So, i deleted the ppf that also served as the diff mount in my nb miata challenge car.

I need to put something th neter to locate the front of the centersection.

Google shows adjustable heims as a solution. But, challenge car budget.

What are the other options? Torque arm/ppf are out due to the trans tunnel being awfully full already.

I thought about a square tube mount to the factory ppf bolt holes, but im not sure if there needs to be articulation at the front to deal with the rubber bushings on the ears of the diff.

Also, anything else i should do while i have the welder at the rear crissmwmber?

In reply to Dusterbd13 :

Add some rubber bushings on either side of the bolts though the front of the diff to your tubular mount, and use bolts ~1mm smaller diameter than stock to allow a slight amount of movement?

Either that, or remove the bushings from the diff ears so the whole diff is mounted rigidly?

Build a little baby PPF and bolt it through the trans tunnel. Make it solid. I did this years ago with my Seven.

In reply to Keith Tanner :

Do you happen to have an install the picture? Having a hard time seeing what you're talking about

Well, that wasn't installed into a Miata so it wouldn't help. I bolted sideways through the trans tunnel - here's the same piece with the captive nuts in place some time later.

Oooo. I see said the blind man.

How much force are we realistically going to be dealing with here?

Math can help you with torque and lever arms. This is a spot that CMC (the manufacturer of my Locost frame) had trouble with, they underestimated them pretty badly and the diffs kept ripping out. That one in the picture showed no signs of problems after quite a bit of hard use, but it was on a light car with a naturally aspirated 1.6. On the V8 cars, we feed the loads into the front of the subframe but the Miata diff may be too long for that.

Note, this is upside down :)

Im not sure what the answer is here, but I imagine the 3rg gen RX7 guys have this figured out with the V8 swaps.

Maybe search for that?

Im not sure what the nomenclature is for 3rd gen rx7, or what they call the ppf.

Ill be happy to search though!

Snrub

HalfDork

11/5/18 5:06 p.m.

Dusterbd13 said:

Im not sure what the nomenclature is for 3rd gen rx7, or what they call the ppf.

FD. PPF is a PPF on a NA-ND, FD, RX-8.

Did we determine that a solid front mount and rubber ear bushings are cool or not? Think i have a solution. But, depends on if it needs to flex up front or not.

Cant do solid ear bushings on remaining budget.....

That's what I did on mine years ago. It's been holding up. May not be ideal, but it'll probably work.

Cool. I just dont want to break stuff.

I may be able to work some sway bar end links in there for flop, but im not sure they're strong enough.

On my stock rearend rx7 (no PPF on 2nd gens), I eliminated all of the slop and bushing in the front of the rearend. I still have stock squishy bushings in the rear part.

No problems after multiple years of running Champcar.

In reply to wvumtnbkr :

Awesome. And the rx7 shares the same widespread aluminium batwing mounts as the miata? Im probably overthinking it.

NickD

UberDork

11/8/18 2:00 p.m.

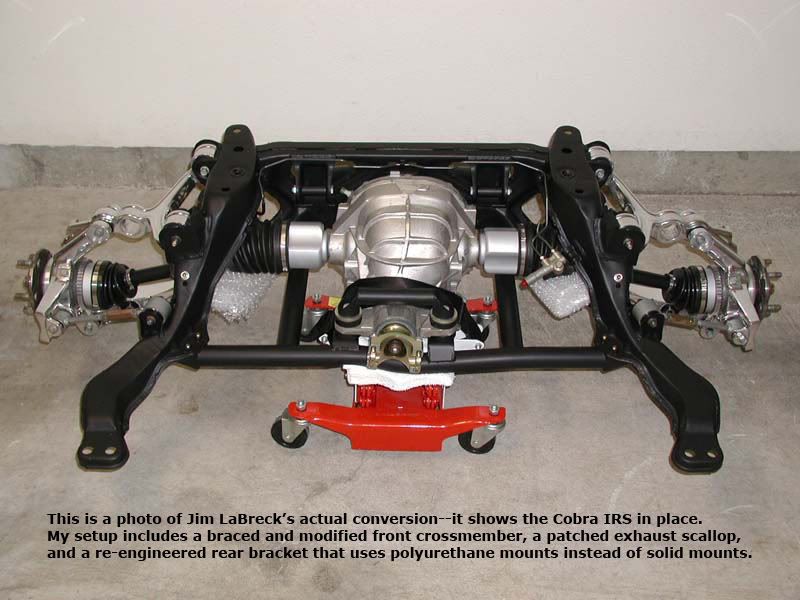

K-Miata makes this little doohickey for use in cars with a BMW trans.

Thats almost exactly what i have planned in my head. Just trying to eliminate failures and add reliability/durability during initial build. My wallet can'tafford breaking parts at an accelerated rate.

My plan (hopefully) is to add sway bar end links in between the two pieces so theres a little up/down movement like the ppf wiuld have had. But i dont think ill have the real estate to do so.

Can you add onto your butterfly brace or is it too far forward?

Dusterbd13 said:

Thats almost exactly what i have planned in my head. Just trying to eliminate failures and add reliability/durability during initial build. My wallet can'tafford breaking parts at an accelerated rate.

My plan (hopefully) is to add sway bar end links in between the two pieces so theres a little up/down movement like the ppf wiuld have had. But i dont think ill have the real estate to do so.

CMC - the manufacturer of the frame for my Locost - decided to add a little flex in that front mount. Turns out there's enough load that the diff takes full advantage of the flex and basically gets a run up and rips itself out. I wouldn't allow any flex. The PPF allows almost no vertical movement of the nose, it's weakest in twist and that's to let the engine rock side to side.

The KMiata pic shows a nice, simple solution.

Patrick said:

Can you add onto your butterfly brace or is it too far forward?

The thought crossed my mind. But id worry about flex in whatever square tube was used, or the andle iron that most of the brace is made out of. Doesn't seem like it would have the needed strength/rigidity. Its also about a foot forward, so were adding a buch of leverage there.

Keith Tanner said:

Dusterbd13 said:

Thats almost exactly what i have planned in my head. Just trying to eliminate failures and add reliability/durability during initial build. My wallet can'tafford breaking parts at an accelerated rate.

My plan (hopefully) is to add sway bar end links in between the two pieces so theres a little up/down movement like the ppf wiuld have had. But i dont think ill have the real estate to do so.

CMC - the manufacturer of the frame for my Locost - decided to add a little flex in that front mount. Turns out there's enough load that the diff takes full advantage of the flex and basically gets a run up and rips itself out. I wouldn't allow any flex. The PPF allows almost no vertical movement of the nose, it's weakest in twist and that's to let the engine rock side to side.

The KMiata pic shows a nice, simple solution.

Thats the piece of engineering advice ive been missing! I ASSUMED the ppf allowed for flex and pinion angle change. Now that you say it, i can see how blatantly wrong i was.

So, rigid and solid are fine, fore/aft/up/down/side to side.

That makes it easy!

How beefy should it be? 1x1x1/8 square tube and 2x2 angle iron be ok?

Mine was 1x1x1/8 if memory serves. The longer the arms, the stronger they'll have to be. I'd just copy that KMiata piece shamelessly.

The kmiata piece is the goal. Only not machined aluminum.

Only problem may be the horizontal brace. Dint think it will clear the exhaust, so i may have to go up.

Or clearance the exhaust.