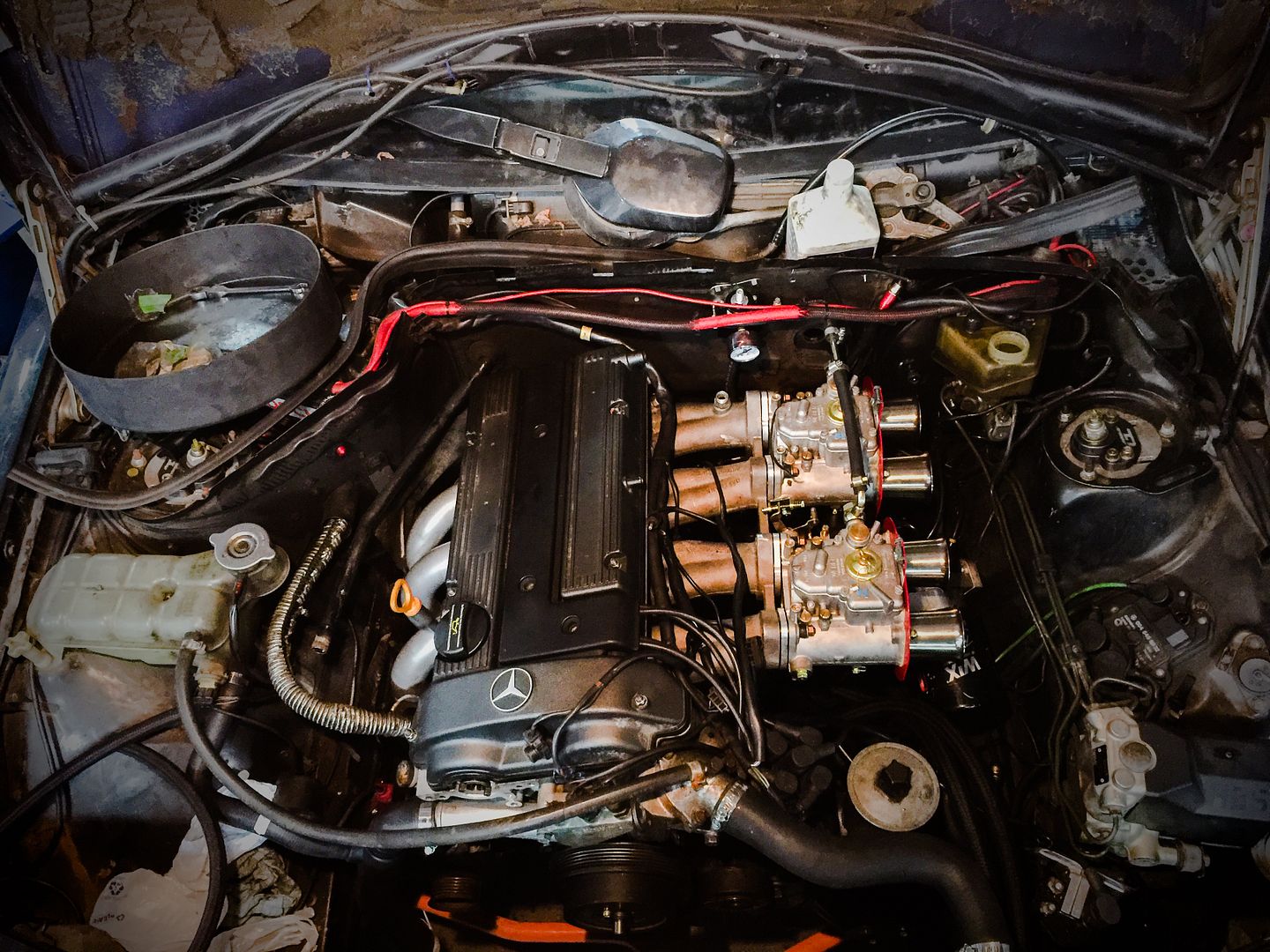

So, over the last year we've had a race engine built. It's an M102 with the Cosworth head (think: S14B23 with shim-under-cup lifters). As part of the build, we've scrapped Bosch/CIS in favor of twin Weber DCO 48 mm race carbs on a DTM manifold...

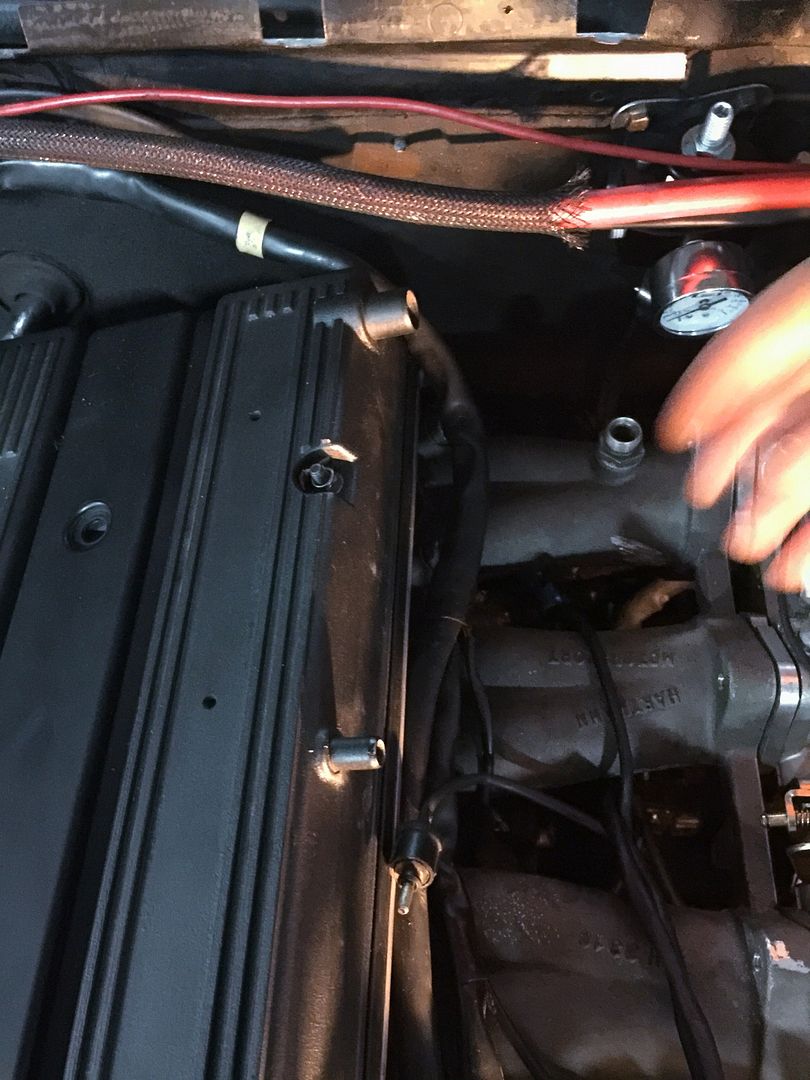

Now, I've got to figure out what to do for crankcase ventilation. I understand that the larger port (at the rear of the valve cover) is where the air goes in and the smaller port (in the middle of the valve cover) is where the air goes out. At least, that's what I think. I don't really know anything about this stuff...

My question is for guys who have swapped in ITBs or carbs on an engine like this. How do I approach this? Just stick a filter on the inlet side and hose/catch-can for the outlet side? Never had to deal with anything like this before and I have close to zero knowledge.

I agree that no air should be going in, though I've heard of some track cars using completely open systems.

Ideally, you want a well-sealed crankcase and a place to source vacuum before the throttle plate(s). An airbox would be the obvious choice. If, however, there's no air box planned, you'll have to settle for the less-than-perfect option of vacuum from behind the throttle plate, regulated so you don't get wild swings and massive vacuum.

I would probably cap the large hole and run a very small-diameter line from the small hole to a sealed catch can, which in turn is T'd into the boss on #4 inlet runner (which is for the brake booster, I'm supposing). Large-diameter line out from the can and small diameter in should provide good ventilation of the crankcase while slowing the transitions. Stick a gauge on the crankcase and see what sort of vacuum you get (slack tube manometer).

Yes, air goes in sometimes. If you have a well sealed engine with little blowby, more air will be pulled out through the PCV valve than is created by internal leakage. That's why there is an inlet going to the air filter on a stock pcv style system. Euro stuff tends to use a calibrated vacuum port, but they use a system to block the vacuum when it gets too high, or you get the famous "whistling crank seal" situation as they pull air past the seals into the engine.

To your specifics- If its race only, it might be as easy as anything to just add a vented puke tank. With your individual runners, any pcv source is going to send all the combustion byproducts into one cylinder, which is not ideal. If you drill and tap all 4 runners to provide the vacuum source, then you could do it with a pcv valve from a Chevrolet or something. The large hole would need to have a little filter, or be plugged into the air box for the carbs.

Vented Puke tank you can go two ways- run the vent line in anywhere, and drain it as required, or mount the can high enough to run the vent line in the bottom, which will allow the condensed oil to drain back into the engine. If the engine is solid, you will not likely need to drain it anyway.

02Pilot wrote: I agree that no air should be going in, though I've heard of some track cars using completely open systems. Ideally, you want a well-sealed crankcase and a place to source vacuum before the throttle plate(s). An airbox would be the obvious choice. If, however, there's no air box planned, you'll have to settle for the less-than-perfect option of vacuum from behind the throttle plate, regulated so you don't get wild swings and massive vacuum. I would probably cap the large hole and run a very small-diameter line from the small hole to a sealed catch can, which in turn is T'd into the boss on #4 inlet runner (which is for the brake booster, I'm supposing). Large-diameter line out from the can and small diameter in should provide good ventilation of the crankcase while slowing the transitions. Stick a gauge on the crankcase and see what sort of vacuum you get (slack tube manometer).

I was all over this post until you suggested that the system be sealed. Not a good idea. Sealed means that blow by will very quickly blow seals and make a lot of leaks.

Since this is a race car, and I assume that you will keep very close track of the oil, I'd put a good catch can at the end of the pipe leading out of that port. Done.

You can vent the can to the air cleaner- as that will reduce any "threat" of oil or hydrocarbons messing up your engine compartment.

But a can to catch the oil so that it does not spill all over the place is what you need.

BTW, a full closed cycle PCV system does a good job at keeping the oil fresh by quickly flowing air through the crank, and keeping the blow by from condensing in the oil. By not having one, you need to change the oil more often. And all systems have an oil separator to keep oil in the air from escaping out- also reducing oil use. Again, not having one means you need to change the oil more often. BUT, since this is a race car, I assume that you will keep far closer track of the oil.

alfadriver wrote: I was all over this post until you suggested that the system be sealed. Not a good idea. Sealed means that blow by will very quickly blow seals and make a lot of leaks.

I'm going primarily on my experience with BMW engines here, which seem to want a sealed crankcase. As streetwiseguy mentioned, the BMW systems I'm familiar with seem to try to regulate vacuum (not very well in some cases, but that seems to be the design intent) with a calibrated port or something similar. If the crankcase isn't sealed, you get lots of flow and much increased oil consumption.

That said, and OT for this post, I've modded my sealed crankcase M54 system to pull large amounts of vacuum (~10inHg) at closed throttle in order to deal with what appears to be a ring float issue causing oil consumption (by equalizing the crankcase and cylinder vacuum under deceleration, I've stopped oil being drawn into the cylinders). It's been doing this for tens of thousands of miles without blown seals or leaks.

A PCV system is a closed system. works fine on a street car.

For a race engine, perhaps going back to the old draft tube would work.

For ITBs I think the simplest approach would be to cap the old inlet and plumb the outlet to a vented catch can. I don't know much about it, but on a race car exhaust scavenged crankcase (using exhaust flow to vacuum down the case) might also be an option. Pulling some degree of vaccuum on the crankcase is generally regarded as a good idea(can't have windage issues without air!).

In reply to 02Pilot:

I think what you are saying that the PCV is sealed from the outside- but there is a loop to scavenge the crank of blowby- via the intake system.

If the crank is totally sealed from venting at all- it will blow seals- however good the rings are, they will never seal 100%, so there will always be flow into the crank from there.

alfadriver wrote: In reply to 02Pilot: I think what you are saying that the PCV is sealed from the outside- but there is a loop to scavenge the crank of blowby- via the intake system. If the crank is totally sealed from venting at all- it will blow seals- however good the rings are, they will never seal 100%, so there will always be flow into the crank from there.

Yes, that's what I was getting at, albeit not as clearly as I should have been. By "sealed" I was trying to make clear that leaks to external unmetered air would compromise the effectiveness of the setup I suggested.

The problem is ITBs.

You need to apply some vacuum to the crankcase to evacuate combustion byproducts. This will help slow down oil contamination.

You need to vent the CC to clean air, this hose may have air flowing in either direction, in at part throttle, out under heavy loads.

If this is a full race setup you should install an extractor system on the exhaust and forgo the vacuum application. As you will be changing oil often this is not critical. Note - the extractor system can make so much vacuum it can suck in gaskets and draw air past seals. I have installed all shaft seals backwards on some of these motors to optimise the vacuum benefits for ring seal.

For a street driven ITB you might consider making a manifold to tee all 6 together for your vacuum source to balance flow between all the cylinders. It would need to be fashioned in a way to allow easy cleaning perhaps a catch can between the VC and the intake side. With a vacuum system the large port should go to the clean side of the air filter.

The alternative would be to vent both ports to the clean side of the air filter, but this will not remove the contaminants from the oil and lead to poor oil life.

Hook one side to an air filter for air going in and plumb the other through a check valve to a scavenger port in the exhaust for air going out. Search for exhaust vacuum scavenger for a kit.

In my experience, it varies depending on the engine. Right now, I know more about Spitfire engines and Volvo B20. Both want a bit of vacuum on the output port, which in both cases is off the valve cover, which is vented to the crankcase via the valve push-rods. The Spit engine, being an old British tractor engine, I suppose they assume there will be enough blow-by past the rings that a crankcase breather isn't required. The Volvo seems to have been built to better tolerances and has a crankcase port which is plumbed to the clean-side of the air filter housing. The valve cover port is plumbed to a metered port in the intake manifold (speaking of D-Jet EFI here).

A simple breather filter may or may not work. On the Spit engine, installing one on the valve cover caused oil to spew from more places than we thought possible. That engine really wants that port to be under a bit of vacuum, so I had to cobble together a PCV system. In both cars, the fuel tank vent line is also plumbed into the PCV system via a carbon canister.

This is really an long-winded way of saying - go back and look at the original breather routing. What was is doing and how did it do it? Now duplicate that with your new intake.

So, can I just plug one of the holes and send the other out to a vented catch-can? Is it more complicated than that?

In reply to LanEvo:

Assuming there isn't anything weird like a PCV valve built into the cover, yes, I'd bet the center port is baffled, so use that one. Based on the responses below my initial one I think you'd be better off with exhaust scavenging though.

LanEvo wrote: So, can I just plug one of the holes and send the other out to a vented catch-can? Is it more complicated than that?

You could, but it's not exactly ideal. If you're willing to put a little more work into it, you could make a much better system (either a vacuum manifold from the ITBs, exhaust scavenging or even a vacuum pump).

On the E30 race car I have a scavenging type checkball vac tube welded into the exhaust. Like this:

The other end goes to the valve cover. There is a hole on the other end of the valve cover with an inlet and a filter (not really... but for 4yr old illustration purposes... unmetered air gets in). All the vapors are burned up in the exhaust so no catch can or gunked up intakes. Checkball keeps the exhaust from pressurizing the crankcase at idle or low flow situations.

Angle is important to make sure it pulls a vacuum.

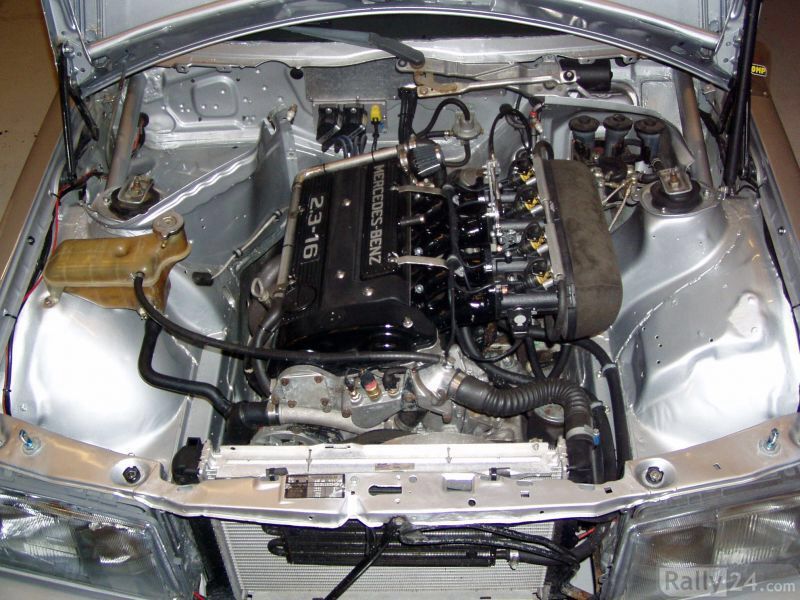

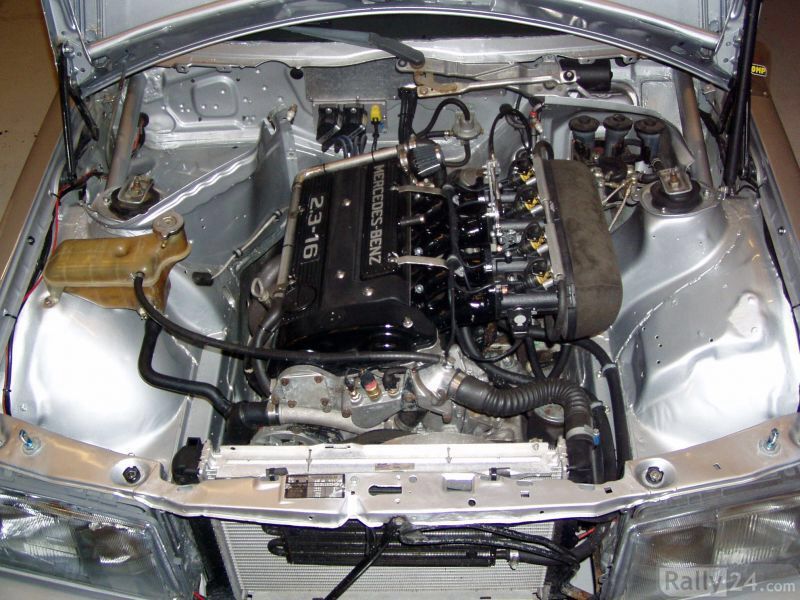

Here's a shot of the engine bay from an '85 Group A touring car. Looks like there's a K&N-style filter on the rear port. The central port appears open (hard to tell from the pic):

In reply to LanEvo:

I see a chunk of hose with a plug in the other end. Which doesn't make a ton of sense.

LanEvo wrote: Here's a shot of the engine bay from an '85 Group A touring car. Looks like there's a K&N-style filter on the rear port. The central port appears open (hard to tell from the pic):

I think they are going to change the oil every time they run it.

They are also going to have a nice mess in the vicinity of that filter. After shutting off the motor it will drip drip drip for days.

outlet should be ran to vacuum, and id put a catch can on it in that position, and generally you would run the inlet to a fresh air source behind the maf and before the TB, but it doesnt look like you have a maf or any intake tubing before the webers, so Id just put a filter.

BrokenYugo wrote: In reply to LanEvo: I see a chunk of hose with a plug in the other end. Which doesn't make a ton of sense.

After some more digging around, I've learned that the central port on the valve cover has something to do with idle and is generally plugged on M102 Cosworth race engines.

More examples...

Opti wrote: outlet should be ran to vacuum, and id put a catch can on it in that position, and generally you would run the inlet to a fresh air source behind the maf and before the TB, but it doesnt look like you have a maf or any intake tubing before the webers, so Id just put a filter.

If I plug the central port, can I just rout the larger port at the rear of the valve cover to a vented catch-can without vacuum? I don't really know how I can get vacuum with this set-up.

You'll need to log in to post.