So let's say you were hypothetically trying to make a winter program where your middle school kids and the science high school got together and built an engine for your Daewoo racecar.

![]() (realizing how unlikely this all sounds ...)

(realizing how unlikely this all sounds ...)

Then the hypothetical high school physics teacher mentions he'd really like to get a hypothetical 2,000 dollar grant from the local technology college but that we can't just build an engine this way, but must instead create a research project out of building the engine.

You are hypothetically excited to hear this and set about hypothetically trying to figure out how to make a 2 liter E-tech build into research project. You would like to end up with a functioning engine at the end of said research.

I am thinking of building and testing some intake manifolds from scratch. Good idea, bad idea, got a better idea?

rapid prototyping is the way to go - youll need someone who can do the modelling in cad or solidworks. Not sure what kinda tech you have there.

As a distant second option, Ive heard of teams building a kind of an adjustable runner manifold for testing. The the runners are 2 pieces - one smaller diameter than the other so one end can slide into the other - this lets you adjust runner length between pulls to see where the optimum length is for your application. This is after youve determined what width you need.

neat idea on the running length idea.

I guess it could be done if you could get fabbed up the part that bolts to the head and another for the ITBs, but with runners you could bolt in and out? I guess that would make it a six piece manifold

2 stroke Go karts used to use a expantion chamber called a "Slippy pipe" cable actuated slip joint so you could tune the pipe to motor rpm out of the hole. the exhaust presure would push it back out to full lenght. You could do the same on the intake side with velocity stacks.

For this project I'm probably limited to a single throttle body and modifying stock manifolds. Although I guess it's possible we could build our own from the ground up.

I won't have anywhere near the budget to make my own throttle bodies or to adapt motorcycle FI to the E-tech.

I guess what I'm asking for is a tutorial on Intake Manifold design. I'm toying with the idea of keeping the variable geometry system off the stock 1.5 manifold too.

To test different runner lengths you could use this idea that I've seen on some FSAE builds...

You could have the flange that bolts to the head and the plenum and use different length couplers or tubing to test various runner lengths.

What does the stock manifold look like? Will it be easily sliced and diced?

Have you given Daewoo reps a call to see if they want to exchange some positive press for financial help or maybe some extra parts to help in case of catastrophic failure?

cghstang wrote: To test different runner lengths you could use this idea that I've seen on some FSAE builds...You could have the flange that bolts to the head and the plenum and use different length couplers or tubing to test various runner lengths. What does the stock manifold look like? Will it be easily sliced and diced?

I've actually got a pretty wide selection of stock manifolds that will bolt on. There are plastic and aluminum versions of the "snail" manifold that went on the 1.5, 1.6 and some 1.8liter engines. The aluminum version you can unbolt in the middle. I'm not sure on the plastic version, but the aluminum one is variable length geometry.

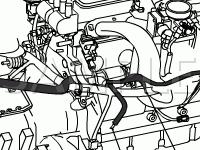

Here's a picture of the aluminum, variable geometry manifold on my current 1.5

I can also bolt on a manifold of this style, which looks a lot like a stock iron puke TBI manifold.

Also available in plastic or aluminum.

Giant Purple Snorklewacker wrote: Have you given Daewoo reps a call to see if they want to exchange some positive press for financial help or maybe some extra parts to help in case of catastrophic failure?

Not yet, will soon. Thanks for the idea!

4g63t wrote: There's a GREAT thread on www.galantvr-4.org concerning fabbing an intake manifold.

Do you remember the title of the thread? I'd like to find it without searching every single thread if possible. ;)

oldeskewltoy wrote: note the variable length velocity stacks

For testing purposes, I could probably approximate this with different lengths of PVC ...

mad_machine wrote: neat idea on the running length idea. I guess it could be done if you could get fabbed up the part that bolts to the head and another for the ITBs, but with runners you could bolt in and out? I guess that would make it a six piece manifold

For example, if I were to cut the runners out of my current, snail type manifold and sink threaded studs into the lower part that mates with the cylinder head different studs in the snail part, then I could connect the two with different length steel tubes and test the variations?

Is this what you're suggesting?

""

In reply to DaewooOfDeath:

In the how to section. Making your own intake manifold. Second thread in the section. I think there's a white paper on design in there too. Hope your computer's up to it, it crashes mine.

You can make intake manifolds with adjustable runners using industrial hose for the center section. The hose is available from McMaster-carr, it's flexible, steel reinforced, petroleum rated, good for over 250F, 100 psi, etc. Look for Minespray hose,etc.Petroleum service hose, etc. This allows you to fab a section that bolts to the head, with 'stubs' just long enough for the hose to clamp to. The outer section can mate to motorcyle carbs/throttle bodies, whatever either has a round section that the hose will clamp directly to, or can take a clamping adapator. The advantage is that things are round, and so you can easily get round stock, which is easy to modify with a lathe (everyone has a lathe, right?). I originally designed my setup for fuel injecting my Spitfire, but built a set for Jeff McNeal to use on his custom Spitfire with Kiehin carbs:

http://www.totallytriumph.net/spitfire/carb_conversion.shtml

http://www.flickr.com/photos/13867611@N04/1517810502/in/photostream

http://www.flickr.com/photos/13867611@N04/1516957701/in/photostream

http://www.flickr.com/photos/13867611@N04/2081915359/in/photostream

Only change needed for fuel injection is to add injector pockets to the adaptors, and use throttle bodies rather than Kiehins.

4 bangers and straight 6 with sidedraft carbs/TB are obviously the easiset to do this way, but the flexibility of the hose enables a number of solutions for V engines, and since it can handle pressure, may enable easier turbo packaging. Visualize 4 IR hoses going to a reversed 4-1 header collector that's bolted to the pressure side of a turbo compressor housing, the flexibility of the hoses allows you to cut them to equal length, but you can then route them as needed.

Once caveat, you should take care where the hose clamps to the tube. A bead is very helpfull, I machined some ridged grooves, like barbs, into my adaptor tubes (see pix above).

Carter

You'll need to log in to post.