Blunder

New Reader

6/21/22 9:25 p.m.

I would really like to learn about reading spark plugs. I recently learned that the aluminum heads (gt40x) in my foxbody tend to do well with more timing than iron heads. I want to start adding more timing and dial it in by reading the plugs. Any information is greatly appreciated.

Tom1200

UltraDork

6/21/22 10:45 p.m.

You can find loads of information from various online articles.

Plug reading is pretty straightforward. The key is to start conservative.

I'm sure some will disagree with me, but IMHO a proper wideband will tell you far more than tea leaf^H^H^H^H^H^H^H^Hplug reading ever will.

Blunder

New Reader

6/22/22 12:04 a.m.

In reply to codrus (Forum Supporter) :

I'm mostly concerned about getting detonation. Will a wide band help detect that through a/f readings? I do have a aem wide band sitting in the garage but unfortunately I can not weld.

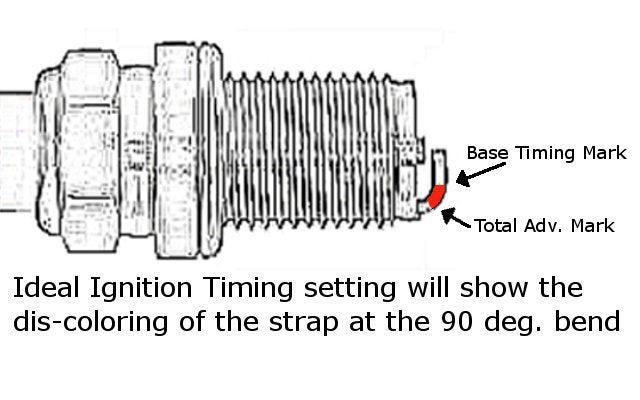

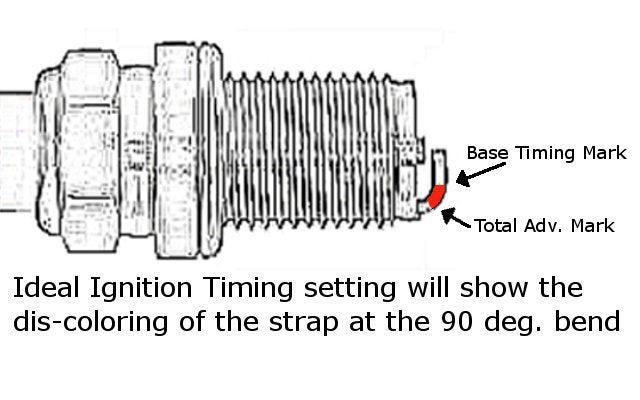

First off you need to start the process with fresh plugs. You also need a place to give it the beans and then shut down right away to check the ground strap.

Get a baseline then advance 2deg and repeat until it's where it should be. You *may* get detonation in the midrange if you do this, and if you have a knock detecting ignition it may be fighting you advancing the timing.

Blunder said:

I'm mostly concerned about getting detonation. Will a wide band help detect that through a/f readings? I do have a aem wide band sitting in the garage but unfortunately I can not weld.

Keeping the engine at a proper air/fuel ratio is half of avoiding detonation, with the other half being related to timing (and boost, compression ratio, octane, etc).

Are you using a fully tunable ECU? If so then IMHO the right way to tune timing is to use a dyno to find the MBT curve that's unique to your engine and build a timing map based off that. If you're just turning the distributor to add a couple degrees across the board then you're locked into whatever advance vs RPM curve is baked into it and your options are much more limited.

As for detecting detonation while tuning (if you don't have the octane to allow reaching MBT), the usual way is to listen for it, either with your ears or with a knock sensor. A knock sensor is basically just a special microphone bolted to the block with a computer that looks at the audio signals coming from it and decides if they're detonation or not. If you're tuning on a dyno then there are a few other signs of detonation as well, such as puffs of smoke out the exhaust and irregularities in the torque curve that the dyno reports.

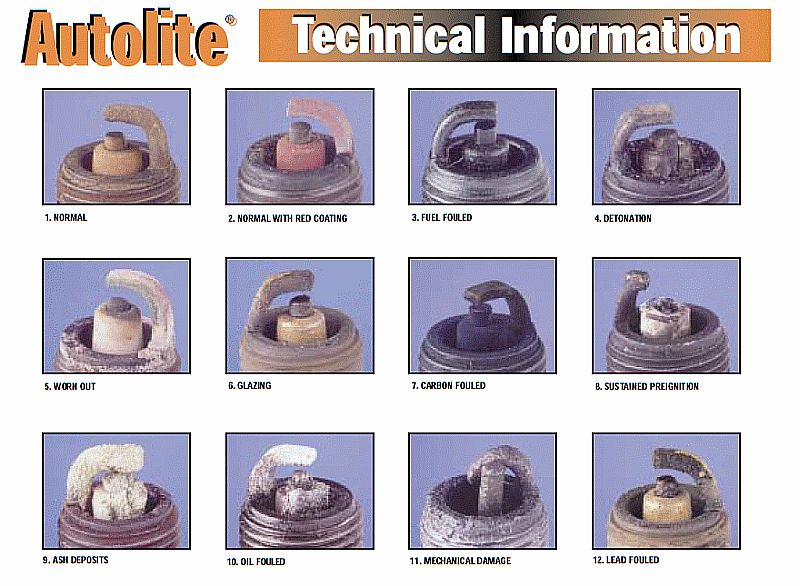

Looking at spark plugs is a very limited tuning method. It gives you very little information, just a crude rich/lean determination, and even that requires that you follow certain procedures to avoid false readings. It doesn't tell you anything about why it's rich or lean, what RPM, throttle setting, or boost level (if forced induction). If you see signs of detonation damage on the spark plug then you've probably already done damage to the piston. Perhaps it made sense in the days of carburetors and points when modern tools were not available, but we can do much better than that now.

I took a knock sensor and wired it in to a microphone jack on my laptop and then recorded it. When you hear a sound like crackling mixed with popcorn (kind of like hot oil crackling) you are getting knock. Not a perfect system but better than reading plugs as you will get knock long before you can actually hear/feel it.

Blunder

New Reader

6/22/22 8:25 a.m.

In reply to Tom1200 :

I did do some reading about it elsewhere on the internet but honestly I just really enjoy this forum and the contributors on it so I wanted to learn about it from the people here.

Blunder

New Reader

6/22/22 8:27 a.m.

In reply to codrus (Forum Supporter) :

I just have the factory a9l computer. I do have an adjustable fpr and will work on getting my wide band bung welded in. I think I remember reading that the bung placement should not be in the bottom side of the exhaust. More towards the middle of the side?

Nomad

Reader

6/22/22 9:51 a.m.

Speaking of plugs... Just bought a used car and I got 3 like this. I read them as: "Screwed".

First time that's ever happened to me. Luckily a bolt extractor got the threaded portion out.

Don't forget the antisieze folks.

In reply to Nomad :

Crazy! NGK's too. I'd have guessed it was some cheap-o plugs. I put plugs in my pathfinder yesterday and my tub of anti-seize was there as always.

Nomad

Reader

6/22/22 10:05 a.m.

Clean snap on each one, very thin area that they cut in (for no apparent good reason) right under the flats. It's basically scoring the metal to break on purpose. Def one of those "uh oh" moments where dollar signes started swimming around my head.

Hmm, I think I may send this to NGK.

In reply to codrus (Forum Supporter) :

Tell that to Smokey Yunick. :)

VegasNick said:

Tell that to Smokey Yunick. :)

I suspect the legendary tuners from that era simply had so much experience that most of the time they already knew what was wrong before they even put a socket on the plug. Glancing at the color of the tip didn't really tell then the answer, it just confirmed what they'd already figured out.

As for wideband bung placement, yes, ideally the bung points straight up but anywhere in the top half of the pipe is generally acceptable. Obviously it needs to go in front of any cat, but you also need to avoid getting it too hot. It sounds like you have a street-driven naturally aspirated V8 so that's probably not a big deal, putting it right before the cat is probably fine. (for turbo, rotary, or track cars they sell a heat sink mount that helps a lot).

On the topic of listening for knock, many people like to use "det cans". This is a device to amplify the sound of the engine knocks so that you can hear them more clearly, either passively (like a stethoscope), or actively (small microphone clipped to the engine block, with an amplifier and a pair of headphones). There are writeups online for how to build one DIY. This can help if you have a car that's got a lot of ambient noise in the cabin or if (like me) your hearing isn't as good as it used to be. You will need to learn to distinguish knock from other engine sounds, one trick if you're trying to determine if a particular noise at a particular RPM is knock is to back off the timing significantly at that spot. If it goes away it's knock, if it doesn't then it's not. This is probably more useful when tuning an ECU though.

Speaking of ECUs, I believe there are aftemarket products that allow you to tune the A9L although I have no idea how well they work. That road also brings with it a lot of complexity that may or may not be worth it.

Google det can or engine ear and you will have some results to point you well. I still have mine made out of some copper piping, rubber hose and old ear muffs. I used them for tuning for the first few years before I started doing the same engines over and over and they've been gathering dust since.

Blunder

New Reader

6/22/22 3:47 p.m.

In reply to Nomad :

Is anti seize ok to use with aluminum heads?

This chart used to be in all repair manuals.

Nomad

Reader

6/22/22 5:04 p.m.

In reply to Blunder :

I always use it. Just a little on the threads and I wipe off excess. Finger tight then basically snug-a-dug 1/8 turn. I don't use a large ratchet and crank on the end of it.

I think the PO went ape. To get them out I had to use a breaker and slowly applied pressure...then... "TINK!"

The threaded part did come out with a good bit of pressure on the bolt extractor using a large crescent wrench.

So what causes the ASH deposits like #9. My JK Wrangler had plugs that looked similar when I got it with 70k

Tom1200

UltraDork

6/22/22 11:35 p.m.

In reply to Blunder :

So I've spent a lot of time reading plugs (two strokes); with some experience it's a pretty handy skill that is useful.

With that said modern technology has made it near obsolete.

In reply to Nomad :

Ash deposits like that are oil burning. Really burning it thoroughly, not enough to foul, and maybe not enough to smoke out the exhaust.

In reply to Blunder :

No seize is far more important on aluminum heads than iron ones. Also if you are installing a plug into a hot engine, put them snug and let them warm up to head temp. before you tighten them fully.

Great advice and comments from codrus.

I think one of the most misunderstood things about reading plugs is that you're mainly reading whatever the last thing the engine did, which is usually idling. The proper way to read a plug for optimal power or WOT tuning or advance is to make a hard WOT pull and then immediately shut down the engine under load and coast to a stop so you're reading the WOT/load timing and mixture not the idle timing and mixture (or part-throttle, etc.). Unless you're on a racetrack or have a really long driveway, it's pretty dangerous to do that because you're reading plugs on the side of the road.

I go to the dyno to figure out the best max advance and a wide-band to get the best mixture (ideally at the dyno). If your budget doesn't support that, I'd suggest setting max advance at whatever rule of thumb is offered for the heads (probably around 36 degrees?) and maybe vary one way or the other by a degree or two and see if you can feel any difference. You may or may not hear pinging, but if it's pinging, you'll feel the power loss (and you may see deposits on the plugs if you read them).

I don't find a wide-band very useful for timing. If timing is way off (5-10 degrees), you'll usually get a rich reading because you're not getting a complete burn. But if you're looking for a degree or two, I doubt you'll see it on a wide band.

Tom1200

UltraDork

6/23/22 8:35 p.m.

In reply to Carl Heideman :

We've used an old abandoned mining road it's 15 minutes from the house...........but I too take the car to a dyno.

Plug chops are really not a thing anymore.

Nomad said:

Clean snap on each one, very thin area that they cut in (for no apparent good reason) right under the flats. It's basically scoring the metal to break on purpose. Def one of those "uh oh" moments where dollar signes started swimming around my head.

Hmm, I think I may send this to NGK.

You could send it to ngk, but they will inform you that the plug was overtorqued on install and that caused the failure upon removal.

Over torquing of plugs is the #1 cause of failure on ngk plugs (or so I was told by one of their reps a few years ago)

It also leads to increased load on the porcelain which causes cracks and premature failure.

Moral of the story, they aren't head bolts people.