JThw8

SuperDork

1/21/10 6:47 p.m.

Ok, so Im piecing this thing together still. The dilemma du jour is as follows.

The distance between the pivot points for the front a-arms is 19 inches.

I have 2 steering racks to work with.

Rack A - 16 inches between the pivot points

Rack B - 22 inches between the pivot points

As I understand it the ideal is to have the pivot points equal to the a-arm points so its it better to be further out or further in?

Ideally I'd like to use rack B for a myriad of reasons not the least of which is its about 1/3 the cost of rack A, but something tells me rack A is the better choice.

Whoa, buck: there's a bit more at work here. Which will allow your tie rods to be closest to the averaged length of the upper and lower control arms, and is the rack above, below or between the control arms?

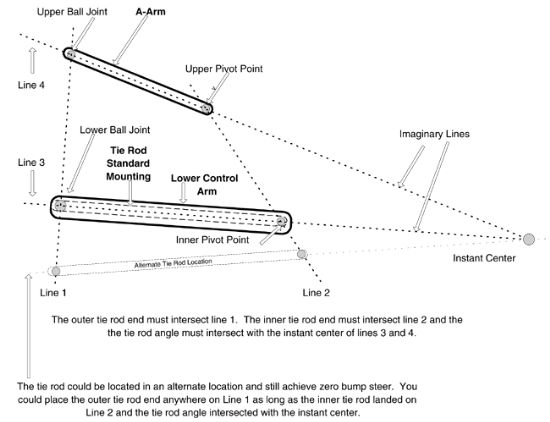

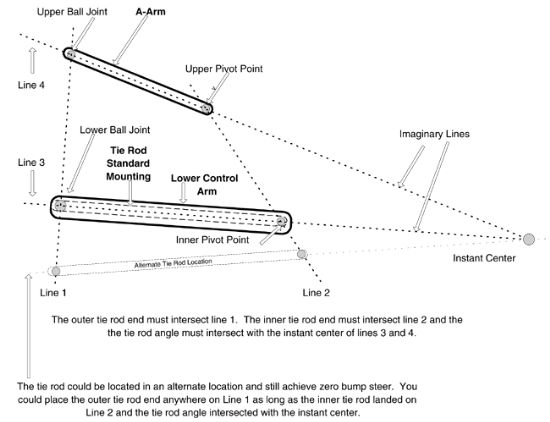

Do this: draw, as nearly as possible, the layout of your inner control arm pivots as near life size as possible (makes this easier). Then plot the position of the rack and see which one has the inner tie rod pivot points closest to that line when it's mounted. In general, the short rack will probably work best if it's below the lower control arm and the long rack may work better if it's mounted between the inner pivot points.

From my fiddling around, if the tie rod is longer than the control arms the wheels will toe out as the rod moves through its arc and toe in if it is shorter. Obviously the 'at rest' angle has a lot to do with this as well.

Also, is your rack ahead of or behind the front axle center line? If it's behind, you want the inner tie rod pivots ahead of the outer as viewed from above, if the rack is ahead of the axle centerline you want the opposite.

That should help you pick the rack that's best for your setup.

Talk to Jensenman about how to shorten or stretch one.

I don't know the answer, but I would think that a shorter rack would be better. The longer tie rods should lessen the the effect of being the wrong length. Maybe.

Well he got in there before me. Like I said talk to Jensenman.

Sonic

Dork

1/21/10 8:00 p.m.

On Sunday we will draw this out. We need to get the knuckles mounted and see how far in the arm on the knuckle will stick out, as the change in tie rod length will make a difference.

Nice to have Jmans diagram

JThw8

SuperDork

1/21/10 8:01 p.m.

Ok a few more factors which confuse me (but THANK YOU for the informative input!)

There is no upper a-arm....now what? Its a macphearson strut suspension, just the lower a-arm

It is front steer so that puts the rack ahead of the axle centerline. Once I get the suspension firmly in place I can get better measurements. Steering is definitely a point that scrambles my brain.

The rack would be mounted slightly above the lower a-arm (approx 1.5 inches between a-arm and tie rod)

I really appreciate the very informative post, if you can tell me how to figure this when there is no upper a-arm I think I can sort it based on the info above.

JThw8

SuperDork

1/21/10 8:02 p.m.

Sonic wrote:

On Sunday we will draw this out. We need to get the knuckles mounted and see how far in the arm on the knuckle will stick out, as the change in tie rod length will make a difference.

Nice to have Jmans diagram

I mocked up one side, the steering arm is in direct line with the ball joint not to the inside.

Sonic

Dork

1/21/10 8:37 p.m.

Ok then. Perhaps we should be looking for more racks. This car is going to be such an evil handler already, last thing we need is more bump steer.

JThw8

SuperDork

1/21/10 8:38 p.m.

Sonic wrote:

Ok then. Perhaps we should be looking for more racks. This car is going to be such an evil handler already, last thing we need is more bump steer.

I dont think anything we've seen yet says we need to rule these out yet. Wont know for sure till we put it all together.

JThw8

SuperDork

1/21/10 9:00 p.m.

Ok, new one for the experts....stumbled across this out on the interwebs.

Looks like it would be easy enough to make that tire rod carrier to fit our longer rack and thus allow the inner pivot to be placed anywhere we want. What say you? Is something like this a workable idea?

JThw8 wrote:

Ok, new one for the experts....stumbled across this out on the interwebs.

Looks like it would be easy enough to make that tire rod carrier to fit our longer rack and thus allow the inner pivot to be placed anywhere we want. What say you? Is something like this a workable idea?

that looks like a terible idea, but I bet it will work

If i recall corestly a chevette rack is closer to 21 center of tie rod to tie rod.

JThw8

SuperDork

1/22/10 7:06 a.m.

44Dwarf wrote:

If i recall corestly a chevette rack is closer to 21 center of tie rod to tie rod.

Any idea if those are set up for front or rear steer?

JThw8

SuperDork

1/22/10 7:15 a.m.

HappyAndy wrote:

JThw8 wrote:

Ok, new one for the experts....stumbled across this out on the interwebs.

Looks like it would be easy enough to make that tire rod carrier to fit our longer rack and thus allow the inner pivot to be placed anywhere we want. What say you? Is something like this a workable idea?

that looks like a terible idea, but I bet it will work

Yeah, I defnitely have a few problems with the concept, but some of them could be corrected. Like what is keeping that whole assembly from just pivoting on the end points?

I did some more mocking up last night and found a few issues but also a few possible solutions. And as it turns out the stock tie rods on rack B are darn near the perfect size so that would make the solution even more budget friendly since I just happened to get the tie rods with the rack. The ball joints are a good fit too.

The other thing I discovered is the design of the inners requires the rack to be mounted further forward than I had anticipated, this may be a good thing but Im not certian. The inner tie rod mounts are angled to face rearward. See attached crappy photo.

Still need to know how to measure when there is no upper a arm. I've been hunting around and everything I find is similar to the above diagram where they assume you have 2 a arms.

JThw8 wrote:

There is no upper a-arm....now what? Its a macphearson strut suspension, just the lower a-arm

The rack would be mounted slightly above the lower a-arm (approx 1.5 inches between a-arm and tie rod)

The lack of an upper control arm pretty much settles your layout. For minimal bump steer you will need to have the rack mounted so that the tie rods and control arm are in the same plane as viewed from ahead. Also in the same minimize bump steer vein, I'd say go with the longer rack and be sure that the control arm is level with the ground at ride height. That way bump steer is in the understeer direction.

To find the instant center with a strut, draw a line at a 90* angle from the strut top to where it intersects with the line from the lowere control arm.

JThw8

SuperDork

1/22/10 10:12 a.m.

Jensenman wrote:

JThw8 wrote:

There is no upper a-arm....now what? Its a macphearson strut suspension, just the lower a-arm

The rack would be mounted slightly above the lower a-arm (approx 1.5 inches between a-arm and tie rod)

The lack of an upper control arm pretty much settles your layout. For minimal bump steer you will need to have the rack mounted so that the tie rods and control arm are in the same plane as viewed from ahead. Also in the same minimize bump steer vein, I'd say go with the longer rack and be sure that the control arm is level with the ground at ride height. That way bump steer is in the understeer direction.

Many thanks, It looks like the longer one will work well then, we can get it mounted to keep the tie rods in the same plane as the a-arm (to Sonic's credit he's been telling me that all along)

We are currently mocking everything up with the control arm level to the ground at ride height but when its all back together I suspect the springs will need to be shortened/replaced/etc to maintain that stance. Wont know for sure until we figure out exactly how much weight we've put in the front of this thing. The strut box is stupidly heavy but I'd rather skew towards overkill since none of us are engineers.

JThw8 wrote: <

HappyAndy wrote:

JThw8 wrote:

Ok, new one for the experts....stumbled across this out on the interwebs.

Looks like it would be easy enough to make that tire rod carrier to fit our longer rack and thus allow the inner pivot to be placed anywhere we want. What say you? Is something like this a workable idea?

that looks like a terible idea, but I bet it will work

Yeah, I defnitely have a few problems with the concept, but some of them could be corrected. Like what is keeping that whole assembly from just pivoting on the end points?

I did some more mocking up last night and found a few issues but also a few possible solutions. And as it turns out the stock tie rods on rack B are darn near the perfect size so that would make the solution even more budget friendly since I just happened to get the tie rods with the rack. The ball joints are a good fit too.

That would work but yeah it is sorta spooky looking.

JThw8 wrote: <

The other thing I discovered is the design of the inners requires the rack to be mounted further forward than I had anticipated, this may be a good thing but Im not certian. The inner tie rod mounts are angled to face rearward. See attached crappy photo.

Still need to know how to measure when there is no upper a arm. I've been hunting around and everything I find is similar to the above diagram where they assume you have 2 a arms.

Still need to know how to measure when there is no upper a arm. I've been hunting around and everything I find is similar to the above diagram where they assume you have 2 a arms.

That diagram shows a steering layout very similar to the Abomination's original one which led to absolutely terrible 'reverse Ackerman', i.e. the outside tire turned more than the inside one, it should be the other way around. It was so bad that in low speed turns with race tires it would literally yank the steering wheel out of your hands in the oversteer direction and in high speed turns the outside tire was forced into very high slip angles. I went through a lot to get the tie rods angled the other way and the steering was vastly improved.

BTW, it's not real hard to shorten a rack if the housing has a steel tube.

JThw8

SuperDork

1/22/10 11:46 a.m.

Jensenman wrote:

BTW, it's not real hard to shorten a rack if the housing has a steel tube.

I belive both of the ones Im working with at the moment are encased in aluminum.

In reference to your post above, I dont see how I could get the tie rods angled the other way on a front steer vehicle unless Im missing something. The rack has to sit in front of the centerline of the axle. I can get the angle alot less or probably even straight on with some reworking on the parts but I dont see how I could get it to angle the other way without moving the rack behind the axle centerline and then the tie rods would be interfering with the struts.

Am I misunderstanding?

JThw8

SuperDork

1/22/10 12:05 p.m.

Just been doing a little reading and FWIW my diagaram there isnt great, there is indeed a steering arm angled inboard on the steering knuckle so its not a parallel setup. As I understand it that will play a large role in ackerman so I fear Im not giving a full picture. I will try to take a picture of the very rough mock up tonight or tomorrow and post it.

44Dwarf

HalfDork

1/22/10 12:32 p.m.

Chevettes are front steer.

I've got a write up somewhere.... i did on seting up a rack.

but Jeneson mans got you on track so far.

Your diagram shows the outer tie rod mount point sharing the same vertical line as the ball joint. On a front steer car, the outer tie rod mount points will be ahead of the axle centerline. I'm assuming what you were referring to was not the exact mount point but rather the rearward 'sweep' of the tie rods.

On the Abomination (which has very similar dimensions to your original post) I turned both knuckles so the tires were pointing straight ahead, then ran a string between the centers of the tie rod mount holes. I put the rack centerline about 3/4" behind that line, it really should have been another 1/2" back but I was going to lose the shock mount's front side if I did that. The rack is still ahead of the axle centerline.

If you get a chance to look at a Miata rack mounting, that shows you a very nearly ideal steering/lower CA relationship.

JThw8

SuperDork

1/22/10 12:47 p.m.

Correct, I was just showing the sweep, sorry for the confusion.

There are some inherent chassis design flaws (it is a Wartburg chassis after all) which would interfere with moving the rack behind the centerline of the mount holes as you suggest.

As it happens I have a miata sitting in my driveway so I will take a look at that.

There is also the potential to flip the knuckles side to side and move to rear steer which migh give me a little more room to work and some other rack options.

Thank you again for all the valuable input. I am learning much today :) Been reading up on other sites too but the best practical advice, as always, is coming from GRM.

If the housings are all aluminum it can still be done, you just need someone who can weld aluminum. I shortened a Triumph rack (steel housing) using a big tubing cutter, a chop saw and my wire feed welder. So far it hasn't killed me or Toyman.

Yet.

The inner tie rod ends are what govern how the inner section of rack is shortened. If the inner tie rods have male thread, you cut off the end of the rack that's furthest from the gearbox end then drill and tap for the thread you need and you are done. No, the rack teeth won't be fully centered then but that is not a big deal, the inner tie rods will stop the rack before it runs out of fangs.

If the tie rods are female, yu'd need to have the tip of the rack turned to the correct diameter and then threaded. Or, you could do what I did: cut the correct amount out of the rack, leaving a ~4" stub with the threads. That might vary, it depends on where the bearing for the rack rides. It's best not to have the cut line go back and forth across the bearing.

Bevel both pieces of rack where they need to go back together, clamp them straight (very important!) then weld them together. Let it cool, then use a 2" grinding disc (the flexible type) to smooth the weld. Grind it till the weld is no longer higher than the rack surface, then roll it on something flat like a piece of glass and check for warp. You can straighten it with a brass hammer.