My assumption:

An adjustable proportioning valve is installed downstream of the factory combination/proportioning valve on the rear brake line and is used to reduce the pressure that reaches the rear brakes.

Is this correct?

Or does the adjustable valve take both the front and rear lines and is it used to adjust the bias of BOTH the front and rear lines; raising the pressure of one while lowering the other?

It's put in place of the factory valve. It will modulate the amount of pressure going to the rear, the front brakes will get 100% of the available pressure all the time.

yes, you put it inline in the rear brakes after the factory prop valve/distribution block to vary the amount of pressure that gets to the rears. sometimes, you have to disable the proportioning function of the factory one or change springs in it to make it act differently (like, say, if you swap discs in the place of the rear drums)..

my personal example: when i put C4 Vette front brakes on my factory 4 wheel drum equipped 71 Nova, i put a Wilwood adjustable prop valve after the factory distribution valve and was able to dial it in so the factory 9" rear drums played well with the big 12" front discs with PBR calipers... in the case of a 4 wheel drum equipped GM car, their is no proportioning done by the distribution block- it's whole purpose is to provide a clean and convenient place to hook up all the lines and activate the "brake" light if a line breaks- so i didn't have to change anything... but some of my research into the brake upgrade i'm doing to my 86 Camaro tells me that i might need to get a stiffer spring for the prop valve and add an inline adjustable valve to the rear line to get the most out of the brakes on that, but i won't know until i get it together and see how well it works..

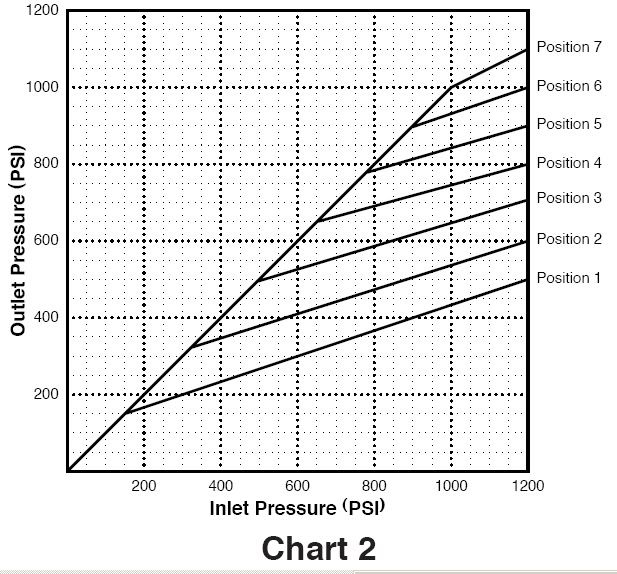

And here is how it adjusts the pressure. It's not completely linear, there is a "knee" in the graph:

They're not as simple as they seem. If you had no weight transfer, a perfectly linear relationship would make sense. Because the rear wheels see less normal force (they get lighter) as you brake harder, you need more front bias as you brake harder.

Don't run more than one valve in the system. You can get weird interactions between them. If you put in an adjustable, get rid of the factory one.

That's my plan. I'm going to run one master cylinder outlet into a 3 port union, put the lines that feed the front brakes on the other 2 ports and run the other outlet to an adjustable proportioning valve and use that to feed the rear.

I can add some personal experience. If you add a proportioning valve downstream of an existing factory proportioning valve, you can only reduce rear brake force from factory, but not increase it. That may (or may not) work on a car that puts a "big brake kit" on the front.

For typical street cars used in competitive environments (autocross, club racing, etc.) you typically want to increase the rear brake force. It that case you'll need to remove or disable the factory proportioning valve. You could possibly install a stiffer spring in the factory unit, but they typically don't provide enough info to know where you're starting from, and it still doesn't give you any control over the reduction percentage after it does start working.

On my Nissan, the factory master cylinder has two pistons inside. The rear piston feeds the front brakes and the signal pressure to the back of the proportioning valve. The front piston feeds the fluid to the proportioning valve, and then to the rear brakes. As the front brake pressure increases, it forces the proportioning valve forward and causes it to restrict pressure to the rear wheels.

If you simply remove the factory proportioning valve, you connect the front and rear circuits together. That's not a problem until one caliper fails and you loose all the brakes! On mine, after removing the proportioning valve I tapped the bore of the hole it was in and installed a pipe plug. I then added a Wilwood proportioning valve in the rear brake line.

Now, the Wilwood proportioning valve doesn't sense the front circuit pressure, so it works on passing a "proportion" of the inlet pressure onto the rear brakes. The "knee" in the pressure curve above is controlled by the spring preload that controls when the proportioning valve starts to move.

In general i am for retaining diagonal split brake circuits when possible, or at least front/rear split. You have to think about such things when you decide where to put your valve (or even how many you need).

Keith Tanner wrote: Don't run more than one valve in the system. You can get weird interactions between them. If you put in an adjustable, get rid of the factory one.

I feel like I should put this in the thread for someone that may wander in: bias bars are not proportioning valves; they work in a different manner. A bias bar can replace the function of a proportioning valve, but if you have both, you can tune your brake bias in a non-linear manner and really extract all the braking performance possible. You use the proportioning valve to adjust the bias requirements due to weight transfer, and the bias bar on the pedalbox to adjust for conditions. This gives you some nice advantages when you need to transition through varying grip levels.

Vigo wrote: In general i am for retaining diagonal split brake circuits when possible, or at least front/rear split. You have to think about such things when you decide where to put your valve (or even how many you need).

If you want to adjust your bias, you definitely don't want a diagonal split. Front/rear all the way. You can't have two independent hydraulic circuits with a diagonal system and one proportioning valve, and hoping you have two matched proportioning valves is just asking for trouble.

You'll need to log in to post.