wae

SuperDork

5/16/18 7:02 a.m.

I've got two, maybe 3 vehicles that need A/C work: Dash air on the motorhome, the $1200 Miata, and maybe the wife's 2013 Mazda5. The first two don't work at all and have no pressure in the system, the Mazda5 has a leak, but maintains pressure for some period of time. If I can hit the 5 with a fourth of a can from the FLAPS once or maybe even twice a year, it's probably not worth fixing, but we've just started measuring how long it takes to leak down. All three systems came from the factory supporting R134a.

The electronic refrigerant detector is about $40, the gauges are about $60, and the vacuum pump is about $100. Figure some smart shopping and coupons and it's about $175 in tools that I'd need to buy. I'd also have to buy the refrigerant, receiver/dryers, and whatever parts are causing the existing systems to not work properly.

A/C systems have always seemed like black magic to me, but in principle they also seem extremely simple. Expansion, contraction, some convection, and a compressor with a handful of pressure switches. With the right tools, is A/C work really all that tough or is there some sort of subtle art to it that takes time and experience to master? Is using the halogen refrigerant detector a straightforward operation, or is more akin to a dowsing rod? Is the money that I'd save sourcing my own parts and doing my own labor worth the aggravation or is this one of those tedious jobs that you're happy to throw dolla dolla billz at someone else just so you don't have to do it? I mean, I feel like I can rebuild an engine, how hard could this be, right?

cdowd

Dork

5/16/18 7:23 a.m.

I have had good sucess with the tools you are describing. Since A/C repairs always seem to come out to $1k min at a shop I figure why not. I have never tackled one with no pressure. I would think first try to vacuum and add 134a to see where it is leaking and go from there.

The basic system is not complicated, devil is in the details.

A few things, do NOT waste your money on a leak detector, I have seen thousands of dollars wasted replacing good parts. The vacuum pump is good if you have it but you can still charge the system without it.

What you should buy is a manifold set with can line (yellow) and UV A/C dye (glasses).

You can used compressed air to test the system basic with this, will the compressor come on, pressure switches working, and large leaks. After testing you can add dye and 134a and run the system checking for leaks.

Another thing to watch out for is to make sure the evap/ discharge sensor is reading the correct temperature (hard for the average person) as this will keep the compressor from coming on.

Paul B

Donebrokeit said:

The vacuum pump is good if you have it but you can still charge the system without it.

What you should buy is a manifold set with can line (yellow) and UV A/C dye (glasses).

Agreed on the manifold set and UV dye. But I disagree on the vac pump. It's 100% necessary. If you've had the system opened up or it's been leaked down to no pressure where air may have gotten in, you CANNOT charge it without pulling a good vacuum first to get all of the air / moisture out.

As far as the original question, A/C work isn't terribly complicated, so I wouldn't be scared of DIY stuff. And it's not all that expensive either. If you look around for deals, R134a can be surprisingly cheap. With a sale and a coupon, I picked up a 30lb tank from Advance Auto for about $80 2 or 3 years ago.

wae

SuperDork

5/16/18 9:16 a.m.

Good info, thank you!

I'm not too concerned with the cost of the refrigerant or the hard parts - The A/C is getting fixed regardless, so I'm spending regardless. But if I can save a buck and stroke my ego by doing it myself: Bonus!

Is the gauge set from The Hammer Store the "right" one to have? https://www.harborfreight.com/ac-r134a-manifold-gauge-set-60806.html

And they also have three different vacuum pumps. One appears to be driven by compressed air, and the other two have varying ratings, a 2.5 and a 3 CFM. From reading the reviews, it appears that the $100 2.5 CFM will get the job done, but would spending the extra bill for the 3 CFM be worth it?

The bigger vac pump might get the job done a hair faster, but it's not necessary.

FE3tMX5

New Reader

5/16/18 9:38 a.m.

I've been using that HF gauge set for years. The connectors wore out, but you can buy replacements on amazon for cheap. I've had the smaller HF vacuum pump for the same amount of time and zero issues. It pulls 30 in. without a problem. I've used on probably six different cars/systems with success- so IMO it is adequate. Will also vote for the using the dye and UV flashlight to find leaks. And will recommend high silver content brazing (solder) rod for patching any aluminum tubing holes. Requires nothing more than a propane torch and a good cleaning. I use Alcor from Harris.

Another +1 for the HF gauge set and electric vacuum pump. I've done so much A/C work with those two tools. Also you need a GOOD can tap. A cheap one will slowly leak out whatever is leftover in the can.

So, if my compressor is crapping out, but I still have refrigerant in the system what am I pulling that existing stuff into when I dump the system to replace the compressor?

The atmosphere, unless you get a shop to recover it for you. It should be very cheap, sometimes free, for a shop to recover refrigerant for you. They will re-use it anyway.

Don't release it into the atmosphere if you can avoid it. It's nasty stuff. Just get it recovered.

AutoZone will do the "loan a tool" program for the vacuum pump. No need to buy (and then store) one. It's a good heavy duty model. +1 on the HF gauge set.

I considered taking an AC class at the local tech school for a little retirement income. Problem is, they want you to take a slew of courses.

wae

SuperDork

5/16/18 12:29 p.m.

In reply to Indy-Barely Functional-Guy :

Oh, that's even better! Thanks for that tip!

You can also get AC work done fairly cheap at a local Community College or VoTech school. I have had AC work done at a CC here a couple of times and I only paid for parts.

java230

UltraDork

5/16/18 3:12 p.m.

Im in the same boat and FWIW Amazon had the gauge set for half of the HF price ($30) .

I didn't get a pump.... Yet

EDIT: does not incl the can pierce adapter thing.

As you get into the newer cars the old gauges, pump, & a couple of cans of 134a doesn't work anymore. The newer systems have precise requirements for freon & an ounce or two too much or too little can make the system inop or damage it. I understand the premise,"It's broke now so WTF?" but spending the cash to have another non functional tool hanging on the wall is a waste also.

A lot of very new stuff doesn't use 134a anymore anyway. Realistically, any system should be charged by weight. But given the pressure charts from the manufacturer's service manual (which don't always match the universal ones), you can generally get it close enough to work fine if you charge by pressure and vent temp.

The beauty of DIY air conditioning repair is that you can shoot the parts cannon at it and it still be cheaper than hiring the work out.

I am a total tool whore so the equipment that I use isn't relevant in this case, but like the fellow above said, the vacuum pump is mandatory. The vacuum boils the moisture out of the system. You cannot have a properly operating AC system with moisture in it. The venturi vacuum pumps that work off of shop air won't do the job well. I've never seen one pull below 20" of vac. You need to see about 30" of vac for a sustained period to get the system dry. 30 minutes is the general guideline for holding it under vacuum.

And, like the other fellow said, the devil is in the details. Clean everything scrupulously clean, use only brand new high-quality orings and seals, lube each one upon assembly and torque it properly. When I say high quality rings and seals, I mean AC spec stuff, not a Harbor Freight generic o ring selection.

And, shotgun it a little. Replace all the seals, schrader valves, and drier while you have it open. Fix it once, fix it right, forget about it for a long time.

In reply to Indy-Barely Functional-Guy :

It’s almost always empty of compressor oil though.

Can someone explain to me, someone who has never done more than replace a compressor and recharge with cans, how i’m using these tools to find the leaks? The wrx leaks down enough in a day that the compressor won’t kick on. I have a vacuum pump, manifold gauges, and uv leak detector but they just collect dust.

I always look at car repairs as an excuse to get new specialty tools.

I picked up a 30lb tank from Advance Auto for about $80 2 or 3 years ago.

Just as an FYI, the EPA changed the law. Effective 1/1/18 you now need to be certified to buy more than 2 lbs of R134a. The cert is easy enough to get but most DIYers will just buy a couple cans at a time anyway. I figured it was worth mentioning.

I have a '71 Ford that has been "converted" to 134a. The compressor runs nonstop, but it doesn't blow cold, it doesn't show any pressure on the gauge on the autozone can, and no material leaves the can. Is there a DIYer here that lives reasonably close to Altoona, PA that wants to take a crack at it?

Vigo

UltimaDork

5/16/18 10:45 p.m.

Can someone explain to me, someone who has never done more than replace a compressor and recharge with cans, how i’m using these tools to find the leaks?

Well, in most cases you rely on the oil in the system to leave you a clue. There is both oil and refrigerant floating around in the system. The molecules are different sizes. It is possible to have a leak that will only leak refrigerant but no oil. That one is tough because while the refrigerant is liquid in a pressurized can, at ambient/outside pressures and temperatures it is an invisible gas that simply floats away leaving no clue as to where it escaped. The compressor oil, on the other hand, is liquid at ambient pressure/temp so it will simply sit there staining whatever part it leaked out of, or possibly dripping off if there's enough of it. Oil dye in combination with UV light and glasses just makes oil residue more visible, but even without glasses or a colored dye at all you can spot 'oil wetness' with the naked eye just as you would on a small engine or transmission leak. Most of the AC system is easy to visually trace and scan for wetness. The evaporator buried in the dash is the one difficult spot. In extremely convenient cases, a leaking evaporator core with oil dye in the system will leave a drip of green fluid coming out of the evaporator drain tube (the tube where 'ac water' comes out of the firewall). In less convenient cases a 'sniffer' stuck up the drain tube will still give a strong reading. If even the sniffer isn't giving you a smoking gun, you're basically down to process of elimination as far as diagnosing an evaporator leak. But leaking out in a day is classified a 'pretty damn big leak' and will light up a sniffer like christmas when you find it, assuming it requires anything more than a keen eye spotting some oil residue in the first place.

FE3tMX5

New Reader

5/17/18 8:42 a.m.

Patrick said:

...how i’m using these tools to find the leaks?

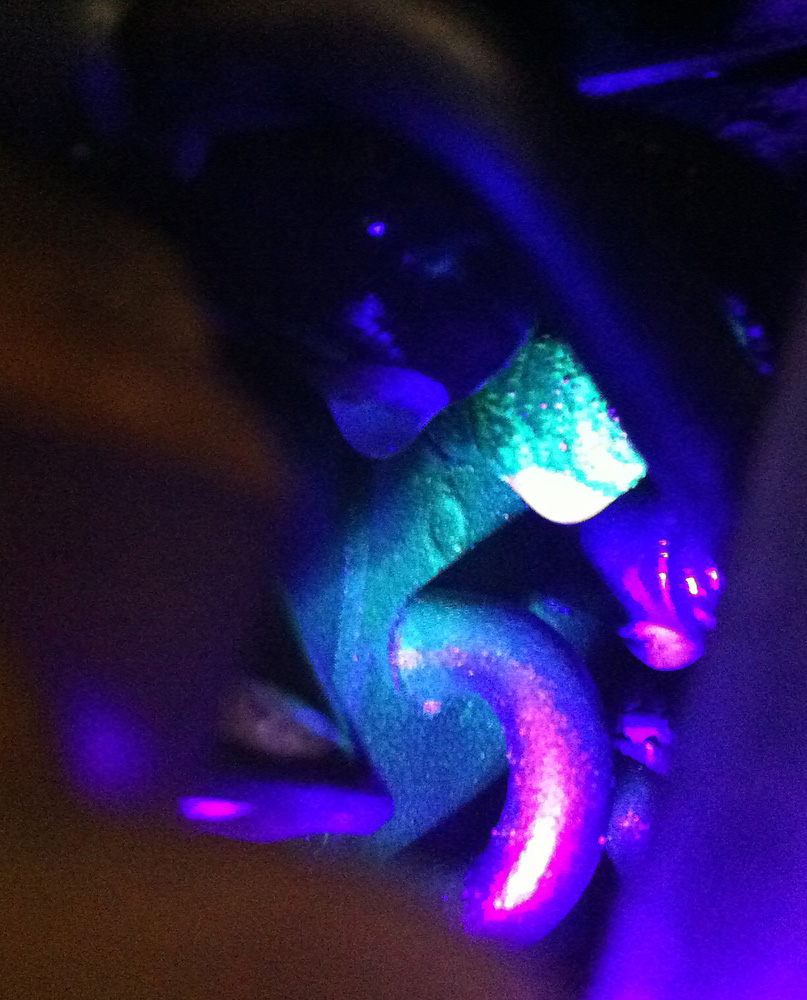

Here's a leak (dayglow yellow/green) on my condenser revealed with a UV flashlight and a charge using refrigerant with dye.