Try a thermostat in a 3400 impala. 9 hours of pain and cursing and tears. Have to remove throttle body and exhaust crossover. Then there are 2 bolts for the stat that are 2.5" long and thread in not square to the block and you can get about 6 degrees of swing on a wrench. Worst fwd ever. I almost quit being a car enthusiast after that one.

The Zetec in my ZX2SR was pretty easy to work on when I had to, which wasn't often since it was so reliable.

Agree with the oil filter. I worked out a method which made it a little easier and less messy.

In reply to Tom Suddard: You probably know that it's also because it's cheaper to manufacture and to ship FWD drivetrains over RWD ones. Then, the handling is better suited for bad, um ..., I mean normal drivers.

I'm surprised the staff hasn't had to do maintenance like that on your old Celica or Civic project cars.

Oh, we have–I've just hid in my pile of cars when that was going on.

codrus

HalfDork

8/26/14 10:21 p.m.

Swank Force One wrote:

pres589 wrote:

It really depends. I enjoyed working under the hood of my Mazda 626 Turbo. I hated working under the hood of my Olds Intrigue. I think transverse V6's aren't nearly as fun to deal with as transverse inline-4's. It also, honestly, seemed like the Mazda engineers did enjoy things like working on cars or driving cars. It seemed like the GM engineers were told by accountants that none of that really mattered.

It's even easier when you remove all the things that aren't absolutely necessary to go down the road.

I CAN SEE EVERYTHING.

I've heard of a wire tuck -- but a valve cover tuck?

Opti

Reader

8/26/14 10:39 p.m.

I think some form of intake tube when you have a turbo car would be required for going down the road, also generally cars require some form of coolant hoses. I appreciate your ode to colin chapman, but I dont think thats what he had in mind. I kid, I kid, but you should update your build thread so I can cry that there are no Mx6s around me.

M2Pilot

HalfDork

8/26/14 10:46 p.m.

Advan046 wrote:

In reply to Tom Suddard:

I guess you missed all of the talk in the industry when Ford designed the Focus. Ford made efforts to communicate to the masses that they were engineering the car to be maintainable by us non special tool mechanics. I remember one delay of its production was due to the engineering team wanting to make something that much easier to replace on the car. I remember one other "feature" they focused on was to get the rain and water management right so that English drivers could drive around with the windows slightly open. Not sure why those Englishmen want to drive around in the rain with windows slightly open but it was a big deal for them.

I heard some thought maintenance was much improved and others thought it wasn't an improvement at all.

Ford also made a big issue of easy maintainence when the introduced the Maverick.

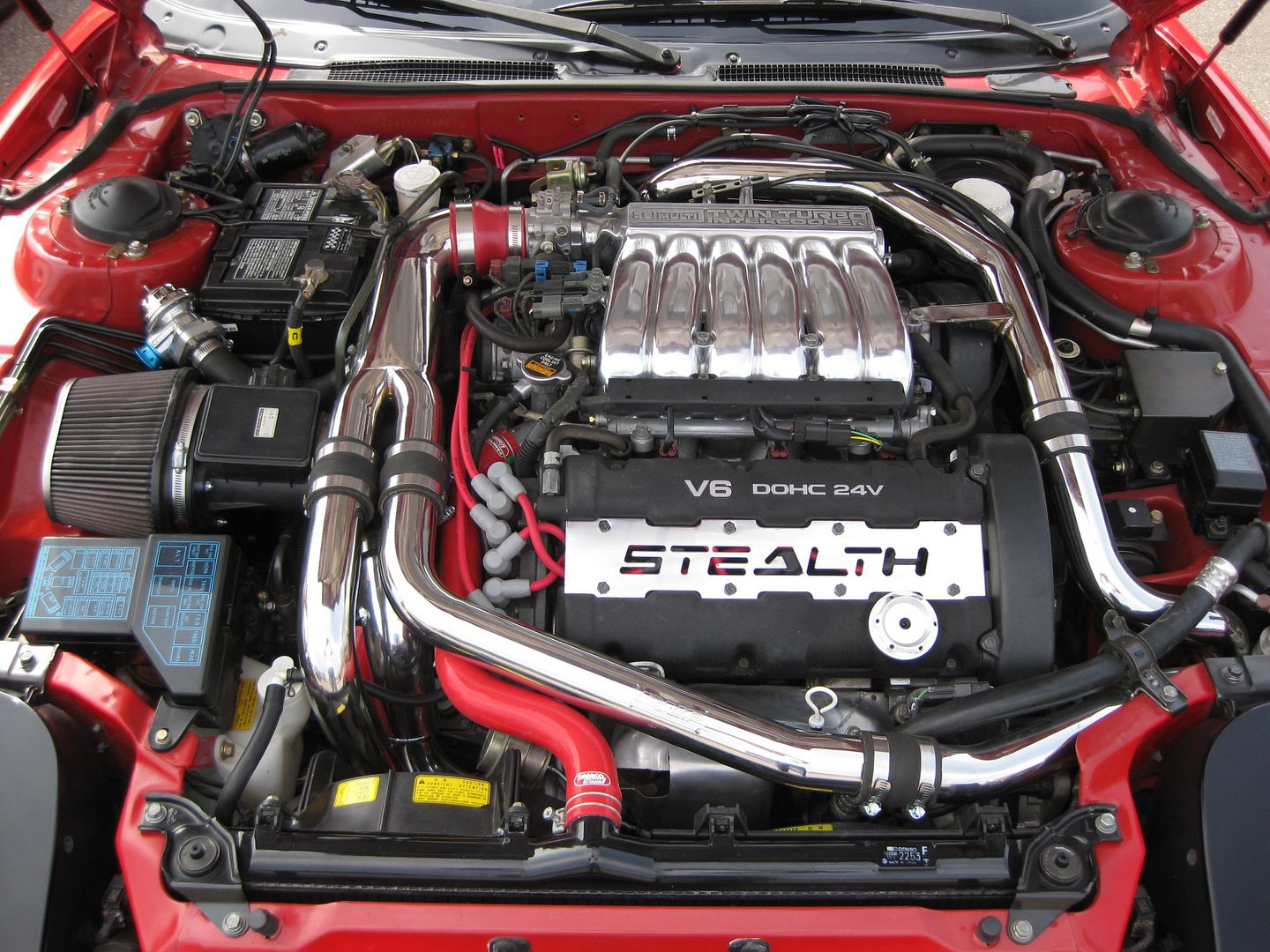

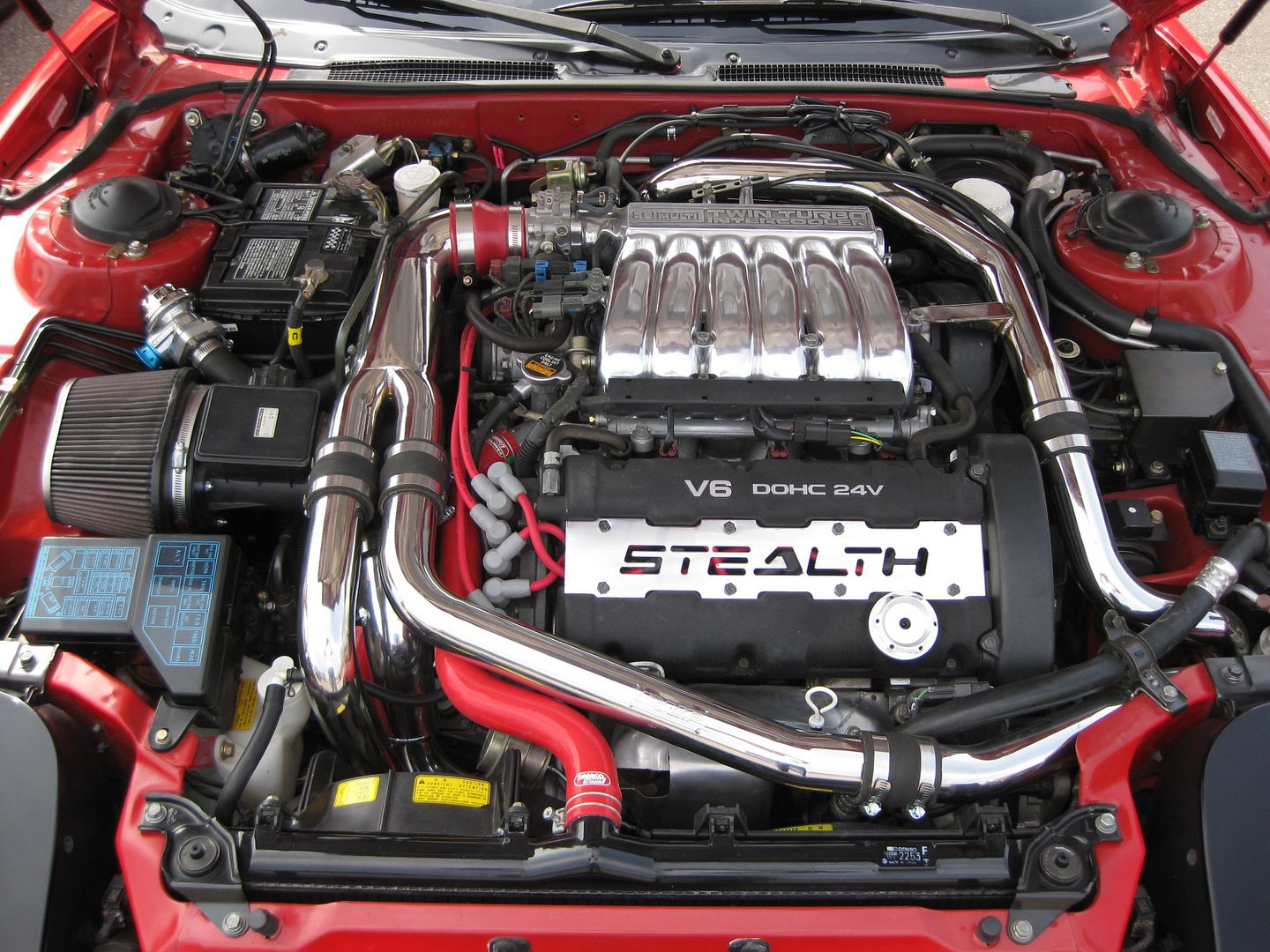

Worst offender is the Mitsubishi 3000GT. Close second are the PT cruiser and V6 FWD minivans.

I'm more terrified of driving a FWD car than I am of working on it

Grizz

UltraDork

8/27/14 12:08 a.m.

In reply to Kenny_McCormic:

Beat me to it.

Simple Rule, if you open the hood and can't see ground looking down, don't bother with it.

Although....

Advan046 wrote:

In reply to N Sperlo:

? Wha cha sayin there mate?

Manual window cranks give you the optimal control you need in your windows.

clutchsmoke wrote:

Still be afraid of doing front brakes on 90s accords. And learn the special handshake before replacing the alternator on a 90s Civic/Integra.

You just hit on a couple of reasons I do not heart Hondas.

Ian F

UltimaDork

8/27/14 9:21 a.m.

In reply to Kenny_McCormic:

I don't know... the 3.3L OHV V6 in my Caravan looks tiny in the engine bay. I'm sure those rear 3 plugs will be annoying to get to, but all things considered, there's a ton of room in there. A side benefit of the chassis being designed for a larger DOHC V6, I suppose.

Which reminds me I'm past due for a 100K mile service...

codrus wrote:

Swank Force One wrote:

pres589 wrote:

It really depends. I enjoyed working under the hood of my Mazda 626 Turbo. I hated working under the hood of my Olds Intrigue. I think transverse V6's aren't nearly as fun to deal with as transverse inline-4's. It also, honestly, seemed like the Mazda engineers did enjoy things like working on cars or driving cars. It seemed like the GM engineers were told by accountants that none of that really mattered.

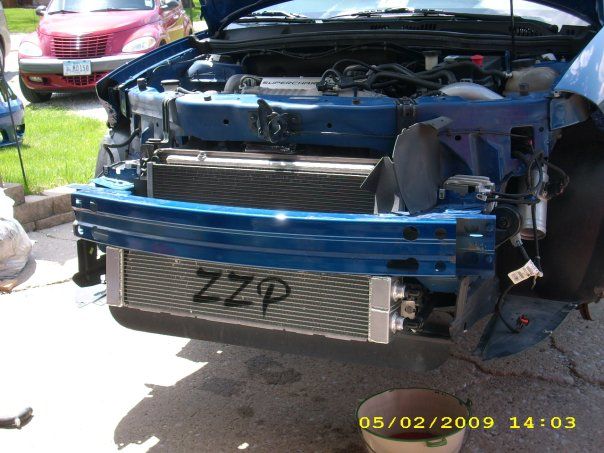

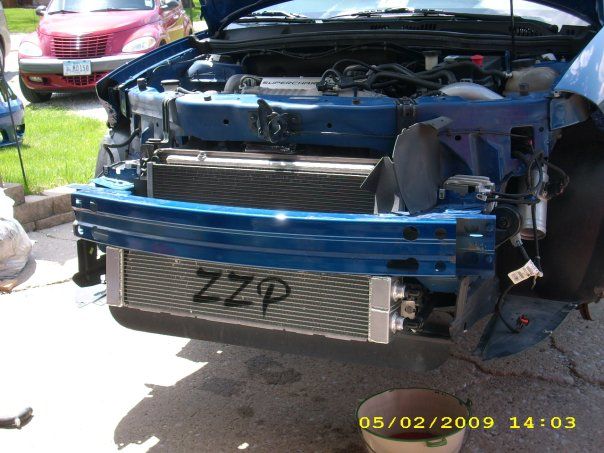

It's even easier when you remove all the things that aren't absolutely necessary to go down the road.

I CAN SEE EVERYTHING.

I've heard of a wire tuck -- but a valve cover tuck?

Didn't want to put it back on until i was done welding it.

Transverse Cadillac V8 FWD

once you pull the plastic off, most FWD's aren't bad at all lol

Tom Suddard wrote:

Oh, we have–I've just hid in my pile of cars when that was going on.

Awesome and honest answer Tom

In reply to Armitage:

Forgot about the northE36 M3 motors. The starter, a crappy GM failure prone starter, is UNDER THE INTAKE.

The two easiest FWD cars to work on are the Chrysler L-body and the MkI Rabbit. All else pale in simplistic comparison. OK Civic up through the early 90s were pretty easy too.

Grizz

UltraDork

8/27/14 4:07 p.m.

Ian F wrote:

In reply to Kenny_McCormic:

I don't know... the 3.3L OHV V6 in my Caravan looks tiny in the engine bay. I'm sure those rear 3 plugs will be annoying to get to, but all things considered, there's a ton of room in there. A side benefit of the chassis being designed for a larger DOHC V6, I suppose.

Which reminds me I'm past due for a 100K mile service...

Which engine was that?

The 3.8 in the vans is OHV as well isn't it?

captdownshift wrote:

In reply to Moparman:

BG chassis mazdas

I wasn't fond of doing the starter or alternator on our Escort GT back when it was still stock.

That said, that was me trying to do everything from the top.

it's still better then the recent alternator job on the first gen xb was :(

novaderrik wrote:

.. and i hear the alternator on a DOHC 3.4 powered Lumina is also not so very much fun, either..

Just reading that made me shiver.

Doing just about anything on my Alfa 164 24V requires removing the passenger-side fender liners and intake plenum. I'm so used to it now it doesn't even register. I would hate to have to replace the rear head gasket. There's absolutely no room to remove the rear cylinder head without somehow tipping the engine forward.

What annoys me more, however is the amount of special tools required to properly align the camshafts and tension the timing belt during a T-belt change, especially because the 164's 24V has a unique tensioner and belt routing compared to later overseas Alfa 24Vs. Of course, that's more an Alfa problem than a FWD problem. I do need to replace the CV boots but the good news for that is they unbolt from the halfshafts, meaning I can replace the boots without removing the CV axles entirely.