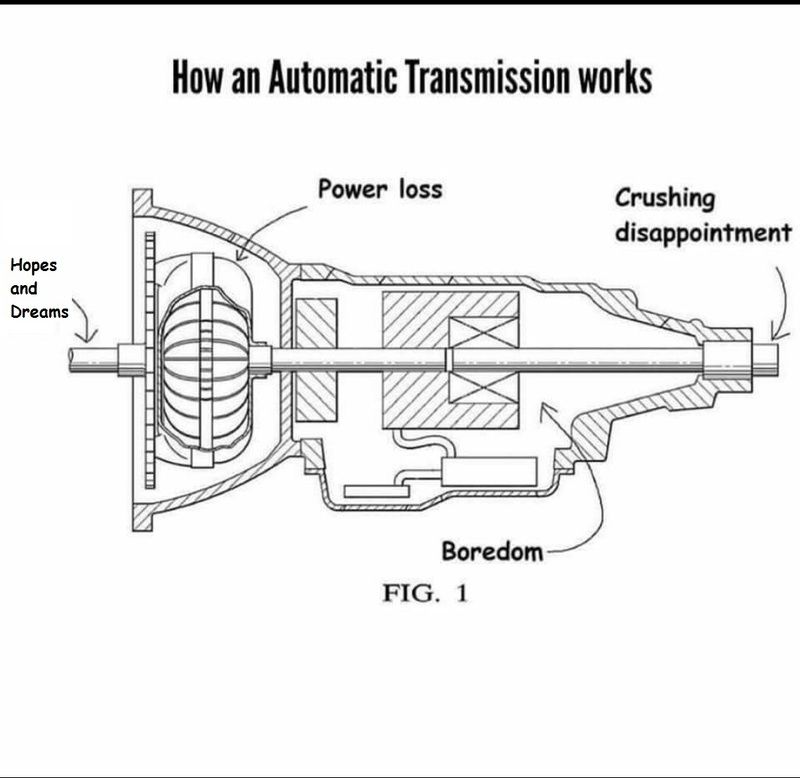

On the surface, the science in that diagram seems compelling but I don't think anyone can claim to understand how an automatic transmission really works. That magic has been lost to the ages. What we do know is that Hopes and dreams go in, and crushing disappointment comes out.

They may be powered by marriage.

I recall reading in "Car" (the story of the Gen-3 Taurus, by Mary Walton) that the chief auto-trans engineer at Ford had a sign over his desk that read, "You do not want to know how an automatic transmission works." I say we take his word for it.

At the rate that manuals are dropping out of the market, there's a pretty good chance that my new FoRS may be the last manual I'll ever own. I'm going to try to keep it forever.

I remember when my father pulled the Hydromatic transmission from his '54 Willys sedan just to see how it worked. He said he got the general idea but it was very complicated.

He put it back in the car and never said another word.

He was a machinist an was always taking things apart to see how they work.

Oh come on, it's just a bunch of planetary gearsets. Of course, they use a specialty fluid coupling mated to a the planetary gearsets which incorporate clutch packs, and each assembled gearset/clutch pack sits inside banded drums. The servos attached to the bands are hydraulically actuated by the valve body, which is controlled by either a computer (most modern cars), or a governor and either a throttle cable or vacuum modulator (older tin) to know when to do what. Lots of little intricate pieces, but nothing beyond grasp. Although to be fair, they make a dual clutch look incredibly simple (two electronically actuated clutches, one which operates the even gears and the other the odd, each gear sequentially pre-selected via computer-actuated physical selectors).

I tell my students that it's Black Magic and VooDoo.

Actually, I have a planetary gearset out of a slushbox, and I can show them how I can get underdrive, overdrive, direct drive, and reverse, out of a single planetary gearset. It's a wonder of engineering.

And I have my box of broken bits and smoked clutches.....

Manuals have gears and bits to select between them. Autos have a pile of stuff to make gears from and magic bits to make it all work.

The gears and clutches are not hard to understand. Even the TC is explainable but when it comes to decoding the valve body and how it controls the other stuff is where the fun begins.

Now we have nine and even ten speeds. I hear it took engineers from both Ford and GM to make the ten speed work. I hear the nine speed is not so great.

Just more to confuse us.

iceracer wrote: The gears and clutches are not hard to understand. Even the TC is explainable but when it comes to decoding the valve body and how it controls the other stuff is where the fun begins.

Is it, though? The manual selector valve directs fluid here and there. When in automatic mode, the governor controls shift speed based off of driveshaft speed, balanced against engine load by the TV cable or vacuum modulator. Governor's just a small, oily distributor advance mechanism. Change the weights or the springs, you change the automatic shift points. The rest of the little stuff is mostly accumulators, just a spool with a spring behind it to take the shock out of a shift. You can alter shift firmness by changing those springs, or making them solid if you like replacing U-joints on a regular basis.

Simple, simple little hydraulic computer.

Of course, as it wears and/or gets sticky, the trans starts to shift goofy. And since it is mechanical, it is adjustable, and anything adjustable has one way to be right and a dozen ways to be wrong. Electronic is waaay nicer in this regard, it's all solenoids that either work, or don't, and the tuning is done in software. If it worked before you messed with it, it will work after.

OHSCrifle wrote: What? No "witchcraft happens" somewhere inside?

According to Jeremy Clarkson, you're thinking of turbochargers.

Knurled wrote: Electronic is waaay nicer in this regard, it's all solenoids that either work, or don't, and the tuning is done in software. If it worked before you messed with it, it will work after.

It sure is. But there are some base design aspects that still impact how an auto trans works- like reverse clutch action plus oil flow capacity- can you do ALL of the clutch actions at the same time or not.

ZF makes a great box that shifts really fast. But it costs a lot of money for a reason. (it's also big and heavy)

And there are similar issues with the interaction of the torque converter/lock up clutch. Some systems can not do lock to lock shifts, or they have to wait to a higher gear to lock up.

Ugh. Drives me nuts to deal with it.

Autos have gotten a lot better, certainly. But much of the reason is because of compromises that are demanded of manual transmissions- such as the no driver action tip in response. An auto can downshift for that event, a manual can not- which is why you see such a big gaps in final drive ratios between autos and manuals.

Still- autos blow a lot of fuel just getting to the point of being able to lock the torque converter. I hate that. They blow more by how they react to the above tip in (many unlock first before downshifting- when a lock-lock downshift would be far more efficient).

noddaz wrote: What? No "And a miracle occurs."?

Nope. Because it's not fun, there's no witchcraft, and you don't generally.go faster.

I was building a clutch set-up to replace the TQ,using a boat bell w/flywheel and pressure plate, down side is losing torque multiplacation provided by said TQ, making it no diff.than a Manual.but it does lock up.

You'll need to log in to post.